How we set up sampling in SIBUR on new rails

And what came of it

Hello!

In production, it is important to monitor the quality of products, both coming from suppliers and the one that we issue at the outlet. To do this, we often carry out sampling - specially trained staff take samplers and collect the samples according to the available instructions, which are then transferred to the laboratory, where they are checked for quality.

')

My name is Katya, I am the owner of the product of one of the teams in SIBUR, and today I will tell you how we improved the life (at least during working hours) of the samplers and other participants in this fascinating process. Under the cut - about the hypotheses and their testing, about the attitude to the users of your digital product and a little bit about how we have everything.

It’s worth starting with the fact that our team is quite young, we have been working since September 2018, and one of our first challenges in the process of digitization of processes is production control. De facto, this is a check of everything at the stage between the receipt of raw materials to us and before the output from our production of the final product. We decided to eat the elephant piece by piece and started with sampling. After all, in order to put laboratory tests on samples on digital rails, these samples must first be collected and brought by someone. Usually with arms and legs.

The first hypotheses concerned the avoidance of paper and manual labor. Previously, the process looked like this - the person had to write on a piece of paper that he was preparing to collect in the sampler, identify himself (read - write his full name on the piece of paper and the time of sampling), stick this piece of paper on the test tube. Then go to the overpass, take a sample from several cars and return to the control room. In the control room, the person had to score the same data in the second round in the sampling report, with which the sample was sent to the laboratory. And then also to write a magazine just for myself, so that in case something happens, check it out who and when took the specific sample. A chemist, registering the sample in the laboratory, then transferred records from the papers to a special laboratory software (LIMS).

The problems are obvious. First, it takes a long time, plus we see duplication of the same operation. Secondly, low accuracy - the sampling time was written partly by the eye, because one thing that you wrote on paper was an approximate selection time, and another thing - until you reached the carriage and began to collect samples, it would be a little different time. For data analytics and process tracking, this is more important than it seems.

As you can see, the field for optimizing the process is truly unplowed.

We had little time, and we needed to do everything quickly, and within the corporate circuit. To do something in the cloud at work is a so-called undertaking, because you work with a lot of data, some of which are trade secrets or contain personal data. To create a prototype, we only needed the carriage number and the name of the product — this data was approved by the security personnel, and we started.

My team now has 2 external developers, 4 internal, designer, scrum master, and junior product. By the way, what vacancies we currently have in general .

Over the week, we gathered an admin panel for the team and an uncomplicated mobile application for users on Django. Then they finished and set up another week, and then gave them to users, trained them and started testing.

