Industrial Revolution. Part 1. Rally Fighter - a car created by the "crowd"

More recently, the most authoritative article “In the Next Industrial Revolution, Atoms Are the New Bits” was published in the authoritative magazine Wired , describing the revolutionary processes currently taking place in industry, similar to those that took place on the Internet. The following is a translation of the first part of the article.

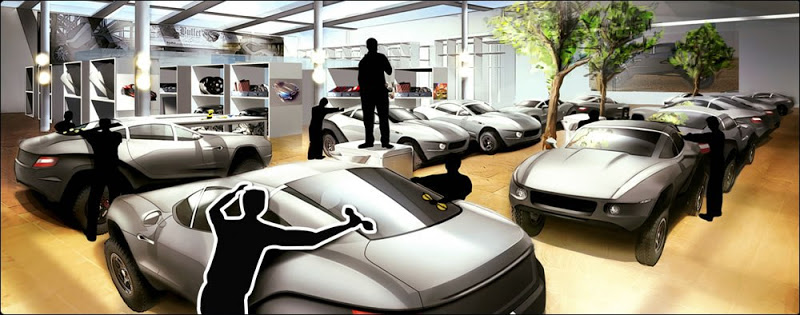

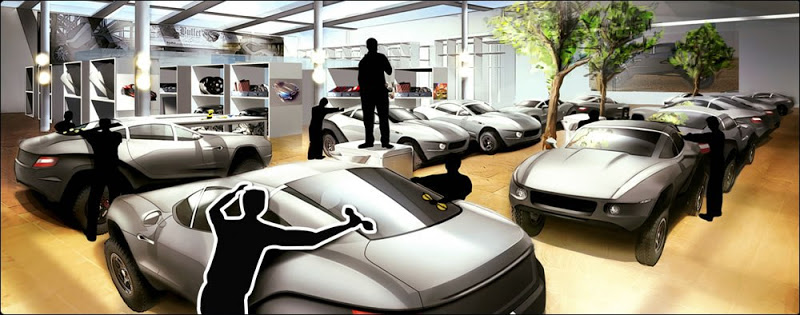

The door, similar to the entrance to the laundry, in the industrial park of Vorhema, Massachusetts, is not very much like the gateway to the future of American engineering, but in fact it is. This is the headquarters of Local Motors , the first open source company that produces cars. One has only to go inside and we will see a shocking example of what can be done in micro plants.

')

In June, Local Motors will officially unveil the Rally Fighter - a hybrid of an SUV and a racing car worth $ 50,000. The project of the car was developed jointly by the community of enthusiasts (crowdsourcing), and its final assembly will be done by the customers themselves in the local assembly centers. Now there are several new models on the way. According to the company, it takes about 18 months to create a new car, from the first drawing to the market launch — the time it takes for the Detroit auto giants only to change the specifications for the interior door. Each product is manufactured under the license "Share Friendly Creative Commons", which allows anyone to take part in the development of the car.

Rally Fighter was designed in a workshop on the back of the office in Warham. Also actively involved in the development was Factory Five Racing - a company for the production of automotive designers (hereinafter referred to as kit cars, kit cars), which is also an investor for Local Motors. The business of whale cars has existed for several decades, proving how small factories can work successfully in the automotive industry. Kit cars are a combination of welded pipe chassis and fiberglass body, with existing engines and components. Enthusiasts collect them in their garages, which frees cars from many legal restrictions. Factory Five, until today, sold about 8,000 of these auto designers.

The only problem with the whale car business is that cars are usually made similar to many models of sports cars, which incurs overhead costs in the form of lawsuits and license fees. This is holding back the growth of the whale-car industry, even during the “DIY” boom!

Jay Rogers, Head of Local Motors, found how to get around these limitations. His company produces completely unique products: instead of reproducing classic cars, they rethink what a car could be! The body of the Rally Fighter was developed by the Local Motors volunteer community. The result is a car that shame many automakers!

