OLED technology

Operating principle

To create organic light emitting diodes (OLED) thin-film multilayer structures are used, consisting of layers of several polymers. When a positive voltage relative to the cathode is applied to the anode, a stream of electrons flows through the device from the cathode to the anode. Thus, the cathode donates electrons to the emission layer, and the anode takes electrons from the conducting layer, or in other words, the anode donates holes to the conducting layer. The emission layer receives a negative charge, and the conductive layer is positive. Under the action of electrostatic forces, electrons and holes move towards each other and recombine at a meeting. This occurs closer to the emission layer, because holes in organic semiconductors are more mobile than electrons. During recombination, a decrease in the electron energy occurs, which is accompanied by the emission (emission) of electromagnetic radiation in the visible light region. Therefore, the layer is called emission. The device does not work when a negative voltage is applied to the anode relative to the cathode. In this case, the holes move toward the anode, and the electrons in the opposite direction to the cathode, and no recombination occurs.

The material of the anode is usually used indium oxide doped with tin. It is transparent to visible light and has a high work function, which contributes to the injection of holes into the polymer layer. Metals, such as aluminum and calcium, are often used for the manufacture of the cathode, since they have a low work function that promotes the injection of electrons into the polymer layer.

')

Management Method Classification

There are two types of OLED displays - PMOLED and AMOLED. The difference lies in the way the matrix is controlled - it can be either a passive matrix (PM) or an active matrix (AM).

PMOLED displays use image sweep controllers for rows and columns. To light a pixel, you must turn on the corresponding row and column: a pixel will emit light at the intersection of the row and column. In one clock cycle, only one pixel can be made to glow. Therefore, in order to make the entire display glow, it is necessary to very quickly give signals to all pixels by iterating through all the rows and columns. As it is done in old CRTs (electron beam tubes).

Displays based on PMOLED are cheap, but because of the need for line-scanning of the image, it is not possible to obtain large-sized displays with acceptable image quality. Typically, the size of PMOLED displays do not exceed 3 "(7.5 cm)

In AMOLED displays, each pixel is controlled directly, so they can quickly reproduce the image. The dimensions of AMOLED displays can be large and today displays with a size of 40 "(100 cm) have been created. Production of AMOLED displays is expensive due to the complex pixel control scheme, unlike PMOLED displays, where a simple controller is enough to control.

Light Emission Classification

At present, basically two technologies are developing that have shown the greatest efficiency. They differ in the use of organic materials: micromolecules (sm-OLED) and polymers (PLED), the latter are divided into simply polymers, polymeric organic compounds (POLED), and phosphorescent (PHOLED). About the last bit in more detail. PHOLEDs use the principle of electrophosphorescence to convert up to 100% of electrical energy into light. For example, traditional fluorescent OLEDs convert approximately 25-30% of electrical energy into light. Due to their extremely high level of energy efficiency, even compared to other OLEDs, PHOLED are being studied for potential use in large displays such as television monitors or screens for lighting needs. Interestingly, OLED technology can significantly improve the quality of LCD panels, since the promising backlight technology for them is PHOLED (PHosphorescent Organic Light Emitting Diode) technology. According to Universal Display Corporation, the use of PHOLED diodes increases the brightness of panels four times.

Schemes of color OLED displays

The first appeared OLED displays based on micromolecules, but they turned out to be too expensive because they were made using vacuum deposition.

The first step towards the creation of polymer displays was made in 1989, when scientists at the University of Cambridge managed to synthesize a special polymer - polyphenylenevinylylene. Displays of this type can be obtained by applying polymeric materials to the substrate with a special inkjet printer. Sometimes these displays are called LEP (Light-Emitting Polymer). The base can be flexible with a bend radius of 1 cm or less.

However, to date, in terms of service life and efficiency, micromolecule-based devices are ahead of LEP devices. Comparative characteristics of durability and radiation efficiency for the two OLED display technologies are given below.

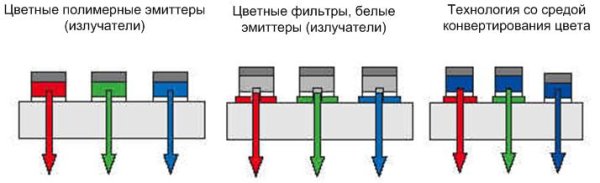

There are three color OLED display schemes:

* scheme with separate color emitters;

* WOLOD + CF scheme (white emitters + color filters);

* scheme with the conversion of shortwave radiation.

The simplest and most familiar option is the usual three-color model, which in OLED technology is called a model with separate emitters. Three organic materials emit light base colors - R, G and B. This option is the most effective from the standpoint of energy use, however, in practice, it turned out to be quite difficult to choose materials that will emit light with the desired wavelength, and even with the same brightness.

The second option is implemented much easier. It uses three identical white emitters that emit through color filters, but it is significantly less efficient in terms of energy efficiency in the first embodiment, since a significant portion of the emitted light is lost in the filters.

In the third version (CCM - Color Changing Media), blue emitters and specially selected luminescent materials are used to convert shortwave blue radiation to longer wavelengths - red and green. The blue emitter naturally radiates "directly." Each of the options has its advantages and disadvantages:

Other types of OLED displays

TOLED - transparent light-emitting devices TOLED (Transparent and Top-emitting OLED) - a technology that allows you to create transparent (Transparent) displays, as well as achieve a higher level of contrast.

