Why do you need a monitoring system on a chip

The British startup UltraSoC introduced on-chip technology to track the characteristics of microchips without sacrificing performance. We tell how the solution is arranged.

/ photo 83DegreesMedia CC BY

Heterogeneous devices are built from several blocks. They may be processors, co-processors or integrated circuits ASIC. Specialization of computational modules improves the performance of the entire system, but the “multi-component composition” leads to difficulties with optimization — each hardware unit needs to be tuned.

')

The problem is exacerbated if the chips are used by a large data center. Monitoring extensive infrastructure is no easy task. Specialized software solutions often damage performance of computing systems. For example, the iPerf bandwidth measurement utility reduces network performance by 10–15%.

To solve this problem, UltraSoC has implemented monitoring tools right on the chip. The company has developed a number of logical semiconductor modules, each of which is responsible for one of the tasks - monitoring, debugging, and security. Chip manufacturers can use these modules and take them out on the same circuit as processors, GPUs, network interfaces. This allows you to collect data from all components of the chip "on site" without invasive software solutions. This technology has already been adapted to work with standard architectures: from ARM and RISC-V to MIPS and Xtensa.

In UltraSoC offer about thirty modules that can be assembled depending on the characteristics of a particular system on a chip (SoC). Modules are divided into three classes:

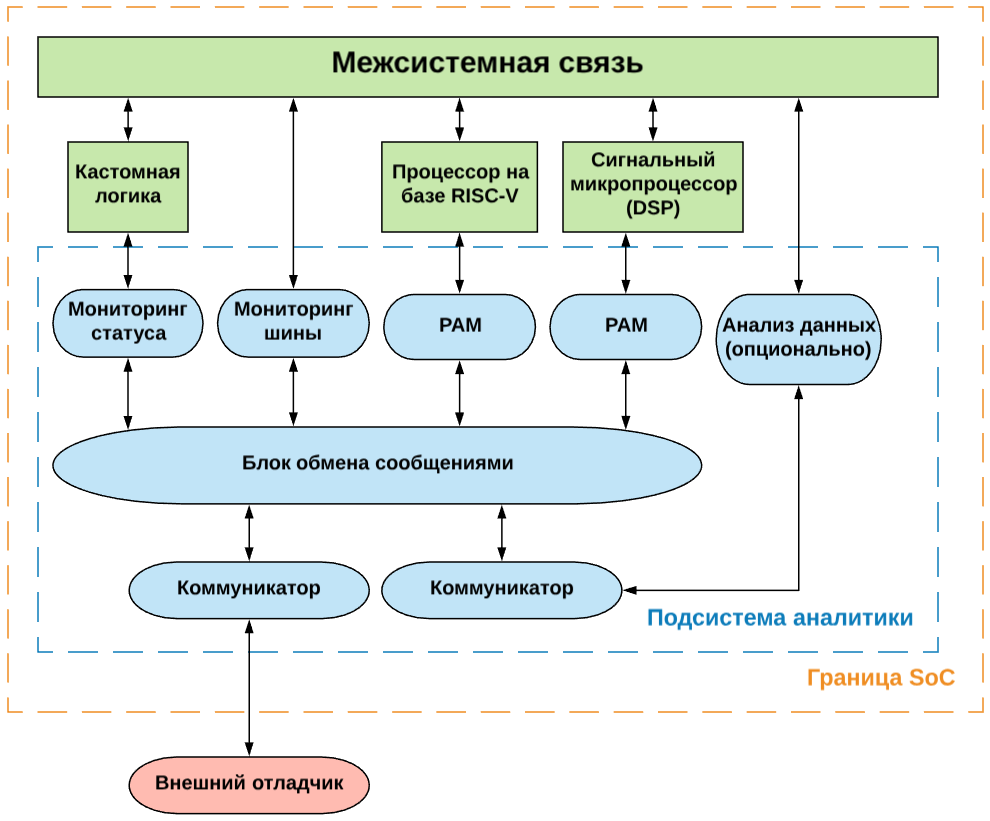

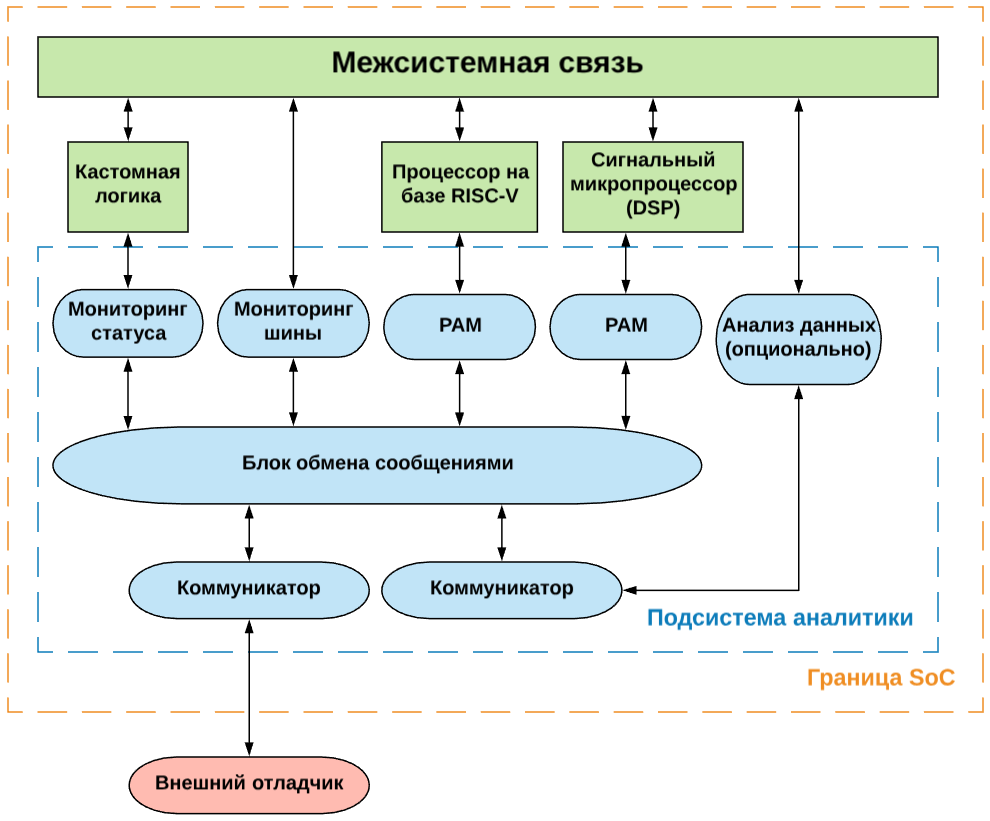

For example, for microprocessors based on the RISC-V architecture, the entire system might look like this:

The obtained data on the state of the chip components can be output via various interfaces: USB, Ethernet, PCI-Express and even Wi-Fi. After this information can be downloaded to any analytical system to search for anomalies in the components.

