Sir, here is your liver: backstage bioprinting

Say goodbye to donor lists and organ shortages. A biotechnology company has created a printer that prints blood vessels using patient cells. In the future, this device has every chance of creating entire organs.

“We are now doing well with typing blood vessels,” says Ben Schaferd, a senior research scientist at the regenerative medical company Organovo. “This week we printed 10 pieces. We continue to study how to improve the condition of the blood vessels, make them stronger. ”

Most of the organs in the human body are riddled with veins, so the ability to print blood vessels is one of the most important structural elements for creating entire organs. Printed veins will soon begin to check on animals, and, ultimately, will be conducted clinical trials on humans. If everything goes well, in a few years you will be able to replace damaged veins (for example, as a result of injections or chemotherapy) with custom-printed veins from your own cells.

')

Printing whole organs rests on the problems of not only the technological plan. The first machine that prints the organs will cost hundreds of millions of dollars - this is with the development, testing, production. And this is not to mention the difficulties that any company will have to face in obtaining permission from the Food and Drug Administration.

“If Organovo can get enough money, the company will have the opportunity to succeed as the first bioprinting company, but time will tell,” says Dr. Vladimir Mironov, director of matter bio-production at the University of Medicine in South Carolina.

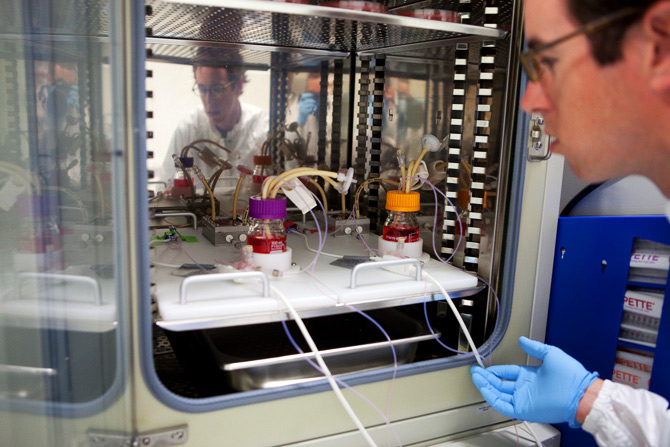

Organovo showed Wired.com the whole process of printing blood vessels on a manufactured bioprinter.

