Cooling systems - from radiator to liquid nitrogen! Part 1

We also know from a school course in physics that any conductor through which electrical current flows produces heat. This leads to the fact that all components of the computer, through which the current flows (from the processor to the connecting wires), heat the air around them.

I wrote this article almost a year ago for one contest ... I decided to post, maybe someone will be interested. It is terribly huge (no joke - Habr did not take it in one piece, so there will be two parts / Part 2 /). Traffic .

The amount of heat released depends on the content of your system unit, on its energy consumption. This does not mean at all that absolutely all involved components of the system unit should be cooled. There is no need to hang up fans at the sockets, but modern processors and video cards cannot do without cooling!

')

Alas, one cannot get away from heat generation, but this problem has quite a few solutions. Another question - how to cool. At the moment there are a lot of cooling systems, they all use the general principle of operation - transfer of heat from a hotter body (cooled object) to a less hot one (cooling system). We will consider only the following systems:

- Radiator;

- Radiator + fan = cooler;

- Liquid cooling system;

- The cooling system on the Peltier elements;

- Phase transition system (freonka);

- Extreme cooling system with liquid nitrogen;

It is possible to use the most effective installations in which various types of the listed systems are combined, but this is already beyond the scope of this article.

We are in order to begin the consideration of the main cooling systems and start from the very first - the radiator.

Radiator (novolat. Radiator, "radiator") - heat exchanger, serves to dissipate heat from the cooled object. The mechanism of heat transfer here is thermal conductivity, the ability of a substance to conduct heat inside its volume. All that is needed is to create a physical contact between the radiator and the object to be cooled, which is why it is always in close contact with what is cooling. After the radiator takes over some of the heat from the object to be cooled, its task is to dissipate it into the surrounding air.

But it is not enough just to provide physical contact! Indeed, sooner or later, the cooling system itself will also heat up from a constantly heated cooling object. A process of heat transfer in the system of bodies with the same temperature, as we know, cannot be. To find a way out of this situation and not face the problem of overheating, it is necessary to organize the supply of some cold substance to cool the cooling system itself. Such a substance is commonly called a refrigerant (refrigerant, a particular case of coolant)

The radiator is an air cooling system, i.e. the coolant in his case is cold air from the environment. Heat from the cooled object goes to the base of the radiator, then is evenly distributed over all its edges, and after that it goes into the surrounding air. This process is called heat conduction. The air around the radiator gradually heats up, due to which the heat exchange process becomes less and less effective. The efficiency of heat transfer can be increased by constantly supplying cold air to the fins of the radiator. Simply put, for efficient cooling, free circulation of cold air is needed.

Physical quantities such as thermal conductivity (the rate of heat propagation through the body) and heat capacity (the amount of heat that the body needs to communicate to increase its temperature by 1 degree) at the radiator must be at a high level. From the same school course, we know that metals have the highest thermal conductivity. In fact, this is not the case - diamond has the highest thermal conductivity :), and it lies in the range from 1000 to 2600 W / (m · K). Of metals, silver conducts best of all - its thermal conductivity is 430 W / (m · K). After silver comes copper [390 W / (m · K)], then gold [320 W / (m · K)]. Completes the chain aluminum [236 W / (m · K)].

Throwing away the jewelry, it becomes clear that the most applicable are the two materials - aluminum and copper. The first is due to the low cost and high heat capacity (930 vs. 385 for copper), the second is due to the high thermal conductivity (the disadvantages of copper include a higher melting point and the complexity of its processing). Silver, for its high thermal conductivity, is sometimes used to make the base of a radiator. Even for the manufacture of radiators can be used aluminum alloy with silicon - silumin. The advantage of using it is cheaper than aluminum.

If the radiator is made of highly heat-conducting material, then the temperature at any point will be the same. Heat generation will be equally effective with the entire surface area. Because Since an object gives off heat from its surface, this means that to achieve the best heat removal, the surface area of the object to be cooled should be maximized. There are two ways to increase the area of the radiator - an increase in the area of the ribs while maintaining the size of the radiator and an increase in the geometric dimensions of the radiator. The second option, of course, is preferable, but it introduces a number of inconveniences - for example, it increases the weight and size of the radiator, which can make the installation difficult. Well, the price, respectively, increases in proportion to the amount spent on the manufacture of material.

