The explosion and the global conspiracy: the story of the creation of lithium-ion batteries

Before you go to reading, count how many devices with batteries are near you within a radius of several meters. Surely, you will see a smartphone, tablet, smart watch, fitness tracker, laptop, wireless mouse? All these devices are equipped with lithium-ion batteries - their invention can be considered one of the most important events in the field of energy.

Lightweight, capacious and compact lithium-ion batteries contributed to the boom of portable electronics, the existence of which was previously impossible. Here are just gadgets over the past 30 years have made a fantastic technological leap, and modern lithium-ion batteries are almost the same as the first production models of the early 1990s. Who and how invented lithium-ion rechargeable batteries, what formulations are used in them and is there a global conspiracy against "perpetual" batteries? We tell.

Legend of the first battery

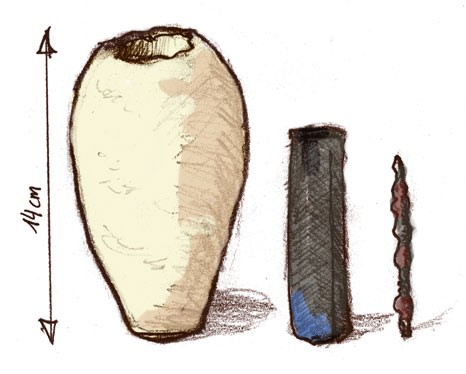

Between the first attempt to produce electricity by chemical means and the creation of lithium-ion batteries, perhaps two thousand years passed. There is an unconfirmed guess that the first man-made electroplating element in the history of mankind was the "Baghdad battery", found in 1936 near Baghdad by archeologist Wilhelm Koenig. The find, dated II-IV century BC. e., is a clay vessel in which there is a copper cylinder and an iron rod, the space between which could be filled with an “electrolyte” - an acid or alkali. Modern reconstruction of the find has shown that by filling the vessel with lemon juice it is possible to achieve voltages up to 0.4 volts.

')

"Baghdad battery" is quite similar to a portable battery. Or a cover for papyrus? Source: Ironie / Wikimedia

What could the “Baghdad battery” be used for, if before the discovery of electricity there remained a couple thousand years? Perhaps it was used for the accurate deposition of gold on statuettes by electroplating - the current and voltage from the "battery" for this is enough. However, this is only a theory, because no evidence of the use of electricity and this very “battery” by the ancient peoples reached us: gilding was applied by amalgamation at that time, and the unusual vessel itself could be just a protected scroll container.

Small bang theory

The Russian proverb “Happiness, yes, misfortune helped” illustrates the progress of work on lithium-ion batteries as well as possible. Without one unexpected and unpleasant incident, the creation of new batteries could be delayed for several years.

Back in the 1970s, the British Stanley Whittingham (Stanley Whittingham), who worked at the Exxon fuel and energy company, used a titanium sulphide anode and a lithium cathode to create a rechargeable lithium battery. The first rechargeable lithium battery showed tolerable performance in terms of current and voltage, only periodically exploded and poisoned it with gas: titanium disulfide released hydrogen sulfide when in contact with air, which is at least unpleasant to breathe, as a maximum is dangerous. In addition, titanium was at all times very expensive, and in the 1970s, the price of titanium disulfide was about $ 1,000 per kilogram (the equivalent of $ 5,000 in our time). Not to mention the fact that metallic lithium burns in the air. So Exxon turned the Whittingham project out of harm's way.

In 1978, Koichi Mizushima, who defended his doctoral degree in physics, was engaged in research work at Tokyo University when he was invited from Oxford to join John Goodenough's group, who was searching for new materials for battery anodes. It was a very promising project, since the potential of lithium power sources was already known, but it was impossible to tame a capricious metal - the recent Whittingham experiments showed that the desired lithium-ion batteries were still far from the start of mass production.