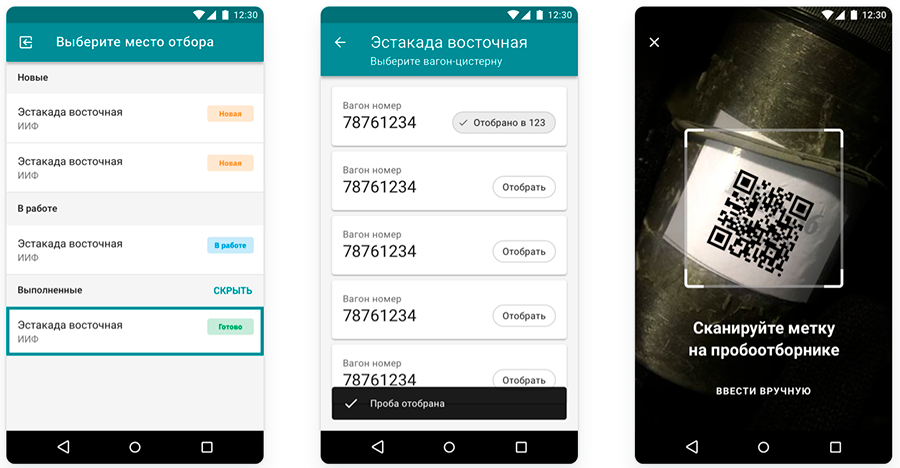

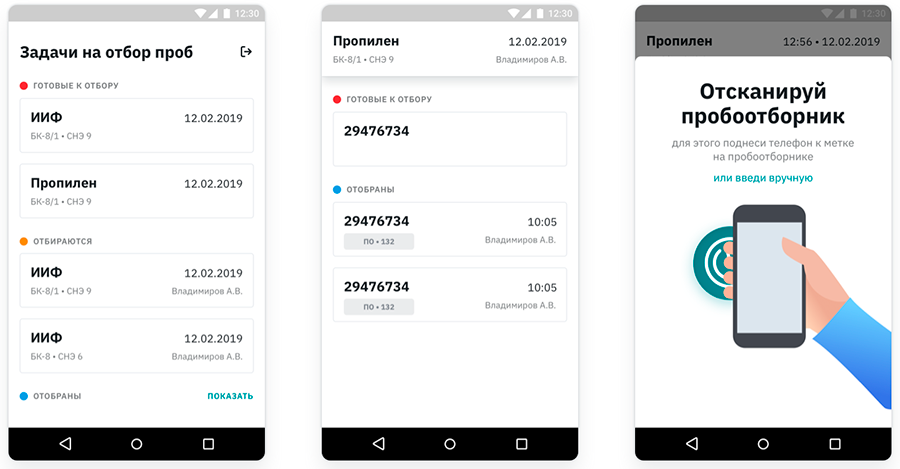

It's simple. There is a web part that allows you to create a task for sampling, and there is a mobile application for employees, where everything is clear, say, go to that overpass and collect samples from that car. At the samplers we first stuck QR codes in order not to reinvent the wheel, because we would have to coordinate a more serious sampler tuning, and then everything was harmless, glued a piece of paper and went to work. The employee only had to select the task in the application and scan the tag, after which the system recorded data that he (a particular employee) at such an exact time took samples from the car with such and such number. Figuratively speaking, "Ivan took the sample from the car number 5 at 13.44." Upon returning to the control room, he could only print out the already finished act with the same data and just put his signature on it.

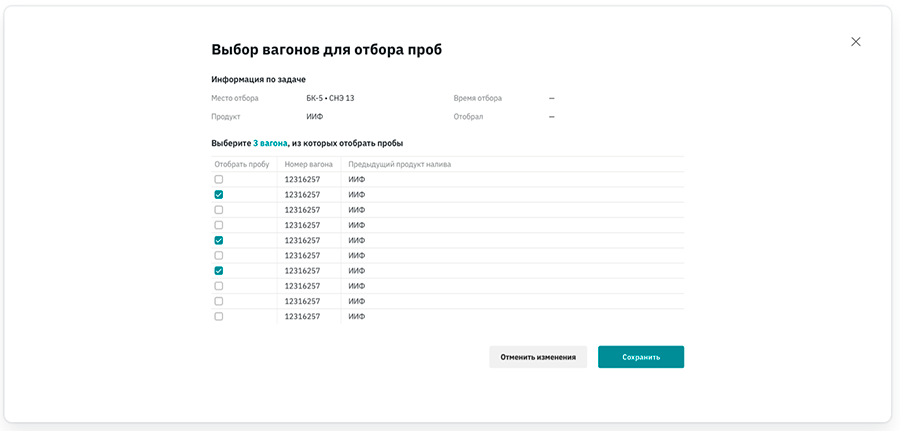

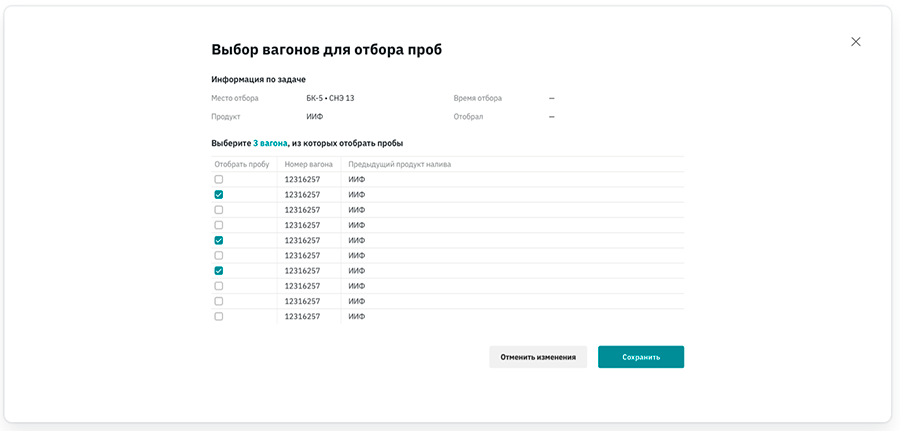

Old admin version

Creating a task in the new admin panel

The girls in the laboratory at this stage also became simpler - now you can not disassemble the inscriptions on the piece of paper, but simply scan the code and immediately understand what is in the sampler.

