Clay → Brick → Furnace

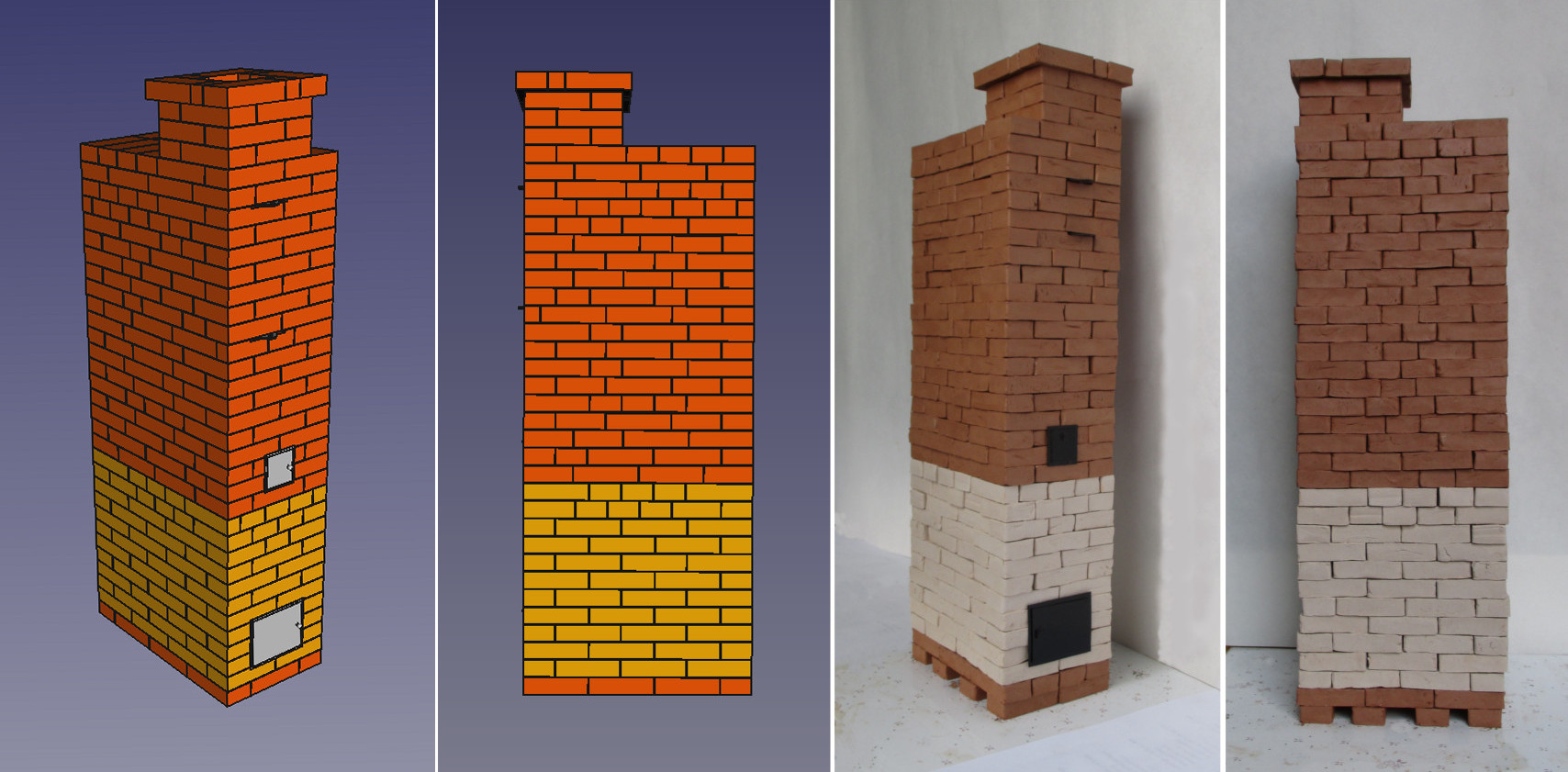

In this article, I want to describe my experience in working with clay, making bricks from it (in a 1: 6 format) and creating a reduced model of a typical PTO-2300 heating furnace.

