I make a big half-bed on solar panels for 250,000 rubles (1 part)

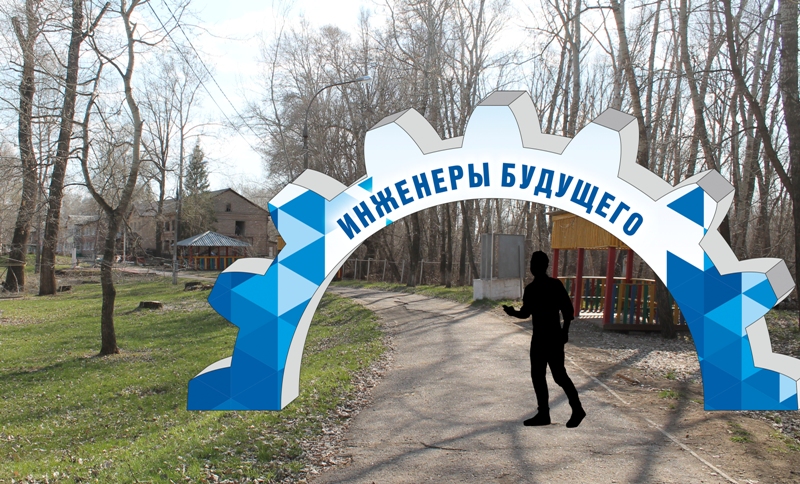

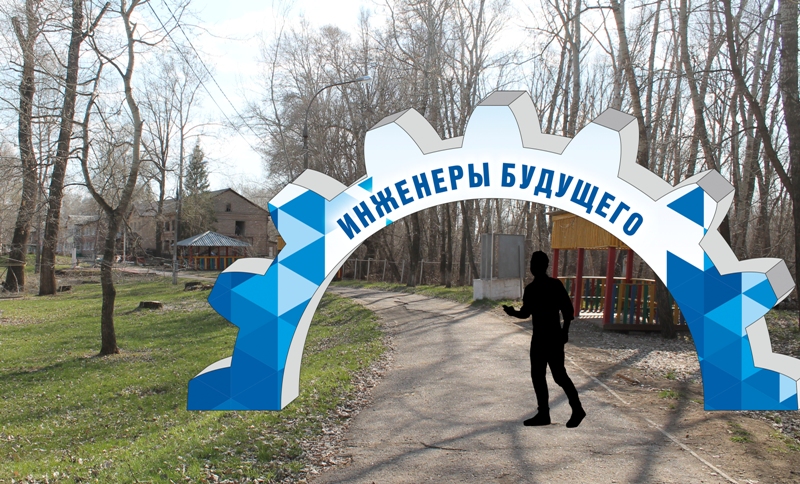

He developed a rather complicated structure: a half-blemish for the international forum “Engineers of the Future”. It will be held in Orenburg. Earlier, in 2015, a similar construction was already under Miass, but not so functional. I added solar charging panels for phones to it, designed a backlight and changed the configuration of the “teeth” of the gear - more realistic.

So it was earlier under Miass: at least 5-6 people should pass under the “arch”.

