FabLab University ITMO: DIY-co-working for creative people - show what's inside

We tell and show what students do in the fablab of the ITMO University . All who are interested in the topic of DIY as part of student initiatives, we invite under the cat.

Fablab University ITMO is a small workshop in which students and teachers of our university can independently create various parts for scientific research or experiments. The idea to create a workshop was given by Alexey Shchekoldin and Evgeny Anfimov .

')

They were engaged in the development of creative DIY projects at home or in the fab labs of other universities. But the guys felt that it would be nice to implement their ideas within the walls of their own high school. The initiative was presented to the Rector of ITMO University. He supported her.

At the time of the emergence of the ideas of the laboratory, Alexey and Eugene were finishing up their fourth year of undergraduate studies. When they switched to the first magistracy course, the lab lab opened doors for everyone.

FabLab was “launched” in 2015 in the building of the Technopark of the ITMO University as part of the 5/100 program , which aims to increase the competitiveness of Russian universities on the world stage. The premises were equipped with places for working on a computer, as well as delimited zones with machines and other equipment.

The goal of the university workshop is to “lure” people with projects, to help them realize their ideas, and, possibly, to set up a startup. The workshop conducts master classes on working with equipment, programming and TRIZ.

Before purchasing the equipment, the university management interviewed students and staff of ITMO University which tools would be most useful in the workshop. So in our fablab appeared MakerBot 3D printers, GCC laser engravers and Roland MDX40 milling machine, as well as soldering stations. Gradually, the laboratory overgrown with new equipment, and now it is possible to find almost any tool for work.