The experimental batteries used a lithium cathode and a sulphide anode. The superiority of sulphides over other materials in the anodes set Mizushima and his colleagues the direction to search. The scientists ordered an on-site sulphide production furnace in their laboratory to experiment with various compounds more quickly. Work with the stove did not end very well: one day it exploded and caused a fire. The incident forced the research team to reconsider their plans: perhaps sulfides, despite their effectiveness, were not the best choice. Scientists have shifted their attention towards oxides, which were much safer to synthesize.

After many tests with various metals, including iron and manganese, Mizushima found that lithium-cobalt oxide showed the best results. It’s only necessary to use it differently, as Gudenaf’s team suggested before, to look for not the material that absorbs lithium ions, but the material that most readily gives lithium ions. Cobalt fits better than others because it meets all safety requirements and also raises the cell voltage to 4 volts, that is, twice as much as the earlier battery variants.

The use of cobalt was the most important, but not the last step in the creation of lithium-ion batteries. Having coped with one problem, the scientists faced another: the current density was too low for the use of lithium-ion cells to be economically justified. And the team that made one breakthrough made the second one: while reducing the electrode thickness to 100 microns, it was possible to increase the current to the level of other types of batteries, with double the voltage and capacity.

First commercial steps

The history of the invention of lithium-ion batteries does not end there. Despite the discovery of Mizushima, Gudenaf’s team did not yet have a sample ready for mass production. Due to the use of lithium metal in the cathode during battery charging, lithium ions did not return to the anode in an even layer, but dendrites - in relief chains, which, growing, caused a short circuit and fireworks.

In 1980, Moroccan scientist Rachid Yazami (Rachid Yazami) discovered that graphite copes well with the role of the cathode, while it is absolutely fire safe. Here are just existing at that time organic electrolytes quickly decomposed by contact with graphite, so Yazami replaced them with solid electrolyte. The graphite cathode Yazami was inspired by the discovery of the conduction of polymers by Professor Hideki Shirakawa, for which he won the Nobel Prize in Chemistry. A graphite cathode Yazami is still used in most lithium-ion batteries.

Run into production? And no again! It took another 11 years, the researchers increased the safety of batteries, increased voltage, experimented with different materials of the cathode, before the first lithium-ion battery went on sale.

The commercial sample was developed by Sony and the Japanese chemical giant Asahi Kasei. The battery for the Sony CCD-TR1 amateur camcorder has become one. It withstood 1000 charging cycles, and the residual capacity after such wear was four times higher than that of a similar type of nickel-cadmium battery.

Cobalt stumbling block

Before the discovery of Koichi Mizushima lithium-cobalt oxide, cobalt was not a particularly sought-after metal. Its main deposits were discovered on the territory of Africa in a state now known as the Democratic Republic of the Congo. Congo is the largest supplier of cobalt - 54% of this metal is mined here. Due to political upheavals in the country in the 1970s, the price of cobalt soared by 2000%, but later returned to previous values.

High demand creates high prices. Neither in the 1990s, nor in the 2000s, cobalt was not one of the main metals on the planet. But what began with the popularization of smartphones in the 2010s! In 2000, the demand for metal was approximately 2,700 tons per year. By 2010, when the iPhone and Android smartphones were victorious on the planet, demand jumped to 25,000 tons and continued to grow from year to year. Now the number of orders exceeds the amount of cobalt sold by 5 times. For reference: more than half of the cobalt mined in the world goes to the production of batteries.

