Nixie clock or warm lamp light to your house

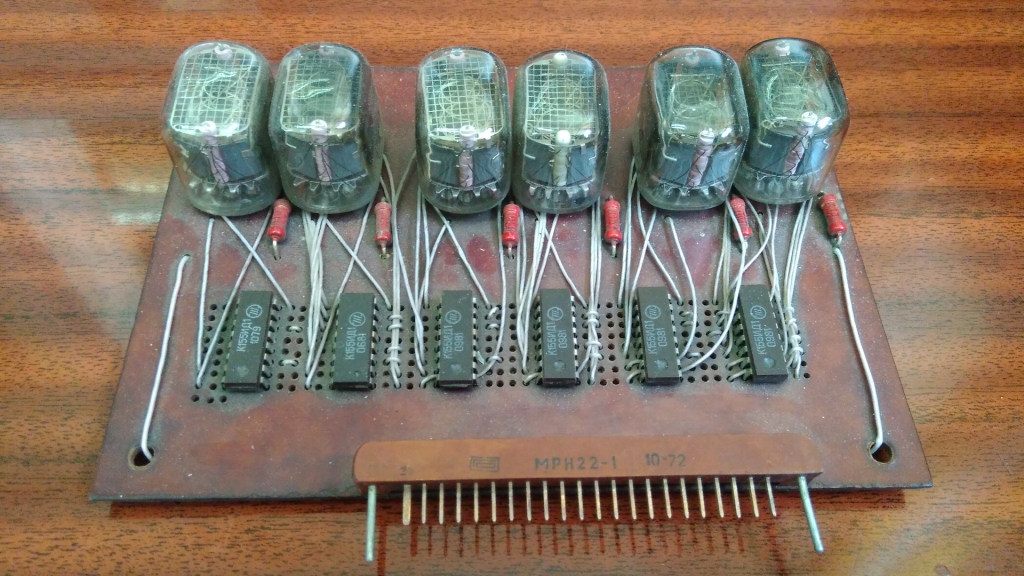

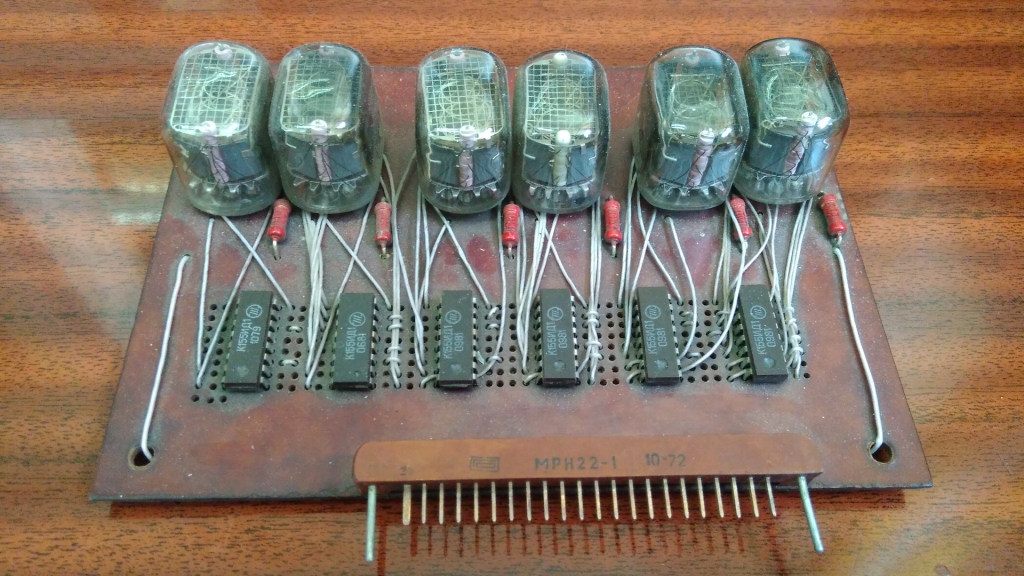

It all started at that moment when at work in one of the boxes with old radio components such an odd job was found. Who made it - the story is silent, whether she, too, is not reliably known.

And then the thought arose of making such a device, especially at my projection clock at home, the projection safely refused. Just look at this, this is wonderful!