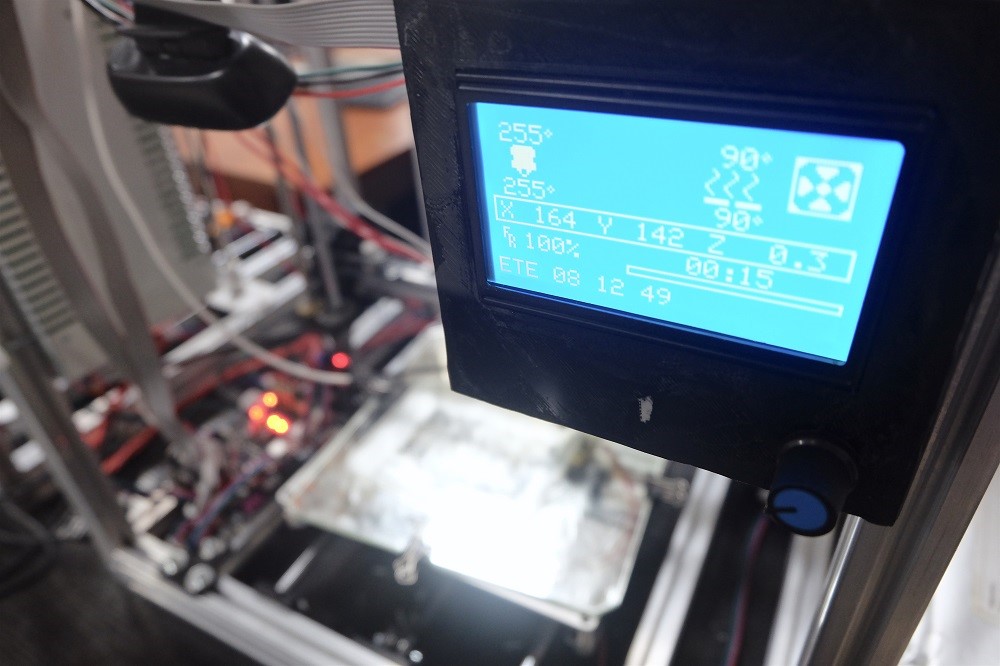

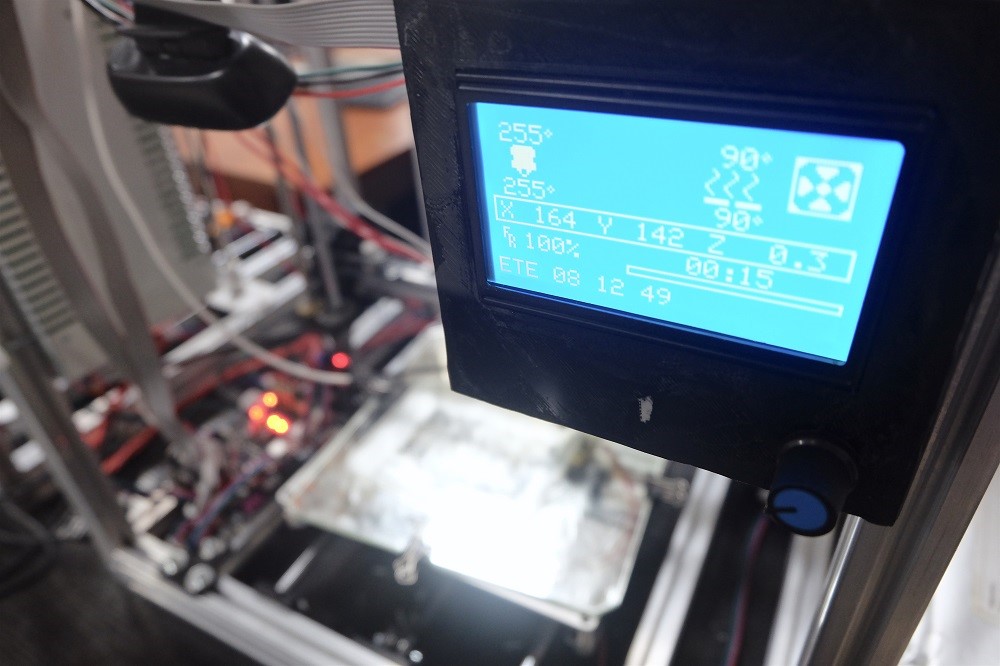

Pictured: MakerBot 3D Printer

In the laboratory there are printing devices assembled from DIY kits:

In the photo: DIY printer, created on the basis of Open Source developments

Many printers and other equipment are being refined by students on their own, creating new equipment and accessories. For example, the printers in the next photo were collected from a set of RepRap. It is part of an initiative to create self-copying devices.

In the photo: DIY printers created on the basis of Open Source developments.