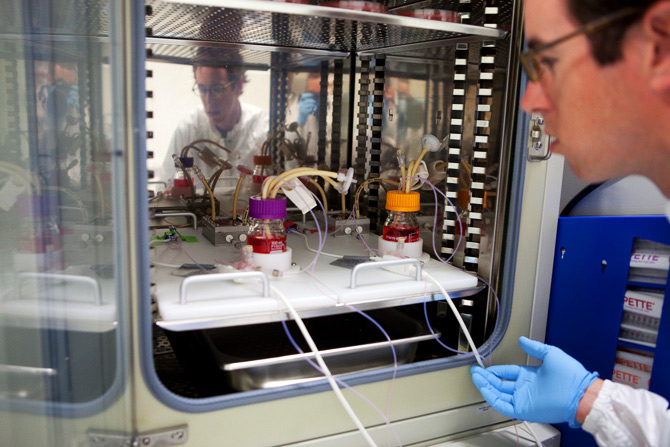

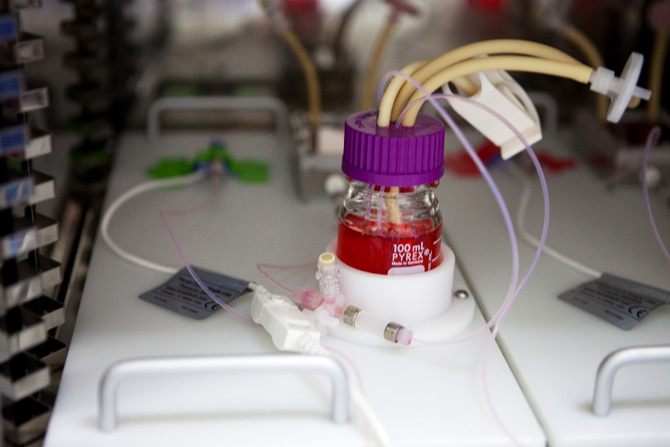

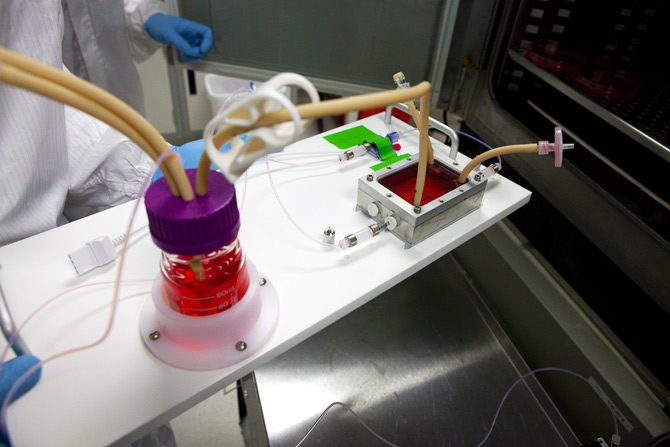

Sheferd placed the bioreactor inside the incubator, where the blood vessels will be pumped along with the growth medium for several days. The bioreactor uses a special mixture of chemicals that is identical to that encountered by the cells, growing in the body - this helps the cells turn into strong vascular tissue.

Photos: Dave Bullock / Wired.com

Senior research scientist Ben Schaferd pulls stem cells from a liquid nitrogen bath. Before the cells get into the printer, they are cultivated to a much larger number. Ultimately, these cells can be taken from different places in the patient's body — fat, bone marrow, skin cells — and turned into new veins.

