3D printing for everyone

In the last post I told you about how the world's leading designers use 3D printing, and today I will present a project that allows anyone to use the full potential of our 3D technologies and share some unique examples of what has already been printed with us - in i .materialise .

i.materialise was founded in August 2009 and is currently in beta. When I first heard about the possibilities of 3D printing, it seemed to me that it was necessary to be at least a guru in 3D modeling in order to be able to print something. But, as practice shows, most of the models we printed were created by people far from 3D modeling.

')

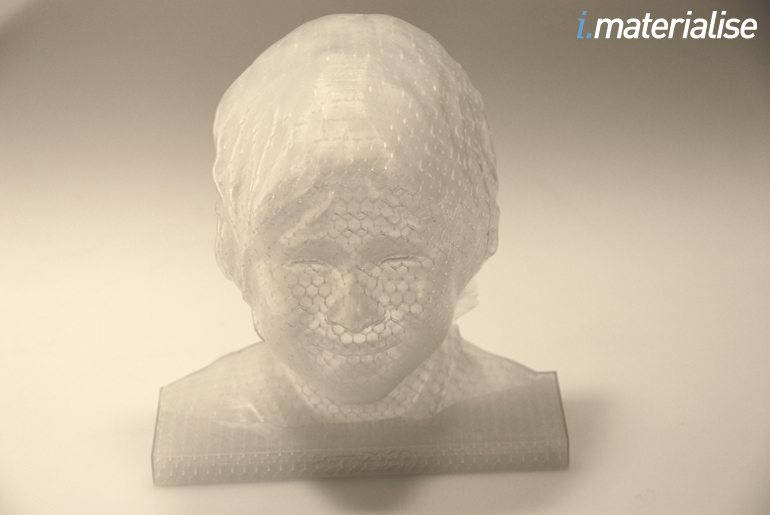

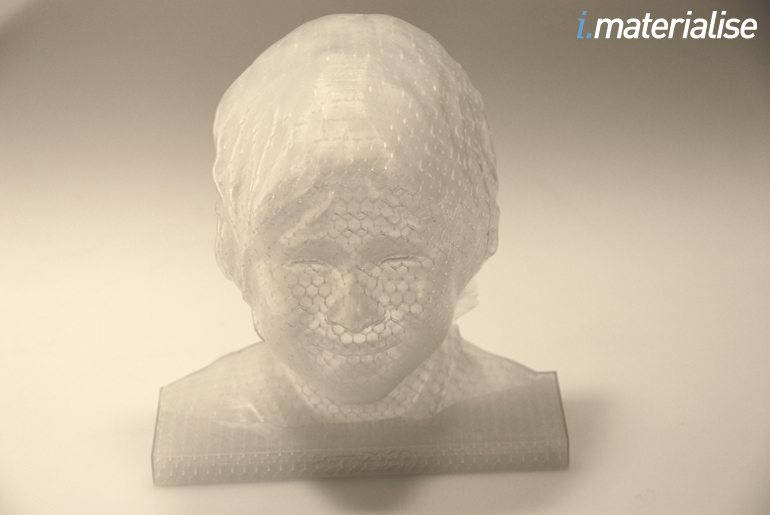

Pouring a bust in bronze by a sculptor is quite expensive and troublesome. But we found the solution easier, cheaper and in many ways better. Using modern 3D scanners, it is possible to scan any surface, including a human face. The scanning procedure takes up to 15 seconds, and all the user needs to do is schedule an appointment and scan themselves. Unfortunately, while we are in the beta stage, our company's 3D scanners are located only in the main office in Belgium. However, this equipment is quite popular, and is available in almost all large cities of Eastern Europe.

After receiving the 3D model, our engineers prepare the file for 3D printing, and using a 3D printer, a form is printed that will be used directly in pouring the model in bronze:

The end result is a complete bronze model, which allows you to save the smallest details of the original 3D file:

It happens. One of our employees literally used a slice of the scanned part of a human bone to create a small desk lamp. The lampshade was printed in a 3D printer, and then, in order to make this model really special, we developed a special stand for it - and this is what we did:

Few people know, but Excel can also be used in 3D design. How? Very simple! Some forms can be based on an algorithm and then exported to a 3D editor to get these results:

This lamp was printed at one time, despite the moving elements. This is another unique feature of 3D printing - the production of moving parts and parts without the need for further assembly.

In continuation of mathematical solutions in 3D printing, the next lamp was based on a parametric curve. The author picked up the appropriate form in the Maxim computer algebra system (this program allows us to visualize the function) and then generated a tube around the curve in our 3D editor - Magics . Our engineers completed the rest themselves - and here is the result:

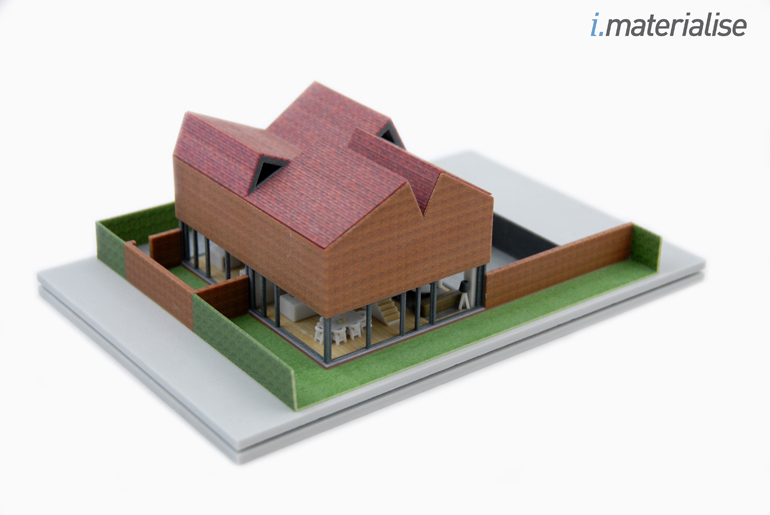

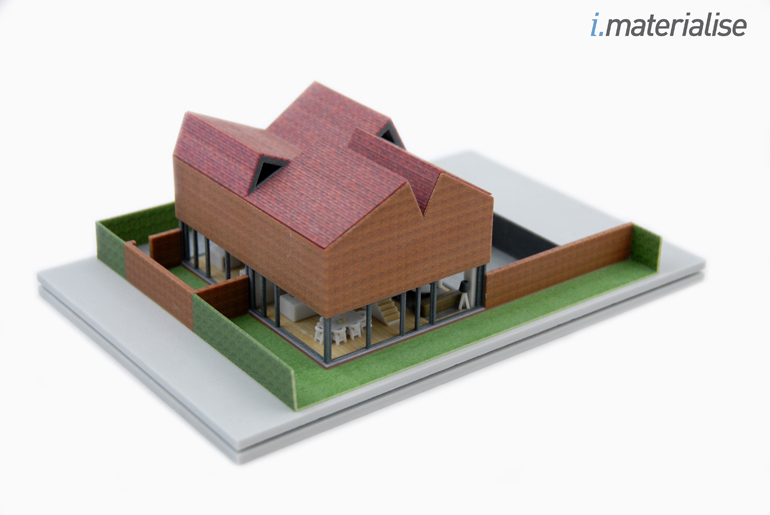

One of the easiest 3D editors to date is Google SketchUp, and in early April we released a small plugin for SketchUp , which allows us to create the layout of our building using our technology. Here are a few layouts that we have already printed, and which have been developed not by designers, but by users:

i.materialise seeks to bring and enable 3D printing to all who are interested. But what awaits us in the future? As Peter Sunde, founder of Pirate Bay, has already noted for quite some time, in the future we will be able to share not only files, but also hardware via the Internet. There are already opportunities for 3D printing in various metals, glass, plastic materials, and even living tissue . Personal 3D printers that are relatively inexpensive and can be used at home are already available. But about it - next time.

i.materialise was founded in August 2009 and is currently in beta. When I first heard about the possibilities of 3D printing, it seemed to me that it was necessary to be at least a guru in 3D modeling in order to be able to print something. But, as practice shows, most of the models we printed were created by people far from 3D modeling.

')

Bronze statues and 3D printing

Pouring a bust in bronze by a sculptor is quite expensive and troublesome. But we found the solution easier, cheaper and in many ways better. Using modern 3D scanners, it is possible to scan any surface, including a human face. The scanning procedure takes up to 15 seconds, and all the user needs to do is schedule an appointment and scan themselves. Unfortunately, while we are in the beta stage, our company's 3D scanners are located only in the main office in Belgium. However, this equipment is quite popular, and is available in almost all large cities of Eastern Europe.

After receiving the 3D model, our engineers prepare the file for 3D printing, and using a 3D printer, a form is printed that will be used directly in pouring the model in bronze:

The end result is a complete bronze model, which allows you to save the smallest details of the original 3D file:

Lamp shade of the part of the scanned human bone?

It happens. One of our employees literally used a slice of the scanned part of a human bone to create a small desk lamp. The lampshade was printed in a 3D printer, and then, in order to make this model really special, we developed a special stand for it - and this is what we did:

Microsoft Excel as a favorite 3D editor?

Few people know, but Excel can also be used in 3D design. How? Very simple! Some forms can be based on an algorithm and then exported to a 3D editor to get these results:

This lamp was printed at one time, despite the moving elements. This is another unique feature of 3D printing - the production of moving parts and parts without the need for further assembly.

In continuation of mathematical solutions in 3D printing, the next lamp was based on a parametric curve. The author picked up the appropriate form in the Maxim computer algebra system (this program allows us to visualize the function) and then generated a tube around the curve in our 3D editor - Magics . Our engineers completed the rest themselves - and here is the result:

Architecture and 3D printing

One of the easiest 3D editors to date is Google SketchUp, and in early April we released a small plugin for SketchUp , which allows us to create the layout of our building using our technology. Here are a few layouts that we have already printed, and which have been developed not by designers, but by users:

The future of 3D printing

i.materialise seeks to bring and enable 3D printing to all who are interested. But what awaits us in the future? As Peter Sunde, founder of Pirate Bay, has already noted for quite some time, in the future we will be able to share not only files, but also hardware via the Internet. There are already opportunities for 3D printing in various metals, glass, plastic materials, and even living tissue . Personal 3D printers that are relatively inexpensive and can be used at home are already available. But about it - next time.

Source: https://habr.com/ru/post/92027/

All Articles