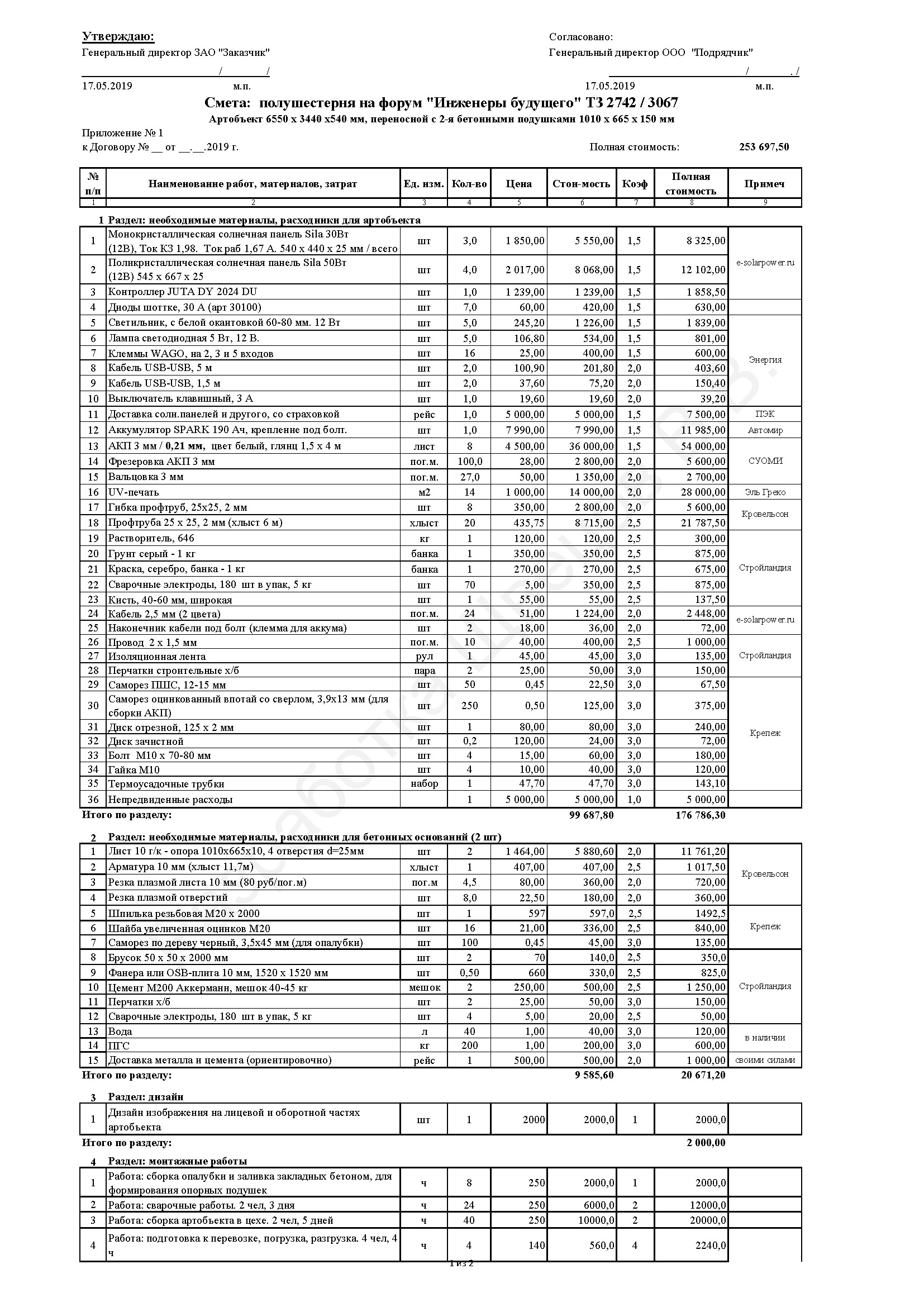

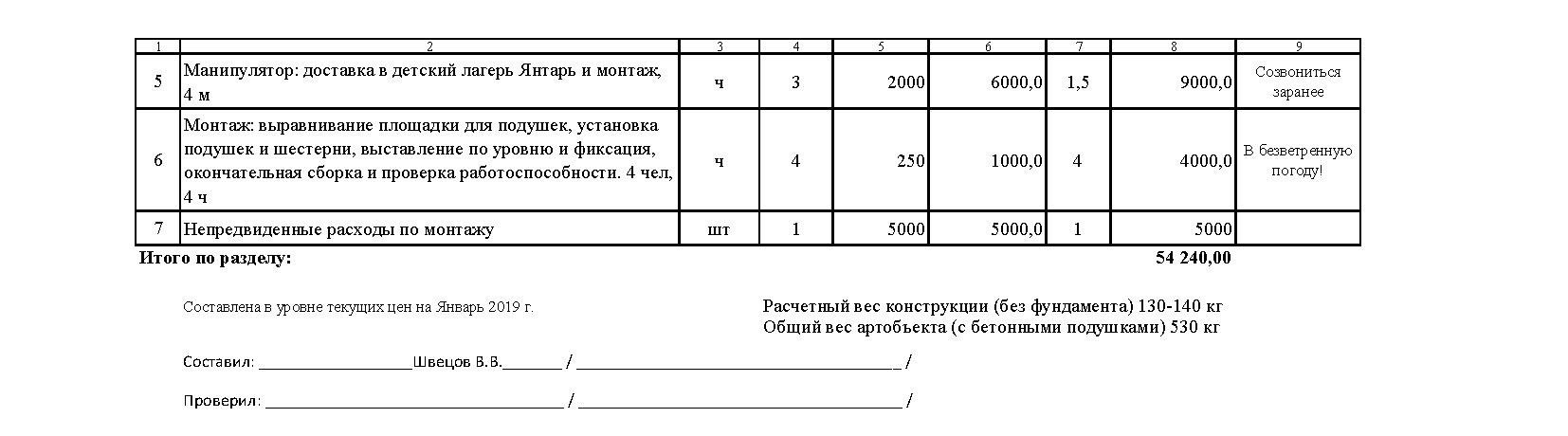

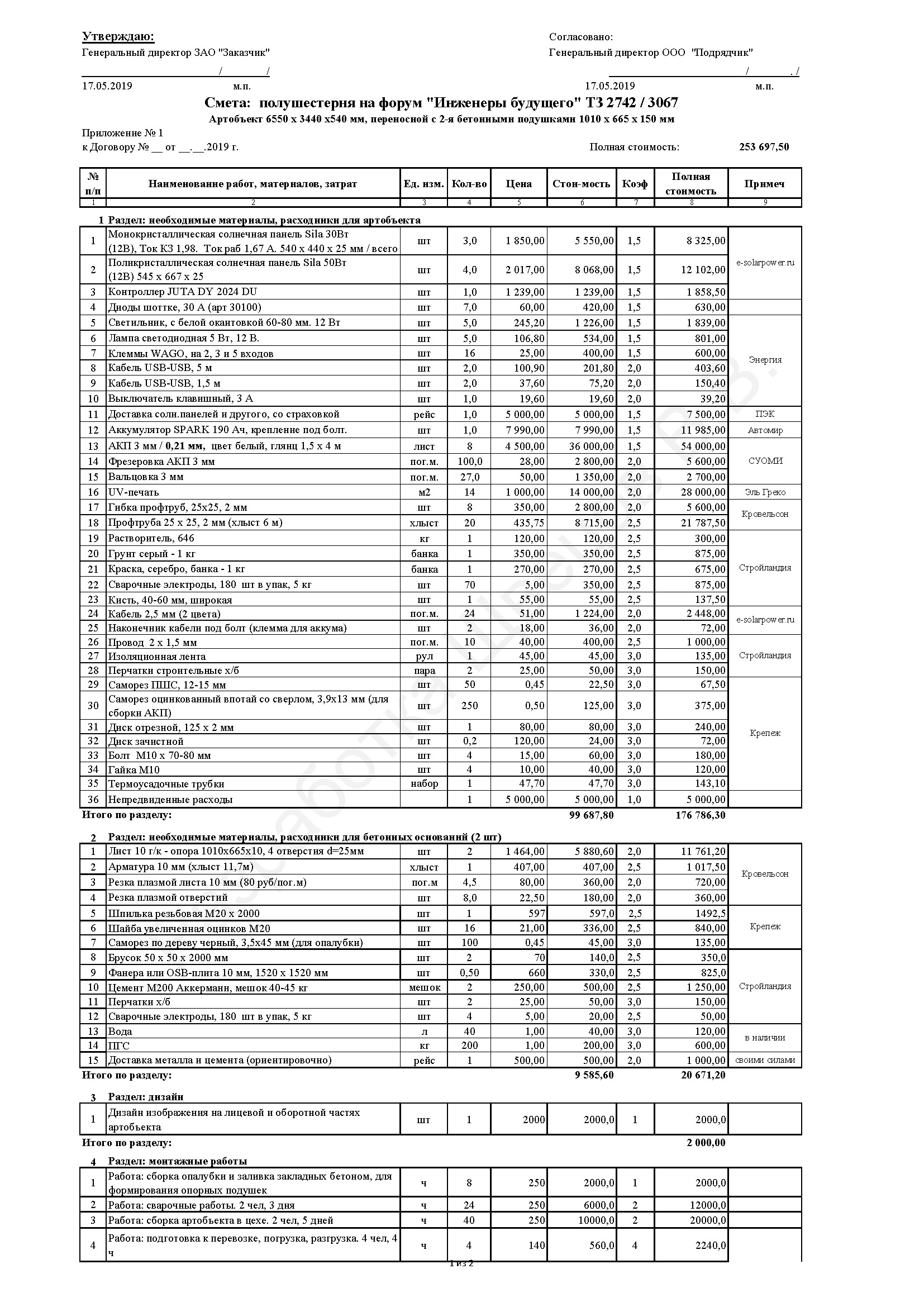

It all started with a trip to Yantar summer camp, where the installation of this miracle was supposed. And so, I leave for the place, and there is completely terrain: the lake, the slopes, the narrow paths. We'll have to put the gear on the concrete cushions with a preliminary alignment of the surface. I calculated the estimate, estimated - 250 000 rubles with a tail, but the customers liked it.

')

Initial photo snap. Print design will undergo dramatic changes later.

When I "defended" my project, I had to lay in the estimate an additional metal on the support frame, since due to the large sail area, an artillery object can easily fall, during a gale and crush ... a fox (like last time).

