Direct printing on T-shirts with Epson SureColor SC – F and its difference from silk-screen printing, decal and sublimation

In one of the recent posts I talked about how small companies make money on video-pinging and how effective it looks, and also somehow considered the main differences between digital printing and offset printing and flexographic printing . This time I want to suggest another idea for a mini-business (which can easily grow into a maxi) - printing on t-shirts .

The post will be interesting if:

- you are a novice entrepreneur, possibly a designer, and you want to make money

and brighten the worldand are looking for a solution that is easy to master and easy to maintain; - you are an advertising agency and large-scale production and you want to add to the range of services the printing of small print runs of T-shirts “on site”. Perhaps - right at exhibitions and events, where a compact stand with equipment for real-time printing will significantly save;

- you are just curious to know how a color pattern from a computer screen falls on a fabric, becomes a print and what methods exist for this.

All this is in today's post.

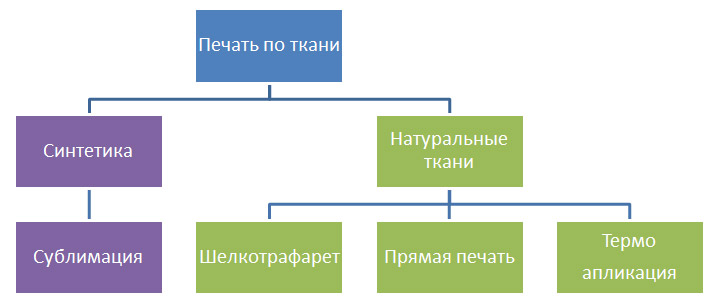

What are the technologies of printing on fabric

Before talking about printing technology, first of all, you should decide on the type of material to which you plan to transfer the image. If you are interested in printing on cotton products, then you can consider screen printing , DTG printing or thermoapplication . If you are thinking of creating sportswear (“souvenir” and decorative elements) from synthetic fabrics, then your choice is a sublimation print .

Now more about all the methods.

Screen printing or silk screen printing

Let's start with the traditional type of printing, in which the ink is pressed through the mesh stencil. A long time ago, when this method was born, silk stretched on a wooden frame was used as a mesh, therefore screen printing is also called silk-screen printing.

')

Silkscreen printing on T-shirts is of high quality: prints withstand repeated washing without loss of quality of the pattern. It is also a cost-effective solution for printing large and medium print runs (from 50 pieces). Unfortunately, with small print runs, this method loses much of direct printing in cost and speed , since it requires making separate forms for each color. But you can add certain effects: for example, print "glitter" (glitter print):

The printing process is as follows:

- The first step is to make a stencil printing form. The net is tensioned onto the frame, fixed and degreased;

- photosensitive layer is applied;

- the form is dried on racks or in specialized dryers;

- then the image is exposed - under production conditions, this happens in exposure devices with a vacuum clamp;

- development: the undelayed areas of the photo layer are dissolved in water, the highlights are left on the grid;

- screen printing form is ready! The number of print forms also depends on the number of colors on the layout.

So print looks at the production:

Next - transfer the image to the fabric:

- Printing takes place on the carousel. Print forms are attached to the print heads, and T-shirts are put on the tables. The paint is pressed through a stencil using a squeegee (polymer or rubber device). For large runs, automatic textile carousel machines are used. An intermediate dryer is installed between the tables;

- when printing of all colors and layers is completed, the T-shirt is removed from the table and passed through a tunnel conveyor dryer. If high productivity is not required, an intermediate dryer can be used for final drying (an absolute advantage is a significant cost savings, minus: a loss of productivity several times).

You can even assemble a simple mini-studio for the production of monochrome prints at home. The video below demonstrates the process of “garage” print production:

DTG-print - direct print "without intermediaries"

DTG (Direct-To-Garment) or “direct printing on fabric” is a fast, affordable and high-quality way to seal a fabric. The printer prints immediately on the fabric, and the fabric at the output "breathes" even through the print. Such products can be washed at a temperature of 30 ° C (a gentle washing mode is desirable) without losing the brightness of the color at least 30–40 times (as practice shows - much more). T-shirts can be ironed: the image does not stick to the iron.