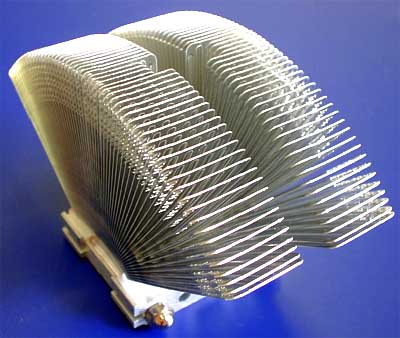

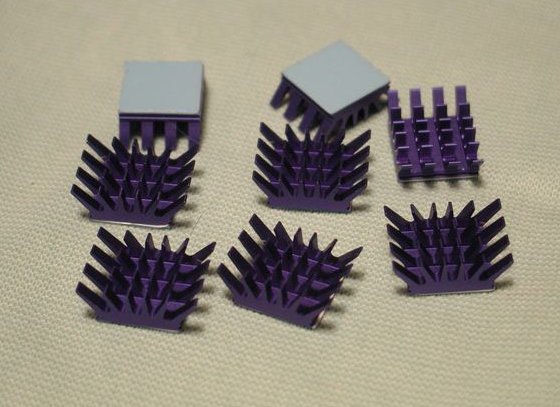

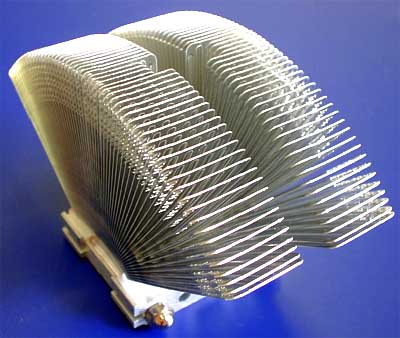

Types of designs of radiator fins there are a huge variety. They can be thick if they were created by an extrusion process. Or vice versa, thin - if the ribs are cast. They can be straight along the entire length of the radiator, and can be lined across. Can be flat, bent of plates, pressed into the base. But the best thing about the work today is that the needle-type radiators show themselves — in such radiators, instead of ribs, square or cylindrical needles.

At the moment, I know 6 methods of production of radiators:

1. Pressed (extrusion) radiators are the cheapest and most common on the market. The main material used in their production is aluminum. Radiators of this type are made by pressing (extrusion), which allows you to get quite complex profiles of the surfaces of the ribs and achieve good heat dissipation properties.

2. Folded (tape) radiators - are obtained when a thin metal band, rolled into an accordion, is soldered (or using adhesive conductive pastes) attached to the base plate of the radiator. The folds of the accordion tape in this case play the role of ribs. Such manufacturing technology allows to obtain compact products in comparison with extruded radiators, but with about the same thermal efficiency.

3. Forged (cold-formed) radiators - radiators obtained as a result of the use of cold-pressing technology. This technology allows you to create the surface of the radiator in the form of rods of arbitrary section, and not just standard rectangular fins. As a rule, they are more expensive than radiators of the first two types, but their efficiency is often much lower.

4. Compound radiators are close relatives of “folded” radiators. Despite this, they are distinguished by a significant moment: in this type of radiators, the surface of the ribs is formed not by an accordion tape, but by thin separate plates, which are fixed by soldering or butt welding on the bottom of the radiator. Radiators of this type are slightly more efficient than extrusion and folded.

5. Molded radiators - in the manufacture of products of this type, injection molding technology is used. The use of this technology allows to obtain the rib surface profiles of almost any complexity, significantly improving heat transfer.

6. Turned radiators - are the most expensive and advanced radiators. Products of this type are created by precision machining (on special high-precision CNC machines) of monolithic blanks and are distinguished by the highest thermal efficiency. If it were not for the cost of production, then this type of radiator would have long been able to oust its competitors in the market.

