Import and installation of equipment in the data center

As we promised, we are moving from the narration about the construction of a data center to more subject areas. Today we will tell and show how import, registration and installation of client equipment in the data center takes place. In principle, there is nothing surprising, or exciting, but those who are interested in questions like “how everything is arranged there” will certainly be interesting.

')

Let's start, as usual, with the hanger, or rather, with how the equipment is brought. It mainly depends on how much equipment arrives at this particular moment. You can easily bring a couple of servers on an ordinary passenger car, but if there are more, you will have to think about the procedure. The author of the post once had the opportunity to participate in the acceptance, unloading, packing and installation of three hundred (!) Servers, and he felt from his own experience the importance of proper organization of the process.

Equipment, if its a lot, it is best to bring at night. Thus, several birds with one stone are killed: a truck (or a regular car) does not interfere with maneuvering, since parking is empty at night, passersby do not get underfoot, and onlookers do not pay any attention to the process simply because they are not there. The main thing is not to interfere with the sleep of citizens who rest after a busy day. We do it, the benefit of the nearest residential buildings are at some distance. However, most often the equipment is imported in the daytime - this is more convenient for customers. In this case, of course, there are some roughness. For example, a lot of cars are parked near the data center and the driver has to maneuver intensively. Equipment pallets also sometimes have to be unloaded directly onto the roadway. This is not very good, but at least we are not ashamed of this fact, and our customers are well aware that the ideal is unattainable.

After the boxes are unloaded from the car, they are moved to the data center. If there are few boxes, you can place them right in the entrance area.

