How we teach the French ecology and collect bottles

Students from the University of Paris-Saclay (France) became participants in a workshop on plastics processing, which takes place from July 1 to July 13, 2019 in FabLab of the National Research and Technical University "MISiS".

The course is dedicated to working with Precious Plastic machines. Precious Plastic, an open project by Dutchman Dave Hackens, is a global community dedicated to creating machines for recycling plastic waste into new raw materials, and then into everyday items (containers, tools, urban furniture, etc.). The project is open: any enthusiast (maker, designer or engineer) can assemble the car, and local communities will use it to recycle plastic waste.

')

Within the framework of their long-standing and active cooperation, NITU “MISiS” and the University of Paris-Saclayt created a team of Russian and French students. During the two-week practice, students participate in the assembly of functional machines, the creation of technologies and the production of products for the development of the project.

You can get acquainted with the results of the work of the international team of students at the final presentation, combined with the exhibition , which will be held on July 12 at 18:00 in FabLab NITU "MISiS" (Krymsky Val, 3, NITU "MISiS", building "K").

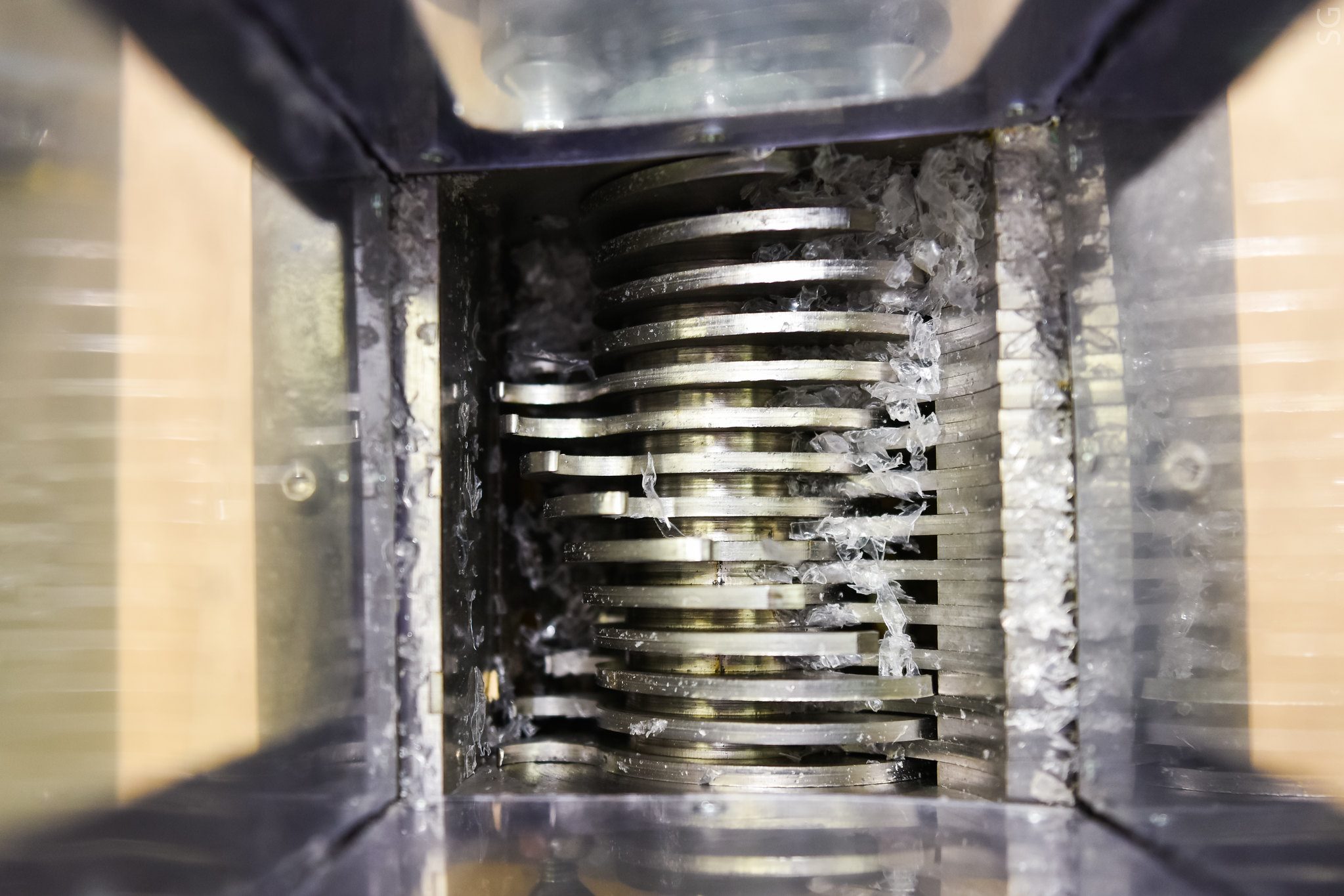

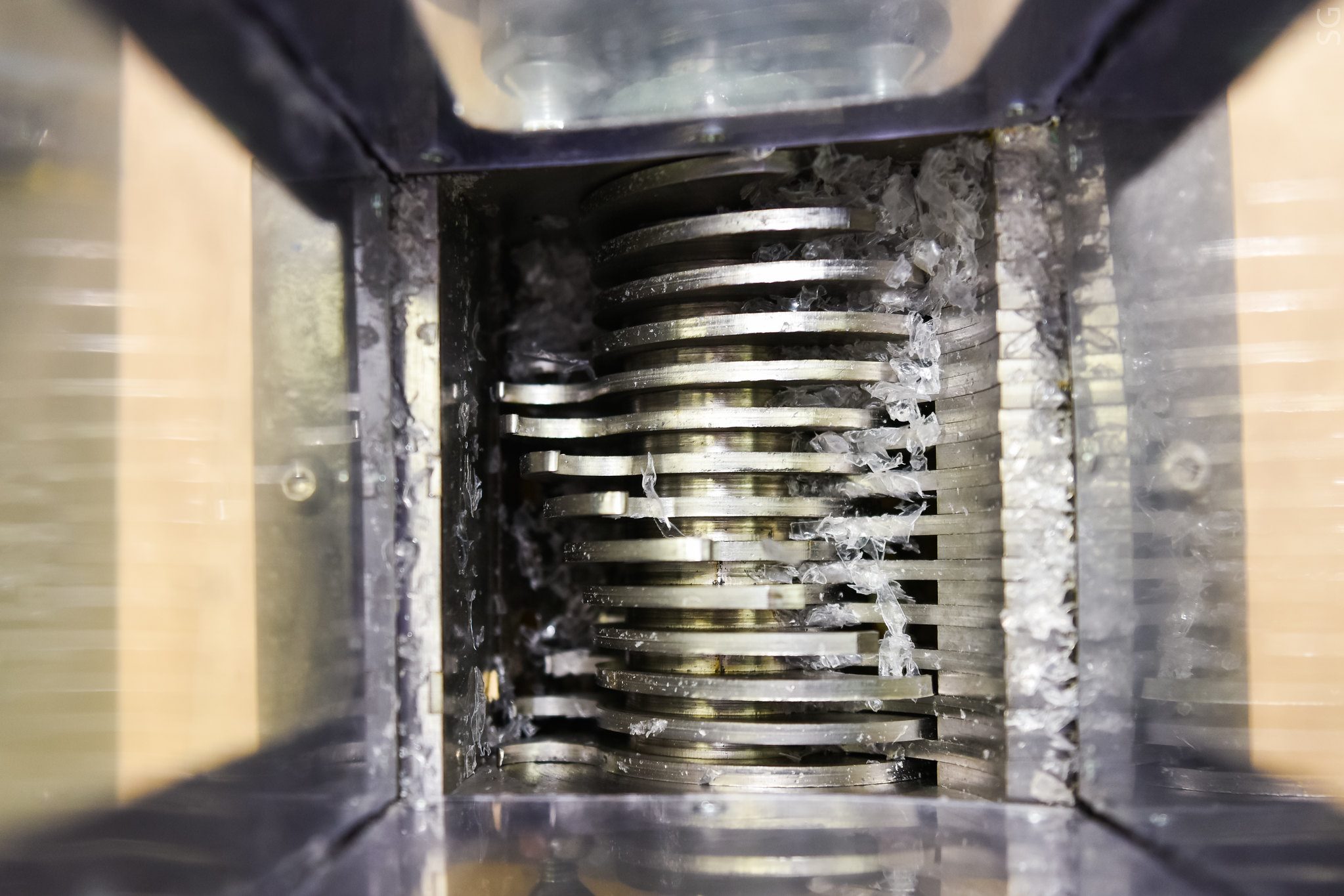

The two-week practical course is not the only environmental initiative of FabLab NITU "MISiS". The center also presented its own development - a graduate of the magistracy "Digital Production Technologies" Artem Korotkov assembled a line for processing household plastic: a metal shredder crushes plastic bottles (and other plastic garbage) into flakes.

