Gametrix Viper steering wheel: looking for weak spots

The Gametrix Viper gaming set has a unique gaming warranty period - 60 months for home use and 12 months for commercial use.

What allows us to be sure that the game set will honestly fulfill the stated period?

This article is a continuation of this material.

In the material Factors affecting the resource of game rudders, I described the main elements of game rudders that affect the overall resource of the device. Because I am one of the developers of the game wheel Gametrix Viper , I can not talk about anything except thewomen of this wheel, as you know.

Accordingly, I want to evaluate the resource of this model according to the method proposed above.

SENSOR

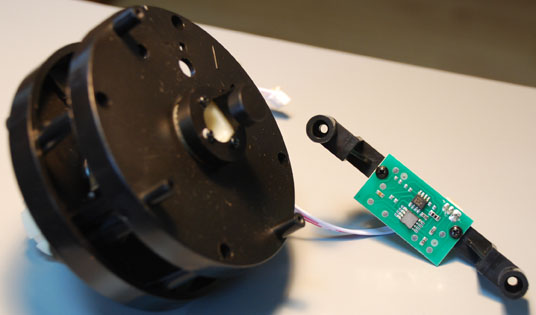

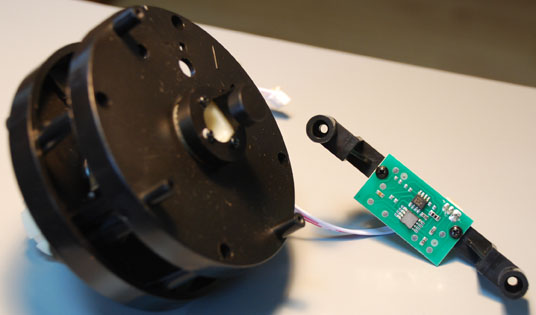

For the first time in the world, magnetic resistive sensors, which we called MaRS , were used in the steering wheel and pedals of the Gametrix Viper. MaRS sensors and a controller for them are designed and manufactured in Russia.

On the photo - MaRS sensors on the group blank

')

The principle of the sensor is to measure the angle between the poles of a permanent magnet.

It is obvious that in this case there are no rubbing elements in the sensor.

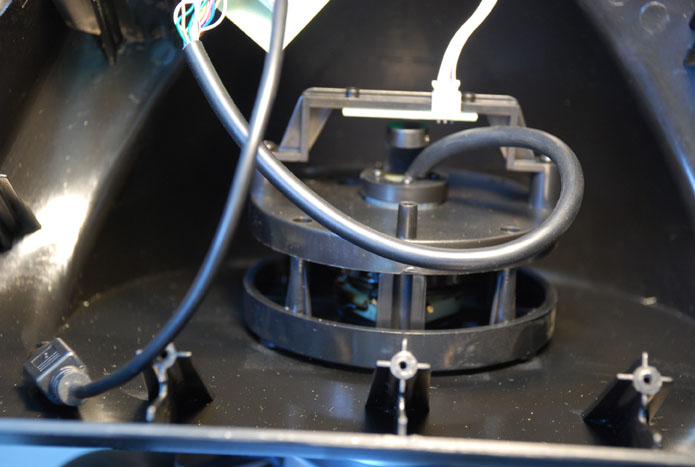

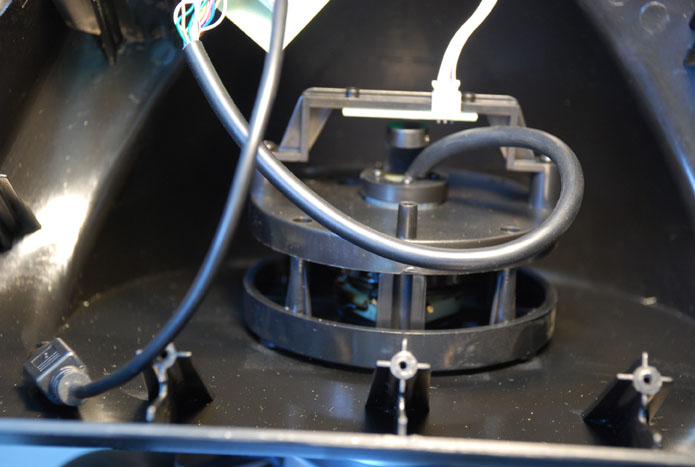

Here is what this node looks like inside the steering wheel physically:

You can clearly see that the sensor and the magnet do not touch

But how this scheme is implemented inside the pedals.

In the axis of rotation of the pedals pressed round magnets:

Next to the magnets installed sensors:

Note that there are two plastic walls between the magnet and the sensor. The convenience of MaRS sensors also lies in the fact that plastic is not a barrier to the magnetic field.

I hope I could convince you that there is no friction in the sensor.

Thus, the resource sensors, we can recognize the infinite.