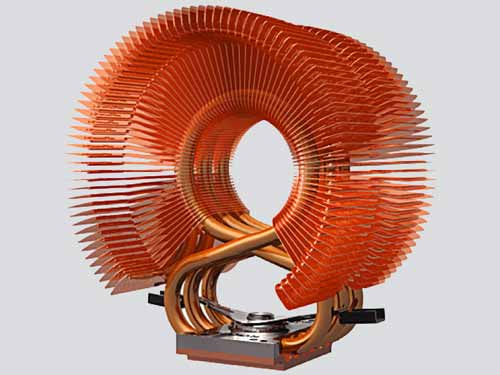

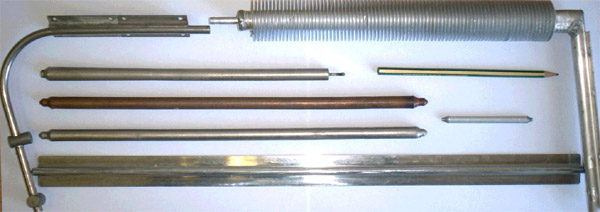

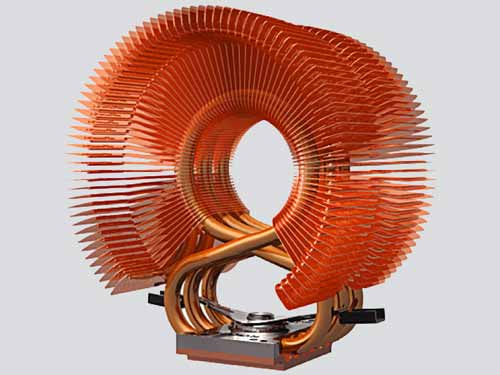

In modern systems, heat pipes or simply heat pipes have ceased to be rare in radiators and coolers.

It is a hermetic heat transfer device that operates on a closed evaporation-condensation cycle in thermal contact with external - the source and heat sink. Thermal energy is taken on the cooled object and is spent on the evaporation of the coolant, which is located inside the heat pipe body. Further, thermal energy is transferred by steam in the form of latent heat of evaporation further, at a certain distance from the point of evaporation, where during condensation the steam is released into the drain. The resulting condensate is returned to the evaporation site either under the action of capillary forces (which are provided by the presence of a specialized capillary structure inside the heat pipe) or due to the action of mass forces (this design is usually referred to as a thermosyphon).

It turns out that instead of the usual electronic mechanism of heat transfer (by heat conduction, which takes place in a continuous metal heat conductor), a molecular transfer mechanism is used in the heat tube (more precisely, the process of transfer of the kinetic and vibrational energy of random motion of vapor particles).

It is necessary to strive to ensure that the contact area between the radiator and the cooled object is as large as possible - after all, it is through this area that the heat from the object will flow to the radiator. But it is necessary to take into account that when two even the smoothest surfaces touch, the smallest cavities and gaps filled with air still remain between them [recall that the thermal conductivity of air is 0.026 W / (m · K)] - this can play a cruel joke.

To get rid of harmful air and allow the radiator to work with maximum efficiency, different thermal interfaces are used, most often it is thermal paste (thermal paste). It has a high thermal conductivity [due to the use in its composition of substances such as aluminum and silver (up to 90% content)] and due to the fluidity it fills all the irregularities in the contacting surfaces.

Thermal grease comes complete with most brand coolers and radiators. It happens in the form of a syringe or a small tube bag. It is recommended to avoid thermal paste on the electrical components of the computer.

One of the parameters of thermal grease is the duration of the period when it comes to maximum efficiency. On average, this time is about a week. Coolink recently produced the first thermopaste with the addition of nanoparticles - its advantage is that there is no waiting period.

In addition to thermal paste, there is another type of thermal interface - conductive pads. The essence of their work is the same, but they are used differently - they are put on the contact surface and, under thermal influence, change their state of aggregation, filling irregularities and displacing the air.

Despite all sorts of variations, the most important advantage of the radiator is that it is not the source of any noise. The disadvantages include relatively low efficiency, lack of capacity to overclock the system and often large dimensions.

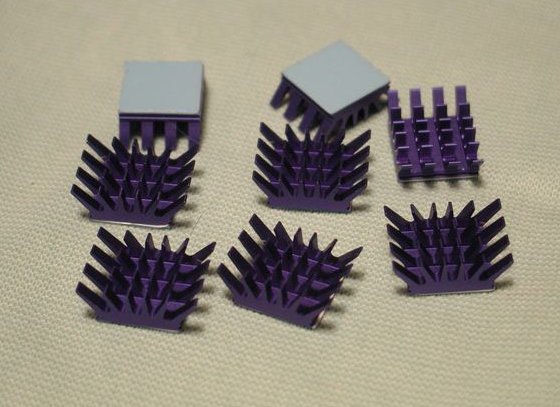

If you trust the cooling of modern video cards and processors to passive radiators is dangerous enough, then the cooling of memory modules, hard drives, chipsets, power circuits - you can rely on.