')

If it seems terrible to you, imagine that you live in the 80s, you have no MC, no fiberglass, no CNC, no exact tools, etc. but there is a great desire and knowledge.

Much passed from the idea to the realization of time, at first the lamps on Avito were ordered, I took IN12b, IN1, INS-1, IN-8-2, IN-14. Next, I looked at the ready-made solutions on this topic, mainly it concerned the high-voltage part (BB). The circuitry of all watches is elementary, for example, a popular circuit from one of the sites, it has all the necessary parts, change it to the available elements.

I read on the forums that for the high-voltage DC-DC, the chip Max1771 is well suited, took 5 pieces, prepared the board while she was driving. Oh, and I tortured with it, the datasheet knew by heart. A very capricious microcircuit, it is not cool, of course, but it is very demanding on the PCB layout, I didn’t grow together with it. But I did the clock on it, I did not bother with the case, I just printed a segment case on the printer. Lamps Ying-14, Arduino Nano, DC-DC on max1771, time module on DS3231, dynamic display, LED backlight.

In all my watches there is a temperature control: if the temperature rises to the threshold, the clock goes into idle mode - the indicators turn off until the temperature drops. Overheating was not observed during operation. There is also a function to counteract the cathode poisoning of lamps, with the frequency of once per hour, all the digits on all indicators are run. The disadvantage is that time is adjusted only through the UART port. With the board there, too, not everything is in order, I decided that it would come down to connect the jumpers, the device works, but it is more difficult to debug and repair.

