SamsPcbGuide Part 10: Technology, Lead-Free Soldering

This article is the first article on PCB assembly technologies. The last seminar from PCB SOFT was devoted to design, ensuring the manufacturability of the printed circuit board (DFM, design for manufacture). The question was raised about the appropriateness of reballing lead-free BGA components for highly reliable applications. Both the organizers of the seminar and the participants spoke confidently that no one was performing this labor-intensive operation and had never encountered any problems. In this article, I will critically examine this issue and try to show the danger of such “industry generally accepted” opinions about the benefits of the universal doubt method of old Rene Descartes.

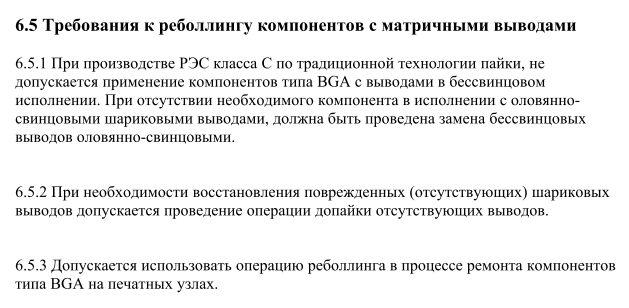

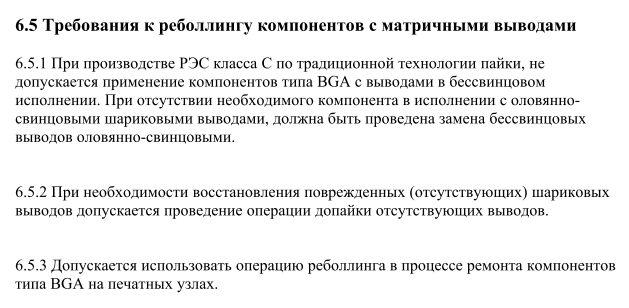

In 2006, the RoHS directive was adopted restricting the use of lead and other recognized harmful elements in consumer and industrial electronics. This led to the fact that most manufacturers of electronic components switched to lead-free housings, and ordering components in versions with lead-containing leads is not always available. At the same time, the technology of soldering using solders with a high content of lead has not gone away (in GOST R 56427-2015 , by the way, it is called traditional). The choice of solder and / or solder paste is up to the PCB developer, so if the choice is made in favor of lead-containing solder, there is a problem of soldering lead-free components (English mixed-alloy process), especially in BGA-type cases (proportionality of the shares of solders). The main issue is the effect of solder mixing on the reliability of the joint. The above GOST gives an unambiguous answer:

For class C RES according to GOST R IEC 61191-1-2010, a failure is unacceptable, the equipment must function at any time, including in harsh conditions. These requirements apply not only to equipment for military and space applications, for example, responsible industrial systems must also be reliable.

')

Where did this requirement arise in GOST? This is a question for the developers of the standard, who, most likely, have translated the foreign standard, which, probably, is already 5-10 years old, and where the demand arose from there, cannot be understood at all. And at the same time, the participants in the seminar, which I wrote about at the beginning, representing a slice of domestic electronics of precisely responsible use, shook their heads negatively at the word “reballing”. Perhaps they have a positive experience, I do not argue, I am simply against generalizations and assurances based on ignorance. Who of them (and of you readers) read the standard? And those who follow the standard are sure that this operation in the manufacturing process is required in their particular case? The operation itself does not reduce reliability? Who conducted an experimental study of the reliability of the surface mount technology used? Because the whole point is in the experiment, in the correctly set experiment. Another source of information is the analysis of available data from third-party researchers. Below I will summarize several articles on the reliability of soldering lead-free components.

The melting temperature ( liquidus , T L ) of lead-free solders is 30–40 ° C higher than that of lead-containing ones; therefore, depending on the thermal profile of the soldering and the distribution of the thermal field on the printed circuit board, it is possible to obtain a different degree of mixing in the soldered joint (Fig. 1). The presence of concentration zones and heterogeneities of both the metals themselves and intermetallic compounds in the solder joint (Fig. 2) reduces its long-term reliability, since such macrostructures are the most likely places for crack formation and propagation (especially at low temperatures). Although most articles from the list of literature provide an analysis of microphotographs of the cross section of the compounds, a unified theory of the cause of cracking is not traced.

