Air Hockey at your home

Good day, Habravchane :)

Today, having come once again from a favorite bar, an idea appeared to make a home table for playing Aero-hockey. After wandering on the Internet, I came across a fairly good instruction for the manufacture of the table itself . I want to provide you with a translation of this article.

Under the cut a lot of text and photos.

So, inspired by the idea of creating a miniature table peeking on YouTube, we decided to build a full-sized (122x244cm) table for playing Aero-hockey. In this manual, we will talk about all the stages of manufacturing this table (without the "legs").

')

Here you will find a 3D model of aero hockey table. We hope that it will help you to understand all the intricacies of the project. In order to view the picture you need the free Google Sketchup Viewer app.

Do not forget to see the instructions for making "bits" for the game.

We hope that this information will be useful to you and start construction right now :)

First act

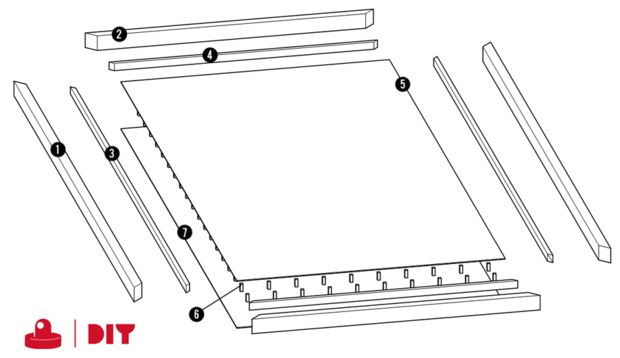

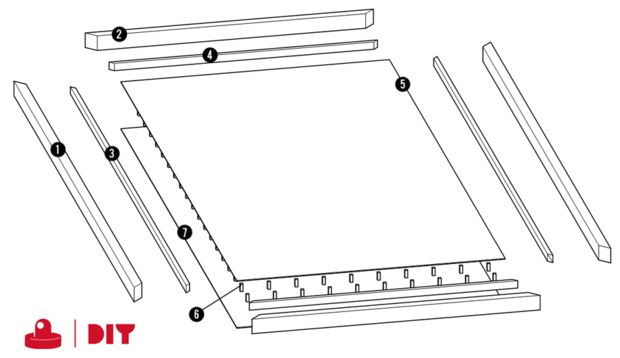

Necessary components (all measurements in millimeters).

D-long, W-width, B-height.

For the manufacture of a frame of spruce will need:

-Two long sides: D = 2530, W = 45, B = 70 (No. 1)

-Two short sides: D = 1310, W = 45, B = 70 (№ 2)

-Two long sides: D = 2440, W = 20, B = 35 (№ 3)

-Two short sides: D = 1220, W = 20, B = 35 (№ 4)

Costs: about $ 37

For the manufacture of the playing surface (MDF):

D = 2440, W = 1220, H = 6 (№ 5)

Costs: about $ 15

Stands:

Small wooden chopics 35 mm high (№ 6)

Costs: about $ 11

Opposite surface (chipboard):

D = 2440, W = 1220, B = 12 (№ 7)

Costs: about $ 15

Air source:

Centrifugal Blower or Vacuum Cleaner (No. 8)

The required capacity for our table is about 400 cubic feet per minute. The average household vacuum cleaner has a capacity of about 140 cubic feet / minute. You will need at least 3 vacuum cleaners to allow the washer to move freely around the table. Such an air source is relatively expensive for home use. There are more powerful industrial vacuum cleaners, but they are quite difficult to purchase.

Centrifugal superchargers are highly specialized. Output power ranges from a few hundred to 1000 cubic feet / min. or more. Such superchargers are commonly used in tables for Aero-hockey. Centrifugal superchargers are also quite expensive.

Air intake:

- One or two meters of pipe with a diameter of about 90mm.

PVC sheets of 250mm x 250mm, with a hole in which our pipe fits. (No. 9)

[If the tube does not directly fit into the holes, purchase a PVC clutch (which fits around the tube and the hole)]

-Two pieces of plywood 250mm x 250mm (No. 10 and 11)

Goal:

- Wooden beams about 400mm long

- A piece of strong fabric 400mm x 400mm

The second action.

