Surprises with 3d printing

With the help of three-dimensional printing, you can reproduce almost any three-dimensional model that fits on the printer platform with a sufficient level of detail.

It would seem that everything is simple - he created a model in a 3D editor, transferred it to a printer, and received it in bulk. But in practice, everything looks a bit more complicated. Next, we describe in more detail the surprises arising in the process of 3D printing, as well as how to avoid them.

With 3D printing, it is desirable to place as many details as possible on one printer platform. This is necessary in order for one print cycle to print the maximum number of parts.

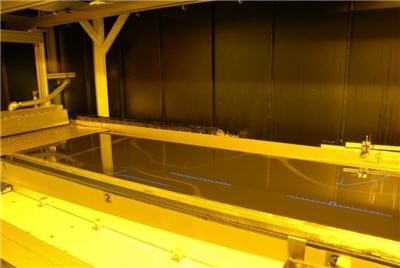

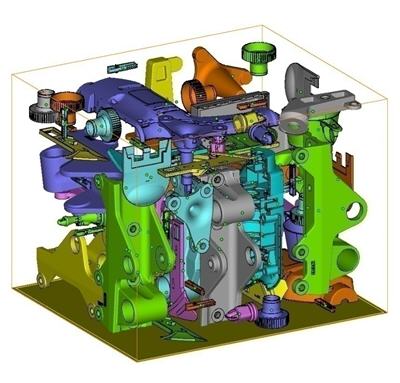

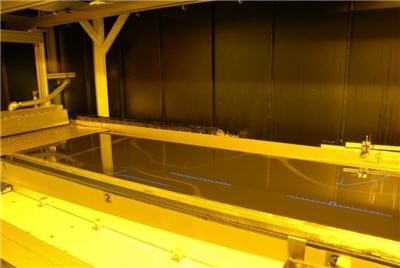

For example, such a model from a variety of automotive parts can be input to a printer:

Here you need to be careful, because there is a chance to get such a surprise:

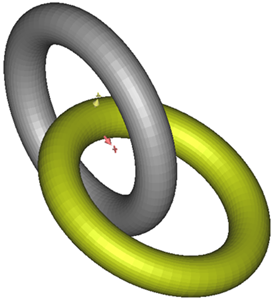

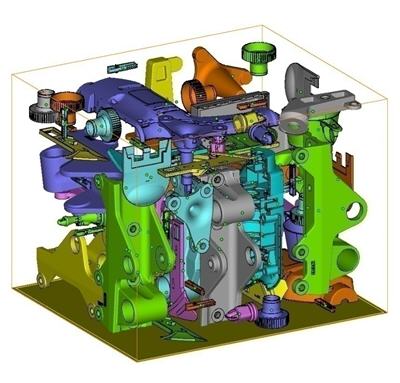

If you wish to print two tori ( "donut" in common), you should be aware that they will need to be disconnected later.

And one more, less obvious, example of the same problem:

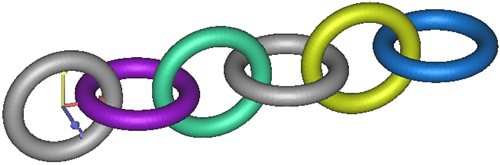

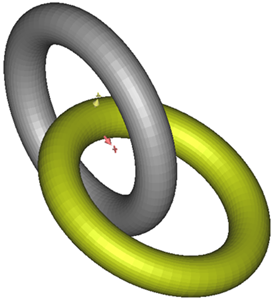

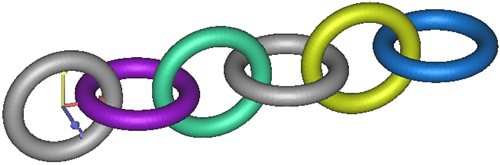

Although, if you look at it from the other side, it becomes possible to print a single piece of several components, for example, a chain of the same tori:

One type of printing is as follows: a laser beam passes through the surface of a special liquid material, and the material hardens at the points where the laser passes. At first there is very little liquid, on one layer - and the laser beam fixes it. Then the liquid is added - the laser passes again, and so on, layer by layer. It would seem no miracles.