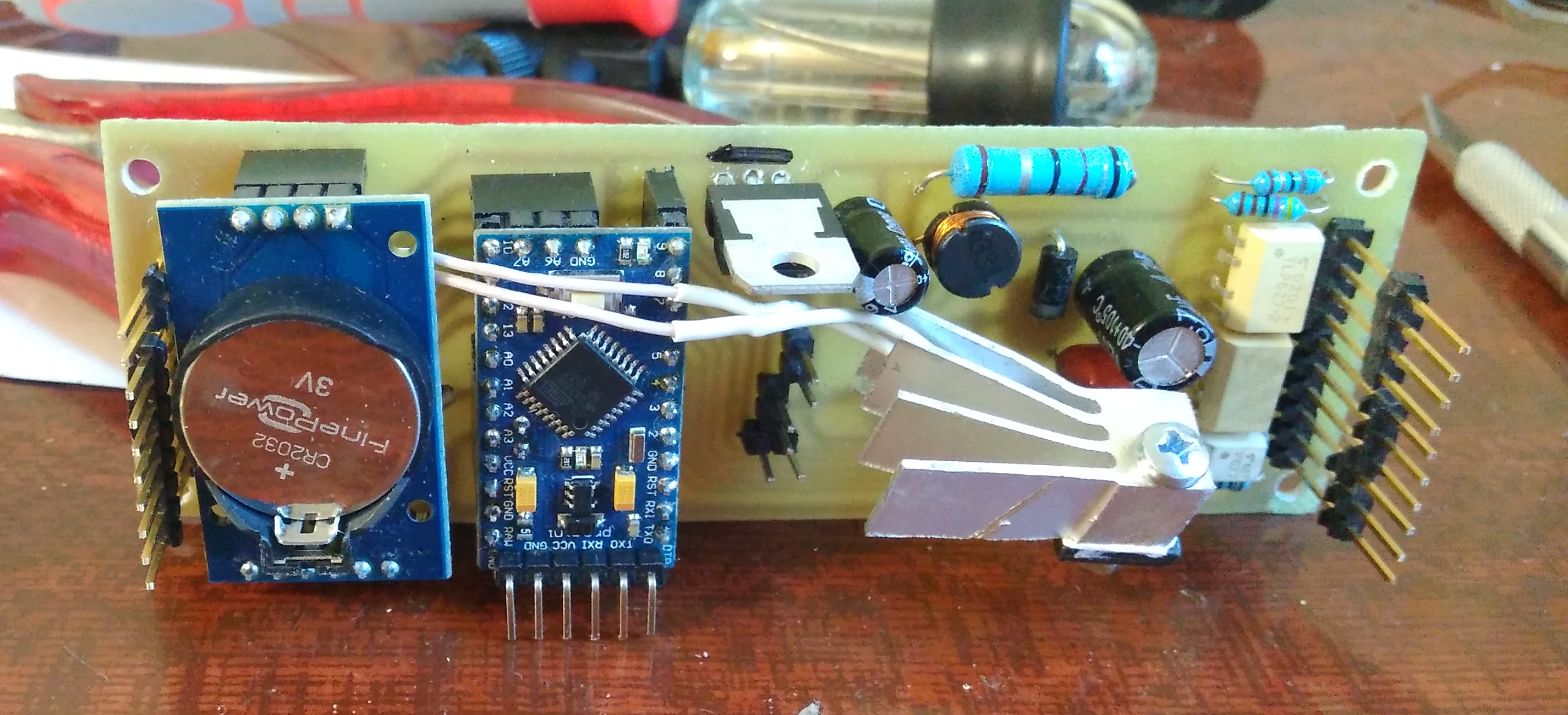

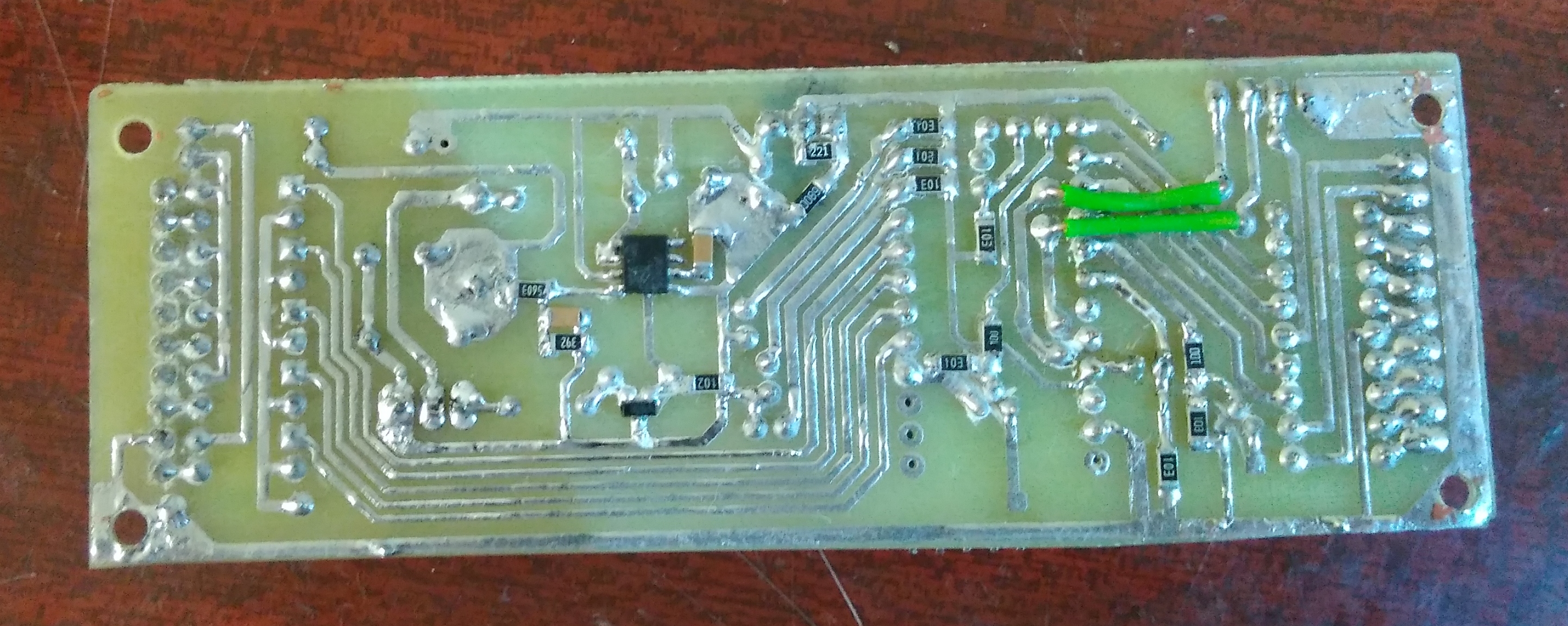

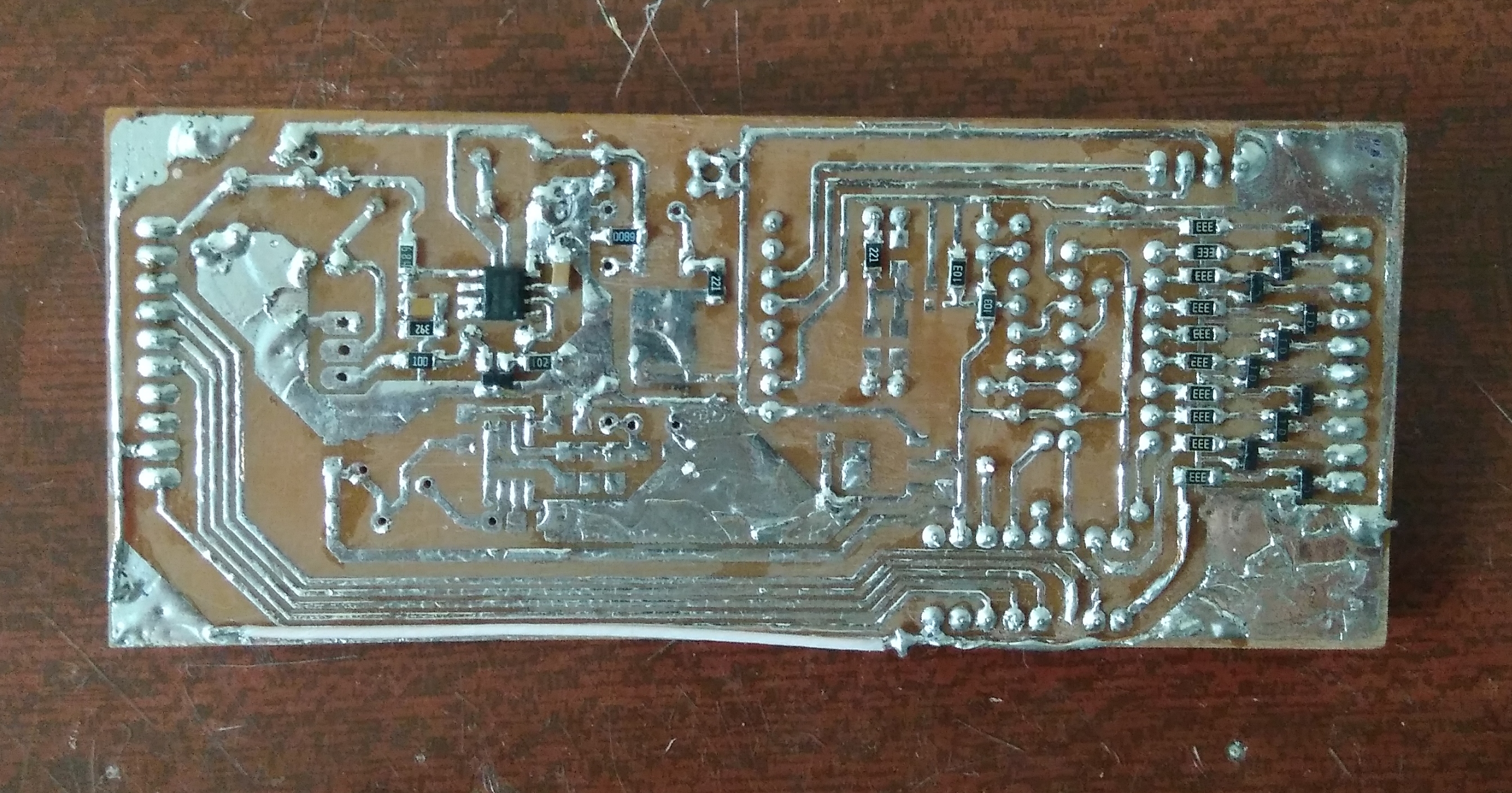

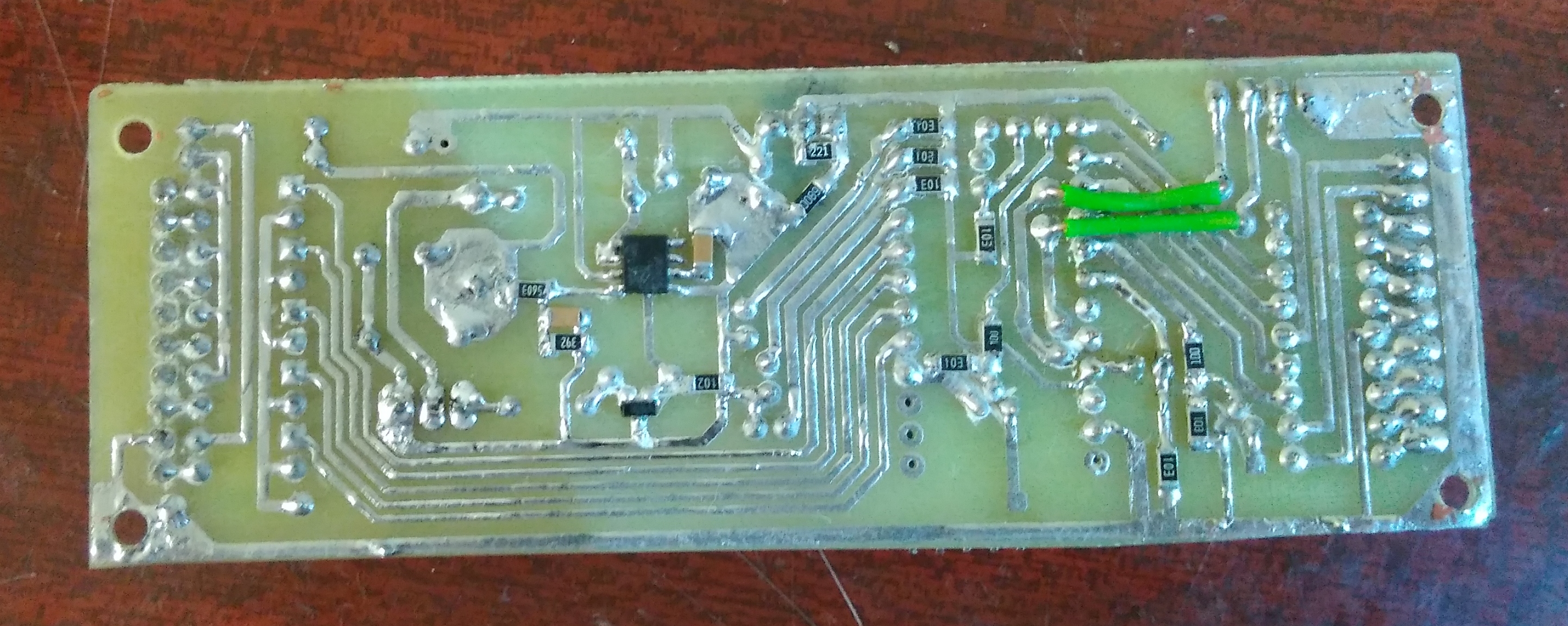

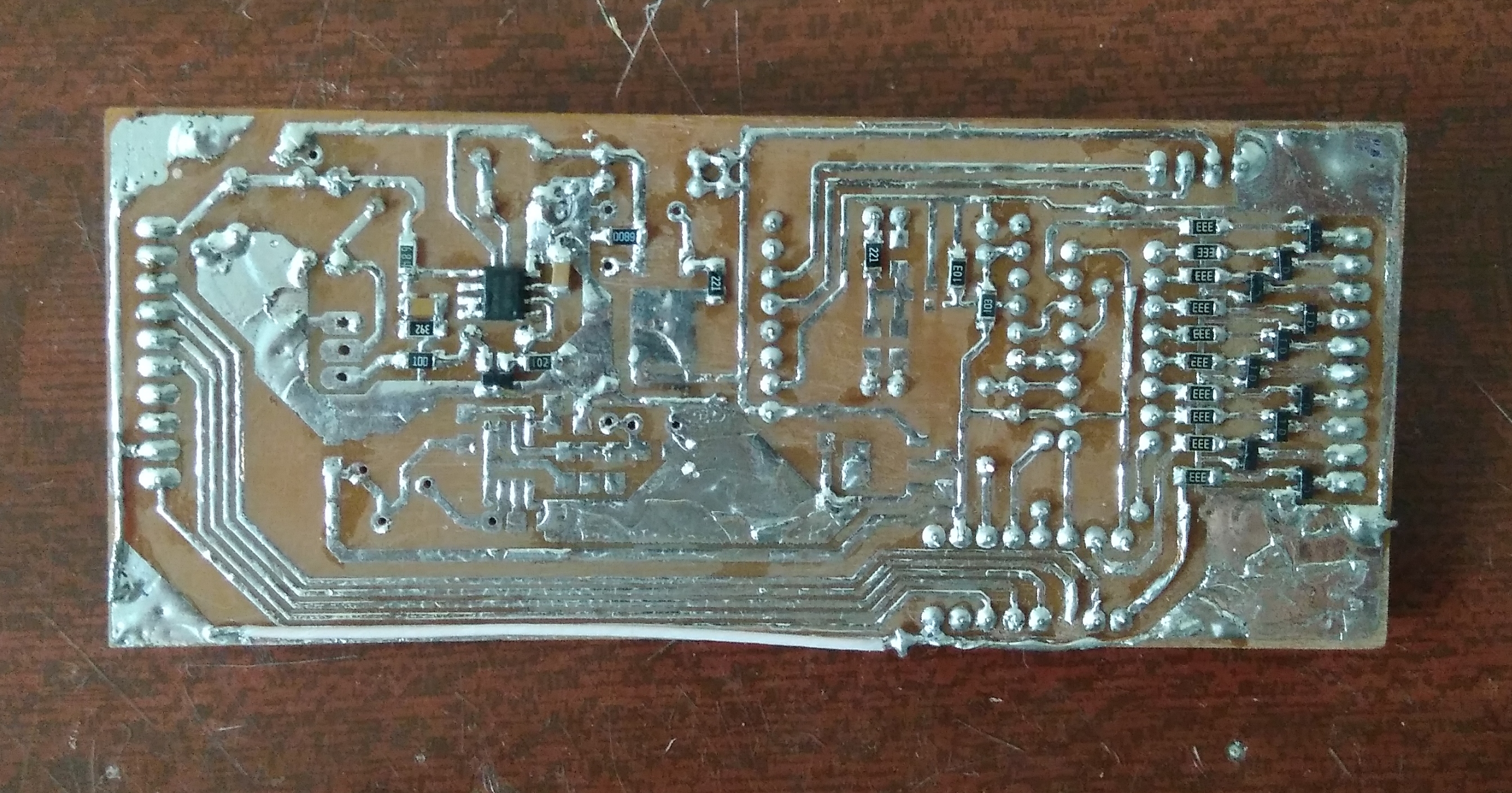

Then I decided to be confused, and to make an aesthetic case, for this the clock on the IN-12 lamps was chosen, it would be better if I made them in a printed case. To reduce the size of the board, I used the Arduino ProMini, DC-DC made on the popular and old MC34063 (this is a trouble-free mikruha, simple as a corner of the house and cheap). Also in this iteration, I decided not to use transistor switches, and replaced them with high-voltage TLP627 optocouplers.

Adjustment of the time takes place through the UART or the buttons on the back of the watch. I could not find / adapt ready-made libraries for my watches, so I had to write the “menu” to adjust the time myself.

The hull is made of end cut of birch. I had to suffer with the case: the lamps have an oblong-rounded shape, it was not possible to choose a forstner drill or to choose a milling cutter for them due to hard conclusions and also because of the difference in the size of the lamp bulb. Therefore it was necessary to drill 2 holes and then with the help of a rasp and a file to give the desired shape, because of this, there are some flaws in the exact fit.

In general, the lamps were not very much liked, it is clear why they are so cheap and in such quantities are sold. Due to the fact that they are designed for horizontal execution, their angle of view is not very impressive, and it is also more noticeable that the cathodes are located at different "depths" in comparison with the same IN-14.

Given the shortcomings of the previous iterations, I made 3 hours option. Solutions with the BB part and the brains are the same as in version 2: Arduino ProMini, MC34063, TLP627, c155id1, IN-14 lamps. The hull made a canon of wood, this time an ash tree, which he took from a friend. The clock turned out pretty tiny.