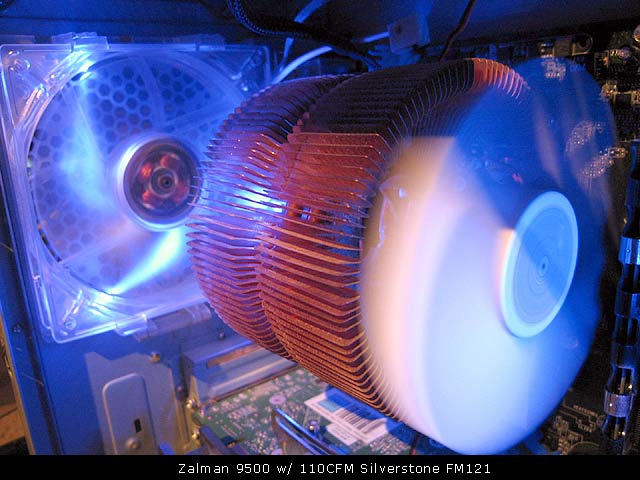

A cooler (eng. Cooler - cooler) is a combination of a radiator and a fan that is installed on the electronic components of a computer with increased heat dissipation. The most important task of the device is to reduce the temperature of the cooled object and maintain it at a certain level. This is achieved due to the continuous flow of air blowing the radiator. That is, a less efficient radiation process turns into a more efficient one — convection. Coolers - this is the easiest, fastest, affordable, and, in most cases, a sufficient way to cool computer components - everything is cooled with air.

There are a huge variety of options. If we talk about the appearance of a long time, then you will not tell a lot about functional differences.

Coolers come in different sizes - usually from 40x40mm to 320x320mm.

The most important part of any cooler is its fan. It is he who makes noise in your system unit. And to be more precise, this noise appears when an air stream collides with a radiator. This noise is especially noticeable on cheap cooler models, since no one works on their design.

The fan consists of an impeller (there is a magnet in its inner diameter) and an electric motor, which this magnet rotates together with the impeller. Through the center of the fan is an axial pin, which is located in the center of the motor. For greater smoothness of the impeller stroke, three types of bearings can be used (the service life of which manufacturers indicate in thousands of hours on the package):

- Sleeve bearing (sleeve bearing) - the cheapest and least reliable option, creating a high level of noise when working.

- 1 sleeve bearing (sleeve bearing) + 1 rolling bearing (ball bearing) - a combined bearing is a more durable design, working on average twice as long as on a sliding bearing.

- 2 or 4 rolling bearings (ball bearings) - the most reliable options with low noise, but these fans are significantly more expensive than the first two.

- Needle and NCB (nano-millimeter ceramic) bearings - installed in fans by a limited number of manufacturers. They are characterized by low noise, low cost and very long service life.

By the way, about the service life (uptime. If the service life is specified in 40-50 thousand hours (almost 5 years. Although it happens more - up to 300,000 hours!), This does not mean that the next time you have to remember about the cooler only after this time. No! This number should be divided by two or three, and still preventive actions should be performed from time to time - wipe off dust, blow, lubricate.If you don’t take care of the cooler, it can start to make noise, and if it’s all about it forget something and stop.

The fan performance (consumption characteristic) is perhaps its main characteristic. It is measured in the number of cubic feet of air discharged by it per minute, abbreviated to CFM (Cubic Feet per Minute). This characteristic mainly depends on the area of the fan, the profile of the blades and the speed of their rotation. The greater this value, the higher the cooling efficiency and, as a rule, the higher the noise level generated by the fan during operation.

The cooler can distill cubic meters of air with its blades at a speed of up to 8000 revolutions per minute (for comparison, the engine of an ordinary passenger car produces 5-8 thousand revolutions. The engine of the Formula-1 car - up to 22,000 revolutions). But it is clear that at such a speed the noise from the cooler will be noticeable. Therefore, it is preferable to take coolers with thermal sensors - which “analyze” the temperature and, depending on the situation, can increase or decrease the number of revolutions. Most often it has a positive effect on the noise from work.

All computer coolers are powered by direct current, the voltage of which is most often 12V. For power, they use Molex connectors (for Smart fans) or PC Plug connectors.

PC-Plug has four wires: two black (ground), yellow (+ 12V) and red (+ 5V).

The Molex connectors on motherboards are used so that the system itself can control the rotational speed of the fan, applying a different voltage to the red wire (usually from 8 to 12 V). From the yellow (signal) wire, the system learns from the cooler information about the speed of rotation of its blades. Using Molex has one major drawback: it is dangerous to hook up fans with power consumption of more than 6W.

The situation is different with the PC-Plug connector - it stands tens of watts. But it didn’t happen without tar - when you connect to it, you will not be able to find out if your fan is working or not.