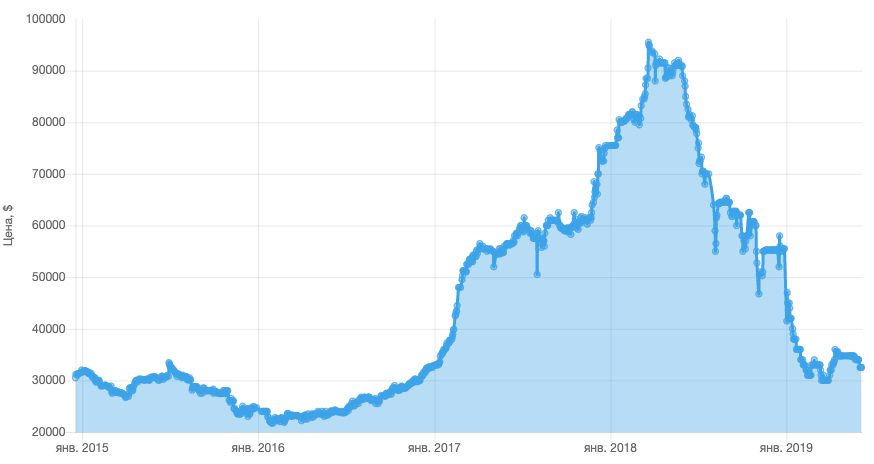

Cobalt price chart for the last 4 years. Comments are superfluous. Source: Elec.ru

If in 2017 the price per ton of cobalt averaged $ 24,000, then in 2017 it went steeply up, reaching a peak at $ 95,500 in 2018. Although smartphones use only 5-10 grams of cobalt, the rise in metal prices has affected the cost of the devices.

And this is one of the reasons why manufacturers of electric cars attended to a decrease in the share of cobalt in car batteries. For example, Tesla reduced the mass of the scarce metal from 11 to 4.5 kg per machine, and plans to find effective compositions without cobalt in the future. The price of cobalt, which has risen abnormally high, dropped to the values of 2015 by 2019, but battery developers have stepped up their efforts to prevent or reduce the proportion of cobalt.

In traditional lithium-ion batteries, cobalt makes up about 60% of the total mass. The lithium-nickel-manganese composition used in automobiles includes from 10% to 30% cobalt, depending on the desired characteristics of the battery. Lithium-Nickel-aluminum composition - only 9%. However, these mixtures are not a complete substitute for lithium-cobalt oxide.

Li-Ion problems

Today, lithium-ion batteries of various types are the best batteries for most consumers. Capacious, powerful, compact and inexpensive, they still have serious drawbacks that limit the scope of use.

Fire hazard For normal operation, the lithium-ion battery necessarily needs a power controller to prevent overcharging and overheating. Otherwise, the battery turns into a very flammable thing, trying to swell and explode in the heat or when charged from a poor-quality adapter. Explosiveness - perhaps the main drawback of lithium-ion batteries. To increase the capacity inside the batteries, the layout is sealed, which causes even minor damage to the casing to instantly cause a fire. Everyone remembers the sensational story of the Samsung Galaxy Note 7, in which, due to the cramping inside the case, the battery shell peppered over time, oxygen penetrated inside and the smartphone suddenly flared up. Since then, some airlines have required to carry lithium-ion batteries only in their carry-on baggage, and on cargo flights they pack a large warning sticker on their battery packs.

Depressurization - an explosion. Recharge - explosion. For the energy potential of lithium has to pay precautionary measures

Aging. Lithium-ion batteries are subject to aging, even if they are not used. Therefore, purchased as a collectible unpacked smartphone 10 years ago, for example, the very first iPhone, will keep the charge significantly less due to the very aging of the battery. By the way, the recommendations to keep the batteries charged up to half the capacity have a basis - when fully charged during long storage the battery loses its maximum capacity much faster.

Self discharge Storing energy in lithium-ion batteries and storing it for many years is a bad idea. In principle, all batteries lose their charge, but lithium-ion batteries do this especially quickly. If NiMH cells lose 0.08–0.33% per month, then Li-Ion-cells lose 2-3% per month. Thus, for a year, the lithium-ion battery will lose a third of the charge, and after three years it will “sit down” to zero. In fairness, let's say that nickel-cadmium batteries are still worse - 10% per month. But that's another story.

