Liquid climbers: manipulations with water droplets to create laboratories on a chip and self-cleaning technology

“Once it started to rain and did not stop for four months. During this time, we learned all kinds of rain: direct rain, slanting rain, horizontal rain, and even rain that comes from the bottom up (Forrest Gump, 1994).

We remember, of course, that Forrest had a special view of the world around him. Speaking of rain "from the bottom up," he was referring to raindrops bouncing off the surface of the reservoir. After all, water can't just move up, right? First, it can. Secondly, upward is not the only direction of water movement. Thirdly, the direction can be controlled. Manipulations with tiny drops of water will allow you to create laboratories on a chip and to impart self-cleaning properties to certain materials. Previously, these statements were only a theory, but more recently they have been confirmed in practice, which we will discuss today. What is a lab on a chip, how can things clean themselves, and how have scientists managed to tame a drop of water? The answers to these questions are hidden in the report of scientists. Go.

')

The basis of the study

We increasingly hear the word "control." Scientists are trying to control almost everything that can help in achieving successful results of a particular study: control of spins, control of molecules, control of the auditory cortex of the mouse, etc. In the case of self-cleaning technologies and digital microfluidics, control of the drops of the fluids used in them is required.

At the moment, there are already a number of droplet handling technologies, but all of them have quite serious drawbacks: complex electrode patterns, too high temperature ( Leidenfrost installation * ), low molecular displacement velocity, the need for piezoelectric substrates, etc.

The Leidenfrost effect * is a phenomenon when, when a liquid comes in contact with a very hot body (the temperature is above the boiling point of the liquid), an insulating vapor layer is formed that prevents the liquid from boiling fast.However, in the study we are considering today, scientists were able to overcome all of the above disadvantages by applying a new method - “mechano-moistening” ( mechanowetting ). This technique allowed moving the drop along the horizontal and inclined surfaces by means of transverse surface waves. The speed of the drop is equal to the speed of the wave. More details about the results of observations below.