Let's start with childhood. I grew up in a house with stove heating. Felling of wood, furnace stove, flames in the furnace, wind noise in the pipe in winter, the nuances of thrust adjustment by the blower and furnace flaps I absorbed from an early age. To return to the opportunity to sit down again by the light, it was possible to plant firewood only in adulthood. At the same time, the desire was born to deal with the design of furnaces; their types and purpose; features of operation; differences and advantages / disadvantages of one type of heating from another.

The reduced format, a certain miniaturization, is deliberately chosen - with the same cognitive effect, we win in terms, volumes of materials used, applied efforts, transportation costs, required areas, etc. You can always increase the scale.

')

The oldest natural resource discovered by mankind. Everything was built from it: wall and roofing materials, stoves, houses, structures and constructions, household and kitchen implements, toys, crafts, works of art. There is it everywhere, it can be mined in any locality, the available reserves are huge.

Over several months of research, I was able to find three clay quarries in the immediate vicinity (and I learned more about three or four potential ones, but did not attend). In them I dug clay of different quality and color. I bought two more types of purified professional clay for modeling in the store. The color palette of clays in nature is very diverse - from white and black - to the whole spectrum of red-yellow, as well as green, blue, etc. By the way, green clay was the first one I met only 200 meters from the house!

Most importantly, if you start mining the clay yourself, it is cleaning it from sand, organic impurities, debris and other inclusions. To designate this process, a special term has been coined - otmuchivanie. The technology is very simple: the accumulated clay is dissolved in water and passed through a series of sieves with an increasingly smaller cell. Large particles are separated, and at the exit we have a suspension with fine particles of clay. After settling, draining excess water and the final drying of the clay, we obtain the raw materials for further experiments.

You can store the finished clay in plastic bags (without losing the desired moisture) for years. And so this product does not deteriorate at all - with time it only gets better.

Having blinded several bricks by hand, I realized that this was an unnecessarily laborious way. In addition, the variation in size was too critical. It was necessary to take on the manufacture of the form, to introduce standards.

In parallel with the manufacture of the form, I was “combing” the Internet, articles and books on the subject of how technology can be used to make bricks in large quantities and quickly. The oldest and simplest is manual molding. Extrusion of the clay mass with the help of augers or hydraulic pushers was also considered, but these too ambitious plans were left for the future :)

I figured that about 300 full bricks (or, about 500 with halves, quarters and other parts) are required for the furnace. Standardly, in an hour and a half I managed to make about 20-25 bricks. Those. around 18-22 pm for tamping clay into a mold and pressing the finished product onto a shelf for drying - and a complete set of products for the assembly of the furnace is ready!

I used a fairly dense, hard clay, leveled all the folds, irregularities, in parallel cut into quarters and halves (and also pretended to need them). Therefore, this process and stretched. Single piece production - the most time-consuming.

Having chosen a reduced scale of bricks, in practice I felt the law of the "square - cube", which reads:

Example : A real standard brick has dimensions of 250x120x65 mm and a mass of 3600 grams. The density of the brick is equal to 1846 kilograms per cubic meter.

Reduce its size by about 6 times. We obtain linear dimensions 42x20x11 mm and a mass equal to 17 grams.

Those. the change in linear dimensions in the ratio of 1: 6 led to a change in weight in the ratio of 1: 211. The experiment can be repeated at home by anyone.

The conclusions are practical (in relation to my experiment) - the mass of the entire model of the furnace will be no more than 5-6 kg. Which is very convenient for construction, transport and storage. Bricks of this size are not yet tiny (tweezers and a magnifying glass are not needed), but no longer “cyclopean” - dragging extra weights and making half a room for a “construction site” will not be necessary. Everything is assembled quickly and comfortably on a table or windowsill.

Roasting - while not touching. For masonry with an excess of enough strength raw brick. Roasting also requires access to fire, furnaces. In the language of IT - these works can be distinguished into a separate subsystem and explored later. In the meantime, we assume that the Firing () method has a temporary “stub”, which always returns “true”.

I began to create a furnace with a study of the theoretical and practical experience of mankind. On this topic, everything has been worked out for a long time in detail - the fuel is expensive and it is expensive to burn it (in all respects). Therefore, people have come to a number of optimal designs, allowing to get the maximum heat from a unit of firewood, coal, peat, etc.