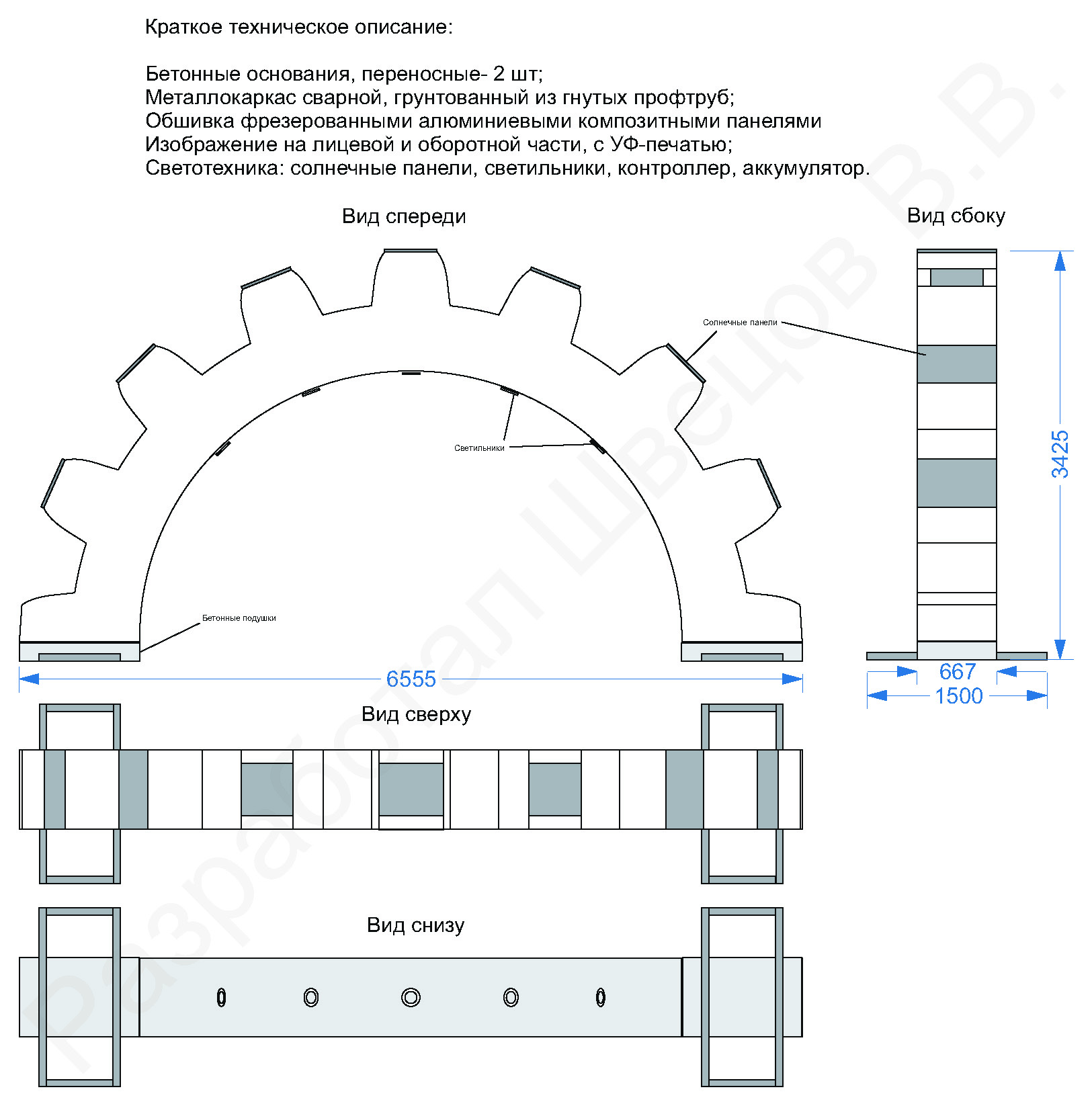

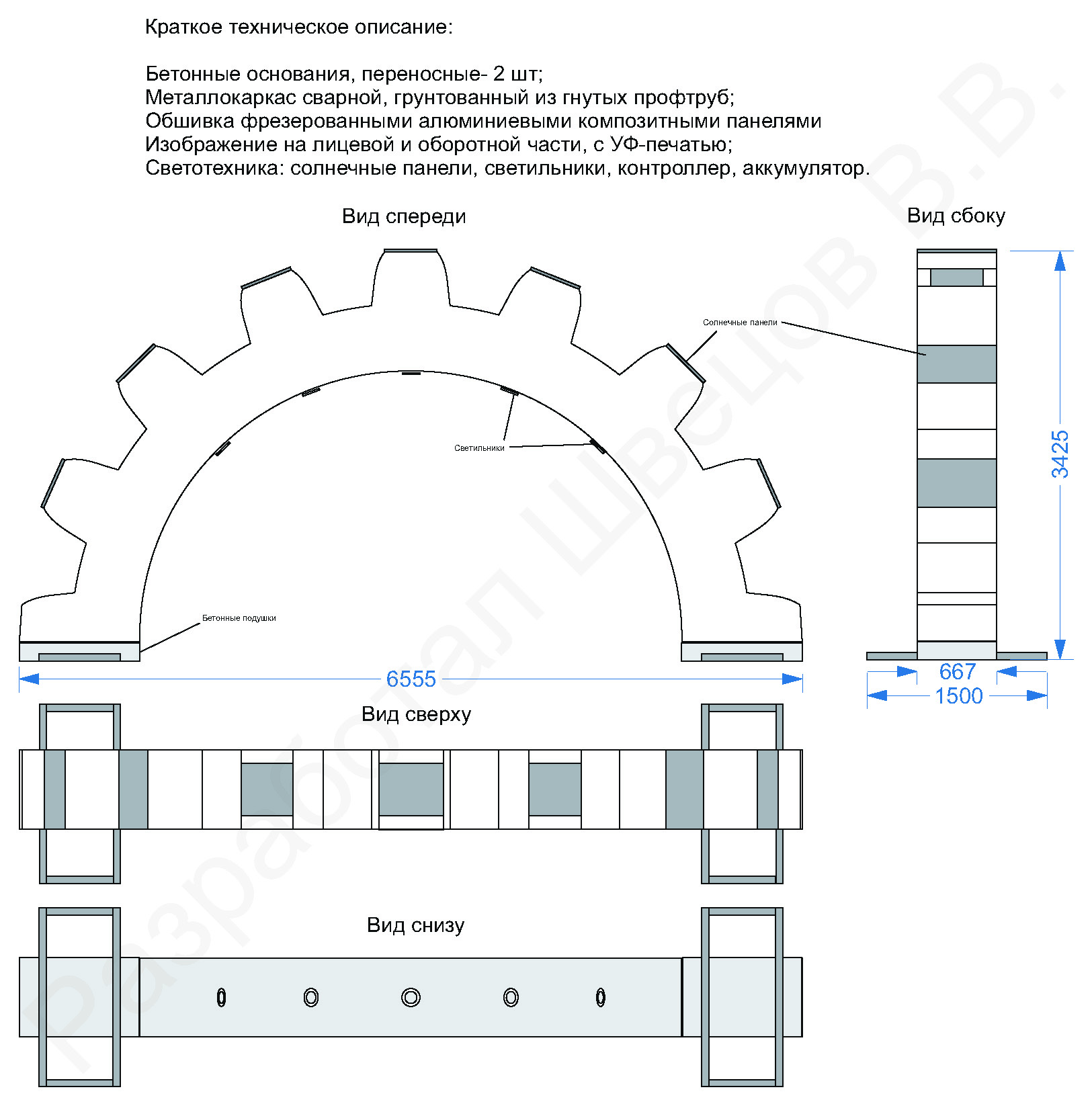

The principle of operation is as follows: I place solar panels on the outer surfaces of the half-gear teeth, they charge the battery at 190 Ah, through the controller, it is powered by 7-watt LED spotlights. And so on 4 USB ports - 5V / 2A, for charging gadgets and mobile phones. During the day, the battery charges, discharges at night, it's simple. Why not just conduct electricity at 220 V? The fact is that I am now engaged in the promotion of my project of solar mobile power plants (not advertising) and this design experience will be useful to me.