Research results

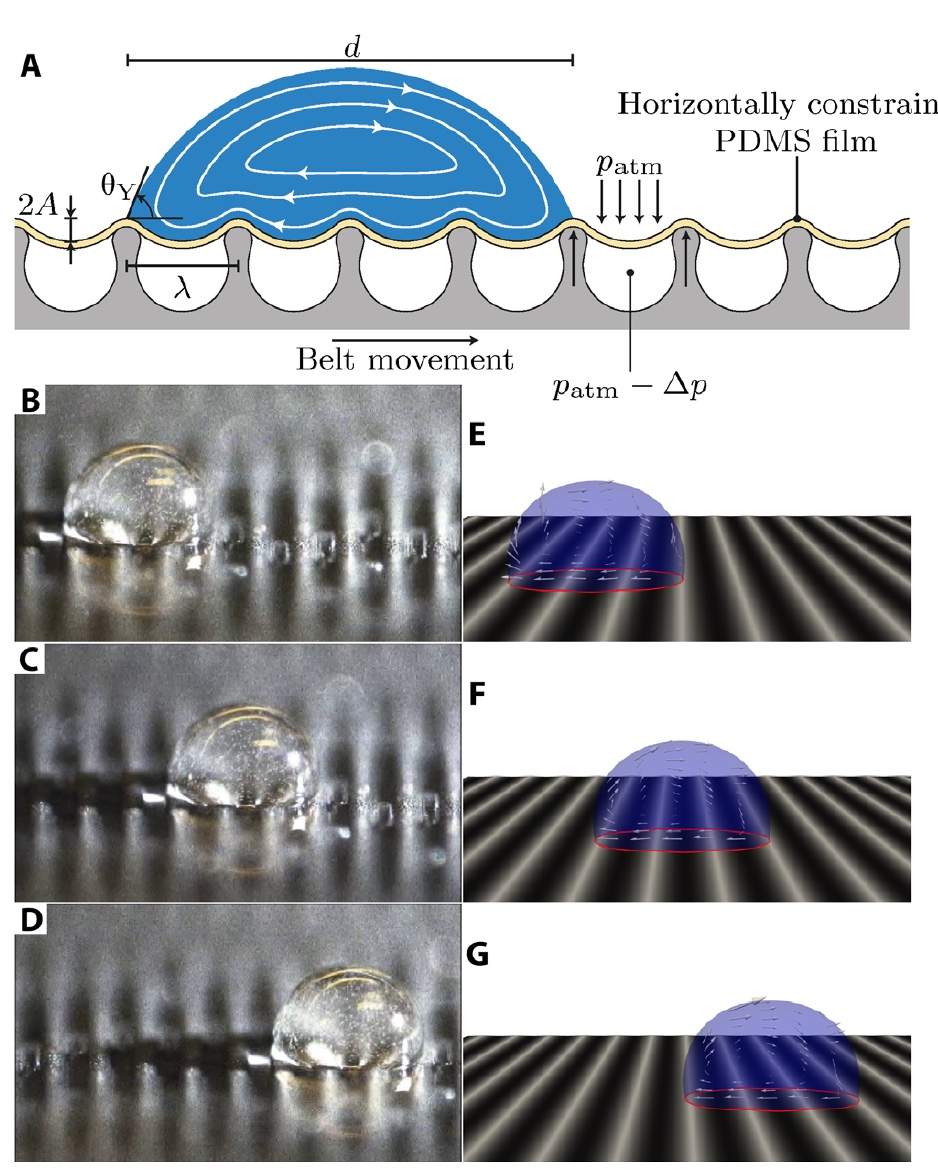

To demonstrate the unusual route of droplets, scientists have developed a device that generates ordinary and controlled transverse surface waves ( 1a ).

Image number 1

The wavelike structure of the surface, which is clearly visible at 1a, was obtained by reducing the pressure under a PDMS * film with a thickness of 50 μm. Because of this, the film is pressed against a moving belt with transverse projections.

PDMS * - polydimethylsiloxane, (C 2 H 6 OSi) n .The wavelength of the film is determined by the distance between the protrusions on the belt, and the wave amplitude (3 to 5 microns) is controlled by vacuum pressure. Scientists have found that individual drops with a volume of 0.1 ... 5 μl (microliter) at transverse waves with a wavelength of 500 μm move at a speed of 0.57 mm / s, which is equal to the speed of the applied wave.

The movement of the drop volume of 1.3 μl (corresponds to the images 1d - 1d ).

Next, scientists conducted CFD modeling (computational fluid dynamics), together with practical experiments and theoretical foundations, in order to better understand the nature of the driving force, describe it quantitatively and, naturally, better control the entire system.

The numerical description of a separate drop was performed using a CFD model with vertically deformable borders (OpenFOAM framework).

CFD droplet model with a volume of 1.4 µl (corresponding to images 1e - 1g ).

Comparing the first and second video, as well as the images of real drops and simulated images, we see that the results are perfectly matched. The simulation fully confirms practical observations.

Scientists analyzed the particles inside the drop, comparing the observations with the internal velocity of the drop in the CFD model, as a result of which a rotational motion was detected.

