Lightsaber Homemade Copper Vapor Laser - Part 3, Final

I decided to make a brief comic book for beginner necromancers who want to pick up copper vapor lasers from the dead. Victor Frankenstein “breathed life” into the dead, and we will do the same with a dead laser tube.

So, you will need the following utensils:

Carrying out the ritual: lay the intact corpse on a rigid dielectric and refractory surface. Cut the glass “warts” on the body, in the left and right side and weld in their place fittings from the same grade of glass for complete survival. Connect the left fitting to the pump, the right - to the source of the "spirit", which the uninitiated call neon. Connect the cable from the high voltage source to the metal limbs on the body. Pump all the air out of the body with a vacuum pump and let in exactly as much neon so that the pressure is within 100 mmHg. Art. Start galvanizing the corpse with a voltage of about 25-30% of the nominal, a bright red-orange glow should be observed. Wait 5-10 minutes. Continue galvanizing with full voltage for half an hour, until the insides of the body heat up the yellow, and the glow acquires the color of a rotten swamp. In speed after this, the corpse should show signs of life in the form of a relatively bright and directed green glow emitted by it in the form of 2 beams. Place the mirror and a piece of glass in the head and legs so that they are parallel and create an infinite number of reflections of our client. In this case, the subject must emit a very bright and destructive light in the form of a narrow parallel beam with the same parameters as a completely live and 100% healthy copper vapor laser. Nevertheless, he is not fully alive, since he needs equipment, disconnecting from which will kill him again, until the next time.

')

Look for additional information not included in these instructions inthe Book of the Dead, Necronomicon in the list of references.

The devil knows if Victor Frankenstein had lasers with vacuum pumps, but he had a power supply for sure.

Now seriously.