In addition, of course, it is much more profitable to print prints "on demand", rather than ordering the circulation of T-shirts with different images in advance, then store and store them for an indefinite time, and even in different sizes. Enough to get a set of "T-shirts templates" in different sizes and basic colors. With a compact DTG printer on hand, the desired print can be printed at any time, as well as offering the client a personal print service based on the image provided by the client.

You ask: “Probably, such a printer does not work with all materials”?

Indeed, there are limitations: the minimum cotton content in the fabric must be at least 50%. For best quality, no more than 10 percent of synthetics.

The printing process - nowhere easier:

White T-shirts

- Prior to printing, a t-shirt is processed by a sticky roller from a “lint roller” (lint roller);

- the product unfolds on a special table so that there are no folds;

- the printer prints the image incorporated in the program;

- The printed image is fixed in a thermopress under the influence of temperature (at ~ 160 ° C).

Dark T-shirts

- Prior to printing, a t-shirt is processed by a sticky roller from a “lint roller” (lint roller);

- using a spray gun, spray gun or a special primer machine, a special primer is applied;

- Be sure to primer need to be rolled in with a special hard roller, which comes with the printer in a T-shirt, so that the pile, which has risen from wetting, lies down along the movement of the printer's print head;

- the primer is fixed under the action of the clamp and temperature in the heat press to create the most even surface (it is here that you need to iron the T-shirt as much as possible);

- the product unfolds on a special table so that there are no folds;

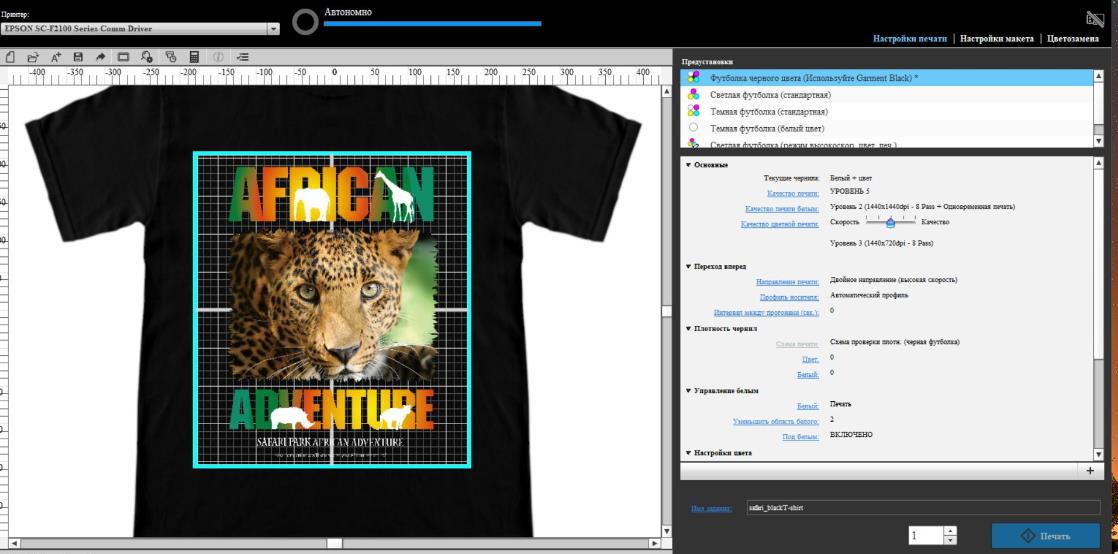

- the printer prints the image put in the program;

- The printed image is fixed in a thermopress under the influence of temperature (at ~ 170 ° C).

… Everything! The shirt is immediately ready to wear.

There is a video of the process from receiving an order to packing a client - KenyonKen shares his impressions of using a new printer:

Accordingly, the work will require:

1. Printer

If we talk about Epson printers, then there are two modifications of the Epson SureColor SC-F2100 model: a four-color (CMYK) printer for printing on light T-shirts and fabrics, and a five-color version of CMYK + White - for printing also on dark ones: white is poured as a substrate followed by color printing.

2. Thermopress

Enough simple horizontal apparatus with heating plates. It is important to pay attention to the temperature range that is required to secure the print.

The option that we use is a rotary thermal press with the ability to leave a minimum gap between the T-shirt and the heating plate. This provides the desired microclimate above the material so that the ink is fully entrenched and held as long as this printing technology allows.