Finding an adapter from one connector to another now is not difficult - they are often included.

Also, to reduce noise, the cooler is sometimes transferred to 5V or 7V. Cables are rounded off, wires are braided into braids or covered with braid and tidied up in a secluded place - so as not to interfere with the well thought-out air circulation.

All coolers are classified according to the noise level issued from their work into the following classes (the lower the noise level, the more comfortable the work at the computer will be):

- Conditionally silent . The noise level of such a cooling system is less than 24 dB. This figure is lower than the typical background noise in a quiet room (in the evening or at night). Thus, the cooler makes almost no significant contribution to the noise picture. Typically, this value is achieved at the minimum fan speed for systems with a speed controller.

- Low noise . The noise level from such a cooling system is in the range of 24 to 30 dB inclusive. The cooler makes a barely perceptible contribution to the PC's acoustics.

- Ergonomic . The noise level of such a cooling system is in the range from 37 to 42 dB inclusive. Noise from such a cooler is likely to be noticeable in most user configurations of the computer.

- Not ergonomic . The noise level of the cooling system under consideration is greater than 42 dB. In such conditions, the cooler will be the main "generator" of computer noise in almost any configuration. Home use of such a cooler is unjustified - it is more suitable for industrial and office premises with background noise of more than 45 dB.

The advantages of coolers include their prevalence, versatility, availability. A small cost can also be attributed to a plus, but it should be borne in mind that you should not be greedy for a good cooler - this is, in fact, the second heart of the computer - it is impossible for it to stop.

By cons, I will take the possible noises that sooner or later appear on any cooler.

Summing up the above. At the moment, the cooler is the most common cooling system, which you can cool anything from the processor to the hard drive and memory. The question is the selection and selection of the desired cooler - after all, there are many of them from dozens of manufacturers.

Someone needs a middle ground between silence and performance. Someone needs gigahertz and don't care about noise, someone on the contrary prefers silence.

I wrote this article almost a year ago for one contest ... I decided to post, maybe someone will be interested. It is terribly huge (no joke - Habr did not take it in one piece, so there will be two parts / Part 2 /). Traffic .

Boring theory

The amount of heat released depends on the content of your system unit, on its energy consumption. This does not mean at all that absolutely all involved components of the system unit should be cooled. There is no need to hang up fans at the sockets, but modern processors and video cards cannot do without cooling!

')

Alas, one cannot get away from heat generation, but this problem has quite a few solutions. Another question - how to cool. At the moment there are a lot of cooling systems, they all use the general principle of operation - transfer of heat from a hotter body (cooled object) to a less hot one (cooling system). We will consider only the following systems:

- Radiator;

- Radiator + fan = cooler;

- Liquid cooling system;

- The cooling system on the Peltier elements;

- Phase transition system (freonka);

- Extreme cooling system with liquid nitrogen;

It is possible to use the most effective installations in which various types of the listed systems are combined, but this is already beyond the scope of this article.

We are in order to begin the consideration of the main cooling systems and start from the very first - the radiator.

Radiators

Radiator (novolat. Radiator, "radiator") - heat exchanger, serves to dissipate heat from the cooled object. The mechanism of heat transfer here is thermal conductivity, the ability of a substance to conduct heat inside its volume. All that is needed is to create a physical contact between the radiator and the object to be cooled, which is why it is always in close contact with what is cooling. After the radiator takes over some of the heat from the object to be cooled, its task is to dissipate it into the surrounding air.

But it is not enough just to provide physical contact! Indeed, sooner or later, the cooling system itself will also heat up from a constantly heated cooling object. A process of heat transfer in the system of bodies with the same temperature, as we know, cannot be. To find a way out of this situation and not face the problem of overheating, it is necessary to organize the supply of some cold substance to cool the cooling system itself. Such a substance is commonly called a refrigerant (refrigerant, a particular case of coolant)

The radiator is an air cooling system, i.e. the coolant in his case is cold air from the environment. Heat from the cooled object goes to the base of the radiator, then is evenly distributed over all its edges, and after that it goes into the surrounding air. This process is called heat conduction. The air around the radiator gradually heats up, due to which the heat exchange process becomes less and less effective. The efficiency of heat transfer can be increased by constantly supplying cold air to the fins of the radiator. Simply put, for efficient cooling, free circulation of cold air is needed.