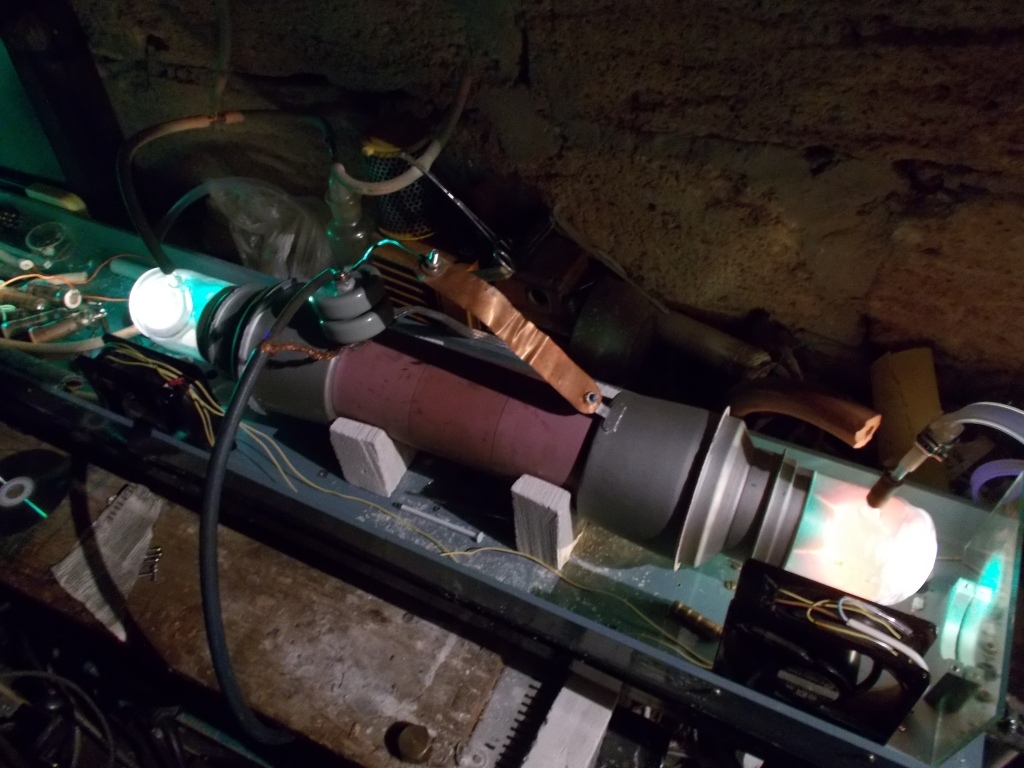

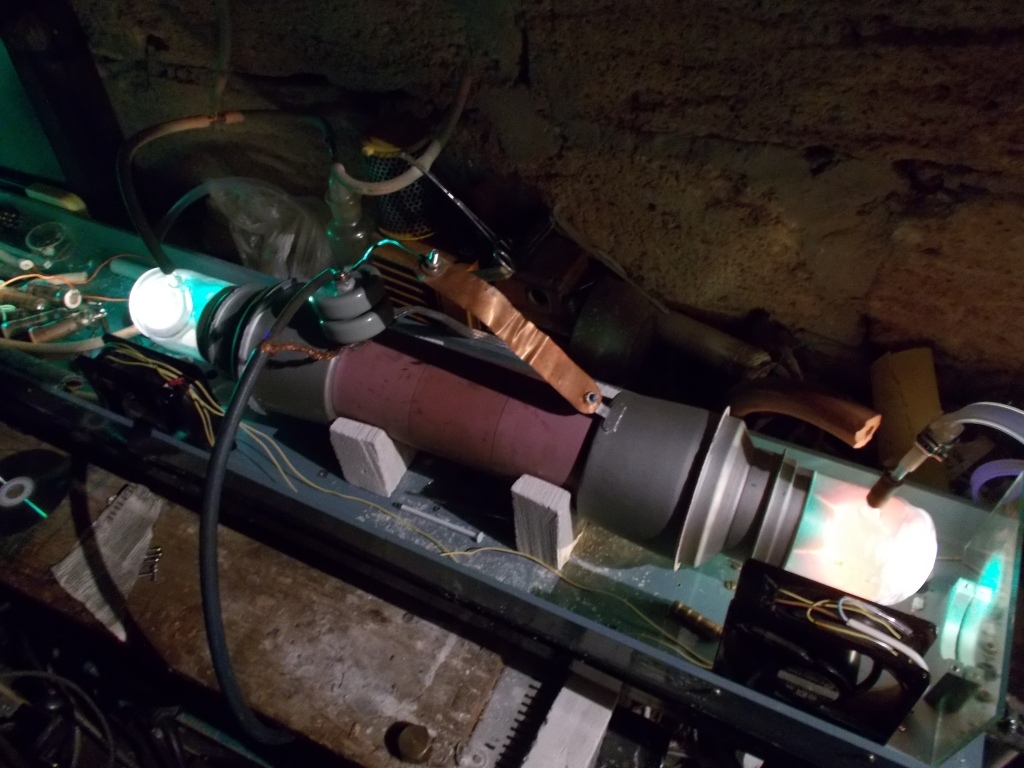

Yes, I haven’t written anything here for a long time. During this time, I managed to do a lot of experiments, along the way I was able to improve working conditions, to acquire new equipment. The main “home laboratory” has moved to a dry and well-protected basement of the house.

It was possible to place a small vacuum post with a forevacuum and diffusion pump.

Nearby is a set of cylinders with the main gases that are needed for lasers - helium, argon OCH 6.0 and still neon OCH 5.0.

Thus, it became possible to pump out and refuel the AE of gas lasers. In the first and second parts, I mentioned that the active element of the UL-102 laser, which served as the basis for this project, suddenly leaked and became more unusable. As a result, I had to search and acquire a new AE, which has been working flawlessly in this laser so far. However, the faulty AE did not remain useless. I decided to practice on it.

To begin with, I had to carefully open the dowels on the glass flasks of the laser tube in the glass-blowing workshop and solder the fittings on them so that hoses could be connected to them. On this glass-blowing operations were completed.