Firstly, it looks amazing - something in between a racing car and a P-51 Mustang fighter! For the creation of the most unorthodox car project, many talented designers have accomplished. The winner was Sangho Kim, a 30-year-old artist and student at the Art Center Colledge of Design in Pasadena, California. When Local Motors asked volunteers to send in their ideas for the next generation cars, Kim's drawings captivated everyone! And, despite the fact that initially there was no prize fund in the competition, the company provided Kim with a prize of $ 10,000. After the whole community united around the Rally Fighter, volunteers began to compete for the development of auxiliary parts, starting from the side holes and ending with the spotlights. Some of them were a designer, someone was an engineer, and many people simply liked to poke around in cars. But all of them were united by the fact that they didn’t want to develop just one more machine, meeting the requirements of the mass market and limited by conventions. They wanted to create something original.

While the community worked on the exterior, Local Motors designed the chassis and selected the engine (BMW) and gearbox. The Penske Automotive Group helped them a lot. This combination of self-development of elements that are critical in terms of performance and safety, with the creation of exterior design with the help of volunteers, allows crowdsourcing to create products that are even critical in terms of life and death.

Local Motors plans to sell from 500 to 2000 copies of each model. This is a niche car: it will not compete with serial models, but, instead, will fill the empty niche of unique cars. Rogers uses as a analogy a jar of stones, where each stone is a production car. Between the stones there is an empty space that can be filled with grains of sand. These grains of sand are Local Motors cars.

Local Motors has only 10 employees (this number will increase to 50 with the opening of new production centers, the first of which will be opened in Phoenix). The company buys the components and starts preparing the assembly kits only after the buyers make an advance payment.

Perhaps the will of fate Rogers headed the company Local Motors. His grandfather, Ralph Rogers, bought the Indian Motorcycle company in 1945. When, after the Second World War, Triumph lightweight motorcycles began to appear in the US, Rogers Sr. realized that the heavy Chief his company was producing could not carry with Triumph. The solution could be the production of a new lightweight engine that would allow the Indian to produce its own cheap and lightweight motorcycles. However, an attempt to develop a new engine failed. It was very difficult to change direction - and, in the end, Rogers Sr. lost his business.

Today, Rogers grandson is going to act even more radically: to create a completely new way of producing cars. His company has already raised about 7 million US dollars and he believes that this is enough to make it profitable. When asked what the difference is between what it was before and what it is now, Rogers replies: “They did not have the resources to enter the market: the production process was closely tied”. Changed the fact that the chain of deliveries is now open for the "ordinary guys."

Rogers, 36, favors military flight simulators as an echo of the time when he was captain of the Navy, taking part in hostilities in Iraq. In addition, he boasts a Harvard MBA degree and entrepreneurial activities in China.

While at Harvard, Rogers saw a presentation of the company Threadless, where anyone can create their own T-shirt! Of course, cars are more complicated than T-shirts, however, in both cases, there are many more people who can create their design than those who already pay for it. Rogers estimated that only less than 30 percent of auto-design students after graduating from university get a job at an auto company. But the rest, the place for which was not found, just and can create a well-organized community for the development of cars. Today, Local Motors web site has about 5,000 members. Thus, the ratio of volunteers to hired workers is 500 to 1.

To be continued.

The door, similar to the entrance to the laundry, in the industrial park of Vorhema, Massachusetts, is not very much like the gateway to the future of American engineering, but in fact it is. This is the headquarters of Local Motors , the first open source company that produces cars. One has only to go inside and we will see a shocking example of what can be done in micro plants.

')

In June, Local Motors will officially unveil the Rally Fighter - a hybrid of an SUV and a racing car worth $ 50,000. The project of the car was developed jointly by the community of enthusiasts (crowdsourcing), and its final assembly will be done by the customers themselves in the local assembly centers. Now there are several new models on the way. According to the company, it takes about 18 months to create a new car, from the first drawing to the market launch — the time it takes for the Detroit auto giants only to change the specifications for the interior door. Each product is manufactured under the license "Share Friendly Creative Commons", which allows anyone to take part in the development of the car.