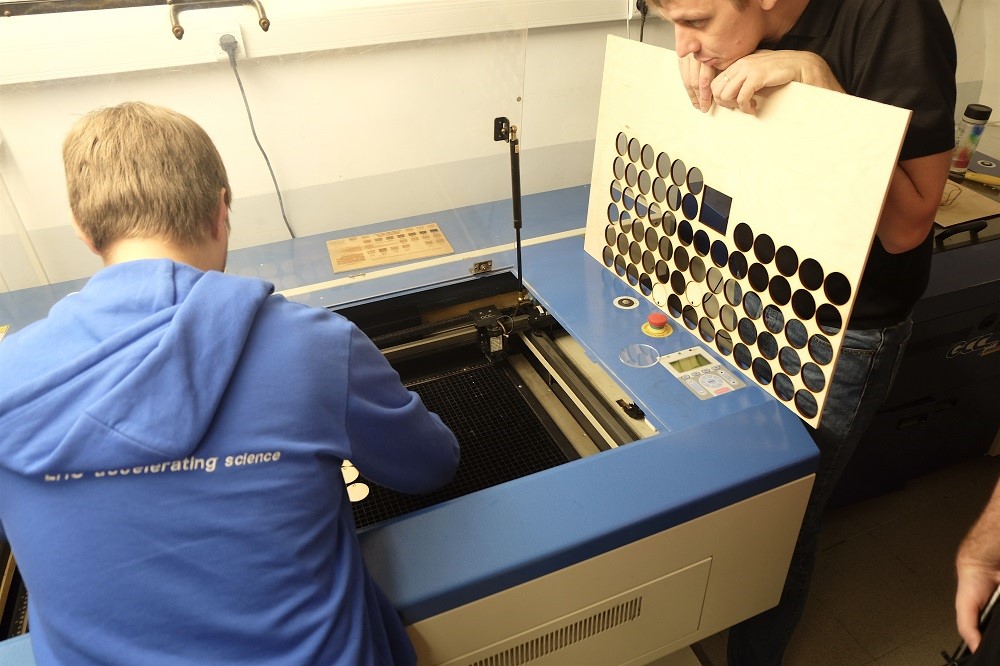

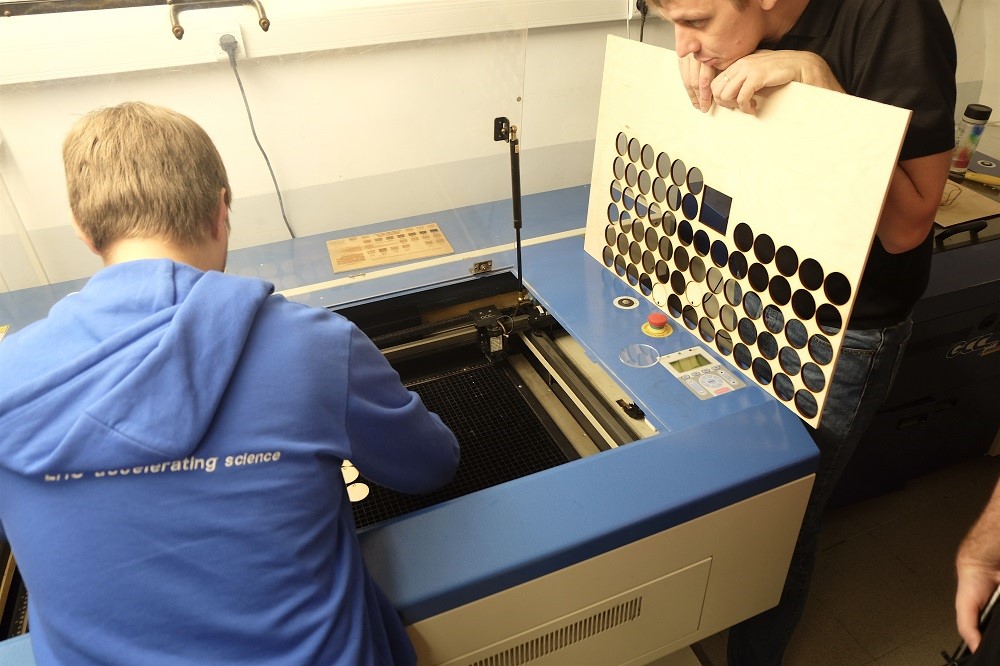

Also in the fablab there is a UV printer and laser engravers GCC Hybrid MG380 and GCC Spirit LS40, as well as various CNC milling machines.