Making a frame.

A: It is necessary to cut 8 different parts with 45-degree cuts at the ends.

B: Fold all the components on the floor and check the accuracy of the cut.

C: With nails and construction (polyurethane) glue, attach four short boards (No. 3 and 4) to the corresponding larger boards (No. 1 and 2).

D: Glue all four sides together, wrap the strap around the base and tighten it. DSP-plate must be in the center of the frame. Leave the glue to dry for at least 4 hours.

E: Drill the corners diagonally and tighten the bolts.

The third action.

Drilling holes / preparation of the playing surface.

F: Before drilling holes, you need to make a mesh on MDF. You need to draw a grid of 25mm squares.

G: Drill holes according to the mesh you just created. Use 1 mm (or 1/32 inch) drill bits. This job is time consuming, but do not rush.

In total, you need to drill 96x48 = 4608 holes.

N: Use a grinding machine to remove burrs on the other side of the sheet. This side will be the playing surface.

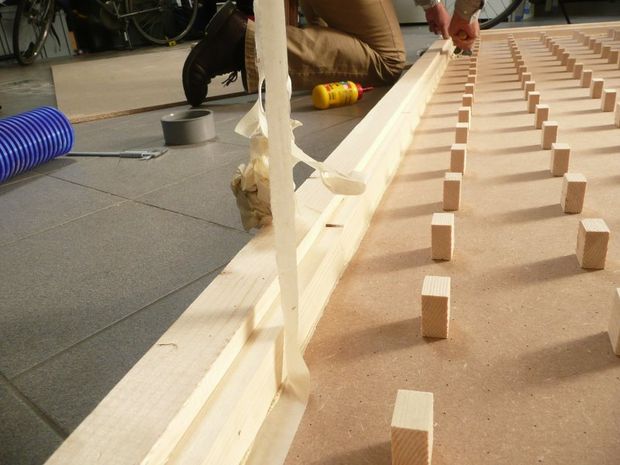

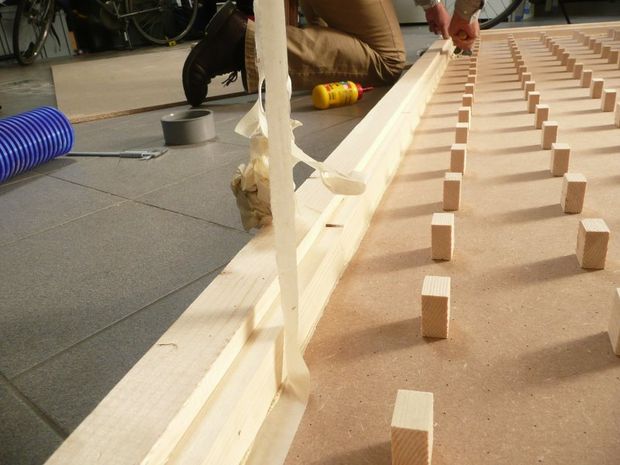

The fourth act.

Place the posts on the surface.

I: You need about 150-200 wooden columns with a height of 35mm. If you can stand on the tabletop without breaking it, you should be on the right track :)

J: We put the columns in 3 'squares' from the edge of the table (75 mm or 3 inches) and separated them with 4 squares from each other. In total, it was: 9x19-2 = 169 columns. But you can experiment with this scheme yourself.

K: With usual white glue for wood we glue the supporting posts on the un-smoothed sides of MDF. It is advisable not to use polyurethane glue, because the table tops can move relative to each other. Give the glue time to harden.

The fifth action.

Attaching the playing surface to the frame.

L: Cover the air holes with a piece of cloth. This will prevent glue from entering the ducts.

M: Then grease the edges of the surface and gently slide it into the frame.

N: Finally, drive 5 nails through the short sides and 10 nails on the long sides in MDF at points 3 and 4.

The sixth action.

Duct mounts.

We decided to connect the fan for cleaning the foliage with the tube in the table not directly, but to mount it into the table. Since excessive vibration can lead to the fall of the fan, if you fix it directly on the table.