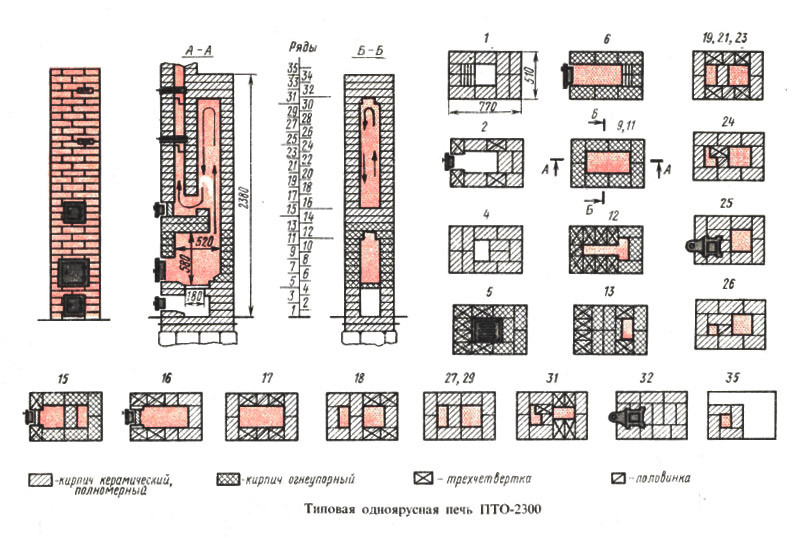

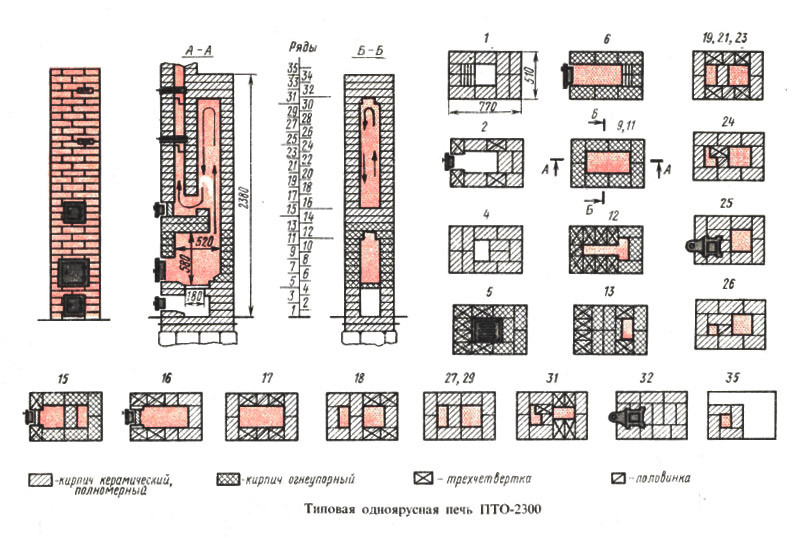

As a sample, I chose a typical heating furnace PTO-2300

Design parameters :

Functional parameters :

Heating capacity (with firebox for firewood):

Material consumption :

With regard to heating furnaces, the situation is as follows: it is necessary to distinguish between the firebox (the place where the combustion processes occur with the formation of heat) and the heat exchanger (the places where heat is removed from the heated gases).