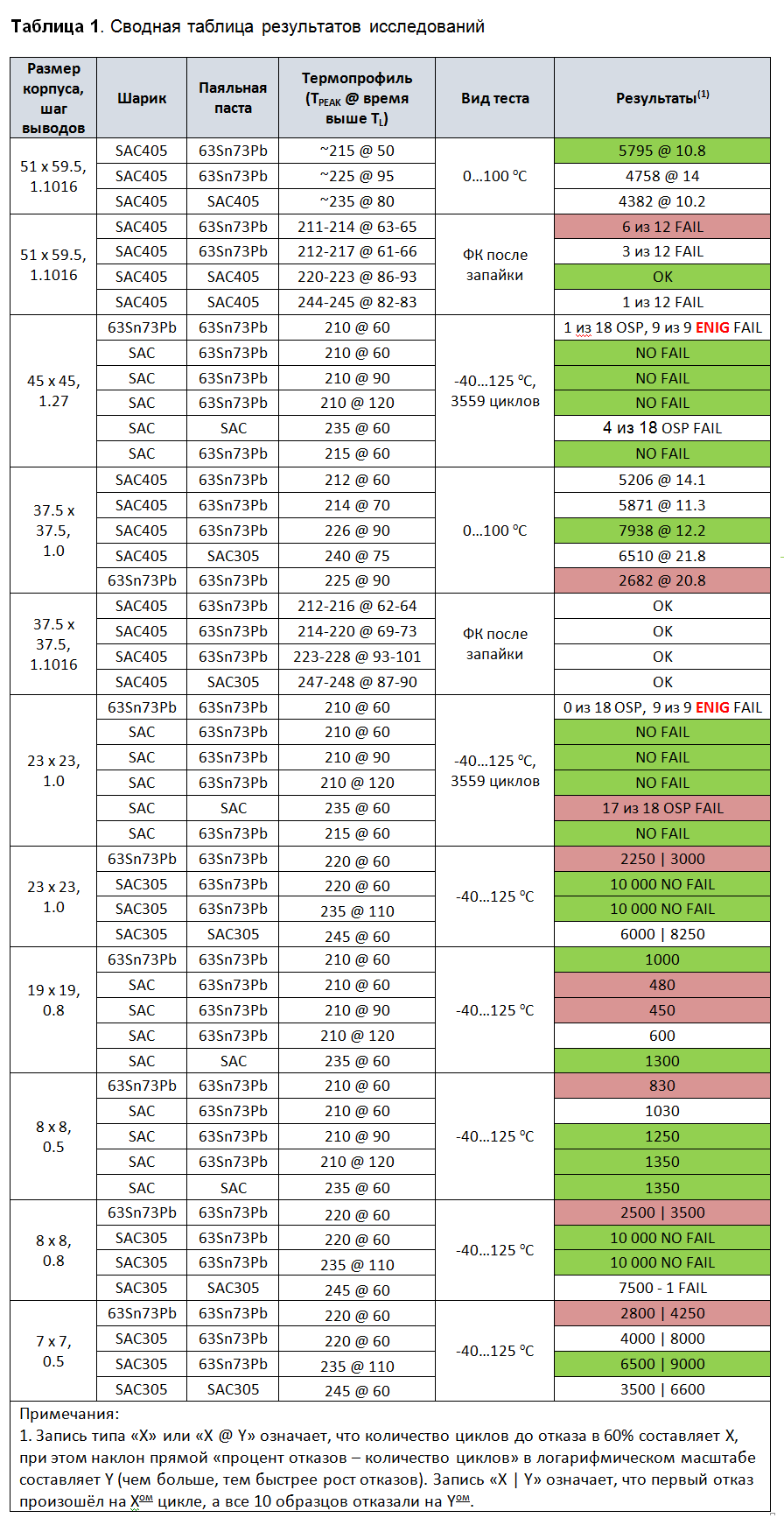

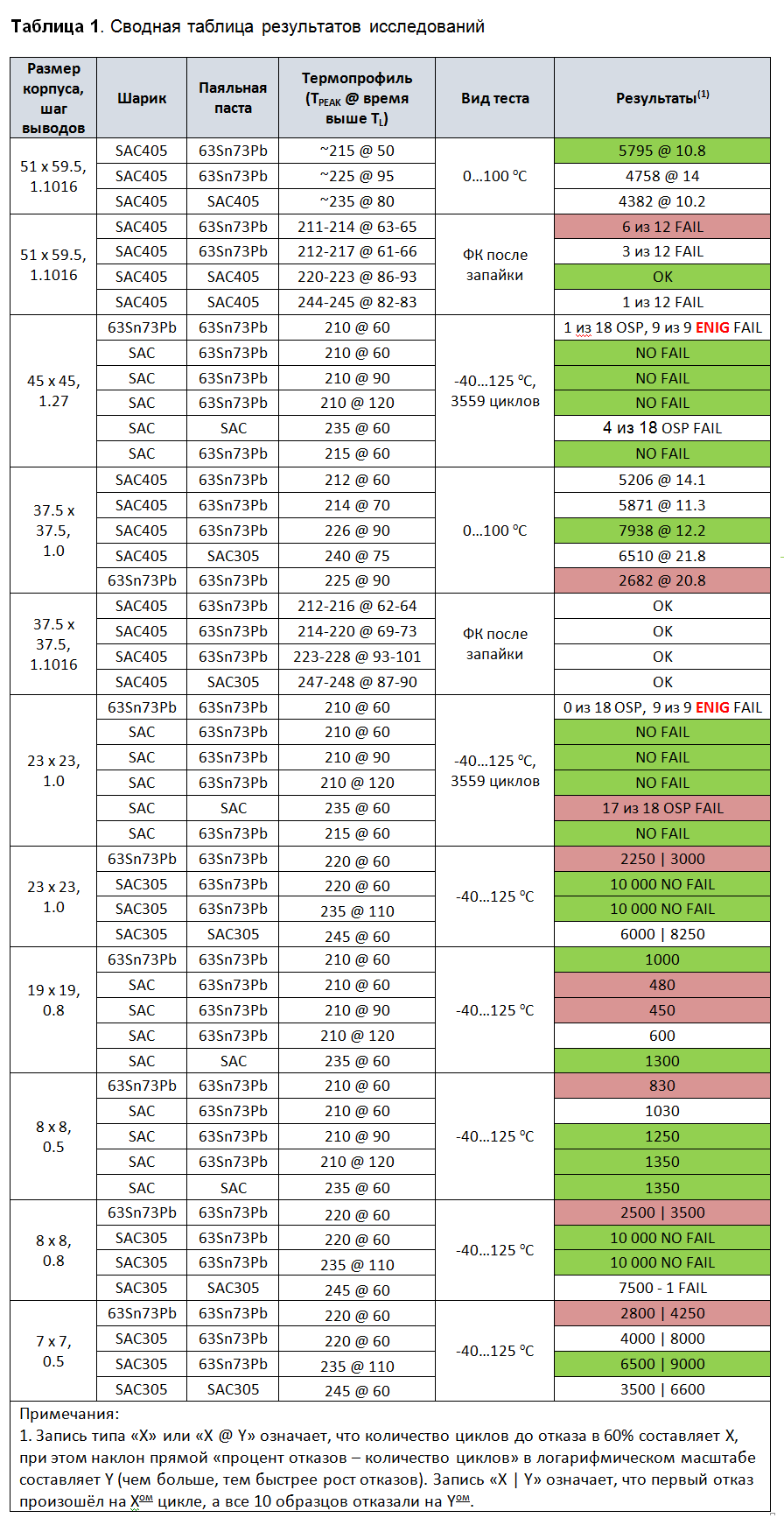

Table 1 summarizes the results of research work, which was based on the following typical experiment: for a fixed combination of solders, a BGA component (in some experiments, this is a non-functional component layout, in which there are only interconnections of pins for constructing a serial circuit), sealed with various thermal profiles, thermocycled until a functional failure or non-contact occurred. Also, the dependence on the size of the case was investigated, in a number of works the effect of the location of the component on the printed circuit board, the effect of adhesive like “underfill”, the finish of the printed circuit board, etc.