The board provides lighting and airflow, but not physically implemented. Practice has shown that with the backlight at night the numbers can be seen worse, at least with my not 100% vision. Airflow is also not needed, since the transistor remains cold. The time setting is done with the buttons on the back of the watch. Now at home I have 3 hours on GRI, you can begin to distribute.

But in this experiment and obtaining a pleasant experience in the design and implementation are not completed. I have already prepared the 4th iteration of the clock, this time I want to abandon the buttons in favor of setting using a web server and a smartphone. For this, I prepared just such a fee for the next hours, until I decided what kind of lamps would be used, but most likely IN1.

Review of all my watches I made in the video, with a demonstration of the guts and design errors.

Links to resources are here .

And then the thought arose of making such a device, especially at my projection clock at home, the projection safely refused. Just look at this, this is wonderful!

')

If it seems terrible to you, imagine that you live in the 80s, you have no MC, no fiberglass, no CNC, no exact tools, etc. but there is a great desire and knowledge.

Iteration 1

Much passed from the idea to the realization of time, at first the lamps on Avito were ordered, I took IN12b, IN1, INS-1, IN-8-2, IN-14. Next, I looked at the ready-made solutions on this topic, mainly it concerned the high-voltage part (BB). The circuitry of all watches is elementary, for example, a popular circuit from one of the sites, it has all the necessary parts, change it to the available elements.

I read on the forums that for the high-voltage DC-DC, the chip Max1771 is well suited, took 5 pieces, prepared the board while she was driving. Oh, and I tortured with it, the datasheet knew by heart. A very capricious microcircuit, it is not cool, of course, but it is very demanding on the PCB layout, I didn’t grow together with it. But I did the clock on it, I did not bother with the case, I just printed a segment case on the printer. Lamps Ying-14, Arduino Nano, DC-DC on max1771, time module on DS3231, dynamic display, LED backlight.

In all my watches there is a temperature control: if the temperature rises to the threshold, the clock goes into idle mode - the indicators turn off until the temperature drops. Overheating was not observed during operation. There is also a function to counteract the cathode poisoning of lamps, with the frequency of once per hour, all the digits on all indicators are run. The disadvantage is that time is adjusted only through the UART port. With the board there, too, not everything is in order, I decided that it would come down to connect the jumpers, the device works, but it is more difficult to debug and repair.

Iteration 2

Then I decided to be confused, and to make an aesthetic case, for this the clock on the IN-12 lamps was chosen, it would be better if I made them in a printed case. To reduce the size of the board, I used the Arduino ProMini, DC-DC made on the popular and old MC34063 (this is a trouble-free mikruha, simple as a corner of the house and cheap). Also in this iteration, I decided not to use transistor switches, and replaced them with high-voltage TLP627 optocouplers.

Adjustment of the time takes place through the UART or the buttons on the back of the watch. I could not find / adapt ready-made libraries for my watches, so I had to write the “menu” to adjust the time myself.

The hull is made of end cut of birch. I had to suffer with the case: the lamps have an oblong-rounded shape, it was not possible to choose a forstner drill or to choose a milling cutter for them due to hard conclusions and also because of the difference in the size of the lamp bulb. Therefore it was necessary to drill 2 holes and then with the help of a rasp and a file to give the desired shape, because of this, there are some flaws in the exact fit.

In general, the lamps were not very much liked, it is clear why they are so cheap and in such quantities are sold. Due to the fact that they are designed for horizontal execution, their angle of view is not very impressive, and it is also more noticeable that the cathodes are located at different "depths" in comparison with the same IN-14.

Iteration 3

Given the shortcomings of the previous iterations, I made 3 hours option. Solutions with the BB part and the brains are the same as in version 2: Arduino ProMini, MC34063, TLP627, c155id1, IN-14 lamps. The hull made a canon of wood, this time an ash tree, which he took from a friend. The clock turned out pretty tiny.

The board provides lighting and airflow, but not physically implemented. Practice has shown that with the backlight at night the numbers can be seen worse, at least with my not 100% vision. Airflow is also not needed, since the transistor remains cold. The time setting is done with the buttons on the back of the watch. Now at home I have 3 hours on GRI, you can begin to distribute.