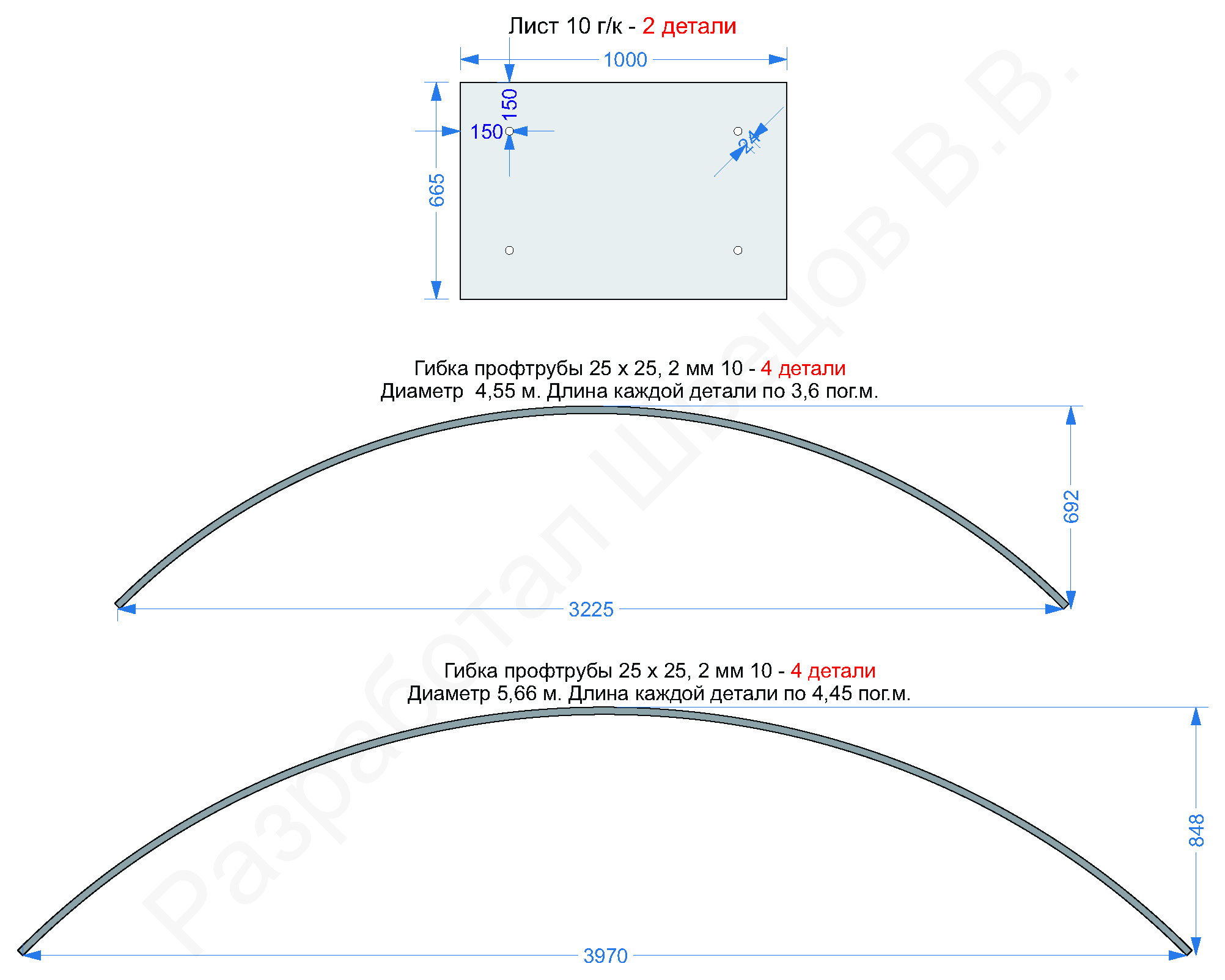

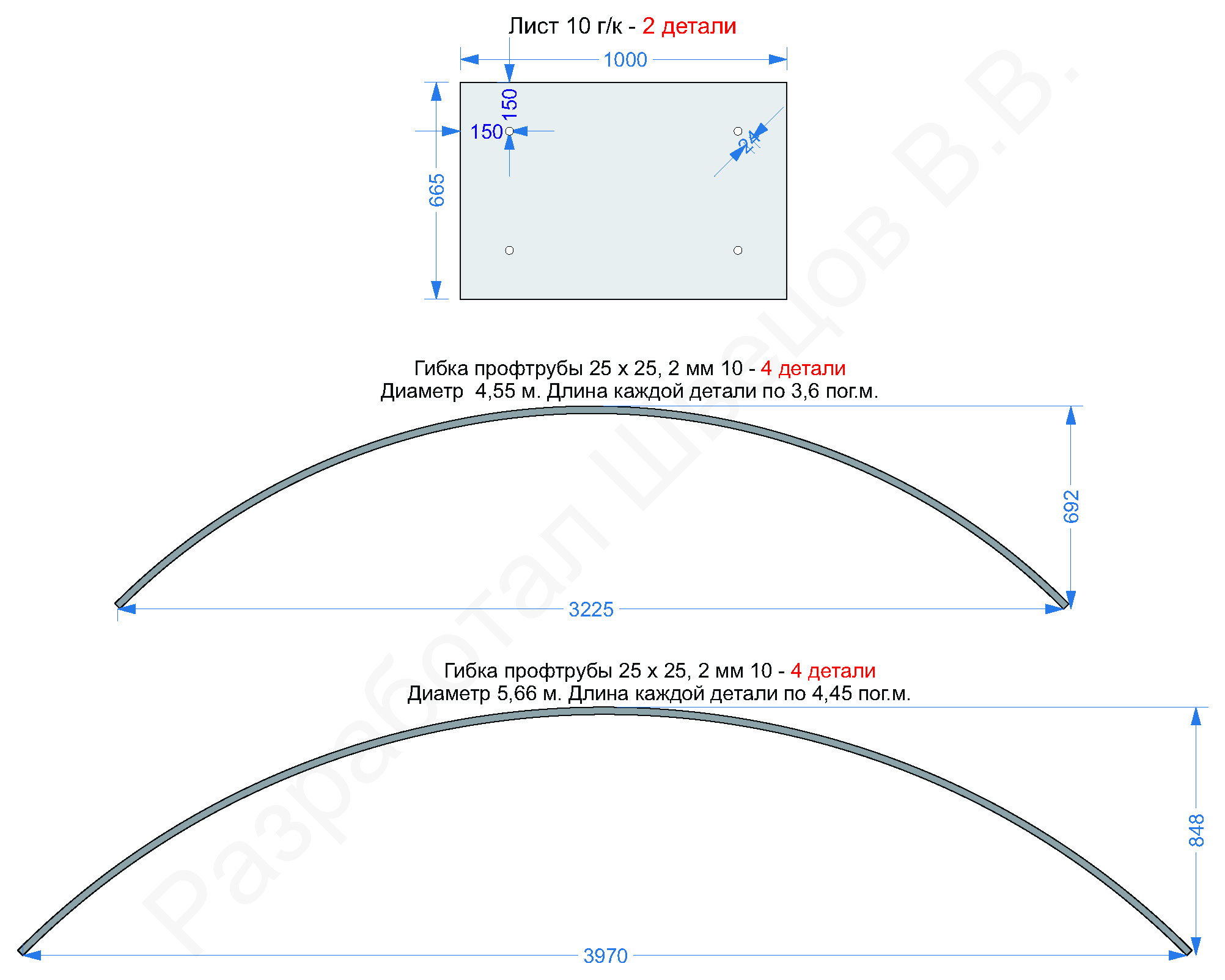

Since our own pipe bender still remains only in dreams - again we have to bend the pipe bends to an outsourcing)), along with cutting and drilling the support sheets. In previous times, Krellson bent very crookedly (which has damaged his reputation), this time I will go personally to check.

The order are flexible pipelines and laser cutting of the base for mortgages.

With the initial calculation, planned that there will be 7 solar panels

monocrystalline 30 W each. Based on their size and designed the area of the "tooth". But when it came time to make an application to the supplier (in Vladik), it turned out that 30 watt remained in the presence of only 3 pcs. I had to "finish off" the order with 50 watt panels - polycrystalline. In principle, it is even better, since mono will be in the center, under direct sunlight, and poly will catch dispersed sunlight at the edges. But, because of this, the dimensions of the teeth and the half-gear in general have changed slightly.