Physical quantities such as thermal conductivity (the rate of heat propagation through the body) and heat capacity (the amount of heat that the body needs to communicate to increase its temperature by 1 degree) at the radiator must be at a high level. From the same school course, we know that metals have the highest thermal conductivity. In fact, this is not the case - diamond has the highest thermal conductivity :), and it lies in the range from 1000 to 2600 W / (m · K). Of metals, silver conducts best of all - its thermal conductivity is 430 W / (m · K). After silver comes copper [390 W / (m · K)], then gold [320 W / (m · K)]. Completes the chain aluminum [236 W / (m · K)].

Throwing away the jewelry, it becomes clear that the most applicable are the two materials - aluminum and copper. The first is due to the low cost and high heat capacity (930 vs. 385 for copper), the second is due to the high thermal conductivity (the disadvantages of copper include a higher melting point and the complexity of its processing). Silver, for its high thermal conductivity, is sometimes used to make the base of a radiator. Even for the manufacture of radiators can be used aluminum alloy with silicon - silumin. The advantage of using it is cheaper than aluminum.

If the radiator is made of highly heat-conducting material, then the temperature at any point will be the same. Heat generation will be equally effective with the entire surface area. Because Since an object gives off heat from its surface, this means that to achieve the best heat removal, the surface area of the object to be cooled should be maximized. There are two ways to increase the area of the radiator - an increase in the area of the ribs while maintaining the size of the radiator and an increase in the geometric dimensions of the radiator. The second option, of course, is preferable, but it introduces a number of inconveniences - for example, it increases the weight and size of the radiator, which can make the installation difficult. Well, the price, respectively, increases in proportion to the amount spent on the manufacture of material.

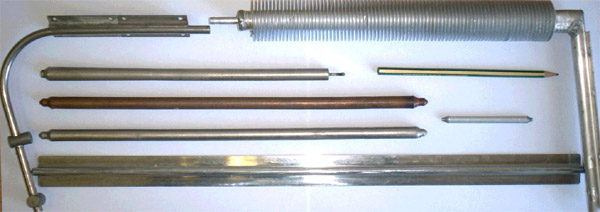

Types of designs of radiator fins there are a huge variety. They can be thick if they were created by an extrusion process. Or vice versa, thin - if the ribs are cast. They can be straight along the entire length of the radiator, and can be lined across. Can be flat, bent of plates, pressed into the base. But the best thing about the work today is that the needle-type radiators show themselves — in such radiators, instead of ribs, square or cylindrical needles.

Manufacturing of radiators

At the moment, I know 6 methods of production of radiators:

1. Pressed (extrusion) radiators are the cheapest and most common on the market. The main material used in their production is aluminum. Radiators of this type are made by pressing (extrusion), which allows you to get quite complex profiles of the surfaces of the ribs and achieve good heat dissipation properties.

2. Folded (tape) radiators - are obtained when a thin metal band, rolled into an accordion, is soldered (or using adhesive conductive pastes) attached to the base plate of the radiator. The folds of the accordion tape in this case play the role of ribs. Such manufacturing technology allows to obtain compact products in comparison with extruded radiators, but with about the same thermal efficiency.

3. Forged (cold-formed) radiators - radiators obtained as a result of the use of cold-pressing technology. This technology allows you to create the surface of the radiator in the form of rods of arbitrary section, and not just standard rectangular fins. As a rule, they are more expensive than radiators of the first two types, but their efficiency is often much lower.

4. Compound radiators are close relatives of “folded” radiators. Despite this, they are distinguished by a significant moment: in this type of radiators, the surface of the ribs is formed not by an accordion tape, but by thin separate plates, which are fixed by soldering or butt welding on the bottom of the radiator. Radiators of this type are slightly more efficient than extrusion and folded.

5. Molded radiators - in the manufacture of products of this type, injection molding technology is used. The use of this technology allows to obtain the rib surface profiles of almost any complexity, significantly improving heat transfer.

6. Turned radiators - are the most expensive and advanced radiators. Products of this type are created by precision machining (on special high-precision CNC machines) of monolithic blanks and are distinguished by the highest thermal efficiency. If it were not for the cost of production, then this type of radiator would have long been able to oust its competitors in the market.

Heat pipes

In modern systems, heat pipes or simply heat pipes have ceased to be rare in radiators and coolers.

It is a hermetic heat transfer device that operates on a closed evaporation-condensation cycle in thermal contact with external - the source and heat sink. Thermal energy is taken on the cooled object and is spent on the evaporation of the coolant, which is located inside the heat pipe body. Further, thermal energy is transferred by steam in the form of latent heat of evaporation further, at a certain distance from the point of evaporation, where during condensation the steam is released into the drain. The resulting condensate is returned to the evaporation site either under the action of capillary forces (which are provided by the presence of a specialized capillary structure inside the heat pipe) or due to the action of mass forces (this design is usually referred to as a thermosyphon).