Then I was able to connect a 31 vacuum pump to one fitting, and a hose to let gas into the laser to the second. An insulin needle is inserted inside the hose, which acts as a trickle for accurate gas metering. With another hose, it is connected directly to the gearbox on the cylinder. Between the laser tube and the pump, an ordinary Drexel flask is included for catching the ejected oil from the pump if it suddenly stops and an accurate vacuum gauge with a division price of about 2 mmHg. Art. Power is connected to the laser as usual - an sharpening capacitor of two k15u-1 of 470 pF 15 kV and a coaxial cable connecting the tube to the power source are connected in parallel with the electrodes. The power source is described in detail in the previous parts.

Initially, the idea was to replace the working gas in the laser - to use argon instead of neon, because according to the literature, the laser remains operational with argon and at the same time the primary training of the tube is greatly reduced in price, aimed at removing all undesirable impurities from the active zone that got there with air. But that did not work. The discharge was ignited with significant overvoltage at the moment of ignition, since argon had a higher ionization potential than the neon and the coordination of the laser tube with the source was greatly violated. In addition, the discharge tended to compress strongly into a thin cord and subsequent unstable combustion, up to ignition not from working electrodes but from surrounding metal parts and further disruption. The result was one - switching off the source for protection against short circuit, since the thyratron in the power unit lost control, or an arc ignited in the source itself. The victims of this experiment were 2 fans in the power block, a relay protection circuit and an autotransformer in the IVN block. To reach the working thermal regime of the laser tube did not work. Variation of argon pressure, pulse repetition rate, voltage did not give results - the work remained unstable. I had to abandon further work with argon in this tube.

After eliminating all the malfunctions, the tube was filled with neon with a pressure of about 150 mm Hg. Art. With neon, the discharge burned stably, the source no longer turned off. At first, a slow neon duct was installed to remove impurities, then the pump was stopped and the neon supply to the tube was shut off. In the short term, no gas leakage was observed and work was continued in a gas-static mode.

The pressure was kept approximately constant, and by the end of heating it increased to 160 mm Hg. Art.