3. PC with necessary software

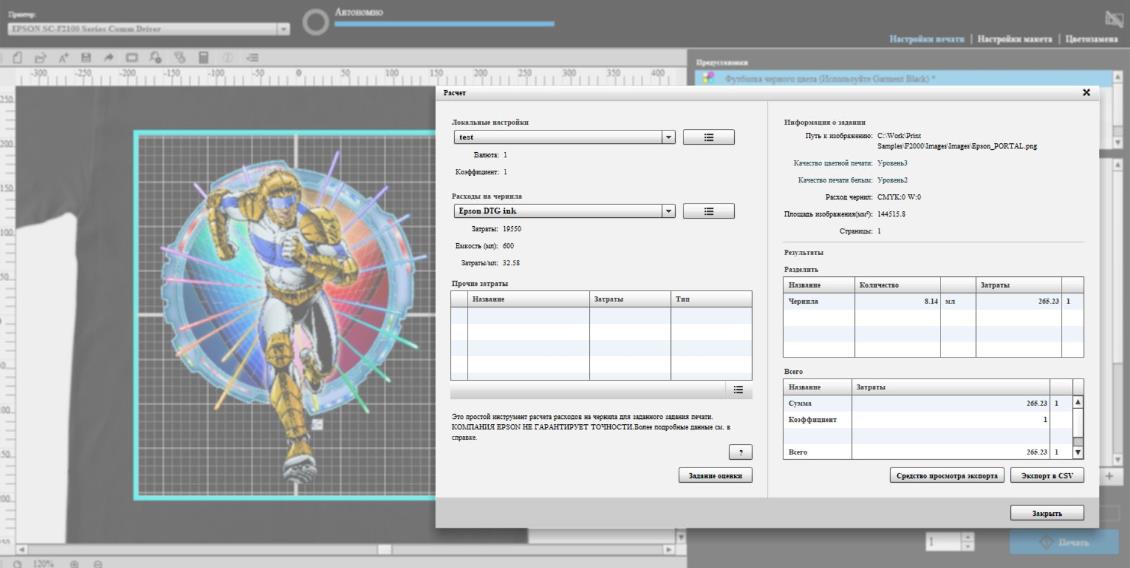

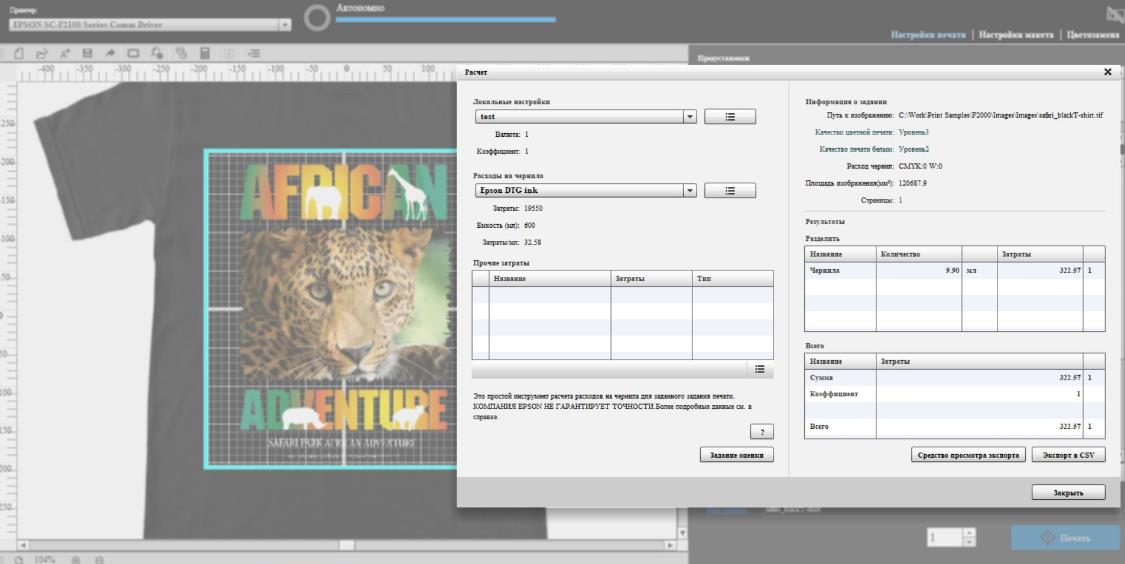

The SureColor SC-F2100 comes with free Garment Creator software (MacOS version available). By the way, the software also shows the ink consumption for printing of one or another image, which allows you to accurately track printing costs.