In the photo: Roland LEF-12 UV printer

In the photo: Laser engraver GCC Hybrid MG380

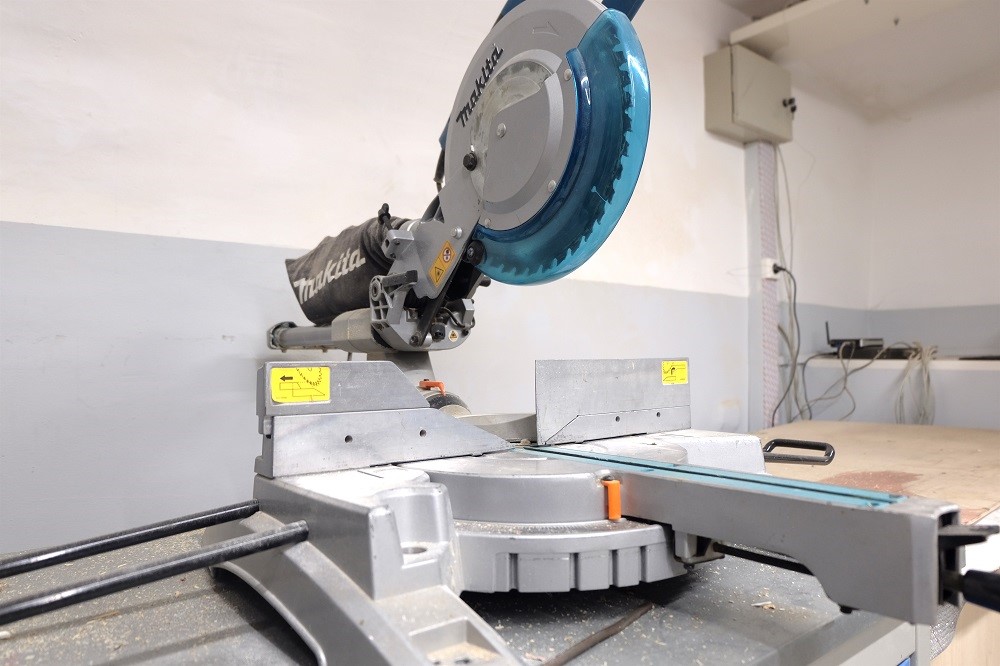

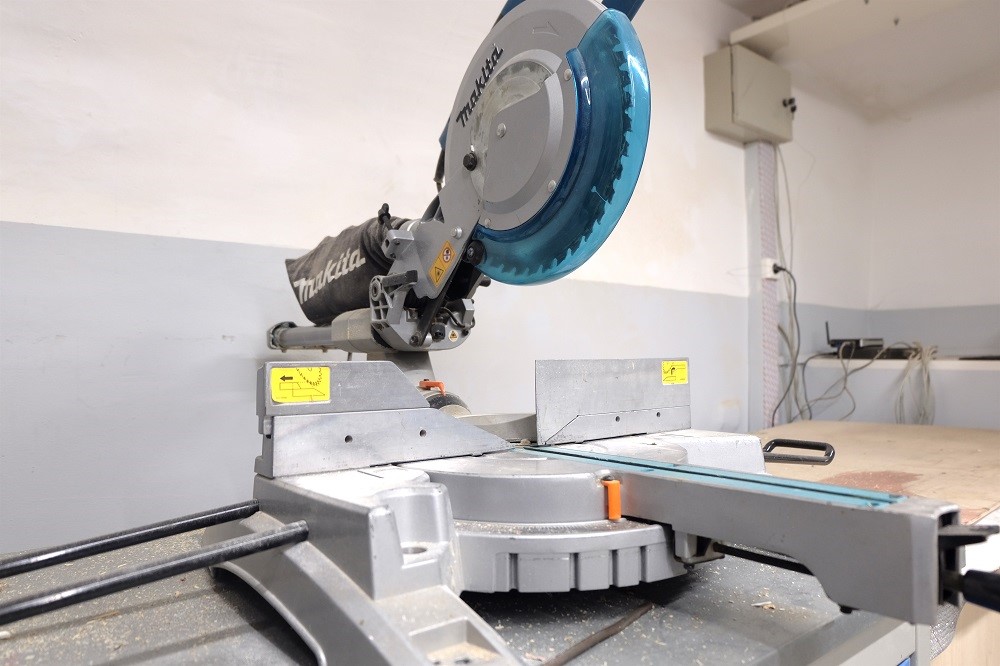

There is also a drilling machine, a circular saw and a hand-held power tool: drills, screwdrivers, and hacksaws. There is almost any power tool, which must be in the workshop of any maker. The fablab even has a string for cutting polystyrene foam, which is very helpful when modeling from foam.

On the photo: Miter saw Makita LS1018L

Also in the laboratory, there are several personal computers installed on which students are engaged in drawing, 3D modeling and programming. Now there are more than 30 items of equipment and tools in the fab lab.

In the photo: Fablab's “computer class”

Students make 3D-models, burn logos on the boards, design art objects. Here everyone can work on a personal project, for example, print a figure of a favorite film character, assemble a milling machine, a quadcopter or an author's guitar. The laboratory instruments, in contrast to the "home" tools, help to realize the idea quickly, with a high level of accuracy.