Image number 2

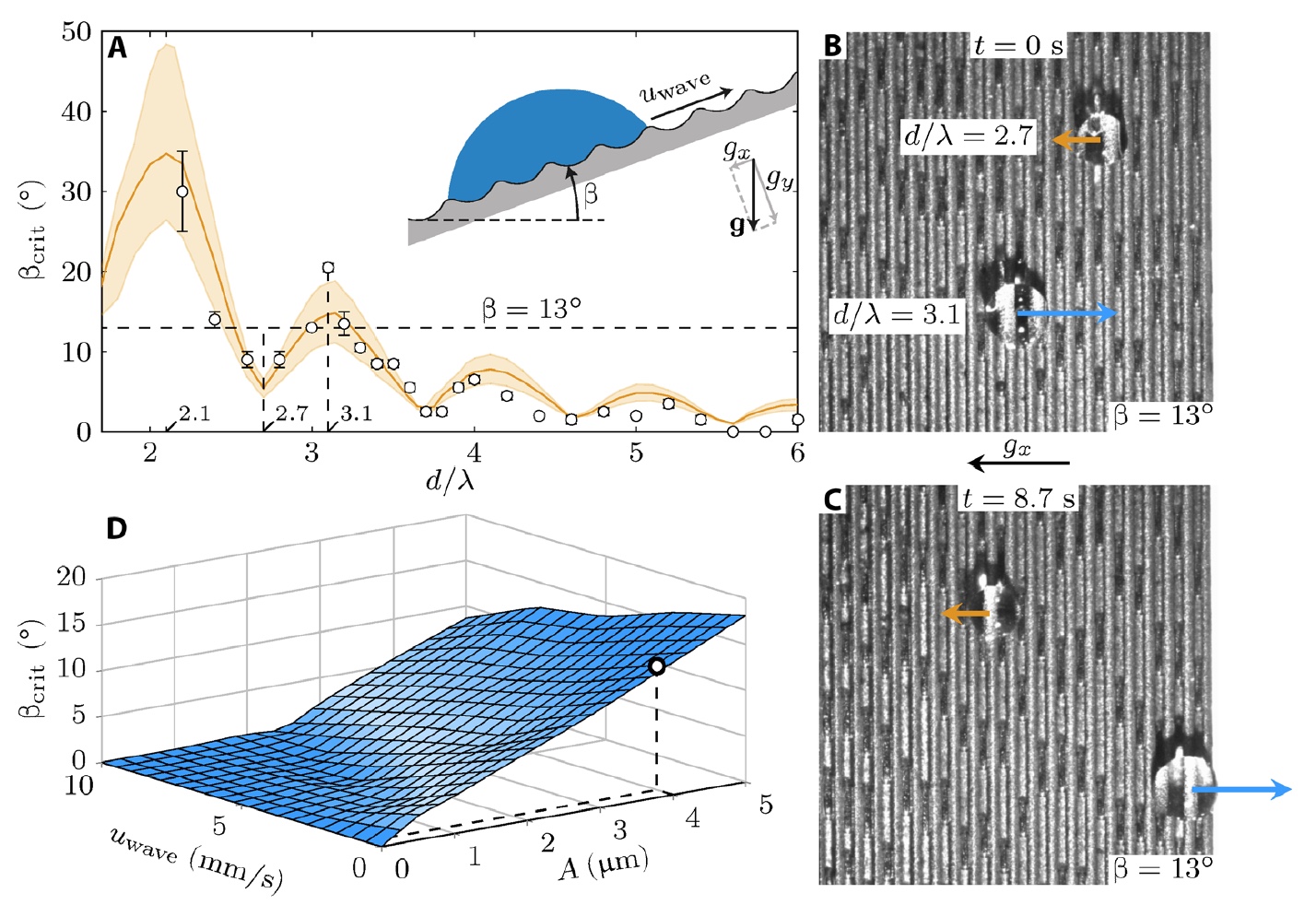

Next, scientists complicated the problem for droplets by changing the slope of the surface ( 2a ) so that the gravitational force did not become more than the driving force of the droplets. Graph 2a shows the results of a series of experiments in which each tested drop volume corresponds to a critical value of the angle of inclination. A certain tendency is seen: the value of the critical angle of inclination decreases with increasing drop volume. The reason is quite simple: the force of gravity increases much faster than the driving force of a drop, which acts through a three-phase contact line (liquid - liquid - air).

It was also found that the value of the critical angle does not decrease linearly (uniformly), instead there is a sharp decline seen on graph 2a .

Two drops of different volume on a surface with an inclination angle of 13 ° (corresponding to images 2b and 2c ).

Since the driving force of the larger drop (3.1) is greater than the gravitational one, the drop moves upwards. And the driving force of the smaller drop (2.7) is less than the gravitational one, because the drop rolls down.

It should be noted that the input data for the model corresponded to the parameters of the actual installation and the drops used in practical experiments.

Next, scientists checked how speed and amplitude affect the value of the critical angle of inclination. As seen from the diagram at 2d , the critical angle decreases with increasing wave speed. It was also found that at a sufficiently high wave speed and at a lower amplitude range, the driving force becomes insufficient to transfer the drop. This is due to the increased viscous resistance associated with an increase in viscous dissipation inside the drop.

The correlation between dissipation and the drop rate is due to the fact that an increase in the drop transfer rate necessarily leads to an increase in the flow rate inside the drop due to the nature of the droplet movement (rotational). In addition, an increase in wave amplitude leads to a linear increase in the critical angle.