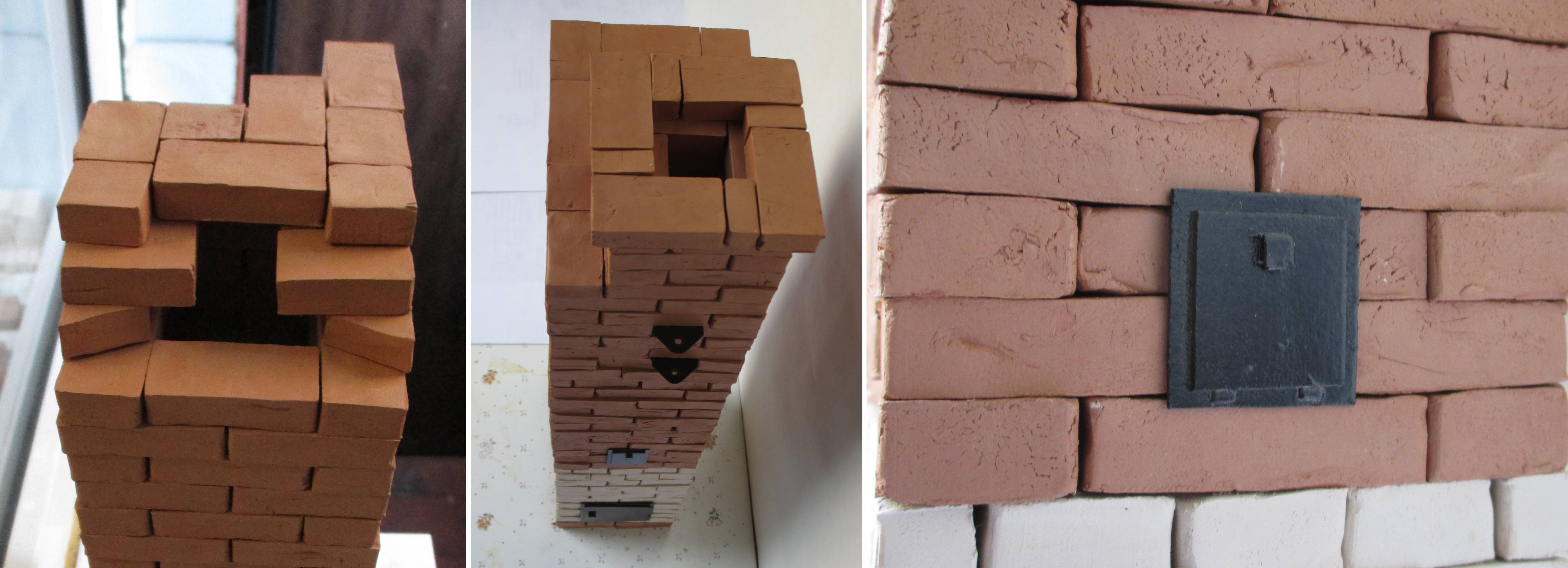

The firelighter is usually made of fireclay bricks (in my model it is white brick), and the heat exchanger (or the system of channels, the furnace mass that stores heat) is made of red brick. The need for fireclay bricks caused by high temperatures resulting from combustion.

For different types of fuel, the firebox is required in various sizes, shapes and designs. And a different air supply. In the case of burning of stone and brown coal, peat requires a smaller firepower and the presence of a blower is obligatory - air supply from the bottom, through the grate.

I designed the stove for wood heating, so I took the dimensions of the firebox more and chose the hearth type of wood burning. In our area, domestic stoves are not drowned with coal and peat (they are simply not available) - only wood is used.