Below are two screenshots from the program with the calculation of the cost of printing a full-color picture:

4. Actually, T-shirts

The quality of a cotton T-shirt directly affects the quality of the image. The parameters of a quality T-shirt are good fabric density and minimal fleecy. The fleecy material is printed worse.

The Epson SureColor SC-F2000 printer model, about which we already told and even printed a t-shirt specifically for readers on Habré , changed to Epson SureColor SC-F2100 . Our colleague at last year’s exhibition, where we presented this model for the first time, spoke well about the differences and improvements.

Clarify: we considered only T-shirt printers. Those. those that are designed for printing on T-shirts or cloths of the fabric, the dimensions of the T-shirt not exceeding In nature, there are large industrial machines for direct printing on larger textiles. For example, Monna Lisa from Epson . But that's another story ...

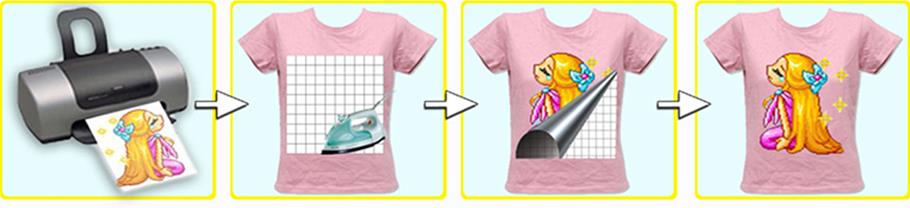

Thermoapplication

The easiest and most childhood familiar way. The drawing is printed on paper or film and transferred to the fabric with an iron or a heat press.

Disadvantages - when using low-quality consumables, the applied pattern will not stick to the fabric, while stretching the fabric - the figure can “crack” (I am sure, this is definitely familiar to everyone!). But such a business can be arranged even at home by purchasing inexpensive equipment and fulfilling orders from private clients.

Unlike the sublimation method, where special sublimation ink plays the most important role, with thermo-application, the key material is paper with a special coating. The structure of such carriers includes a dense paper base and a thin elastic layer attached to the fabric when heated. The image is applied on the surface of such a layer.

By the way, this method is also suitable when works are related either to material that is not intended for printing (for example, burlap), or to form, when accessories or the shape of an object interfere. For example, when printing on a windbreaker with zippers and rivets protruding on the surface.

A more serious option is printing with the help of films: application or printed.

Application - here we are talking about ready-to-apply films - they need only be cut along the contour (in a mirror image) and pressed with a heat press or dried in a special dryer. Of the minuses - the films are already finished and it is desirable to have an assortment of films by color. But from the pros - again, glitter is shiny and iridescent with all the colors of the rainbow!

Printed films are created on eco-solvent printer - we told about printing on ecosolvent in the material about auto-styling . But it turns out that they can be printed on and films for clothes ...