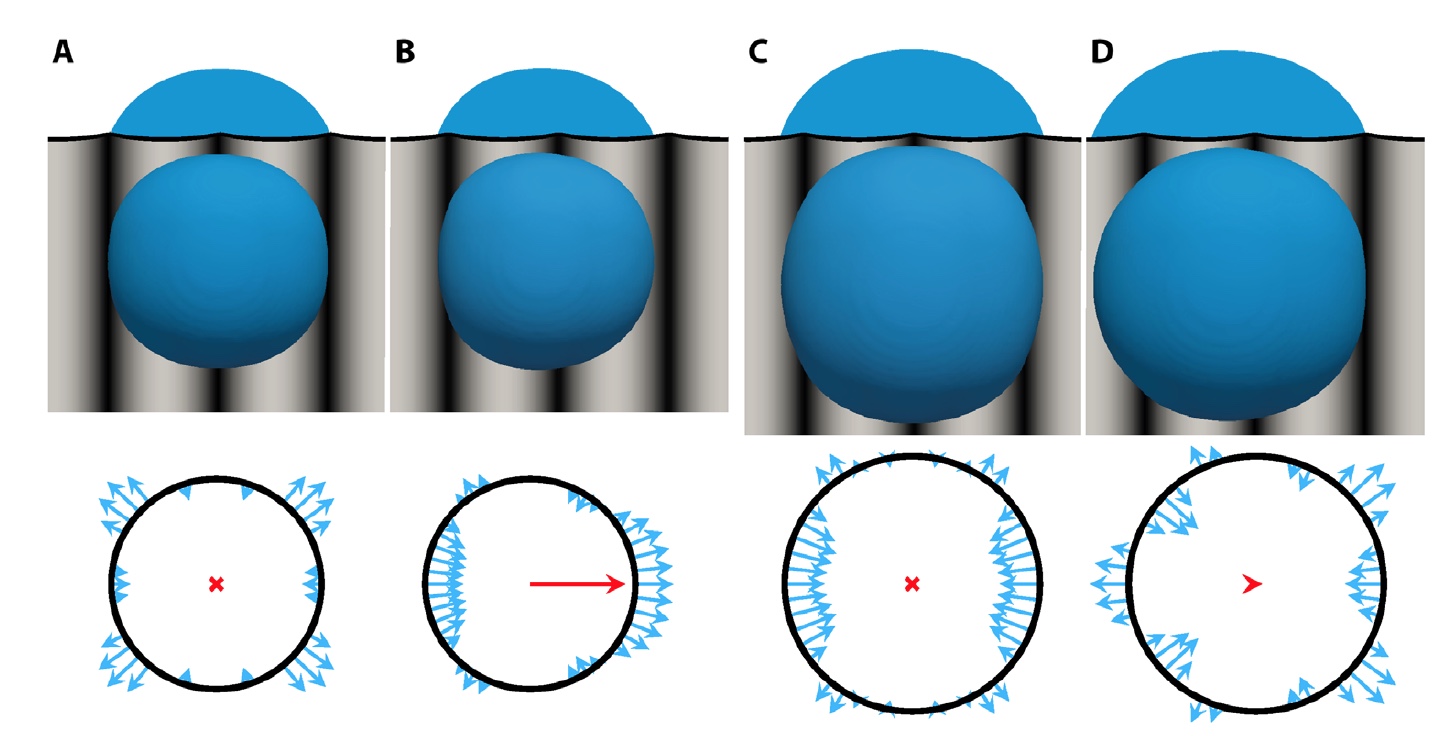

The next step in the study was to clarify the causes of the oscillatory nature of the value of the critical angle of inclination and its possible connection with the shape of the droplets and lines of contact during their movement.

Image number 3

Scientists decided to consider two variants of drops: 2.1, for which the critical angle reaches a maximum (top row at 3a and 3b ), and 2.7, for which the critical angle reaches a minimum (top row at 3d and 3c ).

At zero tilt angle, droplets ( 3a and 3c ) have a symmetric shape. When the wave begins to move, the device bends, which leads to a distortion of the position of the drop relative to the ridges. Because of this, the droplet shape becomes asymmetric ( 3b and 3d ).

Changing the shape of a drop brings the system out of balance and activates the elastic force * , which controls the movement of the drop.

Force of elasticity * - during the deformation of the body, the force of elasticity arises, which tends to return to its former shape (ie, to its original state).A quantitative determination of the elastic force was performed by means of theoretical modeling based on an instantaneous change in the local contact angle when the drop shape was distorted. In the model medium, droplets were described as spherical particles, and the magnitude of the distortion of the droplet shape when the center of mass of the same droplet was shifted relative to the initial (equilibrium) state was fixed. Given this, scientists calculated the force per unit length (tension) arising from the imbalance of surface tension forces (blue arrows in image No. 3) on the contact line.