The developers at UltraSoC say that their system will find application in data centers and help cloud providers monitor a large-scale cloud infrastructure. Since the on-chip system parameters are monitored using hardware that (unlike software) does not affect performance, data center operators will be able to obtain current data on the status of servers in real time.

But before the technology finds widespread use, the UltraSoC team will have to convince manufacturers to implement the solution in their chips. Its implementation will complicate business processes, increase the cost of production and increase the price of microcircuits. Therefore, many companies can opt out, citing the fact that customers will be cheaper to independently use third-party monitoring software.

But a number of manufacturers still want to try out the product. For example, Esperanto is going to introduce UltraSoC technology into a thousand RISC-V based processors and AI / ML accelerators to track their performance.

Other organizations are also developing on-chip systems. In particular, special sensors for tracking voltage and temperature (PVT - Process, Voltage, Temperature). They are sharpened for work on systems on a chip and ASIC. Early last year, Moortec enlisted the support of the chip maker TSMC and implemented its technology in 12-nm chips. The companies are confident that the processors with on-board monitoring systems will find application in data centers, mobile devices, AI systems, IoT, and so on.

Another project - “smart” PVT-sensors - was the result of joint work of companies. The combination of digital UltraSoC monitoring and analysis systems and Moortec physical sensors allows you to comprehensively monitor the state of SoC and optimize the load in real time.

The developers of UltraSoC believe that the growing popularity of high-tech solutions (AI, ML, IoT), as well as the transition to heterogeneous systems, will make embedded monitoring tools irreplaceable.