Sensitivity to temperature. Cooling and overheating strongly influence the parameters of such a battery: +20 ° C degrees are considered the ideal ambient temperature for lithium-ion batteries. If it is reduced to +5 ° C, the battery will give the device 10% less energy. Cooling below zero takes tens of percent from the capacity and also affects the health of the battery: if you try to charge it, for example, from a power bank, a “memory effect” will appear, and the battery will permanently lose capacity due to the formation of metallic lithium on the anode. With average Russian winter temperatures, the lithium-ion cell is non-functional - leave the phone in January outside for half an hour to be convinced of this.

To cope with the problems described, scientists are experimenting with anode and cathode materials. When replacing the composition of the electrodes, one big problem is replaced by smaller problems - fire safety leads to a decrease in the life cycle, and a high discharge current lowers the specific energy consumption. Therefore, the composition for the electrodes is selected depending on the application of the battery.

Who stole the revolution?

Every year on news feeds there are messages about the next breakthrough in the creation of extremely capacious and durable batteries - it seems like smartphones will work for a year without recharging, and they will be charged for ten seconds. And where is the battery revolution that scientists promise to everyone?

Often in such reports, journalists distort the facts, omitting some very important details. For example, a battery with instant charging may have a very low capacity, suitable only for powering a bedside alarm clock. Or the voltage does not reach one volt, although for smartphones it is necessary 3.6 V. And to get a start in life, the battery needs to have low cost and high fire safety. Unfortunately, the vast majority of developments were inferior to at least one parameter, which is why “revolutionary” batteries did not go beyond the laboratories.

In the late 00s, Toshiba experimented with rechargeable fuel cells on methanol (in the photo, refilling the battery with methanol), but lithium-ion batteries were still more convenient. Source: Toshiba

And, of course, we will leave aside the theory of conspiracies “endless batteries are not profitable for manufacturers”. Nowadays, batteries in consumer devices are irreplaceable (or rather, they can be changed, but difficult). 10-15 years ago, it was easy to replace a damaged battery in a mobile phone, but then the power supplies really lost their capacity in a year or two of active use. Modern lithium-ion batteries last longer than the average life cycle of a device. In smartphones, you can think about replacing the battery no earlier than after 500 charging cycles, when it loses 10-15% capacity. And rather the phone itself will lose its relevance before the battery finally fails. That is, battery manufacturers earn not on the replacement, but on the sale of batteries for new devices. So the “eternal” battery in the ten-year-old phone will not harm business.

Gudenath's team is back in business.

And what happened to the scientists of the John Gudnaf group, who discovered the discovery of lithium-cobalt oxide and thereby gave rise to effective lithium-ion batteries?

In 2017, the 94-year-old Gudenaf said that, along with scientists from the University of Texas, he developed a new type of solid-state battery that can store 5-10 times more energy than previous lithium-ion batteries. For this, the electrodes were made of pure lithium and sodium. Promised and low price. But there is still no specifics and forecasts about the beginning of mass production. Considering the long way between the discovery of the Goudénaf group and the beginning of the mass production of lithium-ion batteries, real samples can be expected in 8-10 years.

Koichi Mizushima continues research work at Toshiba Research Consulting Corporation. “Looking back, I am surprised that no one before us had guessed using such simple material as lithium-cobalt oxide at the anode. By that time, many other oxides had been tried, therefore, probably, if not for us, then within a few months someone else would have made this discovery, ”he believes.

Koichi Mizushima with the award of the Royal Society of Chemistry of Great Britain, received for participation in the creation of lithium-ion batteries. Source: Toshiba

History does not tolerate the subjunctive moods, especially since Mr. Mizushima himself admits that a breakthrough in the creation of lithium-ion batteries was inevitable. But it’s still interesting to imagine what the world of mobile electronics would be like without compact and capacious batteries: laptops with a thickness of several centimeters, huge smartphones that require charging twice a day, and no smart watches, fitness bracelets, action cameras, quadcopters and even electric cars. Every day, scientists around the world are bringing a new energy revolution, which will give us more powerful and more compact batteries, and with them - incredible electronics, which we can only dream about.

Source: https://habr.com/ru/post/455513/

All Articles