But if you look closely, not everything is so smooth. Since printing starts from the bottom up, some pieces of the model will simply fall off. Let's see what happens if we, for example, try to print the statue of David:

When a layer of liquid comes up to the hands (highlighted in red) and is fixed by a laser, then the hardened pieces will simply collapse and sink either due to lack of support, or due to the fact that this support is very weak.

Who knows, perhaps the statue of Venus is the result of the first, hitherto unknown, 3D printing technology.

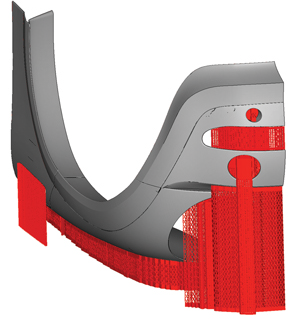

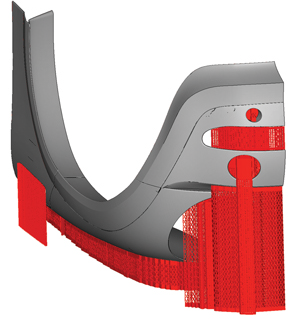

So that we do not receive such surprises, before printing, so-called “support” are created - supports that break off the model after printing. This is how the model with support may look:

In the picture to the gray model of the automotive part, the support has been completed.

And this may look like the result of printing a different model:

After printing, these supports gently break off:

')

Sometimes there is a desire to print a model from your favorite computer toy. For example, if you like to surf on a helicopter, enjoying the landscapes and clouds winking at you, and you have a desire to have this helicopter (in a reduced form) standing on your desk, then you have the opportunity to print it.

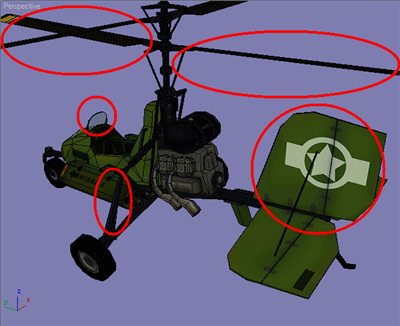

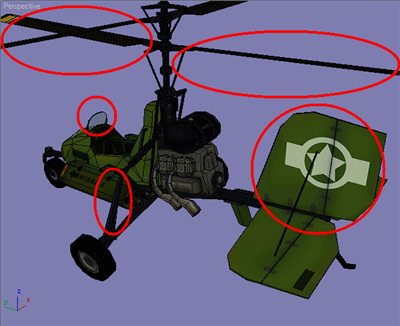

And here we are waiting for another surprise. As a rule, such models consist of fairly highly detailed parts that can be very fragile, and therefore, after printing, there is a risk that they will simply disintegrate under their own weight. Note that the supports will not help here, since they will be broken off immediately after printing.

Here it is necessary to strengthen the model a little: for example, make the propeller and chassis mounts thicker. In the figure below you can see a helicopter with some elements to be strengthened:

Models that arrive on the print must be "waterproof". They consist of triangles that should form a closed volume.

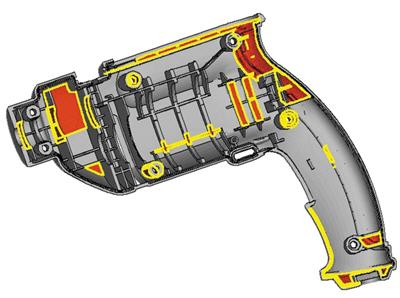

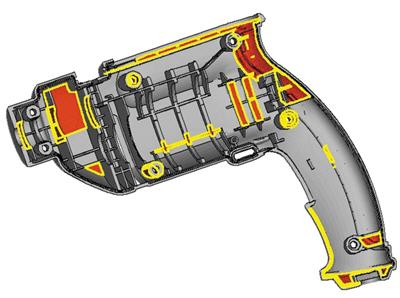

For example, the user needs to print the body of the drill:

This model consists of outer and inner walls, which together should form a three-dimensional body. But in the figure above you can see the holes circled in yellow on the inner wall, which violate the bulkiness of the model. This model is not suitable for printing.