Rally Fighter was designed in a workshop on the back of the office in Warham. Also actively involved in the development was Factory Five Racing - a company for the production of automotive designers (hereinafter referred to as kit cars, kit cars), which is also an investor for Local Motors. The business of whale cars has existed for several decades, proving how small factories can work successfully in the automotive industry. Kit cars are a combination of welded pipe chassis and fiberglass body, with existing engines and components. Enthusiasts collect them in their garages, which frees cars from many legal restrictions. Factory Five, until today, sold about 8,000 of these auto designers.

The only problem with the whale car business is that cars are usually made similar to many models of sports cars, which incurs overhead costs in the form of lawsuits and license fees. This is holding back the growth of the whale-car industry, even during the “DIY” boom!

Jay Rogers, Head of Local Motors, found how to get around these limitations. His company produces completely unique products: instead of reproducing classic cars, they rethink what a car could be! The body of the Rally Fighter was developed by the Local Motors volunteer community. The result is a car that shame many automakers!

Firstly, it looks amazing - something in between a racing car and a P-51 Mustang fighter! For the creation of the most unorthodox car project, many talented designers have accomplished. The winner was Sangho Kim, a 30-year-old artist and student at the Art Center Colledge of Design in Pasadena, California. When Local Motors asked volunteers to send in their ideas for the next generation cars, Kim's drawings captivated everyone! And, despite the fact that initially there was no prize fund in the competition, the company provided Kim with a prize of $ 10,000. After the whole community united around the Rally Fighter, volunteers began to compete for the development of auxiliary parts, starting from the side holes and ending with the spotlights. Some of them were a designer, someone was an engineer, and many people simply liked to poke around in cars. But all of them were united by the fact that they didn’t want to develop just one more machine, meeting the requirements of the mass market and limited by conventions. They wanted to create something original.

While the community worked on the exterior, Local Motors designed the chassis and selected the engine (BMW) and gearbox. The Penske Automotive Group helped them a lot. This combination of self-development of elements that are critical in terms of performance and safety, with the creation of exterior design with the help of volunteers, allows crowdsourcing to create products that are even critical in terms of life and death.

Local Motors plans to sell from 500 to 2000 copies of each model. This is a niche car: it will not compete with serial models, but, instead, will fill the empty niche of unique cars. Rogers uses as a analogy a jar of stones, where each stone is a production car. Between the stones there is an empty space that can be filled with grains of sand. These grains of sand are Local Motors cars.

Local Motors has only 10 employees (this number will increase to 50 with the opening of new production centers, the first of which will be opened in Phoenix). The company buys the components and starts preparing the assembly kits only after the buyers make an advance payment.

Perhaps the will of fate Rogers headed the company Local Motors. His grandfather, Ralph Rogers, bought the Indian Motorcycle company in 1945. When, after the Second World War, Triumph lightweight motorcycles began to appear in the US, Rogers Sr. realized that the heavy Chief his company was producing could not carry with Triumph. The solution could be the production of a new lightweight engine that would allow the Indian to produce its own cheap and lightweight motorcycles. However, an attempt to develop a new engine failed. It was very difficult to change direction - and, in the end, Rogers Sr. lost his business.

Today, Rogers grandson is going to act even more radically: to create a completely new way of producing cars. His company has already raised about 7 million US dollars and he believes that this is enough to make it profitable. When asked what the difference is between what it was before and what it is now, Rogers replies: “They did not have the resources to enter the market: the production process was closely tied”. Changed the fact that the chain of deliveries is now open for the "ordinary guys."

Rogers, 36, favors military flight simulators as an echo of the time when he was captain of the Navy, taking part in hostilities in Iraq. In addition, he boasts a Harvard MBA degree and entrepreneurial activities in China.

While at Harvard, Rogers saw a presentation of the company Threadless, where anyone can create their own T-shirt! Of course, cars are more complicated than T-shirts, however, in both cases, there are many more people who can create their design than those who already pay for it. Rogers estimated that only less than 30 percent of auto-design students after graduating from university get a job at an auto company. But the rest, the place for which was not found, just and can create a well-organized community for the development of cars. Today, Local Motors web site has about 5,000 members. Thus, the ratio of volunteers to hired workers is 500 to 1.

To be continued.

Source: https://habr.com/ru/post/92779/

All Articles