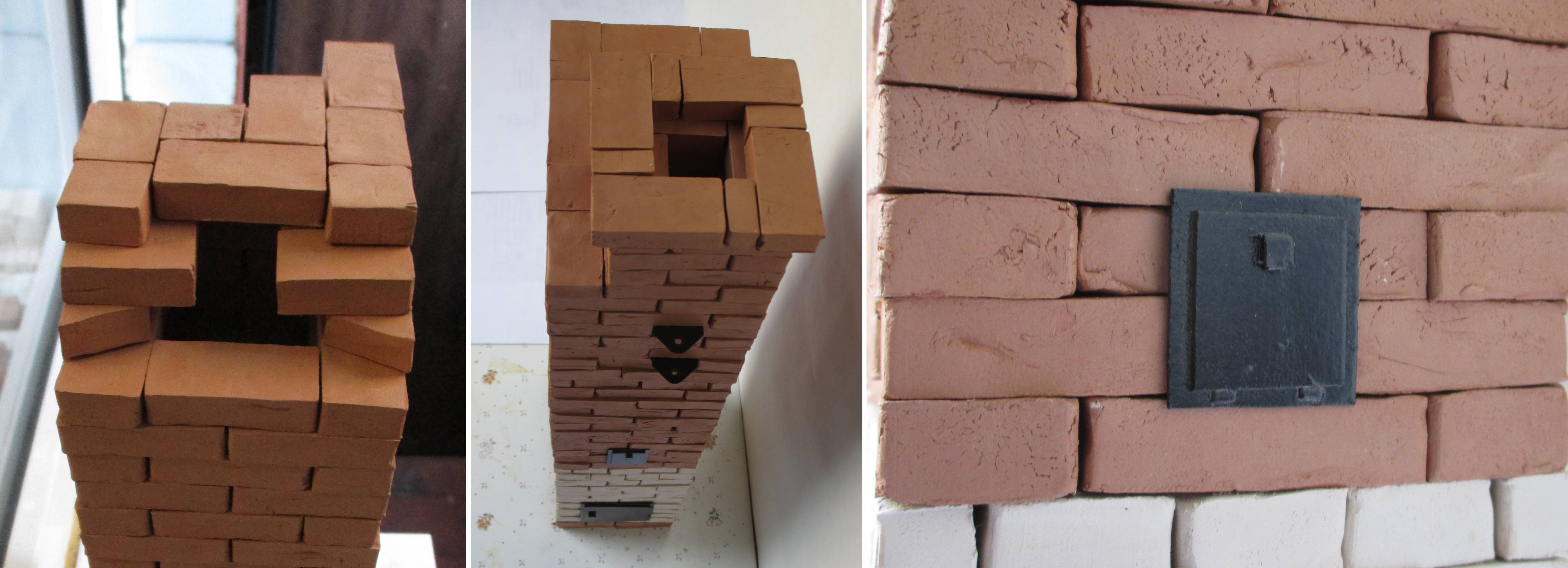

The masonry itself is very simple. If you do not use a binding solution, but simply recruit the constructive furnace in rows, of course. Brick to brick, brick to brick ... We're making a model, not a real sample, right? So you can not worry about jointing. In addition, you may want to burn these bricks in the future or use them in another project.

By the way, stove-houses say that a properly designed stove does not require a solution so that all its elements stick together in a single monolithic structure. Those. sealing of seams is needed only to ensure tightness and to protect people from the entry of combustion products into a dwelling.

At the bottom of the stove, I made trenches — small heat-air ducts in the subfloor part, communicating with the room, through which the air of the heated room circulates. Trenches increase the heat output of the furnace and eliminate overheating of the floor on which the furnace is installed.

Initially, I wanted to mill the furnace and clean-up door of duralumin, and cut out the view valves from tin. Then he changed his mind and quickly assembled and glued these parts from cardboard. Get into the size and fit the appearance of this technology is much easier and faster. We cover everything with glossy paint from a can, we wait for drying - we get the products we need.

Initially, in ancient times, all furnaces were built by hearth. In the process of evolution, man perfected the stove by adding a grate to it (for burning different types of fuel). About what kind of furnace to build - grate or hearth heated discussions are conducted.

In the grate fireboxes, the wood is laid on the grate (grate). The grate, accordingly, serves as a bottom of a fire chamber. Through the grate primary air is supplied for combustion to the fuel.

In the hearth stove firewood is placed on under. The hearth is called the deaf floor of the firebox. In the hearth furnace primary air is supplied through the firebox door.

I discovered a number of advantages of the hearth furnace (compared to the grate, when using firewood as fuel):