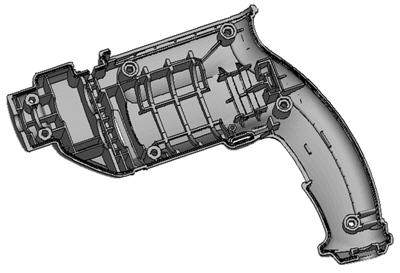

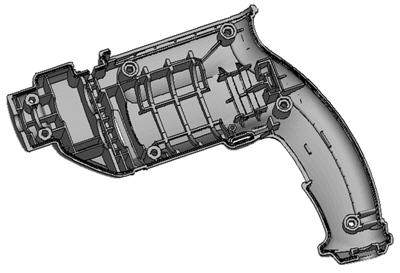

After processing, the ready-to-print package will look as follows:

All holes patched, all entrails are hidden.

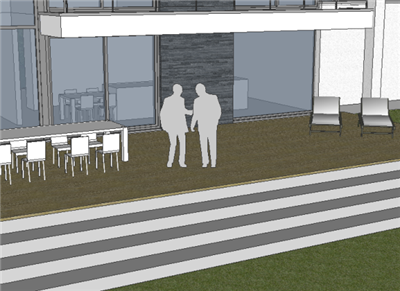

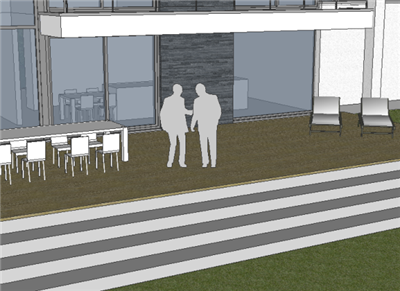

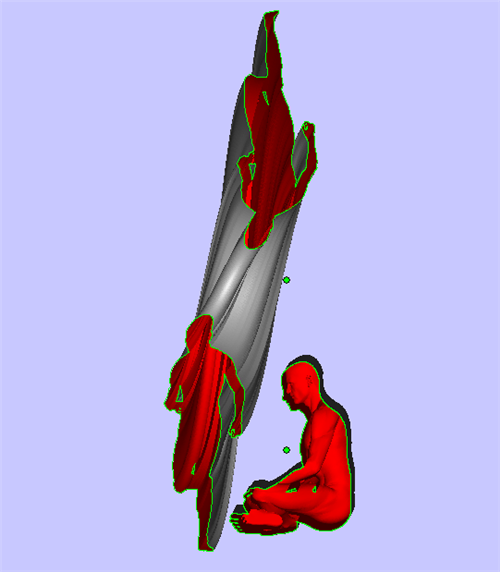

In some data formats, along with bulk models, pictures are also used. For example, we can see in the image below that no matter where the observer is, the silhouettes of the two men do not change:

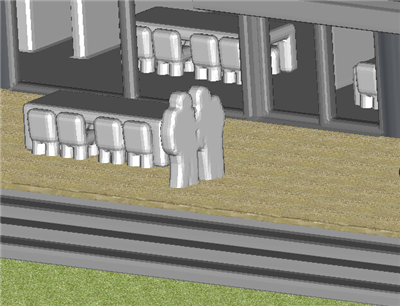

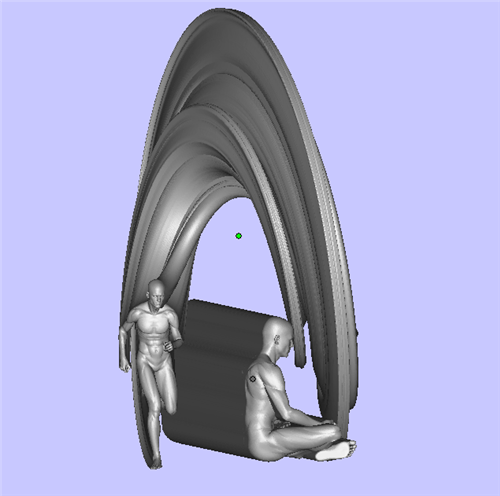

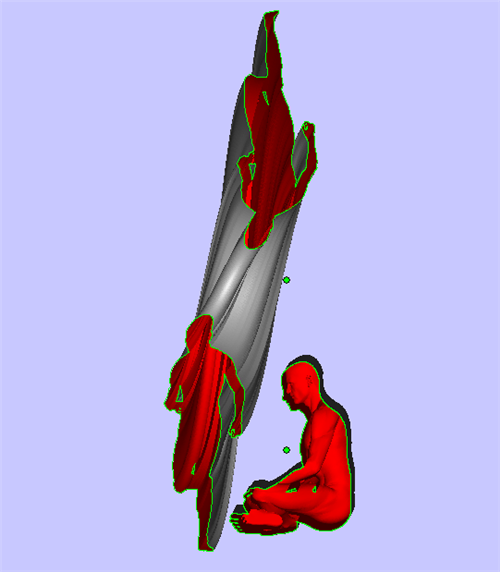

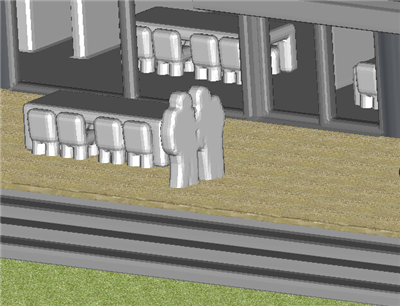

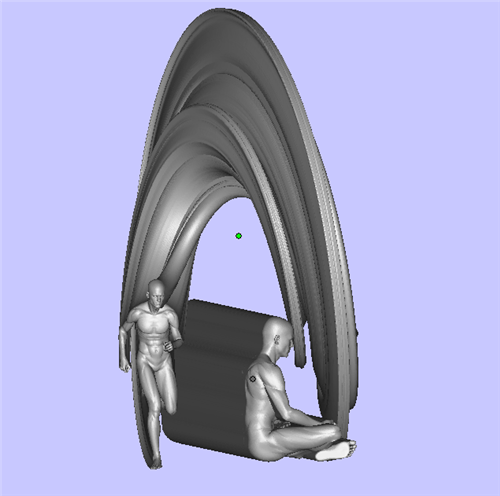

Such models need to be given volume. Immediately before printing, a fragment of the prepared model looks as follows:

And a photo of the printed house:

The material for 3d printing is quite expensive, and therefore, whenever possible, they are trying to save it.

One way is to print only a small layer of the surface. After printing, a thin hole is made in the model and the material is poured or poured out (depending on whether the material is a liquid or powder). In this case, the cost of the model can be significantly reduced.

Consider this on the following model that you want to print:

In section, it looks like this:

The surface of the model limits the printing volume. This volume can be significantly reduced by adding internal walls:

As we see, it is not enough just to send the desired model to the printer. Usually the model is subject to certain processing and refinement, not immediately apparent. Some improvements are made by employees of the company using the software developed by us. Other improvements occur at the touch of a button and practically do not require human intervention. This was made possible thanks to the work of teams of researchers and developers of the company. All this and much more is available in our 3D printing software .