Plastic flakes are the starting material that can be used in other machines. In the injection machine it is possible to cast small plastic products from it, in a compression machine it is possible to manufacture plates and dimensional plastic objects. One kilogram of the source code is about 50 plastic soda bottles. Innovative shredder can turn them into flakes in 10 minutes.

Material - empty plastic packaging, 3D printing waste, etc. - the developer collects directly at the university. Some of the raw materials are plastic waste resulting from the activities of the FabLab center, in addition, plastic for recycling is provided to Artem by student cafes working on the campus.

In addition, the young start-up actively cooperates with other makers, sending the details of his invention around the world. In his client basket are orders from various countries and parts of the world: European countries, the USA, Uganda, Trinidad and Tabago, Hong Kong, Malaysia. The breadth of geography well illustrates the common need for all countries to solve problems of ecology and conscious consumption.

Such a project-oriented approach, which responds to both pressing environmental problems and the personal burden on people to create something unique, is one of the fundamental principles of the FabLab philosophy. The master's program “Digital Production Technologies” based on FabLab NITU “MISiS”, which Artem graduated from, is a vivid example of the fact that the philosophy of making and digital production is fixed in our society. Today, a unique program for Russia is aimed at training creative technical specialists who are able to apply competences from different areas to create their own product from an idea to a full-scale implementation.

However, "personally" does not mean "manually." Students learn to work with the programs Solid Works, Fusion 360, Cura and others, as well as with modern production facilities - laser cutting and engraving machines, 3D-printers. Among other academic disciplines - materials science, product design, machine learning, applied electronics. In general, the entire educational process is built on the principle of CDIO (Think-In-Develop-Embed-Operate), that is, any theory is immediately reinforced by practice.

The admission to the magistracy is open, you can submit documents until July 20, and learn more details here .

The course is dedicated to working with Precious Plastic machines. Precious Plastic, an open project by Dutchman Dave Hackens, is a global community dedicated to creating machines for recycling plastic waste into new raw materials, and then into everyday items (containers, tools, urban furniture, etc.). The project is open: any enthusiast (maker, designer or engineer) can assemble the car, and local communities will use it to recycle plastic waste.

')

Within the framework of their long-standing and active cooperation, NITU “MISiS” and the University of Paris-Saclayt created a team of Russian and French students. During the two-week practice, students participate in the assembly of functional machines, the creation of technologies and the production of products for the development of the project.

You can get acquainted with the results of the work of the international team of students at the final presentation, combined with the exhibition , which will be held on July 12 at 18:00 in FabLab NITU "MISiS" (Krymsky Val, 3, NITU "MISiS", building "K").

The two-week practical course is not the only environmental initiative of FabLab NITU "MISiS". The center also presented its own development - a graduate of the magistracy "Digital Production Technologies" Artem Korotkov assembled a line for processing household plastic: a metal shredder crushes plastic bottles (and other plastic garbage) into flakes.

Plastic flakes are the starting material that can be used in other machines. In the injection machine it is possible to cast small plastic products from it, in a compression machine it is possible to manufacture plates and dimensional plastic objects. One kilogram of the source code is about 50 plastic soda bottles. Innovative shredder can turn them into flakes in 10 minutes.

Material - empty plastic packaging, 3D printing waste, etc. - the developer collects directly at the university. Some of the raw materials are plastic waste resulting from the activities of the FabLab center, in addition, plastic for recycling is provided to Artem by student cafes working on the campus.

In addition, the young start-up actively cooperates with other makers, sending the details of his invention around the world. In his client basket are orders from various countries and parts of the world: European countries, the USA, Uganda, Trinidad and Tabago, Hong Kong, Malaysia. The breadth of geography well illustrates the common need for all countries to solve problems of ecology and conscious consumption.

Such a project-oriented approach, which responds to both pressing environmental problems and the personal burden on people to create something unique, is one of the fundamental principles of the FabLab philosophy. The master's program “Digital Production Technologies” based on FabLab NITU “MISiS”, which Artem graduated from, is a vivid example of the fact that the philosophy of making and digital production is fixed in our society. Today, a unique program for Russia is aimed at training creative technical specialists who are able to apply competences from different areas to create their own product from an idea to a full-scale implementation.

However, "personally" does not mean "manually." Students learn to work with the programs Solid Works, Fusion 360, Cura and others, as well as with modern production facilities - laser cutting and engraving machines, 3D-printers. Among other academic disciplines - materials science, product design, machine learning, applied electronics. In general, the entire educational process is built on the principle of CDIO (Think-In-Develop-Embed-Operate), that is, any theory is immediately reinforced by practice.

The admission to the magistracy is open, you can submit documents until July 20, and learn more details here .

Source: https://habr.com/ru/post/459528/

All Articles