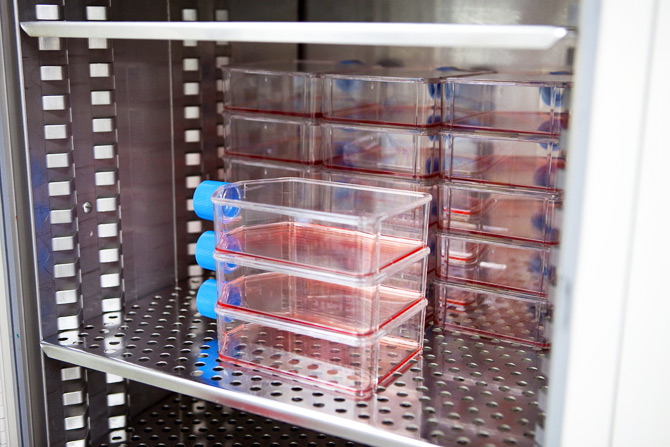

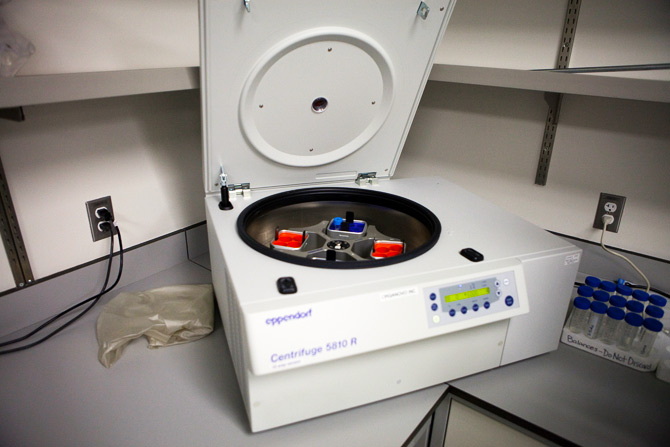

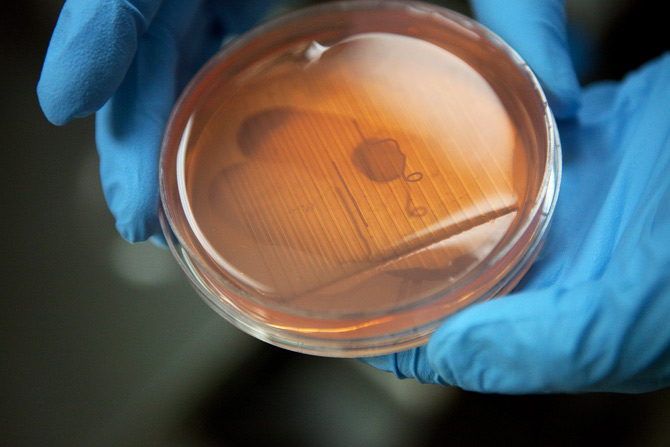

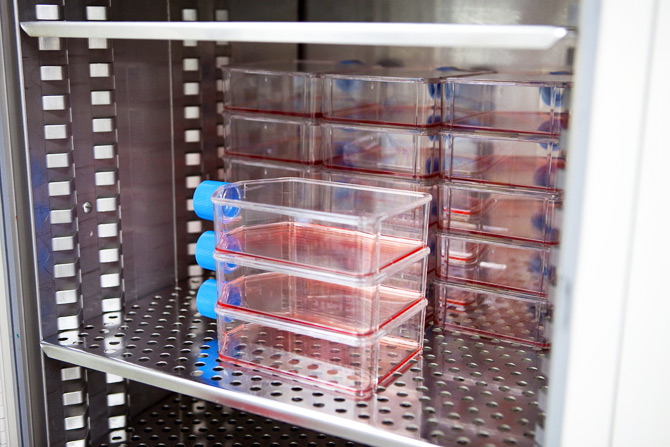

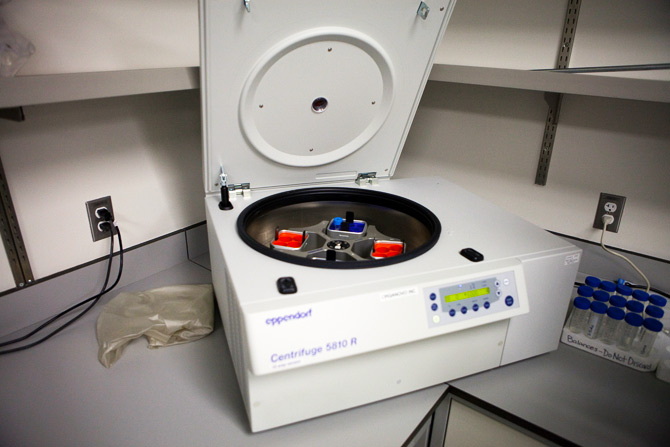

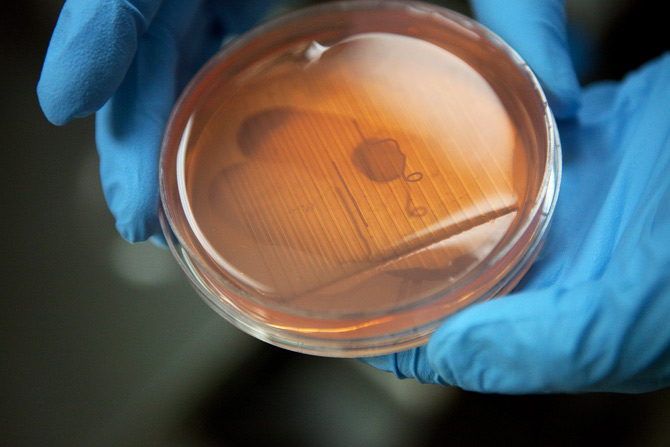

After the cells have thawed, they are cultured in growth medium (photo above). This allows cells to multiply and grow so that they can be used to build veins. In this environment, special chemical products are also used that “indicate” stem cells to grow into the necessary types of cells - in this case - into the cells of blood vessels. As soon as the required number of cells is obtained, they are separated from the growth medium in a centrifuge (photo below) and compressed into balls.

The first step in the entire printing process is to cover a material called a “hydrogel,” which is used as a temporary substrate to support the vein tissue.