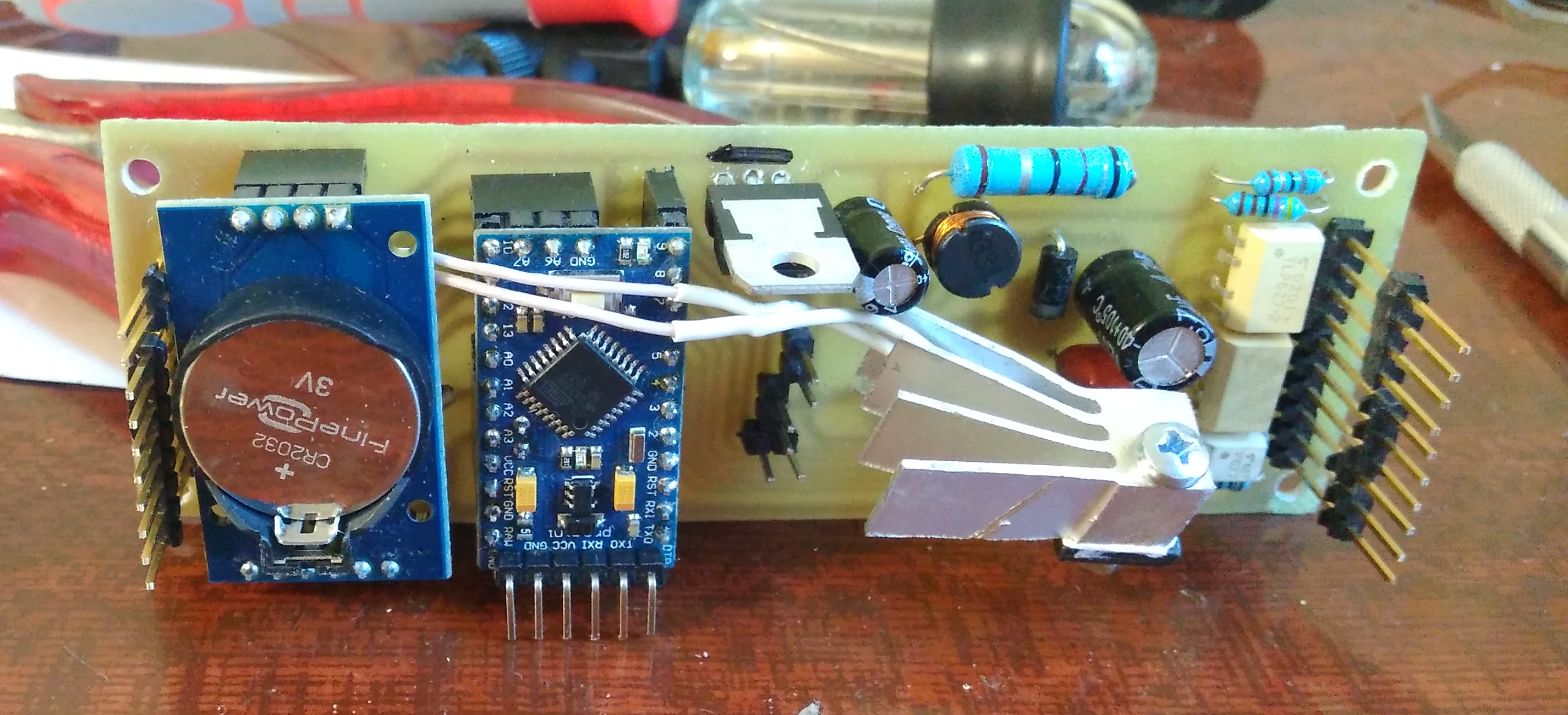

But in this experiment and obtaining a pleasant experience in the design and implementation are not completed. I have already prepared the 4th iteration of the clock, this time I want to abandon the buttons in favor of setting using a web server and a smartphone. For this, I prepared just such a fee for the next hours, until I decided what kind of lamps would be used, but most likely IN1.

Review of all my watches I made in the video, with a demonstration of the guts and design errors.

Links to resources are here .

Source: https://habr.com/ru/post/456506/

All Articles