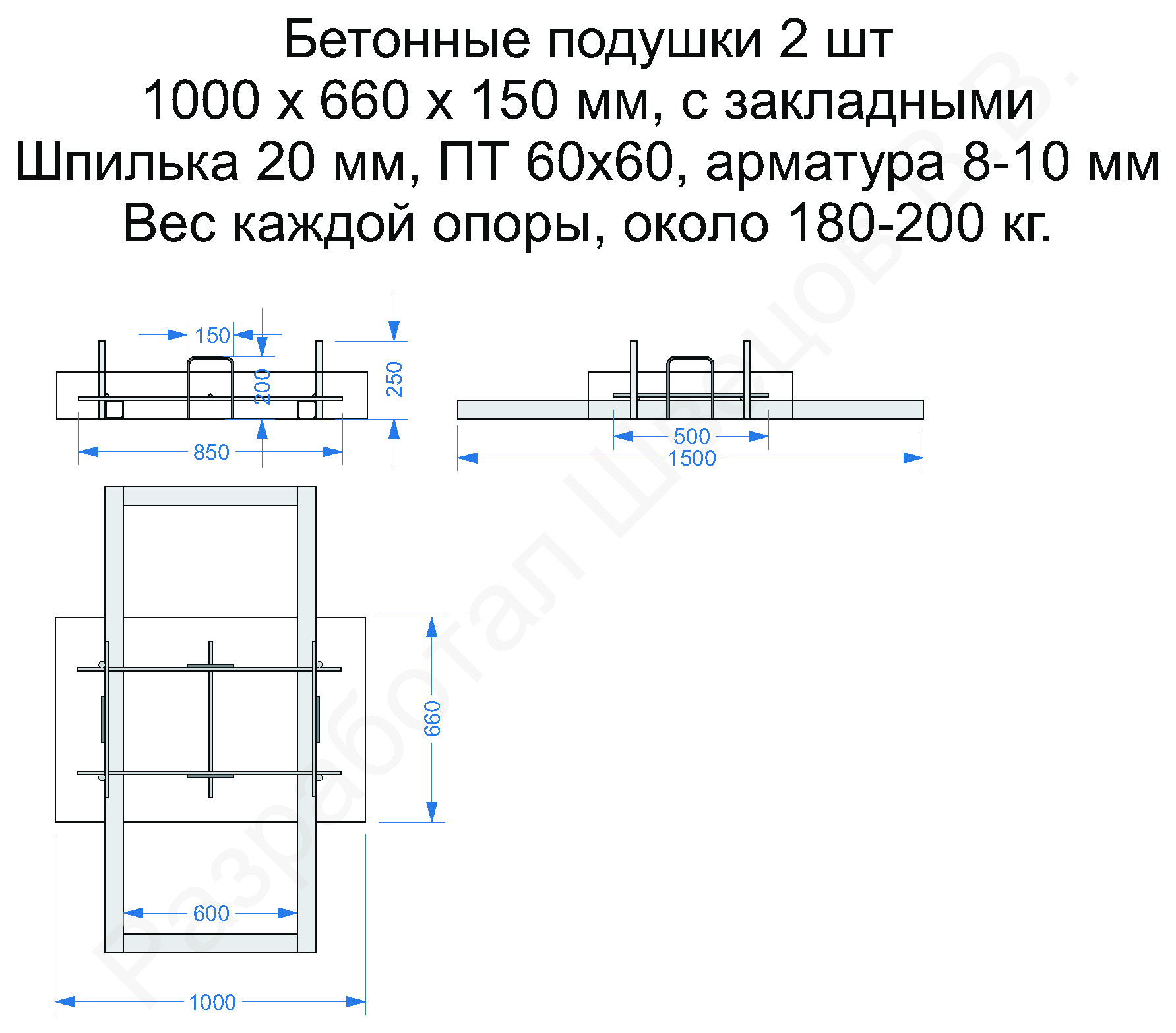

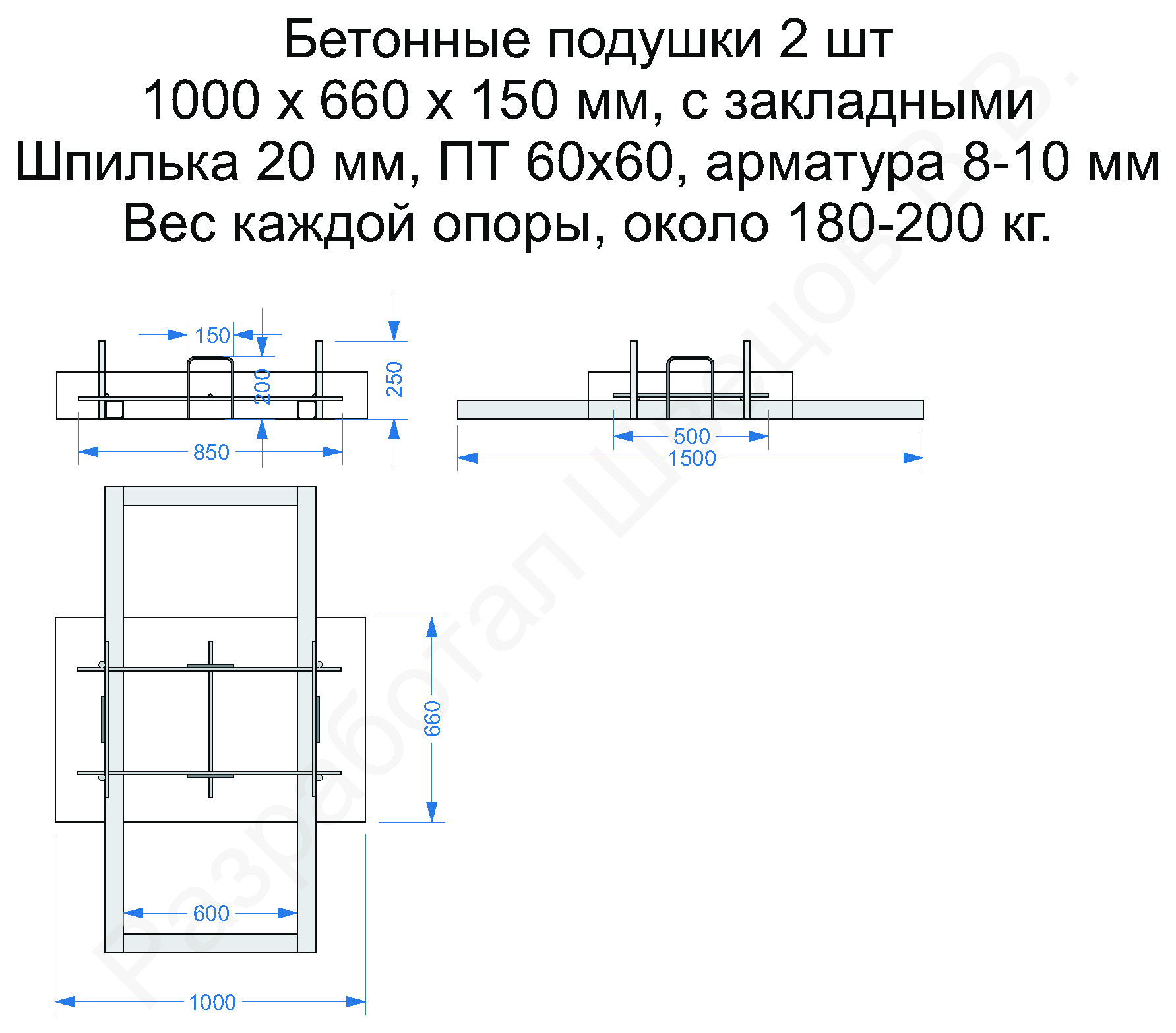

Concrete foundations I plan to do for 1 day, along with the construction of formwork. I'll start doing next Monday. Let's see how it goes. The main thing in advance to weld mortgages. The formwork will be made of OSB-plate moisture-resistant, so that the concrete gained its brand strength longer.