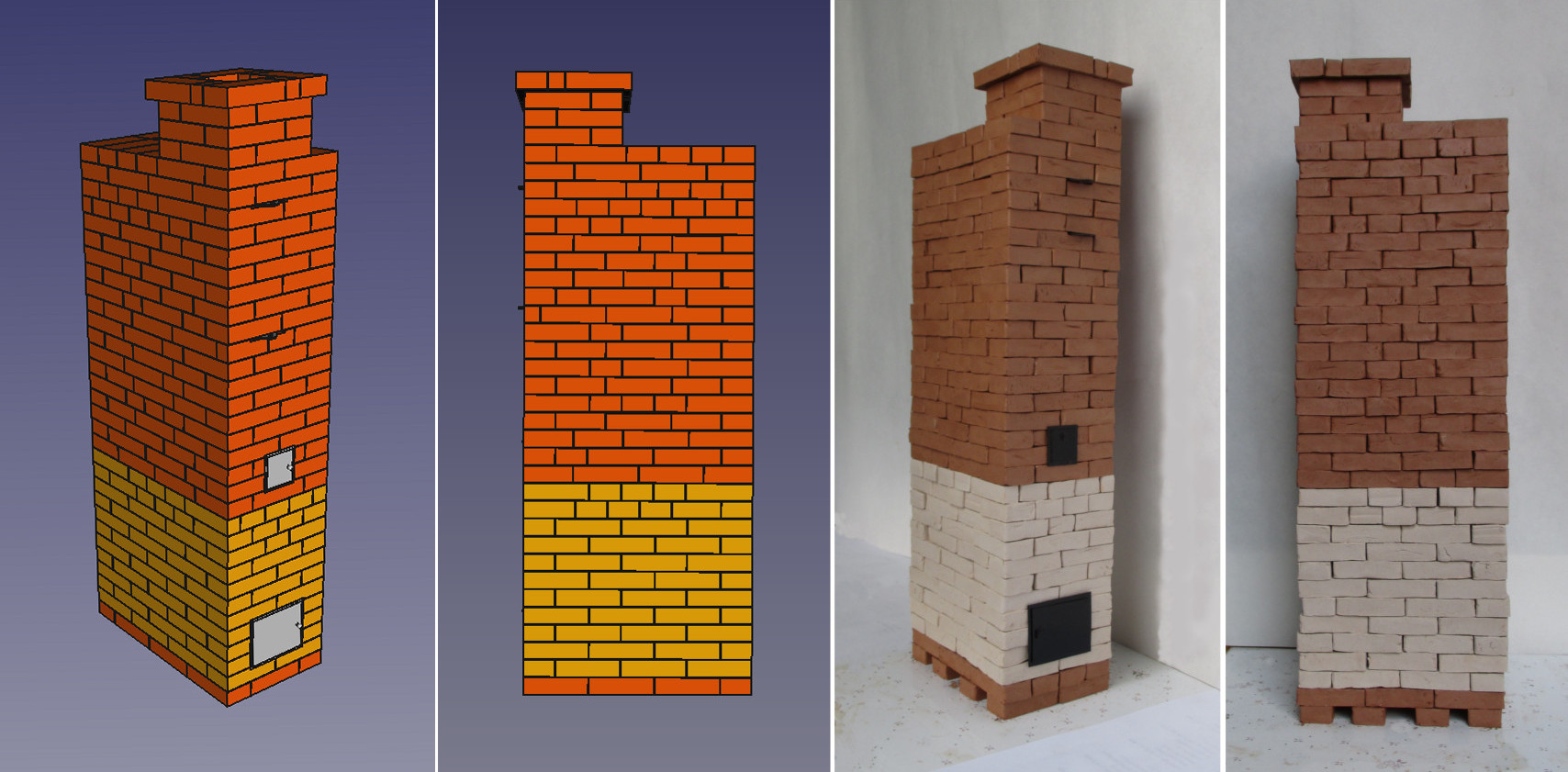

Before starting work, I made a complete model of the furnace in the program of three-dimensional modeling. I use FreeCAD (but any other will do, of course). This made it possible to see the upcoming “scope of work”, to study the nuances of masonry, to present the laboriousness of individual operations and to visualize the desired result. And, of course, I really liked the 3D design process itself.

In terms of time: it took four to five nights to create a model of a furnace (one and a half to two hours of work on average). And this is taking into account the development of virtual masonry technology. The second time, I think, I did it faster. By comparison, the actual work itself, I spent ten times more time. There are advantages of three-dimensional modeling and design.

If there is no possibility to implement the idea live - you can make it virtually. The brain doesn't care if it works with the image or its real embodiment. The pleasure (endorphins) we get is almost the same.

In life there is always a place for a dream, the realization of your unique ideas and extraordinary projects. Live a full life, do not be afraid to let go of your fantasy in flight and follow it.

Introduction

Let's start with childhood. I grew up in a house with stove heating. Felling of wood, furnace stove, flames in the furnace, wind noise in the pipe in winter, the nuances of thrust adjustment by the blower and furnace flaps I absorbed from an early age. To return to the opportunity to sit down again by the light, it was possible to plant firewood only in adulthood. At the same time, the desire was born to deal with the design of furnaces; their types and purpose; features of operation; differences and advantages / disadvantages of one type of heating from another.

The reduced format, a certain miniaturization, is deliberately chosen - with the same cognitive effect, we win in terms, volumes of materials used, applied efforts, transportation costs, required areas, etc. You can always increase the scale.