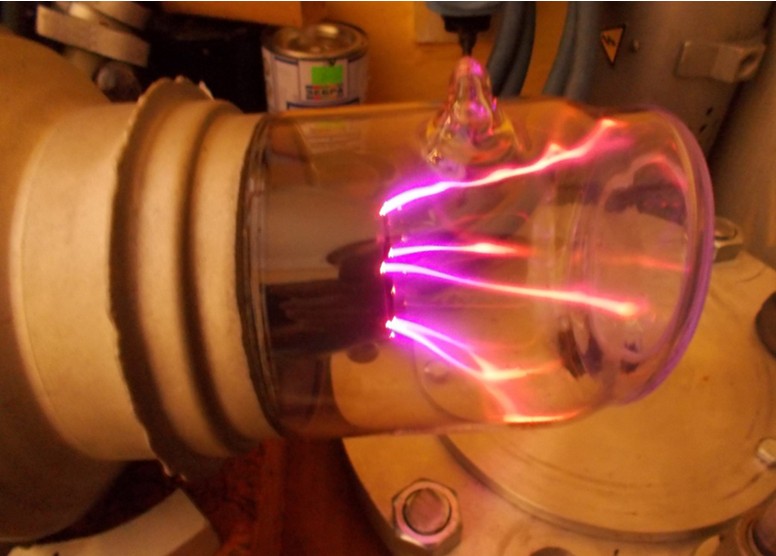

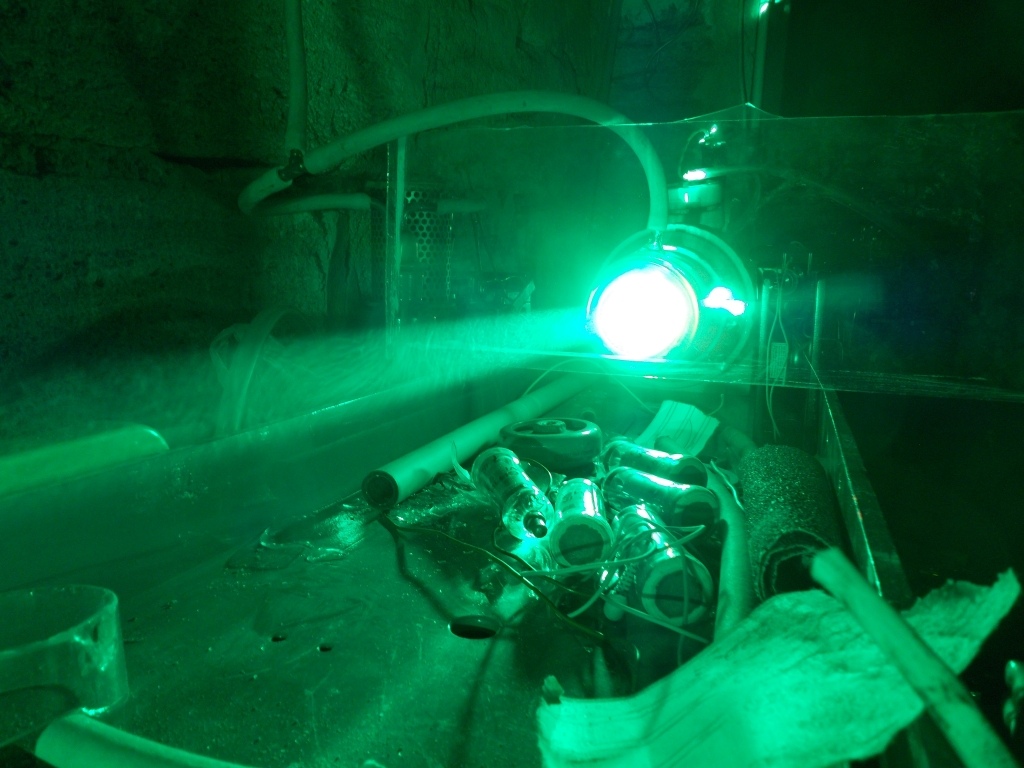

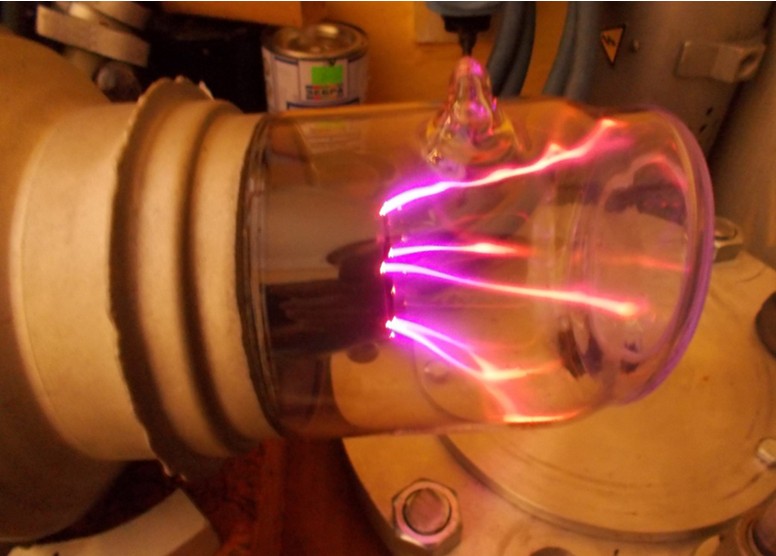

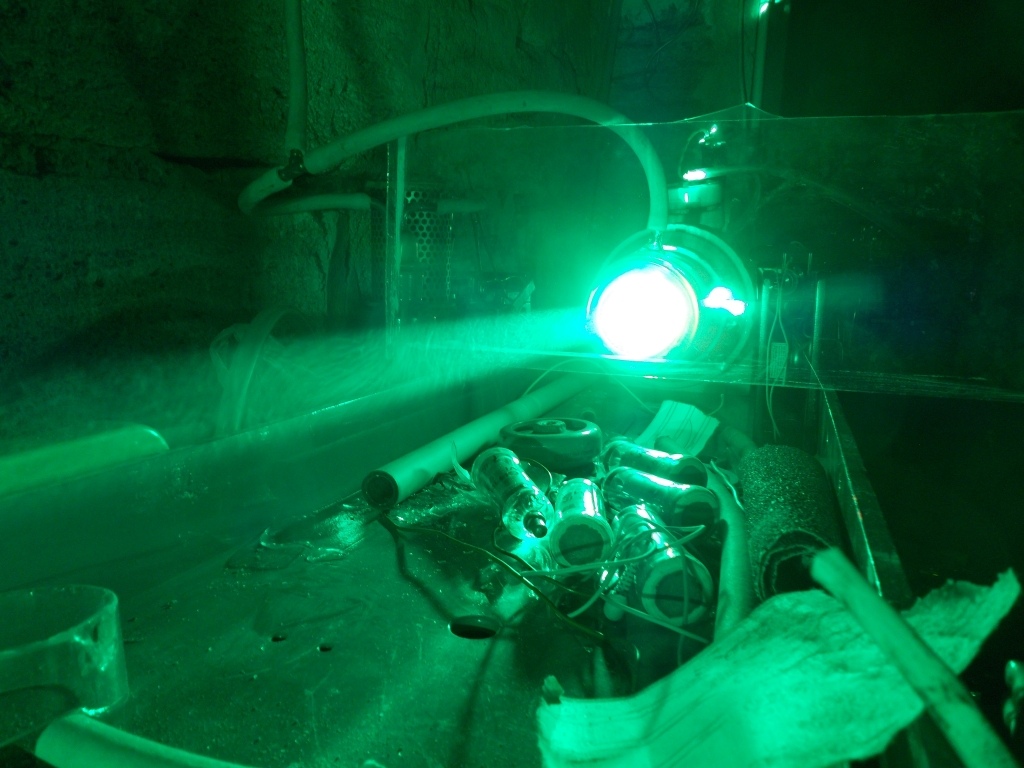

The laser tube warmed up smoothly to operating temperature and produced radiation in the super-luminosity mode, since the gain in copper vapor is huge. Weak radiation did not suit me, then on the one hand I installed an ordinary household mirror with an “internal” reflective layer and a piece of window glass on the other, so that they were as parallel as possible and reflected the radiation back and forth inside the laser tube. The requirements for alignment accuracy of such a "resonator" are so low that you can do without special devices for positioning the "mirrors". This immediately gave an increase in power, offhand up to two watts.

Start of generation.

A beam with one mirror.

With two mirrors.

Having received stable radiation, I decided to experiment with the selection of neon pressure, since it pretty much affects the output power. He turned on the pump again, with a decrease in pressure, the output power began to monotonously increase. After pumping up to about 10 mm RT. Art. let in a tube a new batch of pure neon - power still increased. This suggested that the "exhaust" gas was dirty enough to reduce power. He brought the pressure to 200 mm RT. Art. and again pumped out and again filled a new portion, "flushing" the tube. At this point, the power with the resonator was indistinguishable from the power of the assembled laser with the same active element. Thus, the operation, code-named "rebellion from the dead" was successful.

There are 2 lines in the radiation - green and yellow.

It only remained to know the magnitude of the long-term leakage of the tube. He squeezed the evacuation hose with a clamp and also squeezed the gas inlet hose, making the tube again “soldered”. For 10 days, it flowed approximately 20 mm RT. Art., which gave a leakage rate of 2 mm Hg per day. And this is already consistent with the value that it flowed for 2 months of lying. Perhaps, indeed, the problem is in the marriage that was allowed in the production, or maybe flows through the leaks of my vacuum system. After this, it remained to conduct another experiment. According to the literature, copper vapor lasers remain operational at a neon pressure of ... 760 mm Hg, i.e. atmospheric. In this case, the laser tube generally ceases to be a vacuum device, which means that leakage into such a tube through small leaks will be negligible, and neon, being a heavy and dense gas (compared to air), will not be so readily volatilized. But here a fail happened - the power source did not have enough voltage for through breakdown of the discharge channel. Only a very bright and intense, but corona discharge at the electrodes was observed. Most likely, the statement regarding operation at atmospheric pressure is valid only for small-sized AEs of the Coulomb series.