During the first year of the fablab, a system was developed for organizing a microclimate in the Evapolar room. The project went to the crowdfunding platform Indiegogo and even collected the target amount. Also on the basis of the laboratory appeared the project “Keyboards for the blind” and the FlashStep solution was born - an embedded automated decorative lighting system.

FlashStep was developed by the co-founder of the laboratory, Evgeny Anfimov. This is a system for illuminating the stairs of multi-storey country cottages. The idea even managed to monetize - it is in demand from the owners of "smart" homes.

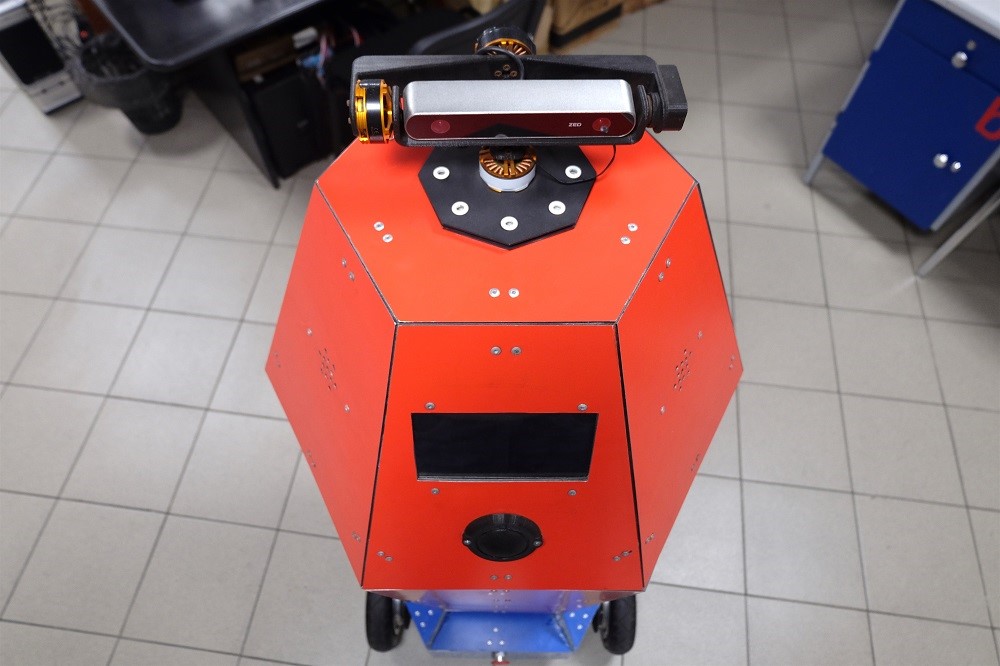

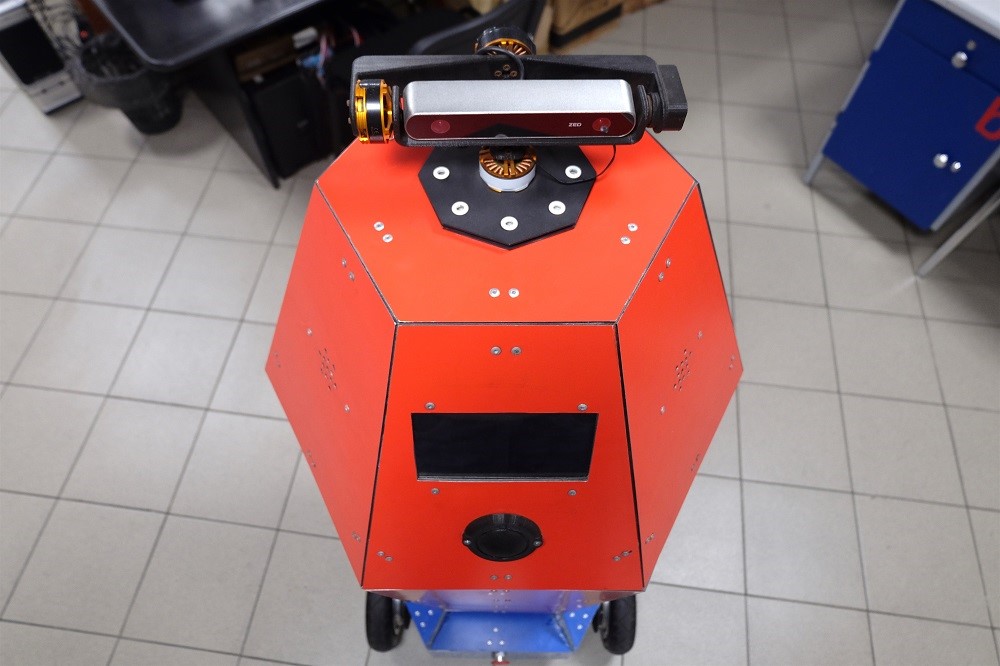

It is also worth highlighting the prototype of the SMARR robot, which works on the basis of VR and AR technologies.

Pictured: SMARR robot

The development of the robot was carried out for two years under the guidance of the founder and head of the laboratory, Shchekoldin Alexey. Ten students of ITMO University took part in its creation. They were helped by university professors, in particular, Sergey Alekseyevich Kolyubin, an associate professor in the faculty of control systems and robotics, took on the role of the project scientific manager.

Man manages SMARR with the help of Oculus Rift virtual reality glasses. In addition to the pictures from the robot's video camera, the user receives information (for example, tables with some data), which is molded by augmented reality technology. In this case, the robot is able to navigate in unfamiliar places, using probabilistic methods for building a map of the room.

In the future, the authors of SMARR plan to sell the robot. One of the possible areas of its application is working in hazardous conditions, for example, on oil rigs. This will reduce the risks to workers when conducting any assessment activities. Developers also see the potential use of their brainchild in tourism. With the help of a robot, people will be able to go on a virtual journey. For example, on large museums.

Pictured: SMARR robot

A startup 3dprinterforkids settled in the fab lab. Its founder - Stanislav Pimenov - teaches children 3D-modeling skills, instills in them an interest in robotics.