')

Clay

The oldest natural resource discovered by mankind. Everything was built from it: wall and roofing materials, stoves, houses, structures and constructions, household and kitchen implements, toys, crafts, works of art. There is it everywhere, it can be mined in any locality, the available reserves are huge.

Over several months of research, I was able to find three clay quarries in the immediate vicinity (and I learned more about three or four potential ones, but did not attend). In them I dug clay of different quality and color. I bought two more types of purified professional clay for modeling in the store. The color palette of clays in nature is very diverse - from white and black - to the whole spectrum of red-yellow, as well as green, blue, etc. By the way, green clay was the first one I met only 200 meters from the house!

Most importantly, if you start mining the clay yourself, it is cleaning it from sand, organic impurities, debris and other inclusions. To designate this process, a special term has been coined - otmuchivanie. The technology is very simple: the accumulated clay is dissolved in water and passed through a series of sieves with an increasingly smaller cell. Large particles are separated, and at the exit we have a suspension with fine particles of clay. After settling, draining excess water and the final drying of the clay, we obtain the raw materials for further experiments.

You can store the finished clay in plastic bags (without losing the desired moisture) for years. And so this product does not deteriorate at all - with time it only gets better.

Bricks

Having blinded several bricks by hand, I realized that this was an unnecessarily laborious way. In addition, the variation in size was too critical. It was necessary to take on the manufacture of the form, to introduce standards.

In parallel with the manufacture of the form, I was “combing” the Internet, articles and books on the subject of how technology can be used to make bricks in large quantities and quickly. The oldest and simplest is manual molding. Extrusion of the clay mass with the help of augers or hydraulic pushers was also considered, but these too ambitious plans were left for the future :)

I figured that about 300 full bricks (or, about 500 with halves, quarters and other parts) are required for the furnace. Standardly, in an hour and a half I managed to make about 20-25 bricks. Those. around 18-22 pm for tamping clay into a mold and pressing the finished product onto a shelf for drying - and a complete set of products for the assembly of the furnace is ready!

I used a fairly dense, hard clay, leveled all the folds, irregularities, in parallel cut into quarters and halves (and also pretended to need them). Therefore, this process and stretched. Single piece production - the most time-consuming.

The law "Square - Cube"

Having chosen a reduced scale of bricks, in practice I felt the law of the "square - cube", which reads:

If a physical object is increased in size while maintaining the same density of the material from which it is made, its mass will increase in proportion to the magnification factor of the third degree, while its surface area will be the square of the scale factor.

Example : A real standard brick has dimensions of 250x120x65 mm and a mass of 3600 grams. The density of the brick is equal to 1846 kilograms per cubic meter.

Reduce its size by about 6 times. We obtain linear dimensions 42x20x11 mm and a mass equal to 17 grams.

Those. the change in linear dimensions in the ratio of 1: 6 led to a change in weight in the ratio of 1: 211. The experiment can be repeated at home by anyone.

The conclusions are practical (in relation to my experiment) - the mass of the entire model of the furnace will be no more than 5-6 kg. Which is very convenient for construction, transport and storage. Bricks of this size are not yet tiny (tweezers and a magnifying glass are not needed), but no longer “cyclopean” - dragging extra weights and making half a room for a “construction site” will not be necessary. Everything is assembled quickly and comfortably on a table or windowsill.

Burning

Roasting - while not touching. For masonry with an excess of enough strength raw brick. Roasting also requires access to fire, furnaces. In the language of IT - these works can be distinguished into a separate subsystem and explored later. In the meantime, we assume that the Firing () method has a temporary “stub”, which always returns “true”.

Bake

I began to create a furnace with a study of the theoretical and practical experience of mankind. On this topic, everything has been worked out for a long time in detail - the fuel is expensive and it is expensive to burn it (in all respects). Therefore, people have come to a number of optimal designs, allowing to get the maximum heat from a unit of firewood, coal, peat, etc.

As a sample, I chose a typical heating furnace PTO-2300

Design parameters :

- weight - 1260 kg

- the heat-transfer surface area is 5.5 square meters.