Transparent TOLED displays: the direction of light emission can be only up, only down or in both directions (transparent). TOLED can significantly improve contrast, which improves the readability of the display in bright sunlight.

Since TOLED is 70% transparent when turned off, they can be mounted directly on the windshield of the car, on shop windows or for installation in a virtual reality helmet ... Also, the transparency of TOLED allows them to be used with metal, foil, silicon crystal and other opaque substrates for displays with forward mapping (can be used in future dynamic credit cards). Screen transparency is achieved by using transparent organic elements and materials for the manufacture of electrodes.

Due to the use of an absorber with a low reflection coefficient for the substrate of a TOLED display, the contrast ratio can surpass the LCD by an order of magnitude (mobile phones and cockpits of military fighter aircraft). Using TOLED technology, it is also possible to manufacture multilayer devices (for example, SOLED) and hybrid matrices (Bidirectional TOLED TOLED makes it possible to double the displayed area at the same screen size - for devices that have the desired output information wider than the existing one).

FOLED (Flexible OLED) - the main feature is the flexibility of the OLED display (Demonstration of the flexible OLED display from SONY). A plastic or flexible metal plate is used as a substrate on the one hand, and OLED cells and a sealed thin protective film on the other. Advantages of FOLED: ultra-thin display, ultra-low weight, durability, durability and flexibility, which allows you to apply OLED-panels in the most unexpected places. (Expansion for the imagination - the area of possible application of OLED is very large).

Staked OLED - a fundamentally new solution from the UDC - Staked OLED, folded OLED devices. The main feature of the new technology is the placement of R-cells (G-, B-) in the vertical (sequentially), and not in the horizontal (parallel) plane, as happens in the LCD display or cathode-ray tube. In SOLED, each element of a subpixel can be controlled independently. The color of a pixel can be adjusted by changing the current passing through the three color elements (in non-color displays, pulse width modulation is used). Brightness is controlled by varying the strength of the current. Advantages of SOLED: high density of filling the display with organic cells, whereby a good resolution is achieved, which means a high-quality picture. (SOLED displays have improved image quality by 3 times compared to LCD and CRT).

Advantages in comparison with LCD displays

* smaller dimensions and weight

* no need for backlighting

* the absence of such a parameter as the viewing angle - the image is visible without loss of quality from any angle

* instant response (much lower than LCD) - in fact, the complete lack of inertia

* better color rendering (high contrast)

* lower power consumption with the same brightness

* the ability to create flexible screens

Brightness. OLED displays provide radiation brightness from a few cd / m2 (for night operation) to very high brightness - over 100,000 cd / m2, and their brightness can be adjusted in a very wide dynamic range. Since the lifetime of the display is inversely proportional to its brightness, it is recommended for devices to operate at more moderate levels of brightness up to 1000 cd / m2. When the LCD display is illuminated with a bright beam of light, glare appears, and the picture on the OLED screen will remain bright and saturated at any level of illumination (even with direct sunlight on the display).

Contrast. Here OLED is also a leader. OLED displays have a contrast ratio of 1,000,000: 1 (LCD contrast of 1300: 1 [source not specified 71 day], CRT 2000: 1)

Viewing angles. OLED technology allows you to look at the display from any side and at any angle, and without losing image quality.

Power usage. The power consumption of OLED displays is one and a half times lower than LCD. PHOLED power consumption is even lower.

The need for benefits demonstrated by organic displays is increasing every year. This fact allows us to conclude that soon humanity will see the flourishing of this technology.

But technology does not stand still and ahead of a new generation of OLED

LEDs based on quantum dots. Immediately, we note that the strengths of QDLED devices (Quantum Dot LED - a quantum dot LED) are high brightness, low production cost, and a wide range of colors. Almost immediately after the invention of the new type of LEDs, they are predicted to have excellent prospects for becoming the basis for displays of mobile devices (handhelds, mobile phones, etc.), and even large-format television panels.

Under a quantum dot, scientists mean a special semiconductor structure that limits the movement of electrons in three dimensions at once. With reference to LEDs on quantum dots, the following variation was used: cadmium selenide forms a “core”, and zinc sulfide acts as a limiting “shell”. The main "protagonists" in this case are electrons, which emit photons during the transition from a high energy state to a lower one, due to which a point is formed. The mechanism of changing the color of the glow of the LED is quite simple - it is only necessary to change the dimensions of the quantum dot, which leads to a change in the wavelength of the light. Thus, having calculated the required dimensions of the semiconductor structure, it is possible to create LEDs of red, orange, yellow, or green colors. Another advantage of the devices is the highest brightness - up to 9000 cd / sq. m. For example, the brightness of modern displays does not exceed 500 cd / sq. That is, the development allows to increase the corresponding parameter by an order of magnitude. Moreover, the technology allows you to easily increase the brightness of the LEDs - just the formation of several quantum dots.

At the end of the spread video to compare the properties of TFT and OLED displays.

Link to a review of monitors based on OLED

Source: https://habr.com/ru/post/66454/

All Articles