In order to provide visitors of the workshop with more technological tools, we study the needs of other laboratories of our university. At the same time, there are plans to turn the fab lab into a small startup accelerator with a DIY bias. We also want to organize more workshops and excursions for schoolchildren, and more often carry out practical exercises for adults.

News from the life of our laboratory: VK , Facebook , Telegram and Instagram .

About what else we tell on Habré:

How did the fab lab appear

Fablab University ITMO is a small workshop in which students and teachers of our university can independently create various parts for scientific research or experiments. The idea to create a workshop was given by Alexey Shchekoldin and Evgeny Anfimov .

')

They were engaged in the development of creative DIY projects at home or in the fab labs of other universities. But the guys felt that it would be nice to implement their ideas within the walls of their own high school. The initiative was presented to the Rector of ITMO University. He supported her.

At the time of the emergence of the ideas of the laboratory, Alexey and Eugene were finishing up their fourth year of undergraduate studies. When they switched to the first magistracy course, the lab lab opened doors for everyone.

FabLab was “launched” in 2015 in the building of the Technopark of the ITMO University as part of the 5/100 program , which aims to increase the competitiveness of Russian universities on the world stage. The premises were equipped with places for working on a computer, as well as delimited zones with machines and other equipment.

ITMO University students can visit the laboratory and use the equipment for free. Such an approach allowed attracting a large number of students and turning the workshop into a kind of coworking in which you can share experiences, ideas and put them into practice.

The goal of the university workshop is to “lure” people with projects, to help them realize their ideas, and, possibly, to set up a startup. The workshop conducts master classes on working with equipment, programming and TRIZ.

Workshop equipment

Before purchasing the equipment, the university management interviewed students and staff of ITMO University which tools would be most useful in the workshop. So in our fablab appeared MakerBot 3D printers, GCC laser engravers and Roland MDX40 milling machine, as well as soldering stations. Gradually, the laboratory overgrown with new equipment, and now it is possible to find almost any tool for work.