REDUCER

Compare these two elements:

This is the same steering centering unit, but implemented on different sensors. On the left - on the potentiometer, on the right - on the MaRS

As you can see, MaRS is installed directly on the axis of rotation of the wheel of the wheel and the gearbox is absent as a class.

The same thing we see inside the pedals:

Gearbox potentiometers

Gearbox missing, MaRS sensors do not need it

We see that the element of reducing the resource "reducer" is completely absent. True, the charge for this is the absence of the Force Feedback system. The Gametrix Viper steering wheel is centered with a spring, and the feedback is realized with the help of vibration.

AXIS ROTATION

Because In the steering wheel of the Viper there is no gear, then exactly three axes of rotation remain - the axis of the steering wheel and the two axles of the pedals.

Actually declared resource in 5 years and is determined by these nodes - there are no more nodes subject to wear, there is no steering wheel.

Let's look at the design of these nodes in more detail.

The most loaded unit is the steering centering mechanism. It is precisely it that is rotated with the greatest speed, and it is on him that the weight of the hands of the player lies.

Consider how it works

Remove the sensor

Remove the magnet mount

Remove the top cover

Remove the spring cover. Note the presence of grease

We take out the central axis, on which the steering wheel rotates

As can be seen from this photo, the plain bearing, which is implemented on the steering axle of the Viper, is formed by two holes in the cover and a circular axis in them.

The first place where there can be a backlash is exactly here.

It should be noted that the gap in this node is present initially. This is due to the fact that it is impossible to ensure such an exact fit as, say, between the crankshaft and the engine connecting rod, since This is a plastic that is extremely difficult to match with such precision. The second reason is that with precise adjustment the sliding bearing requires constant lubrication, otherwise it will rotate too tightly and wear out quickly. Therefore, in these parts initially laid a certain gap that allows the axis to rotate freely.

Another important point that distinguishes the MaRS sensor from the potentiometer. With the MaRS sensor, axle play will NOT cause dead zones to appear . Those. the occurrence of backlash does not lead to poor controllability.

By the way. We reworked this unit and put the bearing in it. Presented on the photo site in home use conditions can be safely recognized as eternal. A wheel with such a centering unit and on proximity sensors can be transferred to the grandchildren - it will work the same way as on the day of purchase. However, the use of such a node will increase the price of the product by $ 7-10 and its production is considered inexpedient. The investor believes that at such a price the buyer will not buy a steering wheel with vibration, but will prefer a steering wheel with FFB. Thus, this improved perpetual steering wheel will not be sold, so this device has not yet been used in serial devices.

The second place where wear will occur is the spring stops.

At this point, the steel spring slides over the plastic, which in the future threatens to wear out. However, the resource of this site is very large, because this place is well lubricated, and the stops are made of thick and durable plastic.

I believe that the resource of this site is at least 3000 hours.

Go to the pedals.

First, I want to note that the design of these pedals is copied from the Microsoft SideWinder Force Feedback Wheel model, i.e. This is a product of American engineering, not the development of our Asian friends. The pedals themselves have a very simple and reliable design, judge for yourself:

In fact, the pedals are made of 4 parts from thick plastic and two springs. The axis of rotation has a large contact area, which means that the resource will be large. Plus axes are well lubricated:

The pedal resource is definitely very large, I estimate it at 5,000 hours (not before destruction, but before the backlash appears).

Actually, these are all nodes where problems may arise.

We estimate the resource design in 3000 hours.

And this does not mean that the steering wheel will fail, no. After 3000 hours, the wear of the steering wheel axle will lead to excessive softness of rotation in the center, no more problems will arise, and, most importantly, the accuracy of the sensors will not change .

I hope that I was able to convince you that we seriously approached the reliability of the design of our steering wheels, which means that buyers will not experience any difficulties with them during operation.

And yet - a new version of the driver has been released, the work of vibration has been seriously improved. Download here

PS

Once again I want to draw your attention to the video we are developing. I would very much like to get some opinions about the video series, how clear / incomprehensible is what you like / dislike, etc.

Fragments from this video.

Potentiometer, its device and resource 47 mb:

The causes of the appearance of dead zones, the backlash of the gearbox (several serious mistakes were made in the episode, in particular, the schedules of the pedals are not properly tied, please note that this is not the final version) 50 mb:

What allows us to be sure that the game set will honestly fulfill the stated period?

This article is a continuation of this material.

"Wherever they say, all one will reduce to women" (c) Filatov

In the material Factors affecting the resource of game rudders, I described the main elements of game rudders that affect the overall resource of the device. Because I am one of the developers of the game wheel Gametrix Viper , I can not talk about anything except the

Accordingly, I want to evaluate the resource of this model according to the method proposed above.

SENSOR

For the first time in the world, magnetic resistive sensors, which we called MaRS , were used in the steering wheel and pedals of the Gametrix Viper. MaRS sensors and a controller for them are designed and manufactured in Russia.

On the photo - MaRS sensors on the group blank

')

The principle of the sensor is to measure the angle between the poles of a permanent magnet.