Chipboard sheets are cheap, but it has one drawback: they are not strong enough. In order to strengthen the connection point of the air duct with the table, it is necessary that the force be distributed. That is why you need a large sheet of PVC (with a hole in it), which covers a large area. We need to tightly connect the pipe coupling and PVC sheet.

A: Glue the sleeve to the blue duct. Connect the other end of the tube to the fan outlet.

P: Using a round sawing nozzle on the drill (see image below), make holes through two layers of plywood. The holes should be larger than in PVC sheets, as this sheet will be sandwiched between plywood. Now decide where you want to install the air inlet (we recommend that you place it in the corner on the bottom plate).

Q: Drill two layers of plywood according to the diagram: one piece of plywood should have four holes in each corner, the second one should have eight evenly distributed holes. The same applies to PVC sheet.

R: Glue a layer of plywood (with four holes) to the hole in the table. Now attach a sheet of PVC and a second piece of plywood. Screw all 8-bolts.

Seventh act.

Installing the playing surface on the frame

S: Remove the glue-resistant cloth and check that all the holes are clean.

T: Apply glue to each bollard and frame borders. Carefully lower the chipboard and slide it into the frame. Press down something heavy and leave the glue to dry.

The eighth act. Final

Making the gate and the end of the work.

U: Drill two holes 15 cm from the center of the short side of the table, so that the playing surface remains unharmed.

V: Use a jigsaw to cut an unnecessary piece between these holes. With sandpaper, give a neat look to the edges of the gate.

X: Fasten two 40cm long beams above and below the cut with a strong cloth between them. By doing this, you create a kind of pocket around the target with holes in the sides, so that you can easily take the puck out of your pocket.

Repeat this process on the other side of the table.

Optional:

-Add aluminum beads that prevent the puck from slowing down on impact.

-Add markup on the field

If you did everything right, feel free to turn on the fan and start the game!

Have fun :)

Today, having come once again from a favorite bar, an idea appeared to make a home table for playing Aero-hockey. After wandering on the Internet, I came across a fairly good instruction for the manufacture of the table itself . I want to provide you with a translation of this article.

Under the cut a lot of text and photos.

So, inspired by the idea of creating a miniature table peeking on YouTube, we decided to build a full-sized (122x244cm) table for playing Aero-hockey. In this manual, we will talk about all the stages of manufacturing this table (without the "legs").

')

Here you will find a 3D model of aero hockey table. We hope that it will help you to understand all the intricacies of the project. In order to view the picture you need the free Google Sketchup Viewer app.

Do not forget to see the instructions for making "bits" for the game.

We hope that this information will be useful to you and start construction right now :)

First act

Necessary components (all measurements in millimeters).

D-long, W-width, B-height.

For the manufacture of a frame of spruce will need:

-Two long sides: D = 2530, W = 45, B = 70 (No. 1)

-Two short sides: D = 1310, W = 45, B = 70 (№ 2)

-Two long sides: D = 2440, W = 20, B = 35 (№ 3)

-Two short sides: D = 1220, W = 20, B = 35 (№ 4)

Costs: about $ 37

For the manufacture of the playing surface (MDF):

D = 2440, W = 1220, H = 6 (№ 5)

Costs: about $ 15

Stands:

Small wooden chopics 35 mm high (№ 6)

Costs: about $ 11

Opposite surface (chipboard):

D = 2440, W = 1220, B = 12 (№ 7)

Costs: about $ 15

Air source:

Centrifugal Blower or Vacuum Cleaner (No. 8)

The required capacity for our table is about 400 cubic feet per minute. The average household vacuum cleaner has a capacity of about 140 cubic feet / minute. You will need at least 3 vacuum cleaners to allow the washer to move freely around the table. Such an air source is relatively expensive for home use. There are more powerful industrial vacuum cleaners, but they are quite difficult to purchase.

Centrifugal superchargers are highly specialized. Output power ranges from a few hundred to 1000 cubic feet / min. or more. Such superchargers are commonly used in tables for Aero-hockey. Centrifugal superchargers are also quite expensive.

Air intake:

- One or two meters of pipe with a diameter of about 90mm.

PVC sheets of 250mm x 250mm, with a hole in which our pipe fits. (No. 9)

[If the tube does not directly fit into the holes, purchase a PVC clutch (which fits around the tube and the hole)]

-Two pieces of plywood 250mm x 250mm (No. 10 and 11)

Goal:

- Wooden beams about 400mm long

- A piece of strong fabric 400mm x 400mm

The second action.