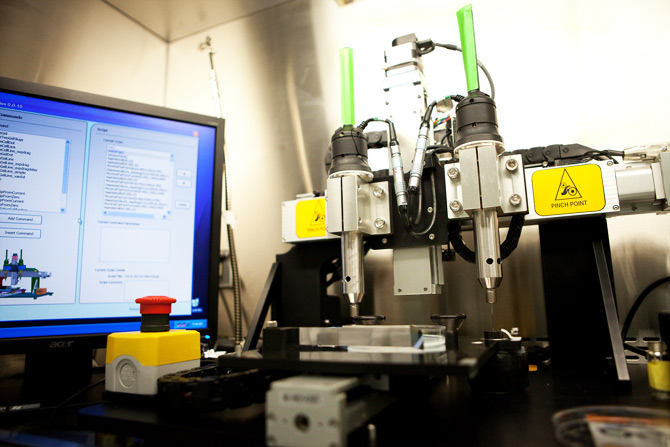

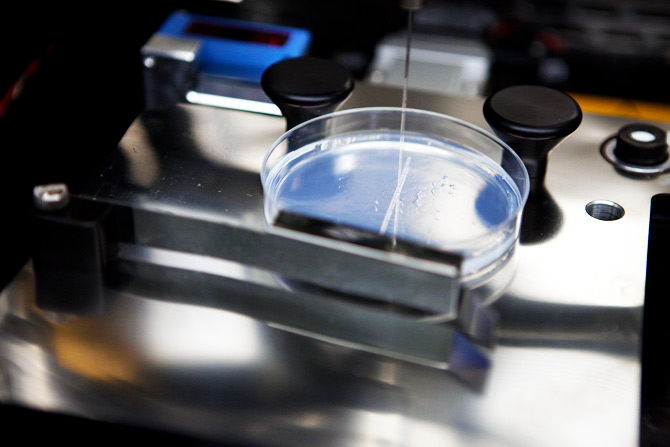

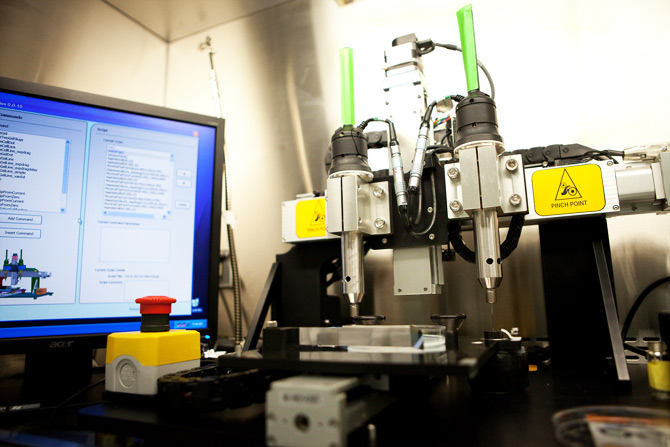

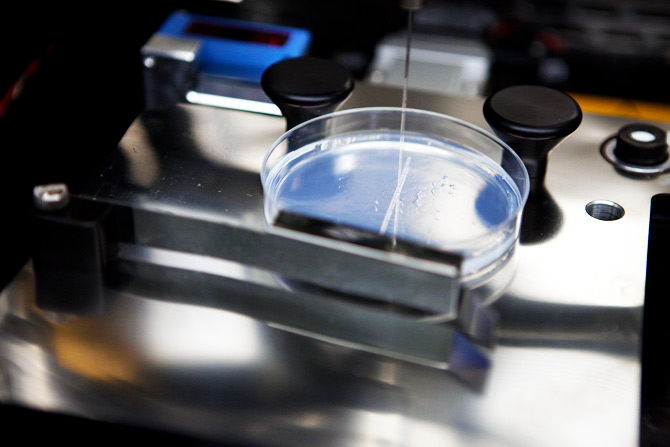

The developed printer uses two pump nozzles that spray either the substrate structure or the cells in the Petri dish (note of the translator is laboratory glassware in the form of a low flat cylinder). Pump nozzles are mounted on an accurate robotic assembly device for microscopic accuracy. In the photo above, the pump on the right is immersed in a container with hydrogel.