It turns out that instead of the usual electronic mechanism of heat transfer (by heat conduction, which takes place in a continuous metal heat conductor), a molecular transfer mechanism is used in the heat tube (more precisely, the process of transfer of the kinetic and vibrational energy of random motion of vapor particles).

There is a contact! What is the area?

It is necessary to strive to ensure that the contact area between the radiator and the cooled object is as large as possible - after all, it is through this area that the heat from the object will flow to the radiator. But it is necessary to take into account that when two even the smoothest surfaces touch, the smallest cavities and gaps filled with air still remain between them [recall that the thermal conductivity of air is 0.026 W / (m · K)] - this can play a cruel joke.

To get rid of harmful air and allow the radiator to work with maximum efficiency, different thermal interfaces are used, most often it is thermal paste (thermal paste). It has a high thermal conductivity [due to the use in its composition of substances such as aluminum and silver (up to 90% content)] and due to the fluidity it fills all the irregularities in the contacting surfaces.

Thermal grease comes complete with most brand coolers and radiators. It happens in the form of a syringe or a small tube bag. It is recommended to avoid thermal paste on the electrical components of the computer.

One of the parameters of thermal grease is the duration of the period when it comes to maximum efficiency. On average, this time is about a week. Coolink recently produced the first thermopaste with the addition of nanoparticles - its advantage is that there is no waiting period.

In addition to thermal paste, there is another type of thermal interface - conductive pads. The essence of their work is the same, but they are used differently - they are put on the contact surface and, under thermal influence, change their state of aggregation, filling irregularities and displacing the air.

Total radiators

Despite all sorts of variations, the most important advantage of the radiator is that it is not the source of any noise. The disadvantages include relatively low efficiency, lack of capacity to overclock the system and often large dimensions.

If you trust the cooling of modern video cards and processors to passive radiators is dangerous enough, then the cooling of memory modules, hard drives, chipsets, power circuits - you can rely on.

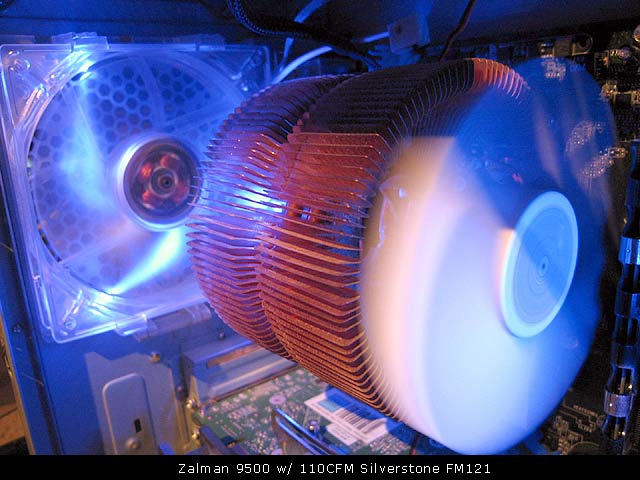

Coolers

A cooler (eng. Cooler - cooler) is a combination of a radiator and a fan that is installed on the electronic components of a computer with increased heat dissipation. The most important task of the device is to reduce the temperature of the cooled object and maintain it at a certain level. This is achieved due to the continuous flow of air blowing the radiator. That is, a less efficient radiation process turns into a more efficient one — convection. Coolers - this is the easiest, fastest, affordable, and, in most cases, a sufficient way to cool computer components - everything is cooled with air.

There are a huge variety of options. If we talk about the appearance of a long time, then you will not tell a lot about functional differences.

Coolers come in different sizes - usually from 40x40mm to 320x320mm.

Balls for videos

The most important part of any cooler is its fan. It is he who makes noise in your system unit. And to be more precise, this noise appears when an air stream collides with a radiator. This noise is especially noticeable on cheap cooler models, since no one works on their design.

The fan consists of an impeller (there is a magnet in its inner diameter) and an electric motor, which this magnet rotates together with the impeller. Through the center of the fan is an axial pin, which is located in the center of the motor. For greater smoothness of the impeller stroke, three types of bearings can be used (the service life of which manufacturers indicate in thousands of hours on the package):

- Sleeve bearing (sleeve bearing) - the cheapest and least reliable option, creating a high level of noise when working.