The total force was obtained by integrating the voltages along the three-phase line, resulting in a net force (red arrow in the image No. 3).

The theoretical model confirmed that, in the initial (equilibrium) state, the tensions of the three-phase lines are symmetrical. And during the distortion of the drop shape, their asymmetry arises. This generates pure force (dynamic fixation), which balances the opposing forces (static fixation, gravity and viscous forces). As a result, it was found that the highest forces can be generated at a contact angle of about 65.5 °.

The intermediate result is that the drops can easily overcome inclined surfaces, rising at a speed of 0.57 mm / s, overcoming the gravitational forces ( 4a ).

Image number 4

Vertical movement of the drop.

Movement of the drop on the ceiling (corresponds to image 4b ).

In the “mechano-moistening” device demonstrated, the maximum generated force was 2 μN (micronewton). The distance that a drop can overcome (in any position) is limited only by the dimensions of the experimental device itself. Increasing the working surface will increase the distance traveled by the droplet at the same speed.

However, many of you will be asked - and from what should there be drops so that all this beauty works? The researchers also asked this question and tested their method on various liquids (water, isopropyl alcohol and mineral oil). Practical tests have shown that there is not much difference between these three options, and all of them are excellent for the implementation of the studied method.

Demonstration of simultaneous movement of multiple droplets of different volume and, accordingly, size (corresponding to image 4c ).

The researchers note that the presence of a critical angle as an important aspect of this technique allows you to sort drops. By tilting the unit at a certain angle, you can see that drops with a critical angle below the threshold value cannot move along the wave, while drops that show large maximum critical angles will be transported. Consequently, only drops of a certain size will move with the wave, while the rest will slide off the inclined surface. When two drops are combined, this sorting process is repeated, and the drop will be sorted based on its new size.

