AAA or AA battery charger

Many of us, buying a Mini-Z radio-controlled car, try to buy a charger as quickly as possible that could charge the batteries into the console and into the model itself. Currently, a lot of companies produce chargers that can work with AA-size and AAA-size batteries, but most of these devices are not always suitable for those who start participating in competitions. The first thing athletes need is battery charging speed. The second is that proper maintenance of batteries usually saves a few tenths of a second on the track, and this is sometimes very critical.

All of the above applies to those who are professionally engaged in photography.

')

Criteria for choosing the right charger:

- 220V power supply

- operation with at least 4 AA or AAA batteries

- possibility of charging and discharging each battery independently of others (side by side charging and discharging)

- possibility to select a mode for each battery separately (charge; discharge; discharge-charge; discharge-charge several times in a row - cycling; battery recovery mode, etc.)

- the ability to manually set the charging current and discharge

- charging current for each battery - from 800mA

- visual indication of operating modes and the status of each battery

- the presence of a temperature sensor (charging off when a certain temperature is exceeded)

- fan for cooling (optional)

So, I would like in this review to tell you about two chargers that have proven themselves well throughout the world for several years. I would like to note that it is these two chargers that you can most often meet with the winners of various Mini-Z championships around the world and professional photographers.

1. Alpha Power Battery Charger BC-900 from La Crosse Technology

Characteristics of Alpha Power Battery Charger BC-900 :

- batteries: AA, AAA, C, D

- charge each battery current up to 1800 mA with a choice

- gambling

- cycling

- recovery mode for old batteries

- mode indication

Feedback (not mine):

If a two-color light bulb is not enough for you and you are sure that you know what and how you want to charge better than any Chinese plastic box, and you also want to see what happens when this happens - the bc-900 is for you.

Instructions and specifications: all parameters are normally painted, incl. Maximum understandable battery capacity (3 Ah). It is quite convenient to use, after reading the instructions there were no questions and no problems with the choice of modes

The charger is almost perfect - it does not try to think for the user, leaving him the right to decide how to charge the battery and what to do with it.

It shows the battery voltage, mode (charge / discharge / infused or removed capacity / time from the beginning of the cycle).

You can measure the actual battery capacity in test mode - first the battery is charged, then discharged, then the charge again - and the display shows the capacity taken during the discharge.

I liked the mode of refresh - successive cycles of charging and discharging to the maximum capacity. Only long before, but if you don’t hurry anywhere, why not take a useful idle charger with something useful?

By the way, this charger returned to operation a set of Varta Photo 1900 batteries - and my old Ansmann digispeed 4 charger simply refused to charge them.

As for the design and configuration, I liked everything, I was pleased with adapters for emulating batteries of type C and D. Well, the carrying bag ftw The 100-240V pulse adapter is perceived as a must have for such a device.

I liked La Crosse BC-900 so much that it would be tiresome to paint all the advantages, it’s easier to point out the shortcomings

So, the minuses (fortunately, not spoiling the impressions of the charger, but only distinguishing it from the absolute and unattainable ideal

- no forced cooling. Temperature protection is good, but I would prefer forced cooling when I need to charge the batteries quickly. I do not like to charge batteries with a current of more than 700mA - they heat quite strongly.

- stupid (imkho) limitation - when the first battery was inserted and its charging current was indicated, for all the others charged simultaneously with it, the current is limited from above by the charging current set for the first element.

- The maximum discharge current is “locked” as half of the charging. Those. if we want to discharge the battery with 500mA current, then the charging current will be 1A. It seems to me logical when the discharge current is greater than the charge current. I would prefer, say, to measure the battery capacity for a camera at the maximum discharge current, and charge it with the minimum charging current.

Summary: the best portable charger. Yes, yes, and without any “possible”

PS We 'll talk about reliability in 3-5 years of operation - how can I put a rating before - I can’t imagine, except to use several dozen devices at the same time.

PPS As for sending the rating, it is required to set the reliability rating, I put “5 ″.