Each pillow will weigh about 200 kg, so it planned for each of 4 "ear" of reinforcement - handles for carrying 4 people. So before the installation I plan to move the manipulator. But when the customer wants to remove the structure, he will have to tinker.

I figured at once on 2 concrete bases, so as not to wait until one hardens and then not to break the formwork before pouring concrete of the second base.

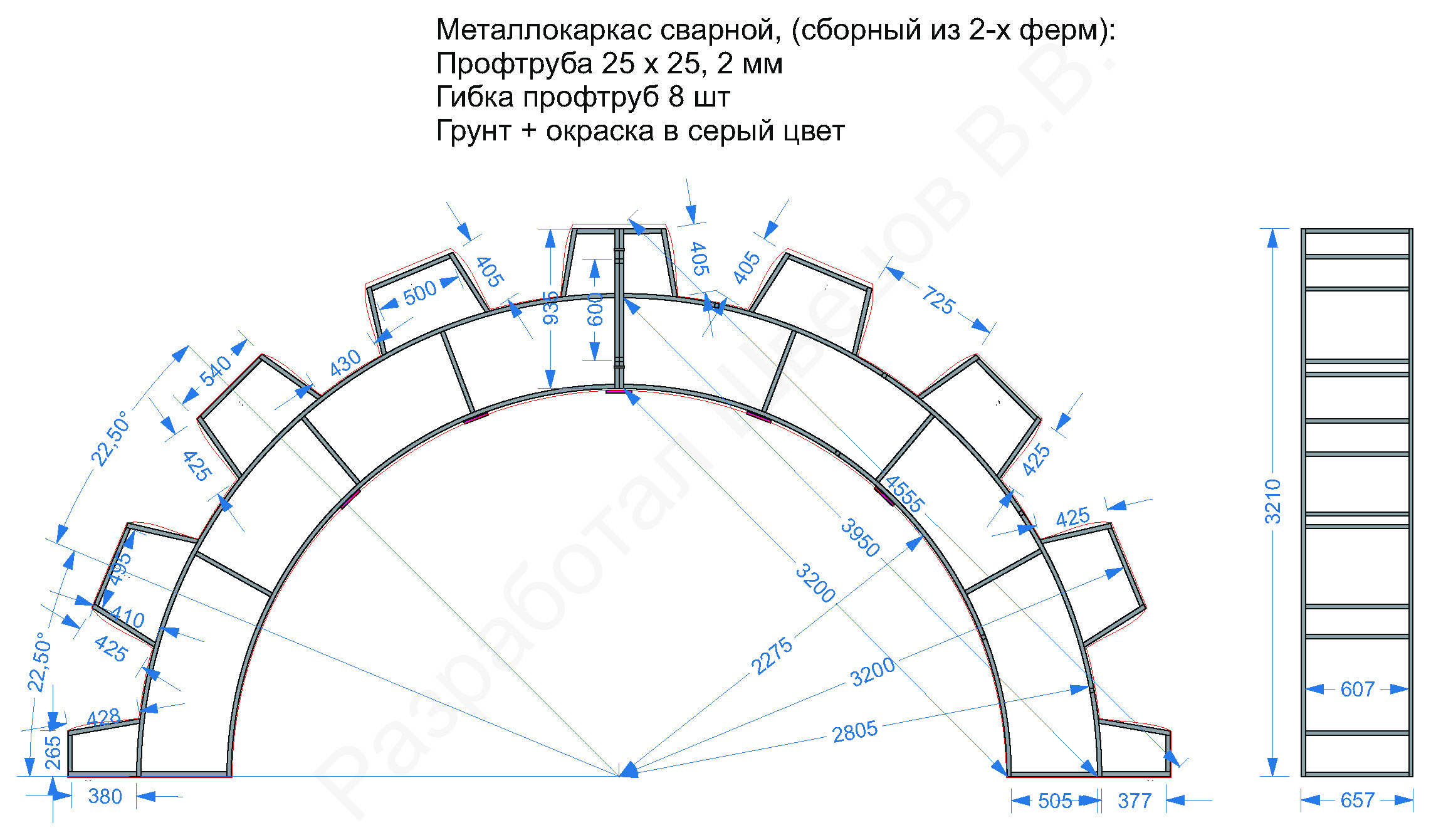

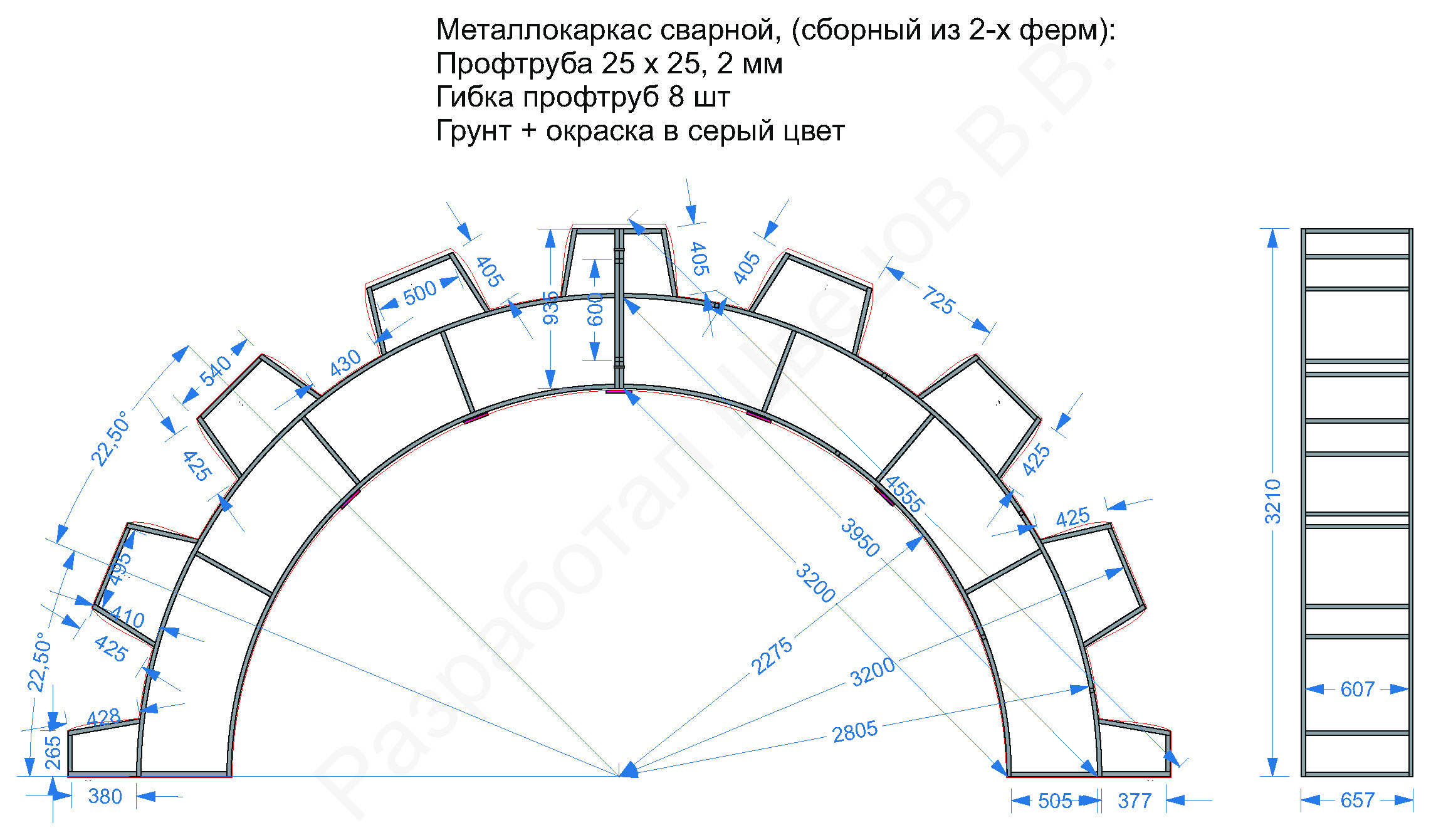

As always, a colleague - the welder saw what I wore in Korela - a skeleton drawing, so he immediately wanted to go to the hospital. And this is despite the fact that he was specially summoned from vacation for this order.