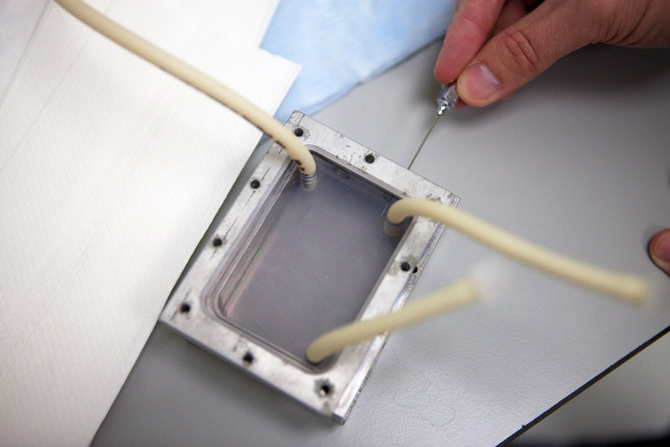

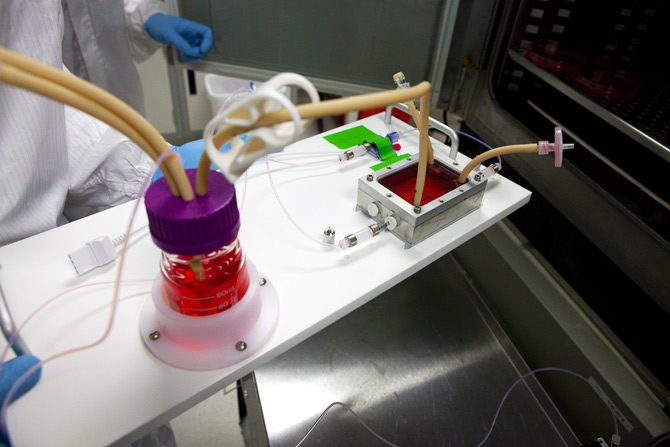

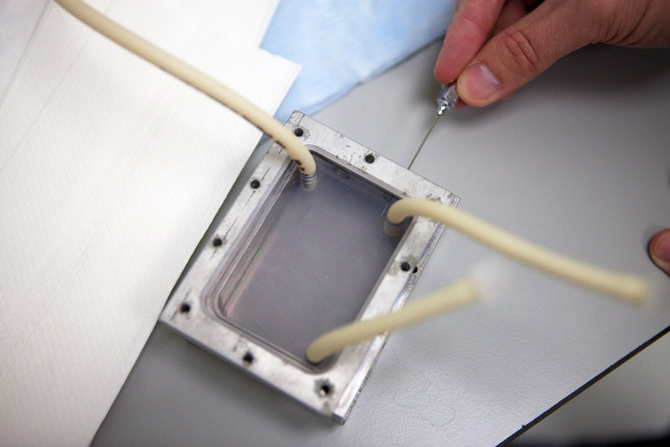

The chamber, called a bioreactor, serves to stimulate a vein — it is prepared just before vein printing. This bioreactor is a fairly standard piece of equipment in biotechnology. It is made from aluminum blocks that are surrounded by a plastic container with a variety of openings. These holes are used to inject chemical products that will feed the growing vein.

Before printing, the veins of the tube of cultured cells are manually loaded into the printhead - this is a kind of printer cartridge with biomass.