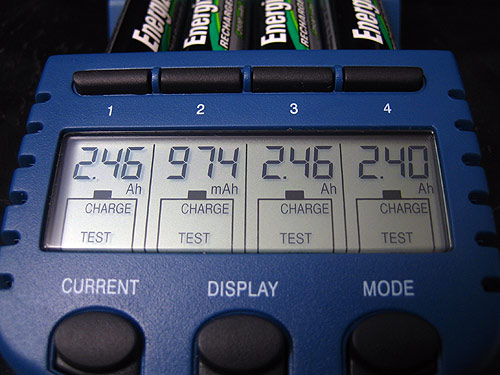

2) MAHA MH-C9000 WizardOne Charger-Analyzer charger from Maha Energy Corporation

His characteristics are wonderful ... screen backlighting ... side-by-side management ... all things!

- Charging Current: Programmable from 0.2A to 2.0A in increments of 0.1A

- Topoff Charging Current: 100mA

- Maintenance Charging Current: 10mA

- Discharge Termination: Voltage 1.00V

- Discharge Current: Programmable from 0.1A to 1.0A in increments of 0.1A

- Capacity Storage Memory: 12 (Cycle mode only)

- Supported Capacity: 100 to 20,000mAh.

- Charger Input Power: 12V 2.0A

- Adapter Input: 100-240V 50 / 60Hz

I decided to order it at the end of last season. And then I stumbled upon the following review and changed my mind, I will take myself another new LaCrosse :

Well, I tested on holidays this new charger from Mahi .

If integrally, then it is worse than Lyacross, although there are some advantages that are missing in the BC-900.

In order not to be unsubstantiated I cite a list of advantages and disadvantages.

Although there is no satisfaction from him in his heart and his “technofitishism” is clearly not satisfying to them.

Disadvantages of Maha MH-C9000:

1. When the AAA battery was charged 800mAh with 700mAh, the MH-C9000 overheated it so much that the battery began to boil, and electrolyte flowed out of it directly into the charger. A detailed investigation of this situation showed immediately the presence of one manufacturing defect, one miscalculation in the design and not until the end of the debugged algorithm for determining the end of the charge by the voltage drop. A manufacturing defect is the absence of thermal paste on all 4 thermal diodes. As a result, the contact of the thermal diode with the external metal thermal contacts of the charger was absent. The miscalculation of the design lies in the very narrow metal thermal contacts of the charger, which are also arranged so that when the AAA batteries are inserted, the thermal contacts touch the batteries only partially. In the BC-900, the location of the metal thermal contacts is more correct, besides, they are wider, have better contact with the battery case of any form factor, and AA and AAA. The sensitivity of the MH-C9000 charger to a voltage drop at the end of the charge is also, as it turned out, unsatisfactory, because it allowed the battery to recharge when the temperature control channel is not working (due to the absence of thermal paste). (According to the manufacturer, the MH-C9000 has “Negative delta V, peak voltage, dT / dt (temperature rise) and max temperature protection”).

2. Despite the restored contact of the thermal diode with the battery, I was not able to simulate the situation of a temporary cessation of charge when overheated with subsequent resumption of the charge when the battery cools even at a charge current of 2000mA. When the temperature rose to 56 degrees, the charge simply stopped, the message “Done” appeared and the re-activation of the charge did not occur. The accumulated energy in the battery was lower than the actual battery capacity measured in the “Refresh & Analyze” mode. In this situation, the BC-900 behaves correctly and resumes its charge when the “test subject” cools.

3. The screen backlight does not turn off. The reliability of this solution immediately caused doubt that, unfortunately, it was confirmed in practice - after a day of testing, the backlight just died. At night, the "night light" in the form of a constantly-lit backlight in the charger looks defiant and unnecessarily necessary. Without the backlight, the charger looks more logical, if only it would not fall off anything else during the operation.

4. On the board, 4 elements, presumably a diode, are decoupled manually, clearly after detecting operational errors and launching the printed circuit board into mass production. This fact speaks of the “dampness” of the charger and not the flexibility of production of MAHA ENERGY CORP.

5. Less reliable fastening of AAA batteries - spring contact lobe is located far from the center of the battery, and the latter can easily jump out when inaccurate installation or shaking.

6. The device is not as high-tech as La Crosse Technology BC-900 - standard components with not such a high degree of integration are used. Specialized beskorpusnye custom chips, as in La Crosse Technology BC-900, no.

7. It is doubtful that the “Refresh & Analyze” mode has two hourly expectations (Rest). Theoretically, of course, in order for the chemical processes in the battery to end and the temperature to go down, the wait is probably useful, but spending two additional hours in the Refresh & Analyze mode completely corresponding to the Test mode of the BC-900 is hardly advisable.