- 1 sleeve bearing (sleeve bearing) + 1 rolling bearing (ball bearing) - a combined bearing is a more durable design, working on average twice as long as on a sliding bearing.

- 2 or 4 rolling bearings (ball bearings) - the most reliable options with low noise, but these fans are significantly more expensive than the first two.

- Needle and NCB (nano-millimeter ceramic) bearings - installed in fans by a limited number of manufacturers. They are characterized by low noise, low cost and very long service life.

By the way, about the service life (uptime. If the service life is specified in 40-50 thousand hours (almost 5 years. Although it happens more - up to 300,000 hours!), This does not mean that the next time you have to remember about the cooler only after this time. No! This number should be divided by two or three, and still preventive actions should be performed from time to time - wipe off dust, blow, lubricate.If you don’t take care of the cooler, it can start to make noise, and if it’s all about it forget something and stop.

The fan performance (consumption characteristic) is perhaps its main characteristic. It is measured in the number of cubic feet of air discharged by it per minute, abbreviated to CFM (Cubic Feet per Minute). This characteristic mainly depends on the area of the fan, the profile of the blades and the speed of their rotation. The greater this value, the higher the cooling efficiency and, as a rule, the higher the noise level generated by the fan during operation.

Healthy food

The cooler can distill cubic meters of air with its blades at a speed of up to 8000 revolutions per minute (for comparison, the engine of an ordinary passenger car produces 5-8 thousand revolutions. The engine of the Formula-1 car - up to 22,000 revolutions). But it is clear that at such a speed the noise from the cooler will be noticeable. Therefore, it is preferable to take coolers with thermal sensors - which “analyze” the temperature and, depending on the situation, can increase or decrease the number of revolutions. Most often it has a positive effect on the noise from work.

All computer coolers are powered by direct current, the voltage of which is most often 12V. For power, they use Molex connectors (for Smart fans) or PC Plug connectors.

PC-Plug has four wires: two black (ground), yellow (+ 12V) and red (+ 5V).

The Molex connectors on motherboards are used so that the system itself can control the rotational speed of the fan, applying a different voltage to the red wire (usually from 8 to 12 V). From the yellow (signal) wire, the system learns from the cooler information about the speed of rotation of its blades. Using Molex has one major drawback: it is dangerous to hook up fans with power consumption of more than 6W.

The situation is different with the PC-Plug connector - it stands tens of watts. But it didn’t happen without tar - when you connect to it, you will not be able to find out if your fan is working or not.

Finding an adapter from one connector to another now is not difficult - they are often included.

Also, to reduce noise, the cooler is sometimes transferred to 5V or 7V. Cables are rounded off, wires are braided into braids or covered with braid and tidied up in a secluded place - so as not to interfere with the well thought-out air circulation.

About noise

All coolers are classified according to the noise level issued from their work into the following classes (the lower the noise level, the more comfortable the work at the computer will be):

- Conditionally silent . The noise level of such a cooling system is less than 24 dB. This figure is lower than the typical background noise in a quiet room (in the evening or at night). Thus, the cooler makes almost no significant contribution to the noise picture. Typically, this value is achieved at the minimum fan speed for systems with a speed controller.

- Low noise . The noise level from such a cooling system is in the range of 24 to 30 dB inclusive. The cooler makes a barely perceptible contribution to the PC's acoustics.

- Ergonomic . The noise level of such a cooling system is in the range from 37 to 42 dB inclusive. Noise from such a cooler is likely to be noticeable in most user configurations of the computer.

- Not ergonomic . The noise level of the cooling system under consideration is greater than 42 dB. In such conditions, the cooler will be the main "generator" of computer noise in almost any configuration. Home use of such a cooler is unjustified - it is more suitable for industrial and office premises with background noise of more than 45 dB.

The total for the coolers

The advantages of coolers include their prevalence, versatility, availability. A small cost can also be attributed to a plus, but it should be borne in mind that you should not be greedy for a good cooler - this is, in fact, the second heart of the computer - it is impossible for it to stop.

By cons, I will take the possible noises that sooner or later appear on any cooler.

Summing up the above. At the moment, the cooler is the most common cooling system, which you can cool anything from the processor to the hard drive and memory. The question is the selection and selection of the desired cooler - after all, there are many of them from dozens of manufacturers.

Someone needs a middle ground between silence and performance. Someone needs gigahertz and don't care about noise, someone on the contrary prefers silence.

Source: https://habr.com/ru/post/64162/

All Articles