Drawing of a welded, collapsible frame half-gear from a professional pipe 25x25, 2 mm.

I think that the whole frame to make teams from 2 farms. So that the door entered when I will sheathe composite panels.

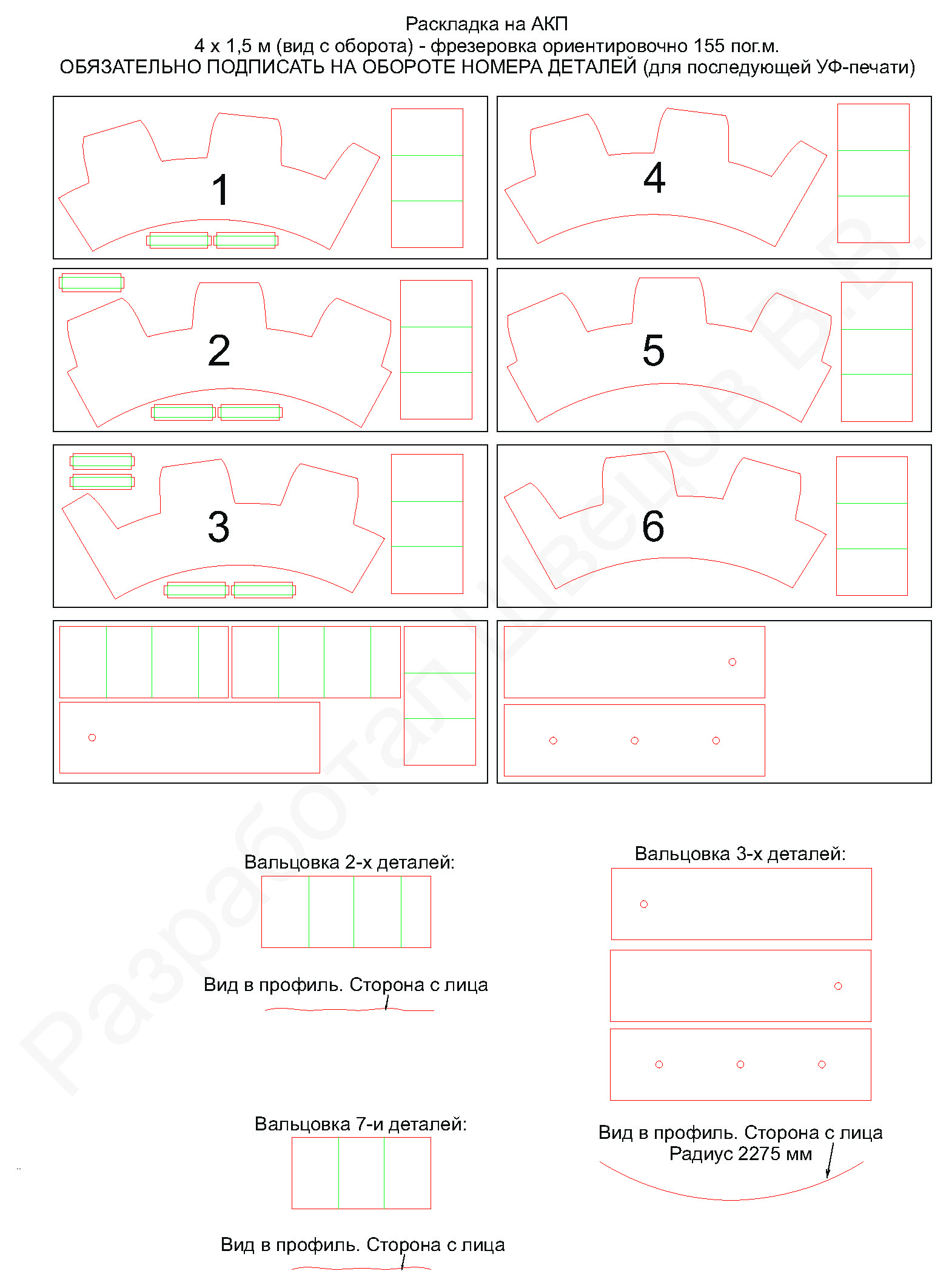

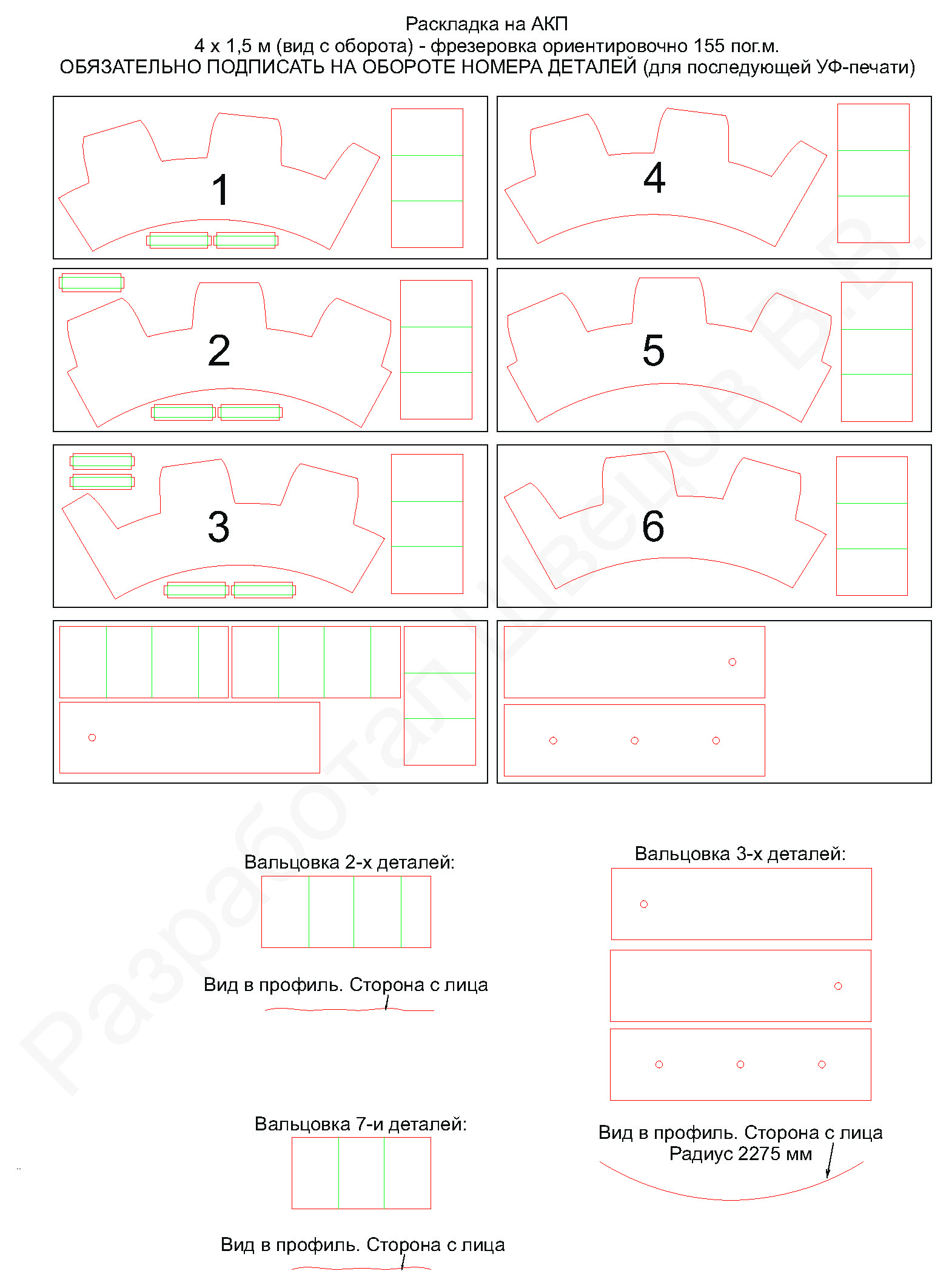

But, unfortunately, since all advertisers are limited to the size of an aluminum composite sheet of 1.5 x 4 m, UV printing will have to be done with joints on the front and back of the image. Moreover, the size of UV printing is a maximum of 3.2 x 2 m.

I figured out how the image printed on aluminum panels will be cut “end-to-end”.

Regarding the connection: if all the panels are connected via MS-4 connectors, then the price tag will be pretty pretty, so I decided to do everything on the WAGO terminal blocks, especially since the design is collapsible. What I don’t really like is that the connection of all panels had to be made parallel. Oddly enough, all solar panels and other equipment flew from Vladik to Orenburg in 3 days. Cool, very cool, delivery of about 5 thousand rubles. (via MSC) by plane, with the help of the EMC of the Russian Post. I did not think that “our postmen” became so nimble.

The wiring diagram (without the "chips"). I will fasten all the wires to the WAGO terminals.

Also, I included Schottky diodes of 30 A in the circuit, so that at night there was no reverse discharge to the solar panels.

Now, on the outer skin: I plan to put all composite sheets to the metal on the brass self-tapping screws “flush”. But only the end panels. The front parts will be screwed on the inside to PVC chopikas, which, in turn, will be mounted on a metal frame. The only thing that is doubtful is anti-vandalism. For any young people from the tent camp (there will be 1,200 people on the forum), they will climb onto the facility - take a selfie. It would not have bent. What do you think will survive?

Drawing milling with rolling.

Laid a few details "in reserve" - for marriage.

Everything, all drawings are ready, materials are paid and received. Starting next Monday, I begin to make the half-curtain. Time for everything before installation - 5 days. I will cover the assembly and installation in the second part. Subscribe - the most interesting is ahead.

So it was earlier under Miass: at least 5-6 people should pass under the “arch”.

It all started with a trip to Yantar summer camp, where the installation of this miracle was supposed. And so, I leave for the place, and there is completely terrain: the lake, the slopes, the narrow paths. We'll have to put the gear on the concrete cushions with a preliminary alignment of the surface. I calculated the estimate, estimated - 250 000 rubles with a tail, but the customers liked it.

')

Initial photo snap. Print design will undergo dramatic changes later.

When I "defended" my project, I had to lay in the estimate an additional metal on the support frame, since due to the large sail area, an artillery object can easily fall, during a gale and crush ... a fox (like last time).

The principle of operation is as follows: I place solar panels on the outer surfaces of the half-gear teeth, they charge the battery at 190 Ah, through the controller, it is powered by 7-watt LED spotlights. And so on 4 USB ports - 5V / 2A, for charging gadgets and mobile phones. During the day, the battery charges, discharges at night, it's simple. Why not just conduct electricity at 220 V? The fact is that I am now engaged in the promotion of my project of solar mobile power plants (not advertising) and this design experience will be useful to me.

Since our own pipe bender still remains only in dreams - again we have to bend the pipe bends to an outsourcing)), along with cutting and drilling the support sheets. In previous times, Krellson bent very crookedly (which has damaged his reputation), this time I will go personally to check.