When analyzing the data presented, one should pay attention only to the relative reliability indicators within the framework of one experiment, as well as to the general laws for all experiments. One of the conclusions is as follows (it is also done in most articles): when using traditional brazing for lead-free components, it is necessary to achieve complete mixing of the solders at a peak temperature of 220 ... 230 o C, while the soldering time above T L (SnPb) should be 60- 120 s, time above T L (SAC) ~ 30 sec.

There is no explicit indication in the articles whether the BGA components were re-balling to produce lead-containing balls, but the reduced reliability values for these cases suggest that re-balling may lead to a decrease in reliability. An article on reballing [8] reports on the positive results of thermal cycling, however, the declared experiment duration of 24 hours could not provide a sufficient number of cycles. Therefore, the question of reducing reliability as a result of reballing remains open, and mixed soldering with experimental selection of a thermal profile is recommended as a basic scenario.

I urge you to treat the presented data with universal doubt and share your experimental experience in the comments.

[1] Rick Gunn, ”Mixed Metals Impact on Reliability”

[2] Richard Coyle, Raiyo Aspandiar, etc. “The Effect of Pb Mixing Levels on Solder Joint Reliability and Failure Mode of Backward Compatible, High Density Ball Grid Array Assemblies”

[3] Robert Kinyanjui, Quyen Chu, etc. “Solder Joint Reliability of Pb-free Sn-Ag-Cu Ball Grid Array (BGA) Components in Sn-Pb Assembly Process”

[4] Robert Kinyanjui, Raiyo Aspandiar, etc, “Challenges in Reflow Profiling Large and High Density Ball Grid Array (BGA) Packages Using Backward Compatible Assembly Processes”

[5] Adam R. Zbrzezny, Polina Snugovsky, etc, ”Reliability Investigation of Mixed BGA Assemblies”

[6] Richard Coyle, Richard Popowich, Peter Read, etc. “The Relationship between Backward Compatible Assembly and Microstructure on the Thermal Fatigue Reliability of an Extremely Large Ball Grid Array”

[7] Alan Brewin, Christopher Hunt, etc. “Reliability Of Joints Formed With Mixed Alloy Solder”

[8] J. Li, S. Poranki, M. Abtew, etc. “Reliability Assessment Of Reballed BGAs”

In 2006, the RoHS directive was adopted restricting the use of lead and other recognized harmful elements in consumer and industrial electronics. This led to the fact that most manufacturers of electronic components switched to lead-free housings, and ordering components in versions with lead-containing leads is not always available. At the same time, the technology of soldering using solders with a high content of lead has not gone away (in GOST R 56427-2015 , by the way, it is called traditional). The choice of solder and / or solder paste is up to the PCB developer, so if the choice is made in favor of lead-containing solder, there is a problem of soldering lead-free components (English mixed-alloy process), especially in BGA-type cases (proportionality of the shares of solders). The main issue is the effect of solder mixing on the reliability of the joint. The above GOST gives an unambiguous answer:

For class C RES according to GOST R IEC 61191-1-2010, a failure is unacceptable, the equipment must function at any time, including in harsh conditions. These requirements apply not only to equipment for military and space applications, for example, responsible industrial systems must also be reliable.