It would seem that everything is simple - he created a model in a 3D editor, transferred it to a printer, and received it in bulk. But in practice, everything looks a bit more complicated. Next, we describe in more detail the surprises arising in the process of 3D printing, as well as how to avoid them.

Parts can be printed linked.

With 3D printing, it is desirable to place as many details as possible on one printer platform. This is necessary in order for one print cycle to print the maximum number of parts.

For example, such a model from a variety of automotive parts can be input to a printer:

Here you need to be careful, because there is a chance to get such a surprise:

If you wish to print two tori ( "donut" in common), you should be aware that they will need to be disconnected later.

And one more, less obvious, example of the same problem:

Although, if you look at it from the other side, it becomes possible to print a single piece of several components, for example, a chain of the same tori:

The item may "fall apart"

One type of printing is as follows: a laser beam passes through the surface of a special liquid material, and the material hardens at the points where the laser passes. At first there is very little liquid, on one layer - and the laser beam fixes it. Then the liquid is added - the laser passes again, and so on, layer by layer. It would seem no miracles.

But if you look closely, not everything is so smooth. Since printing starts from the bottom up, some pieces of the model will simply fall off. Let's see what happens if we, for example, try to print the statue of David:

When a layer of liquid comes up to the hands (highlighted in red) and is fixed by a laser, then the hardened pieces will simply collapse and sink either due to lack of support, or due to the fact that this support is very weak.

Who knows, perhaps the statue of Venus is the result of the first, hitherto unknown, 3D printing technology.

So that we do not receive such surprises, before printing, so-called “support” are created - supports that break off the model after printing. This is how the model with support may look:

In the picture to the gray model of the automotive part, the support has been completed.

And this may look like the result of printing a different model:

After printing, these supports gently break off:

')

Animation Models

Sometimes there is a desire to print a model from your favorite computer toy. For example, if you like to surf on a helicopter, enjoying the landscapes and clouds winking at you, and you have a desire to have this helicopter (in a reduced form) standing on your desk, then you have the opportunity to print it.

And here we are waiting for another surprise. As a rule, such models consist of fairly highly detailed parts that can be very fragile, and therefore, after printing, there is a risk that they will simply disintegrate under their own weight. Note that the supports will not help here, since they will be broken off immediately after printing.

Here it is necessary to strengthen the model a little: for example, make the propeller and chassis mounts thicker. In the figure below you can see a helicopter with some elements to be strengthened:

Water resistant

Models that arrive on the print must be "waterproof". They consist of triangles that should form a closed volume.

For example, the user needs to print the body of the drill:

This model consists of outer and inner walls, which together should form a three-dimensional body. But in the figure above you can see the holes circled in yellow on the inner wall, which violate the bulkiness of the model. This model is not suitable for printing.

After processing, the ready-to-print package will look as follows:

All holes patched, all entrails are hidden.

Printing flat objects

In some data formats, along with bulk models, pictures are also used. For example, we can see in the image below that no matter where the observer is, the silhouettes of the two men do not change:

Such models need to be given volume. Immediately before printing, a fragment of the prepared model looks as follows:

And a photo of the printed house:

Print speed and material savings

The material for 3d printing is quite expensive, and therefore, whenever possible, they are trying to save it.

One way is to print only a small layer of the surface. After printing, a thin hole is made in the model and the material is poured or poured out (depending on whether the material is a liquid or powder). In this case, the cost of the model can be significantly reduced.

Consider this on the following model that you want to print:

In section, it looks like this:

The surface of the model limits the printing volume. This volume can be significantly reduced by adding internal walls:

As we see, it is not enough just to send the desired model to the printer. Usually the model is subject to certain processing and refinement, not immediately apparent. Some improvements are made by employees of the company using the software developed by us. Other improvements occur at the touch of a button and practically do not require human intervention. This was made possible thanks to the work of teams of researchers and developers of the company. All this and much more is available in our 3D printing software .

Source: https://habr.com/ru/post/99314/

All Articles