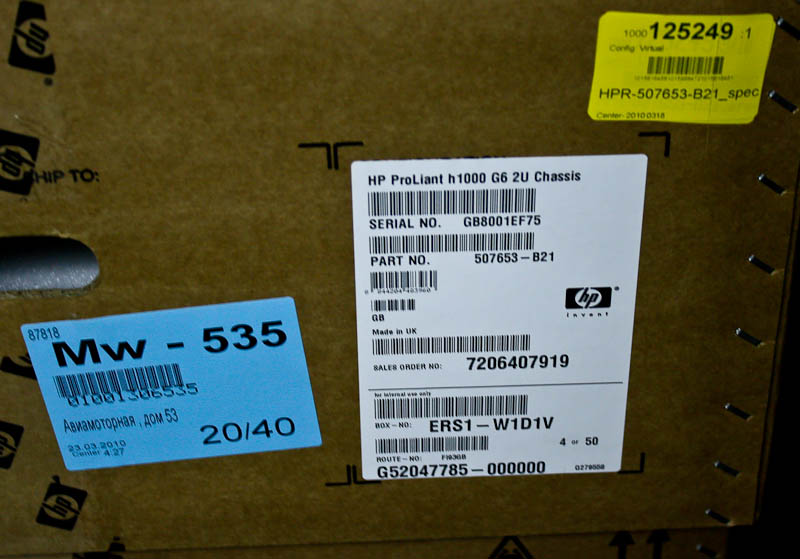

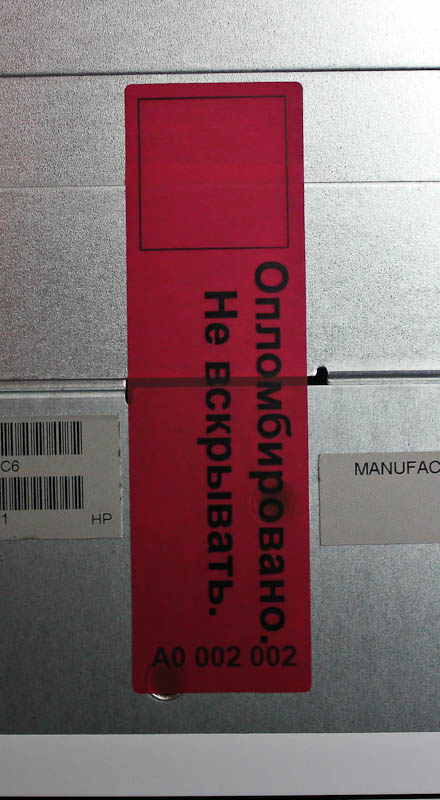

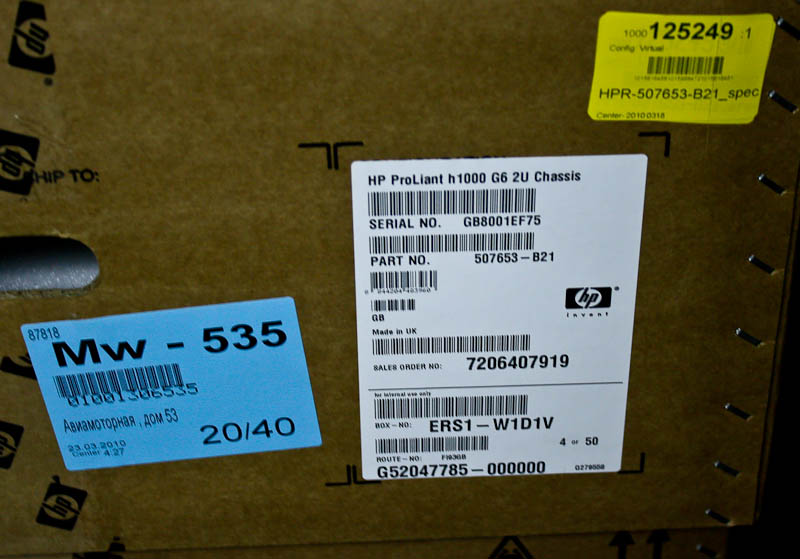

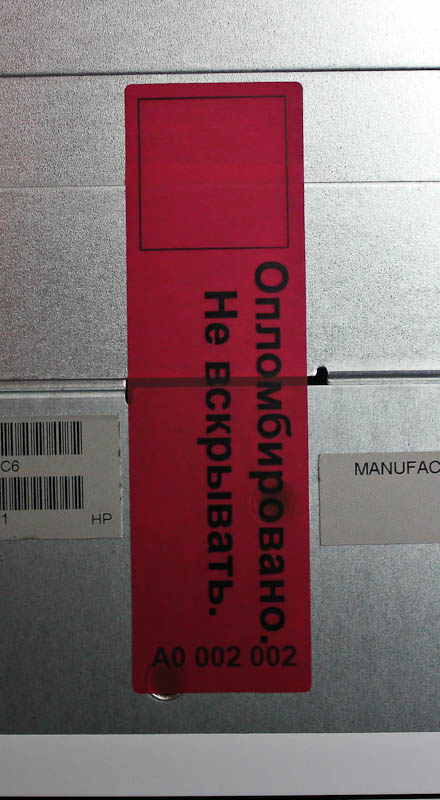

Then the equipment is unpacked, “placed” in the base, glued with stickers and seals. This purpose is served by a special Toshiba printer for printing labels and a Brady portable - we’ll tell about them in more detail in a separate post about inventory.

Ready servers are moved to tight area. The floor in the containment area is clean and durable, so customer engineers are not shy about putting the equipment directly on it. For those who consider this not safe enough, we provide a trolley.

After this step, the rack mounting begins. We didn’t begin to photograph engineers, so you’ll have to imagine the harsh and strong bearded guys with sweater glasses, real iron kings and keyboard jockeys. This, of course, is a joke. Our engineers are modern young people, each with their own interests, very unbanal.