8. I would not like to argue with IEC standards, but a 16-hour charge with current 0.1C on a timer, a wait for 1 hour, a discharge with a current of 0.2C, a wait for one more hour and the final 16-hour charge with a current of 0.1C in the “Break- In ”I also do not consider it advanced, but the opportunity to use an anachronistic method of charging in a modern intelligent device.

9. The “Cycle” mode is considered a pitiful similarity of the “Refresh” mode in the BC-900. La Crosse Technology BC-900 itself will determine when to stop the charge-discharge process by the absence of an increase in capacity discharged at discharge. In the MH-C9000, you must manually specify the number of charge-discharge cycles. In addition, for MH-C9000, the number of cycles is limited to 12, and the BC-900, if necessary, can perform 20 charge-discharge cycles.

10. In the MH-C9000, it is impossible to change the battery mode without re-inserting the battery into the landing slot. BC-900 allows you to change the mode of operation without changing the charge-discharge currents.

11. As the built-in tester shows, the MH-C9000 with less accuracy than the BC-900 withstands user defined charge / discharge currents.

12. When the mains power fails and the MH-C9000 is turned on again when the power supply is restored, a current charge mode of 1A is automatically initiated. This charge current is not desirable for modern AAA batteries. This feature, together with the design features mentioned above, does not allow us to recommend this charger for charging AAA batteries.

13. MH-C9000 does not show the no-load voltage of the battery at the time of its installation in the landing slot. Only after starting a certain mode of operation. The function of displaying the no-load voltage of the battery at the time of its installation in the landing slot would allow determining the internal resistance of the battery at a constant current - one of the characteristics of the “quality” of the battery, without the use of an additional voltmeter.

14. Different chargers represent different loads for charged batteries when disconnected from their power supply or 220V network. In one case, charged batteries can even be stored inserted in the charger, in the other, they can be removed as quickly as possible in order to reduce discharge during storage. In this regard, the MH-C9000 is definitely worse than the BC-900 (the MH-C9000 has a high leakage current) and is no different:

Varta Type 57039 - 0µA;

La Crosse Technology BC-900 - 25µA (11µA at the start of operation; 1.9mA with the plug-in power supply inserted);

GP PowerBank Smart2 GPPB14 - 25-90µA (depending on the channel and does not depend on whether the power supply unit is inserted into the charger or not);

Olympus BU-300E - 75µA;

Acme Power RC-6 340mkA (480mkA when the plug-in power supply is inserted);

Maha MH-C9000 - 0.8mA (1.1mA with the plug-in power supply inserted);

Ansmann Energy 4 - 13mA.

15. Parameter display is very inconvenient. It jumps not only cyclically on the parameters of one selected channel, but on all parameters of all active channels. It seems uncomfortable to me.

16. Very annoying modulated high-frequency whistle of pulse converters, which are located not only in the network power supply, but also the charger itself. The whistle is very strong, you just don’t want to sleep near the table or work at the table where the MH-C9000 is located - you become annoyed and nervous.

17. In the delivery set there are no batteries, a bag and adapters of C / D form factors, despite the fact that the price of the MH-C9000 charger is higher than the BC-900. The “branded” Powerex bag from the optional accessory kit for the MH-C9000, ordered by an extra charge, doesn’t fit the charger itself, not to mention the network adapter.

18. Compared to the BC-900, the MH-C9000 is huge.

Advantages of Maha MH-C9000:

1. When the battery discharges below 0.9v, the MH-C9000, unlike the BC-900, perfectly identifies the inserted battery and starts the charging process.

2. MH-C9000 has a large range and a smaller step charge-discharge currents. In addition, the programmed charge and discharge currents already installed in the battery charger do not have a limiting effect on the magnitude of the charge and discharge currents of the batteries installed later.

3. In order to test the batteries (but not use the batteries in order to free them from the memory effect), the MH-C9000 has a more “correct” “Discharge” mode - after a discharge, the charge is not performed, and the capacity readings are stored on the indicator. This feature, as well as the lack of testing the internal resistance of the element in the “Discharge” mode, allows measuring the capacity even at primary elements of form factors AA and AAA with voltage up to 1.5V, including the recently developed Energizer 1.5-volt lithium (Li / FeS2) elements.

The original article was published on the site of the Russian Mini-Z Club.

Source: https://habr.com/ru/post/63062/

All Articles