Softing, Star Wars ™ and Industrial Automation

1. Introduction

“... a long time ago, in a Galaxy far, far away ...” - of course, but where else can you find a suitable example of an industrial automation network, if not in “one far-distant galaxy”? Strictly speaking, from this point of view, we will be interested in not so positive heroes as, for example, Jedi Luke Skywalker or his colleagues and Sensei, who bravely turn nominal lightsabers into smoking minced (well, metal chips) insidious villains and their droids Companions, much less the "sharply negative" representatives of the "dark" side themselves, especially the persons sniffing with an asthmatic whistle into a black cosmic gas mask. In our case, the fearless adventurer comes to the fore (read - the prokhindey is still that!), A former pirate and smuggler, while later becoming the general of the New Republic, a bold and desperate captain of the Millennium Falcon spaceship ") Han Solo. As a matter of fact, within the framework of this work one should generally pay more attention to the ship itself. Even more precisely - on his famous modifications, implemented with the participation of Captain Solo and his chief mate Chewbacca.

2. The object of automation: a brief overview and at least a brief historical excursion

It should be recalled that the “Millennium Falcon”, a freighter ship produced by the “Correllian Engineering Corporation” (“CEC”), once belonged to smuggler Lando Calrissian and was beaten by the latter in the subaccarat (who does not know - there is - not in the same domino) by captain Solo Khan had already made his first round of Dougie Kessel and was well known in certain criminal and not-so-great circles. The ship was repeatedly rebuilt and modified both by Lando himself and later Solo (in general, it is clear for what purposes) - and, as a result, despite all his worn and patched appearance, he gained fame as one of the most maneuverable and high-speed ships in Galaxy. Enumeration of all the planets and stars, not to mention the debacles and adventures visited by the Millennium Falcon, thanks to its crew and passengers, of course, does not make sense and is beyond the scope of this work, especially since they are all documented in tons. glossy publications and kilometers of film.

The Sokol was built around 60 BC before the Yavinsky Battle on Corellia and was a typical freighter of the YT-1300 class, factory modification “f”. At that time, the YT-1300 model was very popular in criminal circles, as a light cargo ship usually did not arouse suspicion among law enforcement agencies. Moreover, if, nevertheless, a security corporation patrol revealed the smuggling on board, then, thanks to a sufficiently powerful engine, the YT-1300 often managed to escape prosecution. In addition, this, at first glance, absolutely civilian, SES product, intended for cargo-passenger transportation, differed favorably from its competitors' counterparts with a modular design that, after several legal (or not completely legal) modifications, reached the status of a warship with minimal investment .

')

Like any other object of this class, it would seem impossible to imagine YT-1300 without a high-tech integrated automation system, which should provide a solution to a wide range of tasks, including, for example, remote control and monitoring of system objects, creation of comfortable working conditions for the crew, effective consumption livelihoods, access control to technical premises, fire and security measures and much more. It is obvious that the use of a single integrated approach in solving the task of implementing a distributed process control system platform is the key to success. In contrast to the consolidation of a set of autonomous systems that use equipment from different generations of several manufacturers and, accordingly, unequal protocols, a single and scalable platform, provides flexible integration and control of subsystems of functionally different processes, carry out operational routing of information and control data flows between local and central control nodes including beyond the construction of the facility, it is easy to increase the capabilities of the deployed complex and much more st.

Alas, the above does not relate to the YT-1300 at all : as you know, CEC successfully competed on the galactic shipbuilding market, largely due to the large number of talented engineers united in the corporation’s enterprises, as well as well-established commercial ties with leading companies (eg, Girodyne, Quadex, etc.), many years specializing in the production of individual modules, ranging from fragments of the case and ending with a unique IT-stuffing. Pilot installation of units and functional units, as well as commissioning of control subsystems were carried out in the shops of these enterprises, and the assembly of the structure, installation of components and connection to the on-board network at the main shipyard of the corporation by the same “seconded” technical specialists. It is clear that, depending on the purpose and scope of a submodule, and also due to the relationships between the company and the manufacturer of automation system components developed over many years of cooperation, preference was given to a very specific technology, which often does not coincide with the choice of corporate partner. The result is - what? - correctly, a typical distributed control network is well-functioning and fully functioning within the framework of the task set, but, nevertheless, representing (yes, forgive us Chewbacca!) IT-zoo .