- convection system - bell

- chimney - mounted

- type of finish - jointing

Functional parameters :

Heating capacity (with firebox for firewood):

- with a single fire - 1400 W

- with double fire - 2300 W

- at a single fire - 1600 W

- with double fire - 2500 W

Material consumption :

- Ceramic brick - 210 pcs.

- chamotte brick - 76 pcs.

With regard to heating furnaces, the situation is as follows: it is necessary to distinguish between the firebox (the place where the combustion processes occur with the formation of heat) and the heat exchanger (the places where heat is removed from the heated gases).

The firelighter is usually made of fireclay bricks (in my model it is white brick), and the heat exchanger (or the system of channels, the furnace mass that stores heat) is made of red brick. The need for fireclay bricks caused by high temperatures resulting from combustion.

For different types of fuel, the firebox is required in various sizes, shapes and designs. And a different air supply. In the case of burning of stone and brown coal, peat requires a smaller firepower and the presence of a blower is obligatory - air supply from the bottom, through the grate.

I designed the stove for wood heating, so I took the dimensions of the firebox more and chose the hearth type of wood burning. In our area, domestic stoves are not drowned with coal and peat (they are simply not available) - only wood is used.

The masonry itself is very simple. If you do not use a binding solution, but simply recruit the constructive furnace in rows, of course. Brick to brick, brick to brick ... We're making a model, not a real sample, right? So you can not worry about jointing. In addition, you may want to burn these bricks in the future or use them in another project.

By the way, stove-houses say that a properly designed stove does not require a solution so that all its elements stick together in a single monolithic structure. Those. sealing of seams is needed only to ensure tightness and to protect people from the entry of combustion products into a dwelling.

At the bottom of the stove, I made trenches — small heat-air ducts in the subfloor part, communicating with the room, through which the air of the heated room circulates. Trenches increase the heat output of the furnace and eliminate overheating of the floor on which the furnace is installed.

Fittings

Initially, I wanted to mill the furnace and clean-up door of duralumin, and cut out the view valves from tin. Then he changed his mind and quickly assembled and glued these parts from cardboard. Get into the size and fit the appearance of this technology is much easier and faster. We cover everything with glossy paint from a can, we wait for drying - we get the products we need.

Grid or hearth furnace?

Initially, in ancient times, all furnaces were built by hearth. In the process of evolution, man perfected the stove by adding a grate to it (for burning different types of fuel). About what kind of furnace to build - grate or hearth heated discussions are conducted.

In the grate fireboxes, the wood is laid on the grate (grate). The grate, accordingly, serves as a bottom of a fire chamber. Through the grate primary air is supplied for combustion to the fuel.

In the hearth stove firewood is placed on under. The hearth is called the deaf floor of the firebox. In the hearth furnace primary air is supplied through the firebox door.

I discovered a number of advantages of the hearth furnace (compared to the grate, when using firewood as fuel):

- the cold core disappears from the furnace (air duct under the grate). The whole array of the furnace is heated more evenly.

- firewood burns almost completely, higher efficiency, more heat we get

- less soot and ash

- the bottom of the furnace is heated not only by the flame but by the glowing coals

- low level of condensate in the chimney is ensured; tar does not flow. There are no unburned fuel particles entering the pipe.

- in this case, burning occurs from top to bottom, the fuel burns more slowly, more evenly, because only the top layer burns, not the whole mass (as in the grate burning)

Design in 3D

Before starting work, I made a complete model of the furnace in the program of three-dimensional modeling. I use FreeCAD (but any other will do, of course). This made it possible to see the upcoming “scope of work”, to study the nuances of masonry, to present the laboriousness of individual operations and to visualize the desired result. And, of course, I really liked the 3D design process itself.

In terms of time: it took four to five nights to create a model of a furnace (one and a half to two hours of work on average). And this is taking into account the development of virtual masonry technology. The second time, I think, I did it faster. By comparison, the actual work itself, I spent ten times more time. There are advantages of three-dimensional modeling and design.

If there is no possibility to implement the idea live - you can make it virtually. The brain doesn't care if it works with the image or its real embodiment. The pleasure (endorphins) we get is almost the same.

Conclusion

In life there is always a place for a dream, the realization of your unique ideas and extraordinary projects. Live a full life, do not be afraid to let go of your fantasy in flight and follow it.

Source: https://habr.com/ru/post/456820/

All Articles