Pictured: MakerBot 3D Printer

In the laboratory there are printing devices assembled from DIY kits:

In the photo: DIY printer, created on the basis of Open Source developments

Many printers and other equipment are being refined by students on their own, creating new equipment and accessories. For example, the printers in the next photo were collected from a set of RepRap. It is part of an initiative to create self-copying devices.

In the photo: DIY printers created on the basis of Open Source developments.

Also in the fablab there is a UV printer and laser engravers GCC Hybrid MG380 and GCC Spirit LS40, as well as various CNC milling machines.

In the photo: Roland LEF-12 UV printer

In the photo: Laser engraver GCC Hybrid MG380

There is also a drilling machine, a circular saw and a hand-held power tool: drills, screwdrivers, and hacksaws. There is almost any power tool, which must be in the workshop of any maker. The fablab even has a string for cutting polystyrene foam, which is very helpful when modeling from foam.

On the photo: Miter saw Makita LS1018L

Also in the laboratory, there are several personal computers installed on which students are engaged in drawing, 3D modeling and programming. Now there are more than 30 items of equipment and tools in the fab lab.

In the photo: Fablab's “computer class”

Himself inventor

Students make 3D-models, burn logos on the boards, design art objects. Here everyone can work on a personal project, for example, print a figure of a favorite film character, assemble a milling machine, a quadcopter or an author's guitar. The laboratory instruments, in contrast to the "home" tools, help to realize the idea quickly, with a high level of accuracy.

The “products” of the workshop-laboratory are regularly shown at exhibitions and festivals. For example, in July VK Fest showed figures printed on a 3D printer. But in the workshop they make not only art objects and projects for the soul. Students implement in the laboratory and high-tech solutions.

During the first year of the fablab, a system was developed for organizing a microclimate in the Evapolar room. The project went to the crowdfunding platform Indiegogo and even collected the target amount. Also on the basis of the laboratory appeared the project “Keyboards for the blind” and the FlashStep solution was born - an embedded automated decorative lighting system.

FlashStep was developed by the co-founder of the laboratory, Evgeny Anfimov. This is a system for illuminating the stairs of multi-storey country cottages. The idea even managed to monetize - it is in demand from the owners of "smart" homes.

It is also worth highlighting the prototype of the SMARR robot, which works on the basis of VR and AR technologies.

Pictured: SMARR robot

The development of the robot was carried out for two years under the guidance of the founder and head of the laboratory, Shchekoldin Alexey. Ten students of ITMO University took part in its creation. They were helped by university professors, in particular, Sergey Alekseyevich Kolyubin, an associate professor in the faculty of control systems and robotics, took on the role of the project scientific manager.

Man manages SMARR with the help of Oculus Rift virtual reality glasses. In addition to the pictures from the robot's video camera, the user receives information (for example, tables with some data), which is molded by augmented reality technology. In this case, the robot is able to navigate in unfamiliar places, using probabilistic methods for building a map of the room.

In the future, the authors of SMARR plan to sell the robot. One of the possible areas of its application is working in hazardous conditions, for example, on oil rigs. This will reduce the risks to workers when conducting any assessment activities. Developers also see the potential use of their brainchild in tourism. With the help of a robot, people will be able to go on a virtual journey. For example, on large museums.

Pictured: SMARR robot

A startup 3dprinterforkids settled in the fab lab. Its founder - Stanislav Pimenov - teaches children 3D-modeling skills, instills in them an interest in robotics.

What's next

In order to provide visitors of the workshop with more technological tools, we study the needs of other laboratories of our university. At the same time, there are plans to turn the fab lab into a small startup accelerator with a DIY bias. We also want to organize more workshops and excursions for schoolchildren, and more often carry out practical exercises for adults.

News from the life of our laboratory: VK , Facebook , Telegram and Instagram .

About what else we tell on Habré:

Source: https://habr.com/ru/post/434976/

All Articles