The order are flexible pipelines and laser cutting of the base for mortgages.

With the initial calculation, planned that there will be 7 solar panels

monocrystalline 30 W each. Based on their size and designed the area of the "tooth". But when it came time to make an application to the supplier (in Vladik), it turned out that 30 watt remained in the presence of only 3 pcs. I had to "finish off" the order with 50 watt panels - polycrystalline. In principle, it is even better, since mono will be in the center, under direct sunlight, and poly will catch dispersed sunlight at the edges. But, because of this, the dimensions of the teeth and the half-gear in general have changed slightly.

Concrete foundations I plan to do for 1 day, along with the construction of formwork. I'll start doing next Monday. Let's see how it goes. The main thing in advance to weld mortgages. The formwork will be made of OSB-plate moisture-resistant, so that the concrete gained its brand strength longer.

Each pillow will weigh about 200 kg, so it planned for each of 4 "ear" of reinforcement - handles for carrying 4 people. So before the installation I plan to move the manipulator. But when the customer wants to remove the structure, he will have to tinker.

I figured at once on 2 concrete bases, so as not to wait until one hardens and then not to break the formwork before pouring concrete of the second base.

As always, a colleague - the welder saw what I wore in Korela - a skeleton drawing, so he immediately wanted to go to the hospital. And this is despite the fact that he was specially summoned from vacation for this order.

Drawing of a welded, collapsible frame half-gear from a professional pipe 25x25, 2 mm.

I think that the whole frame to make teams from 2 farms. So that the door entered when I will sheathe composite panels.

But, unfortunately, since all advertisers are limited to the size of an aluminum composite sheet of 1.5 x 4 m, UV printing will have to be done with joints on the front and back of the image. Moreover, the size of UV printing is a maximum of 3.2 x 2 m.

I figured out how the image printed on aluminum panels will be cut “end-to-end”.

Regarding the connection: if all the panels are connected via MS-4 connectors, then the price tag will be pretty pretty, so I decided to do everything on the WAGO terminal blocks, especially since the design is collapsible. What I don’t really like is that the connection of all panels had to be made parallel. Oddly enough, all solar panels and other equipment flew from Vladik to Orenburg in 3 days. Cool, very cool, delivery of about 5 thousand rubles. (via MSC) by plane, with the help of the EMC of the Russian Post. I did not think that “our postmen” became so nimble.

The wiring diagram (without the "chips"). I will fasten all the wires to the WAGO terminals.

Also, I included Schottky diodes of 30 A in the circuit, so that at night there was no reverse discharge to the solar panels.

Now, on the outer skin: I plan to put all composite sheets to the metal on the brass self-tapping screws “flush”. But only the end panels. The front parts will be screwed on the inside to PVC chopikas, which, in turn, will be mounted on a metal frame. The only thing that is doubtful is anti-vandalism. For any young people from the tent camp (there will be 1,200 people on the forum), they will climb onto the facility - take a selfie. It would not have bent. What do you think will survive?

Drawing milling with rolling.

Laid a few details "in reserve" - for marriage.

Everything, all drawings are ready, materials are paid and received. Starting next Monday, I begin to make the half-curtain. Time for everything before installation - 5 days. I will cover the assembly and installation in the second part. Subscribe - the most interesting is ahead.

Source: https://habr.com/ru/post/455968/

All Articles