Monitoring in the data center

While the RIF + CIB conference is gaining momentum, we decided to talk a bit about the monitoring system in the data center.

')

How to control the parameters of the equipment, we are thinking at the design stage of the data center. There are several ways to integrate sensors and various devices into a single system, and perhaps the most popular of them is SNMP monitoring, the simple network management protocol. But we decided to go another way, more industrial: to use industrial systems of automatic monitoring and control. Moreover, the air conditioners planned for procurement and installation fully meet the requirements of this approach, having the ability to output data via the Modbus protocol (industrial client-server protocol) and through dry contacts. Uninterruptible power supplies had the same functionality. To them, however, were attached and SNMP-modules. We plan to integrate them into the system when it is planned to be updated within a year or two. They will not make a special weather, but if you integrate it, so to the end. In the meantime, the equipment performance indicators are removed via the Modbus protocol and fed into the system implemented on the components of the Xenta line of the famous Swedish company TAC, now part of the all-encompassing Schneider Group.

Obviously, business is not limited to air conditioners and UPS only. Temperature sensors are installed in racks, temperature and humidity are installed in cold and hot corridors. Usually, all sensors are placed on top, but if necessary (usually, at the request of the customer) we can place additional sensors in an arbitrary location, for example, next to particularly sensitive equipment in the rack.

As a result, each air conditioner, chiller and UPS transmit data about their work in a single system. Moreover, data transfer is two-way, which allows you to start, stop and change the settings of the equipment. This is one of the features of the Modbus protocol: an engineer can connect from almost any device (and from everywhere) and give control commands. But the Italians from Geoclima went the furthest: you can even monitor their production chillers through a GSM gateway.

Some moments are dotted.

In case of failure, the monitoring system is integrated with the access control system. We plan to organize an SNMP gateway in order to send data to the monitoring system (SCADA) through the converter. This will allow, in particular, to accumulate detailed statistics on the workload of the power distribution system (PDU) sockets inside the rack. Diesel generator sets are also connected to the system, this gives you the opportunity to monitor operating parameters and monitor fuel consumption in real time.

Automation cabinet (there are six in the data center). The photo shows the TAC Xenta hubs.

PCO Web interface, dry contact system.

View from the side.

Dry contact system

Rack temperature sensor.

The control device on the front door rack.

Motion Sensor.