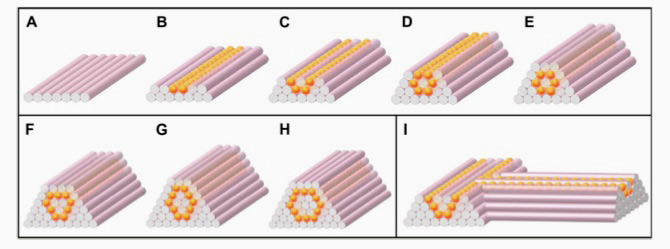

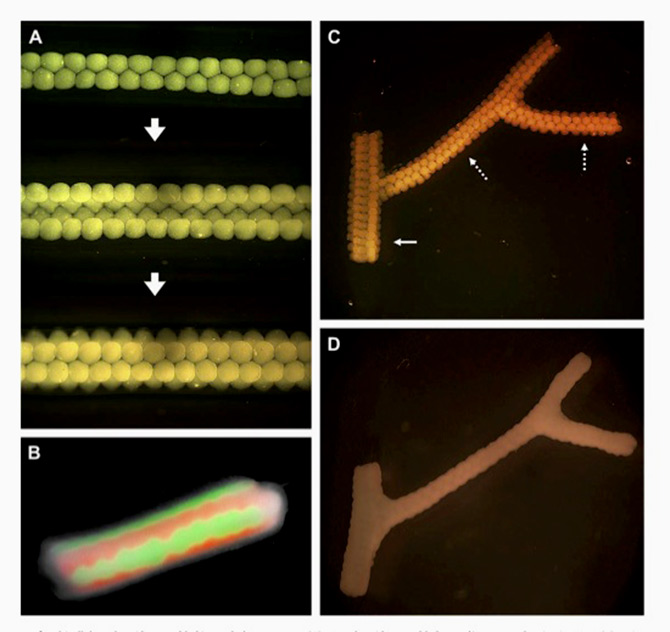

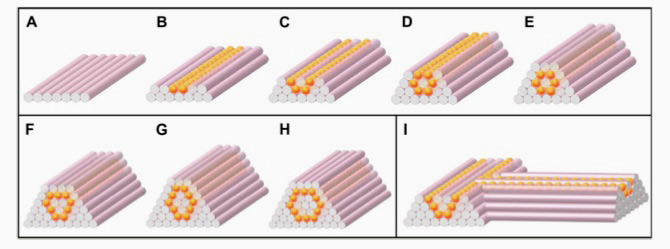

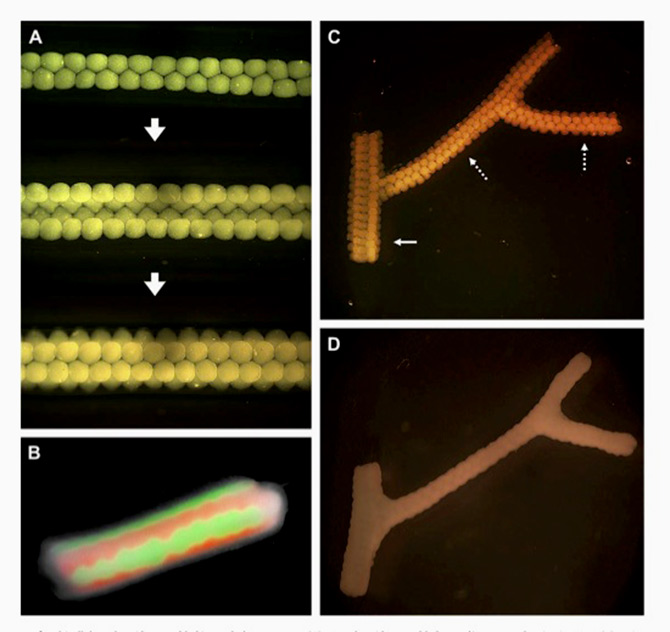

Hydrogel strips are laid out in parallel in a tray on a Petri dish. Then the cylinders of the cellular balls imprinted in this tray. Another hydrogel cylinder is printed in the middle of the cells; it is necessary to create a hole inside the vein through which blood will flow (illustration below).

Illustration courtesy of Organovo.

Printed veins are grown for several weeks in a different growth medium. Soon, the cells will be released from the hydrogel, and as a result, the hollow tubes of the vascular cells will remain.

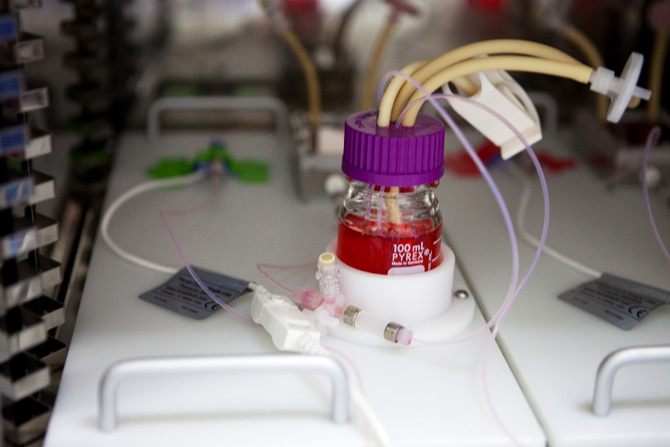

Printed cells in tube form are placed in the bioreactor. A bioreactor (photo above) pumps a special cocktail of proteins, buffer solutions and other various chemical products (photo below) through a printed vein. These are ideal conditions for keeping cells, make the veins strong and generally very good.