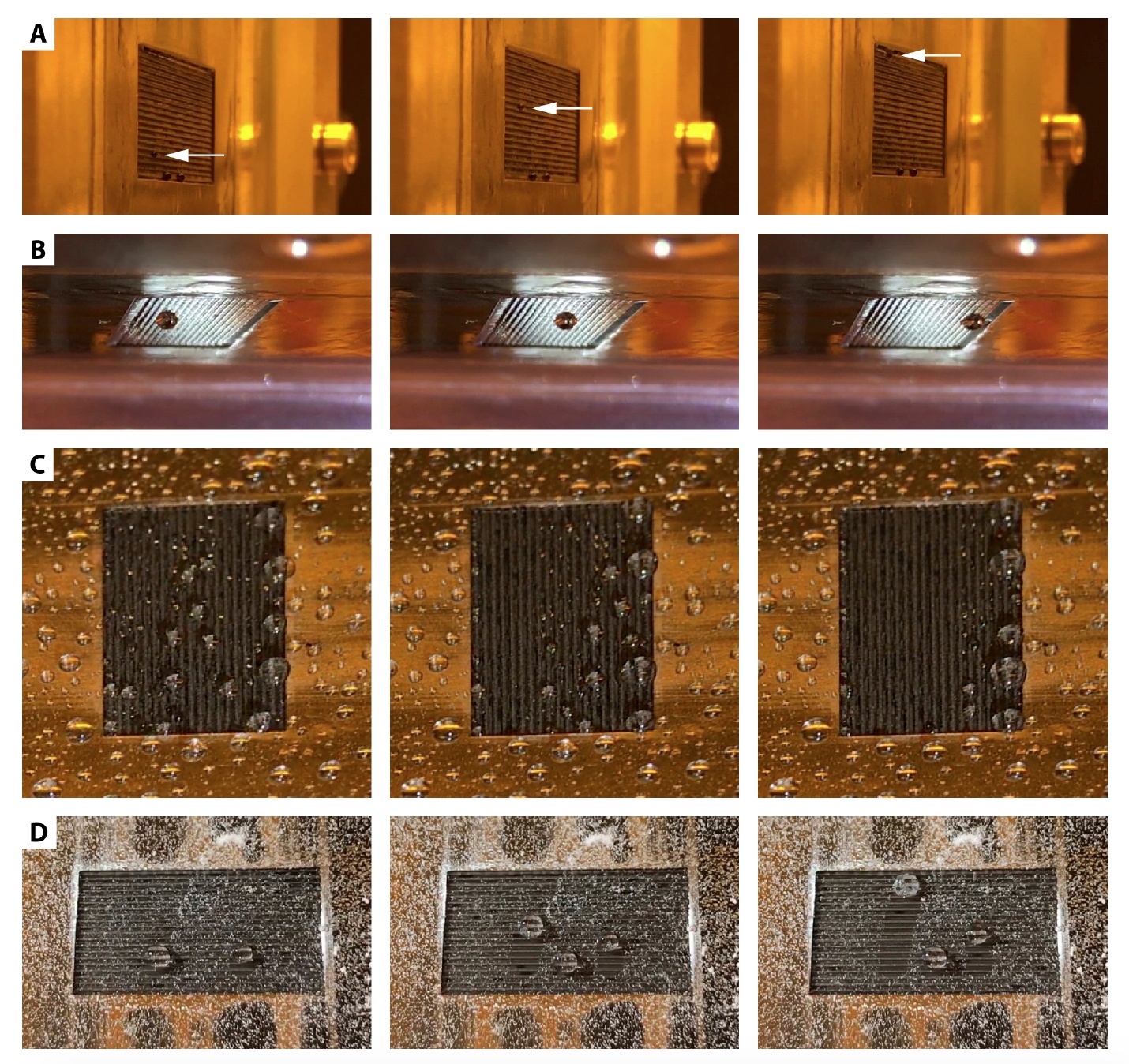

And what about self-cleaning surfaces? This is a pretty useful property, isn't it? So, the researchers conducted observations of the droplets moving in the installation. They determined that these drops are able to clean the surface from contamination.

Next, scientists created a model of the contaminated surface, causing a large amount of calcium carbonate (CaCO 3 with a particle size of <50 μm) on the surface of the PDMS film (covers the device).

Turning on the device of the traveling wave, the CaCO 3 particles did not disappear, but retained their position on the surface, which is due to the transverse nature of the wave. Then drops of water and isopropyl alcohol were applied to the contaminated surface. Drops move across the surface, thereby cleansing it from contamination.

Cleaning the contaminated surface with “running” drops (corresponds to image 4d ).

However, there is a negative effect in this process. The presence of CaCO3 particles on the working surface led to an increase in resistance and a decrease in the effective velocity of the drops to 20% of the wave velocity. But this did not prevent drops to clean the surface along its route.

The provocative moment of the narrowness of the application of traveler droplets exclusively within the experimental setup, scientists also understand perfectly. In the future, they plan to use sensitive surface topography, which is characterized by mechanical deformation in response to external stimuli, such as light, magnetic fields and temperature.

Light-sensitive liquid crystal polymers and elastomers have a special interest for researchers. And all because of their precise space-time control, allowing them to move in a wavelike manner over the surface with the help of structured or moving light sources or under constant illumination by self-shadowing.

For more detailed acquaintance with the nuances of the study I recommend to look into the report of scientists and additional materials to it.

Epilogue

First of all, I would like to note that the experiments conducted with the use of the test setup developed by scientists are not yet a finished product or technology. This setup was used to demonstrate the dynamic droplet technique under study and the self-cleaning function.

In the future, scientists plan to use other technologies, in particular liquid crystal polymers and elastomers, which we talked about earlier. This work is only a confirmation of the fact that the method of mechanical moistening has a full right to exist, since it has advantages over other technologies whose goals are similar to this method.

One of the main areas where it will be possible to apply this miracle of scientific thought is microfluidic, that is, diagnostics of liquids using small-sized devices. A self-cleaning function can find its application in the creation of self-cleaning medical devices, marine sensors, windows, solar panels, and even in the implementation of technologies for collecting dew.

Whatever the future waits for this technology, the very fact of its development speaks about the exceptional nature of human intelligence. Our brain is able to generate the most extraordinary ideas that go beyond the framework, which are sometimes difficult to implement, but the result of this realization confirms that for us nothing is impossible.

Thank you for your attention, stay curious and have a good work week guys! :)

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr's users on a unique analogue of the entry-level servers that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

Dell R730xd 2 times cheaper? Only we have 2 x Intel TetraDeca-Core Xeon 2x E5-2697v3 2.6GHz 14C 64GB DDR4 4x960GB SSD 1Gbps 100 TV from $ 199 in the Netherlands! Dell R420 - 2x E5-2430 2.2Ghz 6C 128GB DDR3 2x960GB SSD 1Gbps 100TB - from $ 99! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?

Source: https://habr.com/ru/post/456510/

All Articles