The company plans to make the solution architecture more flexible and customizable. To do this, UltraSoC began to develop UltraDevelop 2. It is an integrated development environment (IDE), with which you can configure, debug, and optimize chip component parameters. Its release is scheduled for the second quarter of 2019.

What we write about in the corporate blog:

Several posts from our Telegram channel:

/ photo 83DegreesMedia CC BY

Why implement monitoring systems in the chip

Heterogeneous devices are built from several blocks. They may be processors, co-processors or integrated circuits ASIC. Specialization of computational modules improves the performance of the entire system, but the “multi-component composition” leads to difficulties with optimization — each hardware unit needs to be tuned.

')

The problem is exacerbated if the chips are used by a large data center. Monitoring extensive infrastructure is no easy task. Specialized software solutions often damage performance of computing systems. For example, the iPerf bandwidth measurement utility reduces network performance by 10–15%.

To solve this problem, UltraSoC has implemented monitoring tools right on the chip. The company has developed a number of logical semiconductor modules, each of which is responsible for one of the tasks - monitoring, debugging, and security. Chip manufacturers can use these modules and take them out on the same circuit as processors, GPUs, network interfaces. This allows you to collect data from all components of the chip "on site" without invasive software solutions. This technology has already been adapted to work with standard architectures: from ARM and RISC-V to MIPS and Xtensa.

System device

In UltraSoC offer about thirty modules that can be assembled depending on the characteristics of a particular system on a chip (SoC). Modules are divided into three classes:

- Analytics blocks - monitor and monitor the components of the chip;

- Messaging blocks - connect UltraSoC modules to each other;

- Communicators - interfaces for communication with external systems and internal components.

For example, for microprocessors based on the RISC-V architecture, the entire system might look like this:

The obtained data on the state of the chip components can be output via various interfaces: USB, Ethernet, PCI-Express and even Wi-Fi. After this information can be downloaded to any analytical system to search for anomalies in the components.

Solution potential and disadvantages

The developers at UltraSoC say that their system will find application in data centers and help cloud providers monitor a large-scale cloud infrastructure. Since the on-chip system parameters are monitored using hardware that (unlike software) does not affect performance, data center operators will be able to obtain current data on the status of servers in real time.

Due to the fact that the technology evaluates the work of low-level components directly, it will help to quickly determine the cause of the so-called heisenbags - “floating errors”, which are difficult to catch because they regularly change properties.

But before the technology finds widespread use, the UltraSoC team will have to convince manufacturers to implement the solution in their chips. Its implementation will complicate business processes, increase the cost of production and increase the price of microcircuits. Therefore, many companies can opt out, citing the fact that customers will be cheaper to independently use third-party monitoring software.

But a number of manufacturers still want to try out the product. For example, Esperanto is going to introduce UltraSoC technology into a thousand RISC-V based processors and AI / ML accelerators to track their performance.

Alternative Development

Other organizations are also developing on-chip systems. In particular, special sensors for tracking voltage and temperature (PVT - Process, Voltage, Temperature). They are sharpened for work on systems on a chip and ASIC. Early last year, Moortec enlisted the support of the chip maker TSMC and implemented its technology in 12-nm chips. The companies are confident that the processors with on-board monitoring systems will find application in data centers, mobile devices, AI systems, IoT, and so on.

Another project - “smart” PVT-sensors - was the result of joint work of companies. The combination of digital UltraSoC monitoring and analysis systems and Moortec physical sensors allows you to comprehensively monitor the state of SoC and optimize the load in real time.

What the future holds for technology

The developers of UltraSoC believe that the growing popularity of high-tech solutions (AI, ML, IoT), as well as the transition to heterogeneous systems, will make embedded monitoring tools irreplaceable.

The company plans to make the solution architecture more flexible and customizable. To do this, UltraSoC began to develop UltraDevelop 2. It is an integrated development environment (IDE), with which you can configure, debug, and optimize chip component parameters. Its release is scheduled for the second quarter of 2019.

What we write about in the corporate blog:

- How to place 100% of the infrastructure in the cloud and not regret it

- Serverless computing in the cloud: the trend of today or the need?

- Why companies use virtual machines, not containers

Several posts from our Telegram channel:

Source: https://habr.com/ru/post/442788/

All Articles