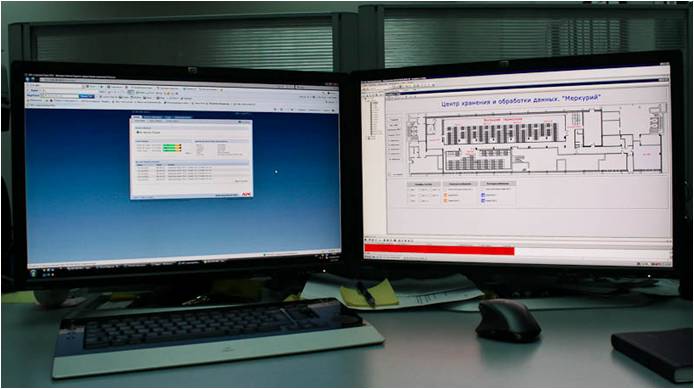

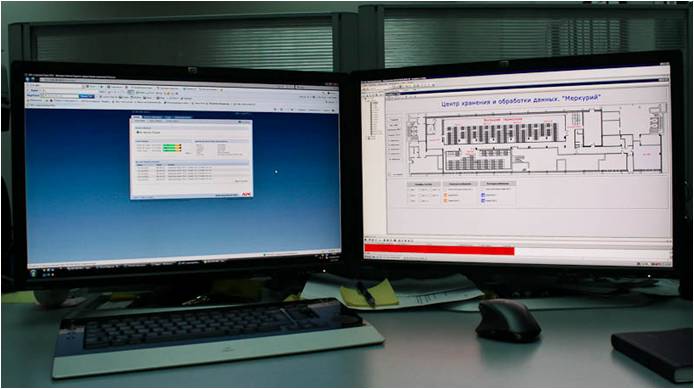

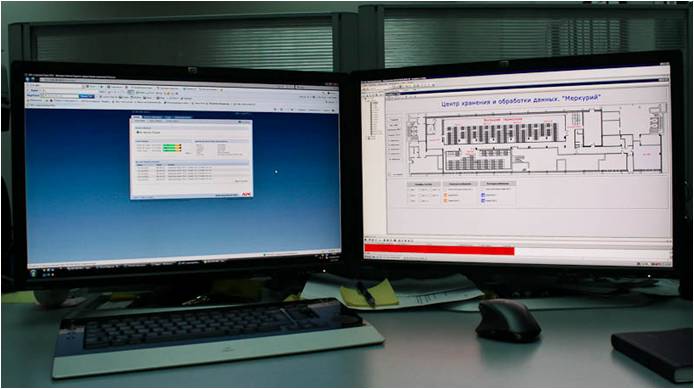

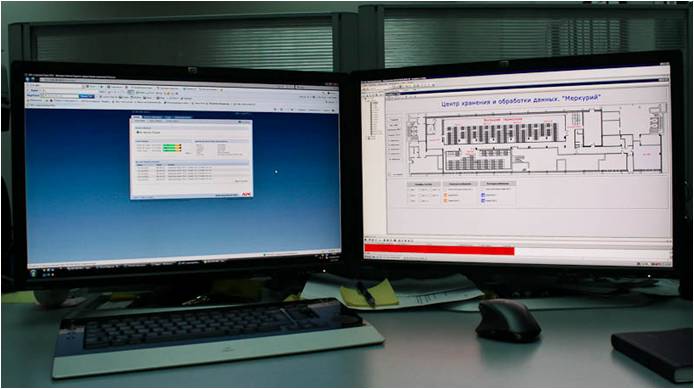

Workstation in the network control center (NOC).

')

How to control the parameters of the equipment, we are thinking at the design stage of the data center. There are several ways to integrate sensors and various devices into a single system, and perhaps the most popular of them is SNMP monitoring, the simple network management protocol. But we decided to go another way, more industrial: to use industrial systems of automatic monitoring and control. Moreover, the air conditioners planned for procurement and installation fully meet the requirements of this approach, having the ability to output data via the Modbus protocol (industrial client-server protocol) and through dry contacts. Uninterruptible power supplies had the same functionality. To them, however, were attached and SNMP-modules. We plan to integrate them into the system when it is planned to be updated within a year or two. They will not make a special weather, but if you integrate it, so to the end. In the meantime, the equipment performance indicators are removed via the Modbus protocol and fed into the system implemented on the components of the Xenta line of the famous Swedish company TAC, now part of the all-encompassing Schneider Group.

Obviously, business is not limited to air conditioners and UPS only. Temperature sensors are installed in racks, temperature and humidity are installed in cold and hot corridors. Usually, all sensors are placed on top, but if necessary (usually, at the request of the customer) we can place additional sensors in an arbitrary location, for example, next to particularly sensitive equipment in the rack.

As a result, each air conditioner, chiller and UPS transmit data about their work in a single system. Moreover, data transfer is two-way, which allows you to start, stop and change the settings of the equipment. This is one of the features of the Modbus protocol: an engineer can connect from almost any device (and from everywhere) and give control commands. But the Italians from Geoclima went the furthest: you can even monitor their production chillers through a GSM gateway.

Some moments are dotted.

In case of failure, the monitoring system is integrated with the access control system. We plan to organize an SNMP gateway in order to send data to the monitoring system (SCADA) through the converter. This will allow, in particular, to accumulate detailed statistics on the workload of the power distribution system (PDU) sockets inside the rack. Diesel generator sets are also connected to the system, this gives you the opportunity to monitor operating parameters and monitor fuel consumption in real time.

Automation cabinet (there are six in the data center). The photo shows the TAC Xenta hubs.

PCO Web interface, dry contact system.

View from the side.

Dry contact system

Rack temperature sensor.

The control device on the front door rack.

Motion Sensor.

Workstation in the network control center (NOC).

Source: https://habr.com/ru/post/91549/

All Articles