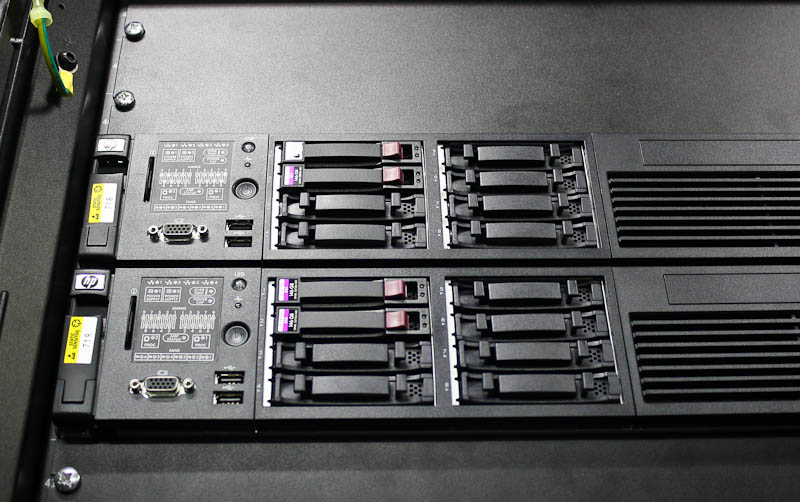

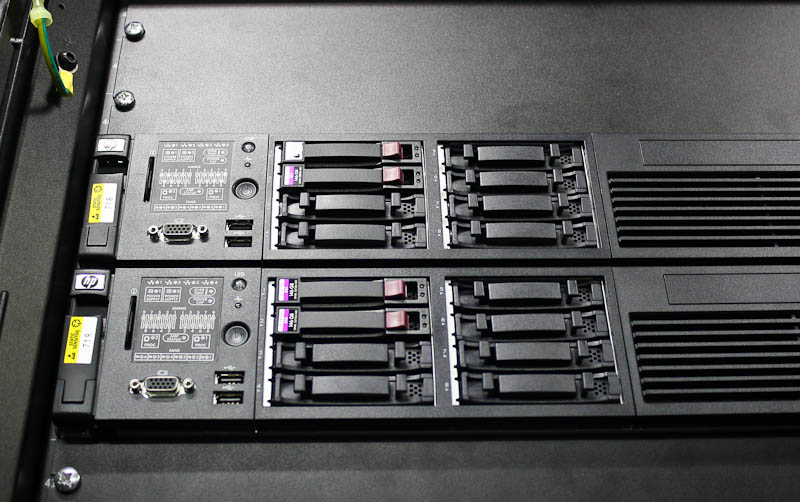

When installing any equipment in the rack, be sure to go broke on the false panels (blanking plates). At unclosed intervals, the cold air evaporates in huge quantities - it is often possible to solve cooling problems just by installing panels, so saving them is the last thing. The photo panel is not yet installed, but visible between servers and storage systems.