Making a frame.

A: It is necessary to cut 8 different parts with 45-degree cuts at the ends.

B: Fold all the components on the floor and check the accuracy of the cut.

C: With nails and construction (polyurethane) glue, attach four short boards (No. 3 and 4) to the corresponding larger boards (No. 1 and 2).

D: Glue all four sides together, wrap the strap around the base and tighten it. DSP-plate must be in the center of the frame. Leave the glue to dry for at least 4 hours.

E: Drill the corners diagonally and tighten the bolts.

The third action.

Drilling holes / preparation of the playing surface.

F: Before drilling holes, you need to make a mesh on MDF. You need to draw a grid of 25mm squares.

G: Drill holes according to the mesh you just created. Use 1 mm (or 1/32 inch) drill bits. This job is time consuming, but do not rush.

In total, you need to drill 96x48 = 4608 holes.

N: Use a grinding machine to remove burrs on the other side of the sheet. This side will be the playing surface.

The fourth act.

Place the posts on the surface.

I: You need about 150-200 wooden columns with a height of 35mm. If you can stand on the tabletop without breaking it, you should be on the right track :)

J: We put the columns in 3 'squares' from the edge of the table (75 mm or 3 inches) and separated them with 4 squares from each other. In total, it was: 9x19-2 = 169 columns. But you can experiment with this scheme yourself.

K: With usual white glue for wood we glue the supporting posts on the un-smoothed sides of MDF. It is advisable not to use polyurethane glue, because the table tops can move relative to each other. Give the glue time to harden.

The fifth action.

Attaching the playing surface to the frame.

L: Cover the air holes with a piece of cloth. This will prevent glue from entering the ducts.

M: Then grease the edges of the surface and gently slide it into the frame.

N: Finally, drive 5 nails through the short sides and 10 nails on the long sides in MDF at points 3 and 4.

The sixth action.

Duct mounts.

We decided to connect the fan for cleaning the foliage with the tube in the table not directly, but to mount it into the table. Since excessive vibration can lead to the fall of the fan, if you fix it directly on the table.

Chipboard sheets are cheap, but it has one drawback: they are not strong enough. In order to strengthen the connection point of the air duct with the table, it is necessary that the force be distributed. That is why you need a large sheet of PVC (with a hole in it), which covers a large area. We need to tightly connect the pipe coupling and PVC sheet.

A: Glue the sleeve to the blue duct. Connect the other end of the tube to the fan outlet.

P: Using a round sawing nozzle on the drill (see image below), make holes through two layers of plywood. The holes should be larger than in PVC sheets, as this sheet will be sandwiched between plywood. Now decide where you want to install the air inlet (we recommend that you place it in the corner on the bottom plate).

Q: Drill two layers of plywood according to the diagram: one piece of plywood should have four holes in each corner, the second one should have eight evenly distributed holes. The same applies to PVC sheet.

R: Glue a layer of plywood (with four holes) to the hole in the table. Now attach a sheet of PVC and a second piece of plywood. Screw all 8-bolts.

Seventh act.

Installing the playing surface on the frame

S: Remove the glue-resistant cloth and check that all the holes are clean.

T: Apply glue to each bollard and frame borders. Carefully lower the chipboard and slide it into the frame. Press down something heavy and leave the glue to dry.

The eighth act. Final

Making the gate and the end of the work.

U: Drill two holes 15 cm from the center of the short side of the table, so that the playing surface remains unharmed.

V: Use a jigsaw to cut an unnecessary piece between these holes. With sandpaper, give a neat look to the edges of the gate.

X: Fasten two 40cm long beams above and below the cut with a strong cloth between them. By doing this, you create a kind of pocket around the target with holes in the sides, so that you can easily take the puck out of your pocket.

Repeat this process on the other side of the table.

Optional:

-Add aluminum beads that prevent the puck from slowing down on impact.

-Add markup on the field

If you did everything right, feel free to turn on the fan and start the game!

Have fun :)

Source: https://habr.com/ru/post/83140/

All Articles