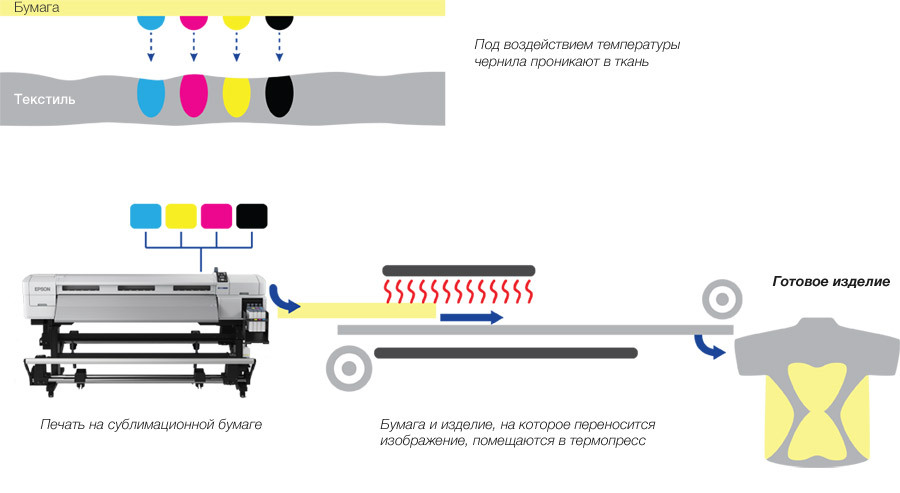

Sublimation

Thermosublimation (thermal transfer) or simply sublimation is a technology that involves printing an image on special sublimation paper and then transferring the image directly to the material in the heat press and calender (for rolls). Sublimation printing can be very bright. Direct DTG-print on natural fabrics such bright colors do not get.

Sublimation allows you to create very high-quality and resistant prints: they withstand many washings. But there is one drawback (although, depending on which side to look at) - it is only suitable for synthetic materials (the content of synthetics is at least 70%). If you move the image to 100% cotton, the print is quickly washed off with water.

But sublimation allows you to transfer the print on almost anything, if we talk about souvenir printing:

And even like this:

All the pillows, the screen, the lampshade, the floor lamp, the painting, the cups are all sealed by sublimation. By the way, this is why sublimation printers are often called “souvenir”.

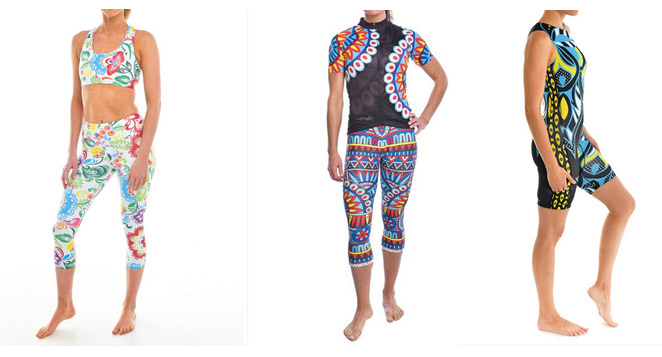

If we talk about clothes, then sublimation is actively used to create sportswear, which is made exclusively on a synthetic basis. Swimwear ski and cycling suits and much more.

The printing process is as follows:

- The printer prints a mirror image on a special sublimation paper (most often the print goes directly to the roll, i.e. the print is rolled up immediately to the roll);

- The printed roll is loaded into a calender (a system of shafts through which paper passes) along with a roll of white cloth. Sublimation printers print only on white fabric, they completely create a pattern from scratch;

- when heated, the image is transferred from paper to matter. The ink used for such printing has the special property of heating up from a solid to a gaseous state, penetrating deep into the fabric. Such a print is not erased, does not fade and does not look like a sticker.

Epson for sublimation printing has three printers at once - Epson SureColor SC-F6300 with a print width of 44 inches, Epson SureColor SC-F7200 and Epson SureColor SC-F9300 for 64 inches.

For example, British designer Richard Quinn creates such gorgeous dresses in his laboratory using Epson SureColor SC-F7200:

We summarize

| Printing on finished products and cut (natural fabrics) | ||

| Silk-screen | Direct printing | Thermal transfer |

What equipment is needed | Printing or carousel machine + intermediate dryer + exhibiting dryer + flushing booth | Printer + thermal press | Printer + paper / film + iron / thermopress |

What fabrics are suitable for? | Natural fabrics, with a cotton content of at least 50% | ||

Print resolution | Low | 1440x1440, high detail | Application - usually monochrome, printed film = printer resolution |

Approximate price of printing (excluding the cost of t-shirts) | Depends on the complexity of the image and the number of colors. | ||

Favorable circulation | Not less than 50 pieces | From 1 piece | From 1 piece |

Number of washings * | ~ 40-50 (tentatively, practice shows that much more) | ||

* Indicated approximate number of washes, in which the image will not lose the brightness of colors.

Questions?

DTG printing is our professional field. Given the development of technology and the desire of more and more people to look unique, direct textile printing is gaining momentum and is considered a very promising business area. You can try out Epson SureColor SC-F2100 in our showroom - come and show everything.

Well, if you have questions about other types of printing - check with our partners.

Thank you for attention.

Source: https://habr.com/ru/post/460091/

All Articles