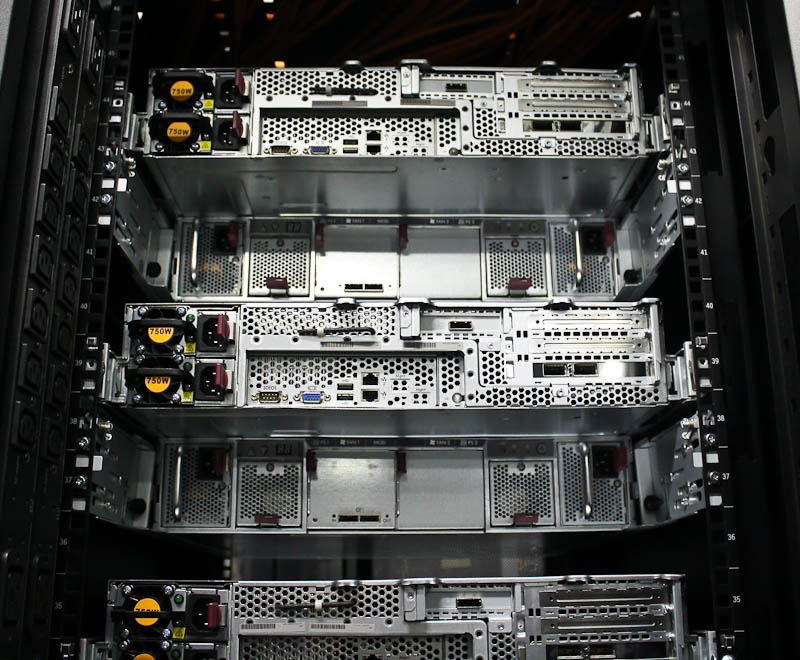

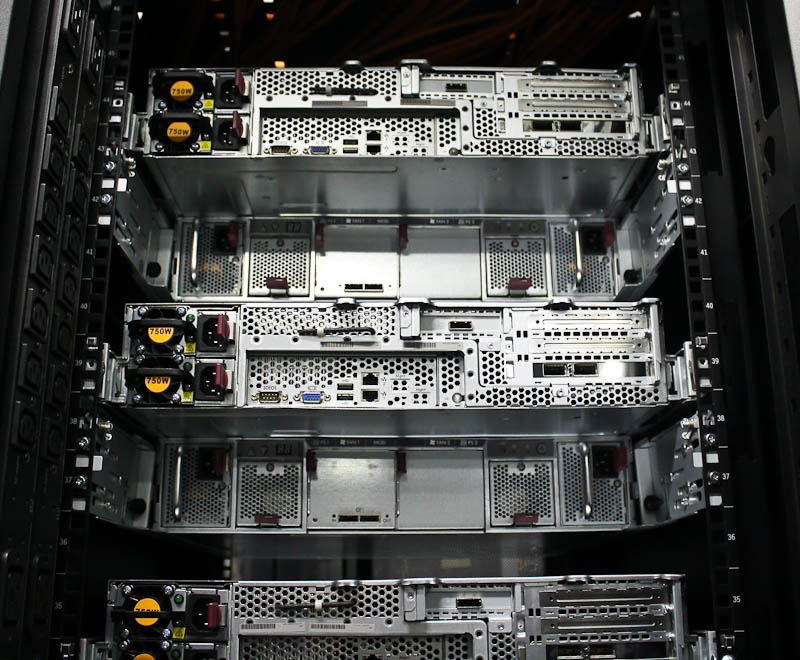

So neat and pretty everything looks in the end.

The final stage is the connection and configuration. We will write about him soon too!

')

Let's start, as usual, with the hanger, or rather, with how the equipment is brought. It mainly depends on how much equipment arrives at this particular moment. You can easily bring a couple of servers on an ordinary passenger car, but if there are more, you will have to think about the procedure. The author of the post once had the opportunity to participate in the acceptance, unloading, packing and installation of three hundred (!) Servers, and he felt from his own experience the importance of proper organization of the process.

Equipment, if its a lot, it is best to bring at night. Thus, several birds with one stone are killed: a truck (or a regular car) does not interfere with maneuvering, since parking is empty at night, passersby do not get underfoot, and onlookers do not pay any attention to the process simply because they are not there. The main thing is not to interfere with the sleep of citizens who rest after a busy day. We do it, the benefit of the nearest residential buildings are at some distance. However, most often the equipment is imported in the daytime - this is more convenient for customers. In this case, of course, there are some roughness. For example, a lot of cars are parked near the data center and the driver has to maneuver intensively. Equipment pallets also sometimes have to be unloaded directly onto the roadway. This is not very good, but at least we are not ashamed of this fact, and our customers are well aware that the ideal is unattainable.

After the boxes are unloaded from the car, they are moved to the data center. If there are few boxes, you can place them right in the entrance area.

Then the equipment is unpacked, “placed” in the base, glued with stickers and seals. This purpose is served by a special Toshiba printer for printing labels and a Brady portable - we’ll tell about them in more detail in a separate post about inventory.

Ready servers are moved to tight area. The floor in the containment area is clean and durable, so customer engineers are not shy about putting the equipment directly on it. For those who consider this not safe enough, we provide a trolley.

After this step, the rack mounting begins. We didn’t begin to photograph engineers, so you’ll have to imagine the harsh and strong bearded guys with sweater glasses, real iron kings and keyboard jockeys. This, of course, is a joke. Our engineers are modern young people, each with their own interests, very unbanal.

When installing any equipment in the rack, be sure to go broke on the false panels (blanking plates). At unclosed intervals, the cold air evaporates in huge quantities - it is often possible to solve cooling problems just by installing panels, so saving them is the last thing. The photo panel is not yet installed, but visible between servers and storage systems.

So neat and pretty everything looks in the end.

The final stage is the connection and configuration. We will write about him soon too!

Source: https://habr.com/ru/post/89005/

All Articles