References:

So, you will need the following utensils:

- The intact body of a person who has suddenly died. Damaged, fragmented, deformed bodies are not suitable.

- High voltage power supply with the required output parameters.

- Vacuum pump (any two-stage rotary pump is enough).

- A vessel with a compressed spirit for our client. Where to get it - ask the merchants of dead souls. Not any "spirit" is suitable, beware of counterfeiting.

- Any mirror and any piece of any transparent glass.

- Hoses, pressure gauge, the thinnest medical needle for dosing.

Carrying out the ritual: lay the intact corpse on a rigid dielectric and refractory surface. Cut the glass “warts” on the body, in the left and right side and weld in their place fittings from the same grade of glass for complete survival. Connect the left fitting to the pump, the right - to the source of the "spirit", which the uninitiated call neon. Connect the cable from the high voltage source to the metal limbs on the body. Pump all the air out of the body with a vacuum pump and let in exactly as much neon so that the pressure is within 100 mmHg. Art. Start galvanizing the corpse with a voltage of about 25-30% of the nominal, a bright red-orange glow should be observed. Wait 5-10 minutes. Continue galvanizing with full voltage for half an hour, until the insides of the body heat up the yellow, and the glow acquires the color of a rotten swamp. In speed after this, the corpse should show signs of life in the form of a relatively bright and directed green glow emitted by it in the form of 2 beams. Place the mirror and a piece of glass in the head and legs so that they are parallel and create an infinite number of reflections of our client. In this case, the subject must emit a very bright and destructive light in the form of a narrow parallel beam with the same parameters as a completely live and 100% healthy copper vapor laser. Nevertheless, he is not fully alive, since he needs equipment, disconnecting from which will kill him again, until the next time.

')

Look for additional information not included in these instructions in

The devil knows if Victor Frankenstein had lasers with vacuum pumps, but he had a power supply for sure.

Now seriously.

Yes, I haven’t written anything here for a long time. During this time, I managed to do a lot of experiments, along the way I was able to improve working conditions, to acquire new equipment. The main “home laboratory” has moved to a dry and well-protected basement of the house.

It was possible to place a small vacuum post with a forevacuum and diffusion pump.

Nearby is a set of cylinders with the main gases that are needed for lasers - helium, argon OCH 6.0 and still neon OCH 5.0.

Thus, it became possible to pump out and refuel the AE of gas lasers. In the first and second parts, I mentioned that the active element of the UL-102 laser, which served as the basis for this project, suddenly leaked and became more unusable. As a result, I had to search and acquire a new AE, which has been working flawlessly in this laser so far. However, the faulty AE did not remain useless. I decided to practice on it.

To begin with, I had to carefully open the dowels on the glass flasks of the laser tube in the glass-blowing workshop and solder the fittings on them so that hoses could be connected to them. On this glass-blowing operations were completed.

Then I was able to connect a 31 vacuum pump to one fitting, and a hose to let gas into the laser to the second. An insulin needle is inserted inside the hose, which acts as a trickle for accurate gas metering. With another hose, it is connected directly to the gearbox on the cylinder. Between the laser tube and the pump, an ordinary Drexel flask is included for catching the ejected oil from the pump if it suddenly stops and an accurate vacuum gauge with a division price of about 2 mmHg. Art. Power is connected to the laser as usual - an sharpening capacitor of two k15u-1 of 470 pF 15 kV and a coaxial cable connecting the tube to the power source are connected in parallel with the electrodes. The power source is described in detail in the previous parts.