')

Where did this requirement arise in GOST? This is a question for the developers of the standard, who, most likely, have translated the foreign standard, which, probably, is already 5-10 years old, and where the demand arose from there, cannot be understood at all. And at the same time, the participants in the seminar, which I wrote about at the beginning, representing a slice of domestic electronics of precisely responsible use, shook their heads negatively at the word “reballing”. Perhaps they have a positive experience, I do not argue, I am simply against generalizations and assurances based on ignorance. Who of them (and of you readers) read the standard? And those who follow the standard are sure that this operation in the manufacturing process is required in their particular case? The operation itself does not reduce reliability? Who conducted an experimental study of the reliability of the surface mount technology used? Because the whole point is in the experiment, in the correctly set experiment. Another source of information is the analysis of available data from third-party researchers. Below I will summarize several articles on the reliability of soldering lead-free components.

The melting temperature ( liquidus , T L ) of lead-free solders is 30–40 ° C higher than that of lead-containing ones; therefore, depending on the thermal profile of the soldering and the distribution of the thermal field on the printed circuit board, it is possible to obtain a different degree of mixing in the soldered joint (Fig. 1). The presence of concentration zones and heterogeneities of both the metals themselves and intermetallic compounds in the solder joint (Fig. 2) reduces its long-term reliability, since such macrostructures are the most likely places for crack formation and propagation (especially at low temperatures). Although most articles from the list of literature provide an analysis of microphotographs of the cross section of the compounds, a unified theory of the cause of cracking is not traced.

Table 1 summarizes the results of research work, which was based on the following typical experiment: for a fixed combination of solders, a BGA component (in some experiments, this is a non-functional component layout, in which there are only interconnections of pins for constructing a serial circuit), sealed with various thermal profiles, thermocycled until a functional failure or non-contact occurred. Also, the dependence on the size of the case was investigated, in a number of works the effect of the location of the component on the printed circuit board, the effect of adhesive like “underfill”, the finish of the printed circuit board, etc.

When analyzing the data presented, one should pay attention only to the relative reliability indicators within the framework of one experiment, as well as to the general laws for all experiments. One of the conclusions is as follows (it is also done in most articles): when using traditional brazing for lead-free components, it is necessary to achieve complete mixing of the solders at a peak temperature of 220 ... 230 o C, while the soldering time above T L (SnPb) should be 60- 120 s, time above T L (SAC) ~ 30 sec.

There is no explicit indication in the articles whether the BGA components were re-balling to produce lead-containing balls, but the reduced reliability values for these cases suggest that re-balling may lead to a decrease in reliability. An article on reballing [8] reports on the positive results of thermal cycling, however, the declared experiment duration of 24 hours could not provide a sufficient number of cycles. Therefore, the question of reducing reliability as a result of reballing remains open, and mixed soldering with experimental selection of a thermal profile is recommended as a basic scenario.

I urge you to treat the presented data with universal doubt and share your experimental experience in the comments.

Literature

[1] Rick Gunn, ”Mixed Metals Impact on Reliability”

[2] Richard Coyle, Raiyo Aspandiar, etc. “The Effect of Pb Mixing Levels on Solder Joint Reliability and Failure Mode of Backward Compatible, High Density Ball Grid Array Assemblies”

[3] Robert Kinyanjui, Quyen Chu, etc. “Solder Joint Reliability of Pb-free Sn-Ag-Cu Ball Grid Array (BGA) Components in Sn-Pb Assembly Process”

[4] Robert Kinyanjui, Raiyo Aspandiar, etc, “Challenges in Reflow Profiling Large and High Density Ball Grid Array (BGA) Packages Using Backward Compatible Assembly Processes”

[5] Adam R. Zbrzezny, Polina Snugovsky, etc, ”Reliability Investigation of Mixed BGA Assemblies”

[6] Richard Coyle, Richard Popowich, Peter Read, etc. “The Relationship between Backward Compatible Assembly and Microstructure on the Thermal Fatigue Reliability of an Extremely Large Ball Grid Array”

[7] Alan Brewin, Christopher Hunt, etc. “Reliability Of Joints Formed With Mixed Alloy Solder”

[8] J. Li, S. Poranki, M. Abtew, etc. “Reliability Assessment Of Reballed BGAs”

Source: https://habr.com/ru/post/460851/

All Articles