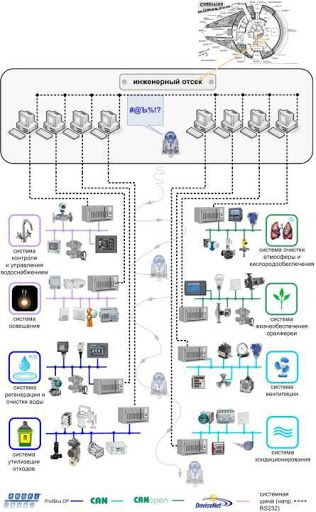

We intentionally do not provide a detailed description of all the subsystems of the YT-1300 - this is certainly beyond the scope of this work: only listing the names will take several pages of text. Therefore, we confine ourselves to a few conditional examples on a generalized structural diagram corresponding to a typical distributed control network of an industrial automation system, characteristic not only of the object under consideration, but also of a number of enterprises, organizations and companies. Recall that such networks usually represent a hierarchical structure consisting of three levels. The first, lower level - Device Level - is traditionally referred to as FieldBus (fieldbus). The main purpose of this level is to ensure the exchange of real-time information between field devices (sensors, gauges, actuators) and devices of a higher level - programmable logic controllers (PLC). The data exchange rate is usually hundreds of Kbps, but depending on the technology chosen, it can reach more than 10 Mbps. At the same time, taking into account the requirements for real-time mode implementation, the cycle time should not exceed 10 ms. That is why specialized protocols are used at the lower level of the network: for example, Profibus, CAN, Foundation FieldBus, etc. The next level of the Industrial Level network for automation is the control level. At this level, there are PLC, technological automated SCADA control systems, distributed DCS control systems and automated control systems developed on their basis. Typical cycle time at this level should not exceed 100 ms, however modern systems in some cases impose more stringent requirements, reducing the value of this parameter by two or more times to 50 ms or less. The interaction between the lower level and the network management level is carried out using a parallel or serial switching circuit. In the first case, each individual port of the PLC is connected with a separate guide system (copper wire, optical fiber) with a separate transducer of the sensor or mechanism. This scheme requires the installation of a large number of physical lines, which significantly increases the amount of work during network installation and significantly complicates its operation. Therefore, the vast majority of low-level networks of industrial automation systems use a sequential switching scheme to interact with the control level. Such a scheme operates on the basis of a serial data exchange channel implemented using the common bus, ring, and star topology. Finally, Corporate Level forms a top-level network, which is the basis for building control systems with a distributed computing process organization. In fact, Ethernet is currently dominating at this level. Systems conforming to the IEEE 802.3ae (10 GbE) standard are being actively implemented. The IEEE 802.3ba standard, which supports two data transfer rates of 40 and 100 Gbit / s, is currently under development. The 40GbE application is data transfer between high-performance storage area network server clusters (SAN). In turn, 100GbE is supposed to be used on trunk switching nodes, to support routing and aggregation of data in computer centers.

To describe the basic distributed network management system automation YT-1300, which, as mentioned above, uses several specialized protocols of lower-level networks, it is proposed to allocate four conventional groups of systems. Each group includes a set of subsystems conditionally implemented using a particular fieldbus protocol, the correspondence between which is summarized in Table. one.

Tab. one.

First, consider the group "1" of infrastructure management and life support systems (Fig. 1).

Suppose that the subsystem control subsystems of the infrastructure of an object belonging to group “1” in the basic configuration of YT-1300 suppose integration into a common low-speed top-level network (for example, based on the RS232 system protocol). Each of them is built on the basis of an industrial computer and a corresponding PLC, the processor module of which provides logical and technological control functions, and the software (software) of the PLC - sequential control of the executive elements of the system in accordance with a given mode of operation. The controller is programmed using a software package installed on a computer (PC), which can be connected to the PLC via an appropriate interface (for example, RS232). Monitoring of the functioning of the system is performed by the operator according to the results of data analysis displayed on the PC monitors of engineering (operator) stations centrally located in the technical room (in this case, according to the YT-1300 drawings regulated by CEC - in the engineering compartment). Similarly, data can also be removed by personnel directly from the operator’s console panel (this routine position of a “crawler” in our case can be assigned to one of the resilient droids - for example, the famous R2-D2). Management of technological processes is carried out both remotely using a PC engineering station, and from the operator’s console.

Unfortunately, you need to stop. There is too much material, it does not fit into the framework of one post. The full article is here .

The authors:

- Idea and implementation: Anton Burdin

- Some ideas and hot discussion: Shopin

- Consultant: Sidorov Artem

PS Yes, but what about Softing, you ask. Thanks for the question! About this in the article.

PPS The authors did not smoke grass, on the issue of purchase, please do not contact.

Source: https://habr.com/ru/post/97471/

All Articles