Initially, the idea was to replace the working gas in the laser - to use argon instead of neon, because according to the literature, the laser remains operational with argon and at the same time the primary training of the tube is greatly reduced in price, aimed at removing all undesirable impurities from the active zone that got there with air. But that did not work. The discharge was ignited with significant overvoltage at the moment of ignition, since argon had a higher ionization potential than the neon and the coordination of the laser tube with the source was greatly violated. In addition, the discharge tended to compress strongly into a thin cord and subsequent unstable combustion, up to ignition not from working electrodes but from surrounding metal parts and further disruption. The result was one - switching off the source for protection against short circuit, since the thyratron in the power unit lost control, or an arc ignited in the source itself. The victims of this experiment were 2 fans in the power block, a relay protection circuit and an autotransformer in the IVN block. To reach the working thermal regime of the laser tube did not work. Variation of argon pressure, pulse repetition rate, voltage did not give results - the work remained unstable. I had to abandon further work with argon in this tube.

After eliminating all the malfunctions, the tube was filled with neon with a pressure of about 150 mm Hg. Art. With neon, the discharge burned stably, the source no longer turned off. At first, a slow neon duct was installed to remove impurities, then the pump was stopped and the neon supply to the tube was shut off. In the short term, no gas leakage was observed and work was continued in a gas-static mode.

The pressure was kept approximately constant, and by the end of heating it increased to 160 mm Hg. Art.

The laser tube warmed up smoothly to operating temperature and produced radiation in the super-luminosity mode, since the gain in copper vapor is huge. Weak radiation did not suit me, then on the one hand I installed an ordinary household mirror with an “internal” reflective layer and a piece of window glass on the other, so that they were as parallel as possible and reflected the radiation back and forth inside the laser tube. The requirements for alignment accuracy of such a "resonator" are so low that you can do without special devices for positioning the "mirrors". This immediately gave an increase in power, offhand up to two watts.

Start of generation.

A beam with one mirror.

With two mirrors.

Having received stable radiation, I decided to experiment with the selection of neon pressure, since it pretty much affects the output power. He turned on the pump again, with a decrease in pressure, the output power began to monotonously increase. After pumping up to about 10 mm RT. Art. let in a tube a new batch of pure neon - power still increased. This suggested that the "exhaust" gas was dirty enough to reduce power. He brought the pressure to 200 mm RT. Art. and again pumped out and again filled a new portion, "flushing" the tube. At this point, the power with the resonator was indistinguishable from the power of the assembled laser with the same active element. Thus, the operation, code-named "rebellion from the dead" was successful.

There are 2 lines in the radiation - green and yellow.

It only remained to know the magnitude of the long-term leakage of the tube. He squeezed the evacuation hose with a clamp and also squeezed the gas inlet hose, making the tube again “soldered”. For 10 days, it flowed approximately 20 mm RT. Art., which gave a leakage rate of 2 mm Hg per day. And this is already consistent with the value that it flowed for 2 months of lying. Perhaps, indeed, the problem is in the marriage that was allowed in the production, or maybe flows through the leaks of my vacuum system. After this, it remained to conduct another experiment. According to the literature, copper vapor lasers remain operational at a neon pressure of ... 760 mm Hg, i.e. atmospheric. In this case, the laser tube generally ceases to be a vacuum device, which means that leakage into such a tube through small leaks will be negligible, and neon, being a heavy and dense gas (compared to air), will not be so readily volatilized. But here a fail happened - the power source did not have enough voltage for through breakdown of the discharge channel. Only a very bright and intense, but corona discharge at the electrodes was observed. Most likely, the statement regarding operation at atmospheric pressure is valid only for small-sized AEs of the Coulomb series.

References:

- Grigoryants A. G., Kazaryan M. A., Lyabin N. A. Copper vapor lasers: design characteristics and applications. Fizmatlit, 2005

- Batenin V.M., Bohan P.A., Buchanov V.V., Evtushenko G.S., Kazaryan M.A., Karpukhin V.T., Klimovsky I.I., Malikov M.M. Lasers based on self-limited metal transitions. Fizmatlit, 2011

- Lyabin N. A. Creation of modern industrial lasers and laser systems based on copper vapor for precision processing of materials. The dissertation for the degree of Doctor of Technical Sciences, Moscow, 2014

Source: https://habr.com/ru/post/461563/

All Articles