After staying in the bioreactor, the balls of cells grow together, forming veins that can be transplanted to the patient. Since the veins were grown from the patients' own cells, such veins are more likely to be taken up by the body.

“We are now doing well with typing blood vessels,” says Ben Schaferd, a senior research scientist at the regenerative medical company Organovo. “This week we printed 10 pieces. We continue to study how to improve the condition of the blood vessels, make them stronger. ”

Most of the organs in the human body are riddled with veins, so the ability to print blood vessels is one of the most important structural elements for creating entire organs. Printed veins will soon begin to check on animals, and, ultimately, will be conducted clinical trials on humans. If everything goes well, in a few years you will be able to replace damaged veins (for example, as a result of injections or chemotherapy) with custom-printed veins from your own cells.

')

Printing whole organs rests on the problems of not only the technological plan. The first machine that prints the organs will cost hundreds of millions of dollars - this is with the development, testing, production. And this is not to mention the difficulties that any company will have to face in obtaining permission from the Food and Drug Administration.

“If Organovo can get enough money, the company will have the opportunity to succeed as the first bioprinting company, but time will tell,” says Dr. Vladimir Mironov, director of matter bio-production at the University of Medicine in South Carolina.

Organovo showed Wired.com the whole process of printing blood vessels on a manufactured bioprinter.

Bioreactor

Sheferd placed the bioreactor inside the incubator, where the blood vessels will be pumped along with the growth medium for several days. The bioreactor uses a special mixture of chemicals that is identical to that encountered by the cells, growing in the body - this helps the cells turn into strong vascular tissue.

Photos: Dave Bullock / Wired.com

Stem cells

Senior research scientist Ben Schaferd pulls stem cells from a liquid nitrogen bath. Before the cells get into the printer, they are cultivated to a much larger number. Ultimately, these cells can be taken from different places in the patient's body — fat, bone marrow, skin cells — and turned into new veins.

After the cells have thawed, they are cultured in growth medium (photo above). This allows cells to multiply and grow so that they can be used to build veins. In this environment, special chemical products are also used that “indicate” stem cells to grow into the necessary types of cells - in this case - into the cells of blood vessels. As soon as the required number of cells is obtained, they are separated from the growth medium in a centrifuge (photo below) and compressed into balls.

Hydrogel backing

The first step in the entire printing process is to cover a material called a “hydrogel,” which is used as a temporary substrate to support the vein tissue.

The developed printer uses two pump nozzles that spray either the substrate structure or the cells in the Petri dish (note of the translator is laboratory glassware in the form of a low flat cylinder). Pump nozzles are mounted on an accurate robotic assembly device for microscopic accuracy. In the photo above, the pump on the right is immersed in a container with hydrogel.

The chamber, called a bioreactor, serves to stimulate a vein — it is prepared just before vein printing. This bioreactor is a fairly standard piece of equipment in biotechnology. It is made from aluminum blocks that are surrounded by a plastic container with a variety of openings. These holes are used to inject chemical products that will feed the growing vein.

Before printing, the veins of the tube of cultured cells are manually loaded into the printhead - this is a kind of printer cartridge with biomass.

Hydrogel Potting Mold for Blood Vessels

Hydrogel strips are laid out in parallel in a tray on a Petri dish. Then the cylinders of the cellular balls imprinted in this tray. Another hydrogel cylinder is printed in the middle of the cells; it is necessary to create a hole inside the vein through which blood will flow (illustration below).

Illustration courtesy of Organovo.

Vein growing

Printed veins are grown for several weeks in a different growth medium. Soon, the cells will be released from the hydrogel, and as a result, the hollow tubes of the vascular cells will remain.

Very good veins

Printed cells in tube form are placed in the bioreactor. A bioreactor (photo above) pumps a special cocktail of proteins, buffer solutions and other various chemical products (photo below) through a printed vein. These are ideal conditions for keeping cells, make the veins strong and generally very good.

Finished product

After staying in the bioreactor, the balls of cells grow together, forming veins that can be transplanted to the patient. Since the veins were grown from the patients' own cells, such veins are more likely to be taken up by the body.

Source: https://habr.com/ru/post/98932/