It is obvious that in this case there are no rubbing elements in the sensor.

Here is what this node looks like inside the steering wheel physically:

You can clearly see that the sensor and the magnet do not touch

But how this scheme is implemented inside the pedals.

In the axis of rotation of the pedals pressed round magnets:

Next to the magnets installed sensors:

Note that there are two plastic walls between the magnet and the sensor. The convenience of MaRS sensors also lies in the fact that plastic is not a barrier to the magnetic field.

I hope I could convince you that there is no friction in the sensor.

Thus, the resource sensors, we can recognize the infinite.

REDUCER

Compare these two elements:

This is the same steering centering unit, but implemented on different sensors. On the left - on the potentiometer, on the right - on the MaRS

As you can see, MaRS is installed directly on the axis of rotation of the wheel of the wheel and the gearbox is absent as a class.

The same thing we see inside the pedals:

Gearbox potentiometers

Gearbox missing, MaRS sensors do not need it

We see that the element of reducing the resource "reducer" is completely absent. True, the charge for this is the absence of the Force Feedback system. The Gametrix Viper steering wheel is centered with a spring, and the feedback is realized with the help of vibration.

AXIS ROTATION

Because In the steering wheel of the Viper there is no gear, then exactly three axes of rotation remain - the axis of the steering wheel and the two axles of the pedals.

Actually declared resource in 5 years and is determined by these nodes - there are no more nodes subject to wear, there is no steering wheel.

Let's look at the design of these nodes in more detail.

The most loaded unit is the steering centering mechanism. It is precisely it that is rotated with the greatest speed, and it is on him that the weight of the hands of the player lies.

Consider how it works

Remove the sensor

Remove the magnet mount

Remove the top cover

Remove the spring cover. Note the presence of grease

We take out the central axis, on which the steering wheel rotates

As can be seen from this photo, the plain bearing, which is implemented on the steering axle of the Viper, is formed by two holes in the cover and a circular axis in them.

The first place where there can be a backlash is exactly here.

It should be noted that the gap in this node is present initially. This is due to the fact that it is impossible to ensure such an exact fit as, say, between the crankshaft and the engine connecting rod, since This is a plastic that is extremely difficult to match with such precision. The second reason is that with precise adjustment the sliding bearing requires constant lubrication, otherwise it will rotate too tightly and wear out quickly. Therefore, in these parts initially laid a certain gap that allows the axis to rotate freely.

Another important point that distinguishes the MaRS sensor from the potentiometer. With the MaRS sensor, axle play will NOT cause dead zones to appear . Those. the occurrence of backlash does not lead to poor controllability.

By the way. We reworked this unit and put the bearing in it. Presented on the photo site in home use conditions can be safely recognized as eternal. A wheel with such a centering unit and on proximity sensors can be transferred to the grandchildren - it will work the same way as on the day of purchase. However, the use of such a node will increase the price of the product by $ 7-10 and its production is considered inexpedient. The investor believes that at such a price the buyer will not buy a steering wheel with vibration, but will prefer a steering wheel with FFB. Thus, this improved perpetual steering wheel will not be sold, so this device has not yet been used in serial devices.

The second place where wear will occur is the spring stops.

At this point, the steel spring slides over the plastic, which in the future threatens to wear out. However, the resource of this site is very large, because this place is well lubricated, and the stops are made of thick and durable plastic.

I believe that the resource of this site is at least 3000 hours.

Go to the pedals.

First, I want to note that the design of these pedals is copied from the Microsoft SideWinder Force Feedback Wheel model, i.e. This is a product of American engineering, not the development of our Asian friends. The pedals themselves have a very simple and reliable design, judge for yourself:

In fact, the pedals are made of 4 parts from thick plastic and two springs. The axis of rotation has a large contact area, which means that the resource will be large. Plus axes are well lubricated:

The pedal resource is definitely very large, I estimate it at 5,000 hours (not before destruction, but before the backlash appears).

Actually, these are all nodes where problems may arise.

We estimate the resource design in 3000 hours.

And this does not mean that the steering wheel will fail, no. After 3000 hours, the wear of the steering wheel axle will lead to excessive softness of rotation in the center, no more problems will arise, and, most importantly, the accuracy of the sensors will not change .

I hope that I was able to convince you that we seriously approached the reliability of the design of our steering wheels, which means that buyers will not experience any difficulties with them during operation.

And yet - a new version of the driver has been released, the work of vibration has been seriously improved. Download here

PS

Once again I want to draw your attention to the video we are developing. I would very much like to get some opinions about the video series, how clear / incomprehensible is what you like / dislike, etc.

Fragments from this video.

Potentiometer, its device and resource 47 mb:

The causes of the appearance of dead zones, the backlash of the gearbox (several serious mistakes were made in the episode, in particular, the schedules of the pedals are not properly tied, please note that this is not the final version) 50 mb:

Source: https://habr.com/ru/post/85676/

All Articles