And here we stumbled upon a similar problem already on the laboratory side. The girls here also have their own sophisticated software, LIMS (Laboratory Information Management System), in which they had to interrupt everything from the received acts of sampling with handles. And at this stage of their pain, our prototype did not solve it in any way.

Therefore, we decided to do the integration. The ideal situation seems to be when all the stuffing that we made to integrate these opposite ends, from sampling to laboratory analysis, will help get rid of the paper altogether. The web application will replace paper logs, the selection report will be filled out automatically using an electronic signature. Thanks to the prototype, we realized that the concept can be applied, and we started the development of MVP.

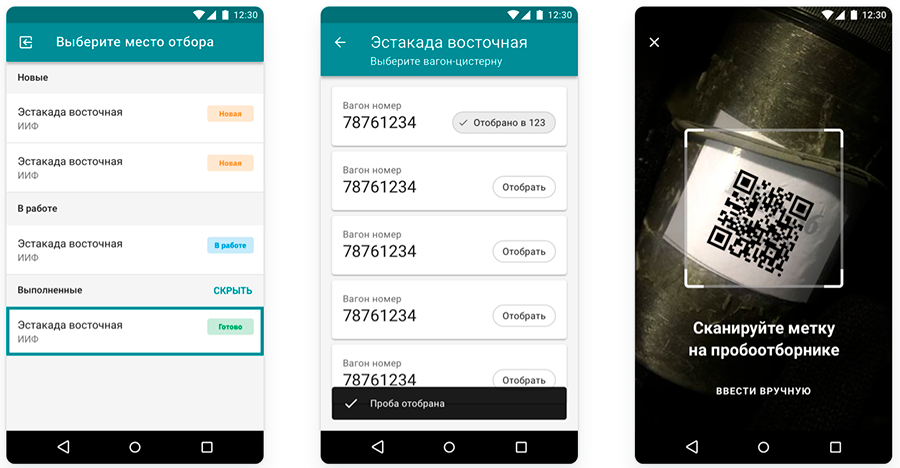

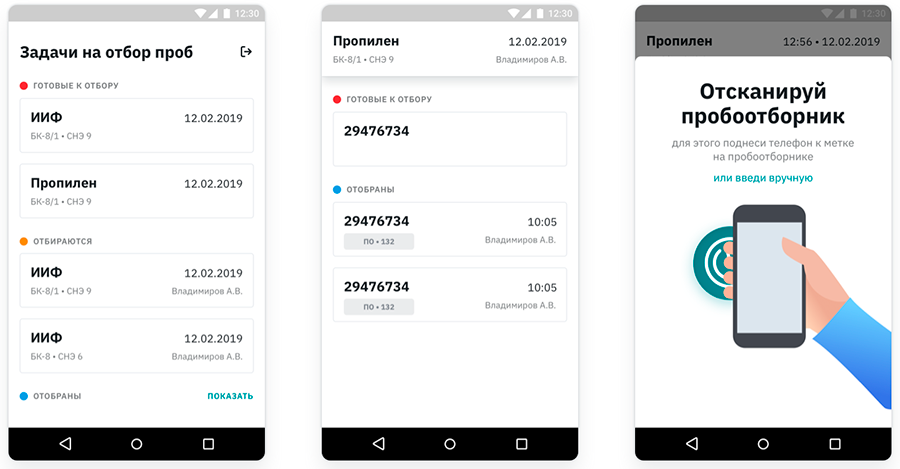

Prototype of the previous version of the mobile application

MVP new mobile app

Here it is necessary to take into account the fact that work in production is not +20 and a light breeze rattling the straw hat fields, and at times -40 and outright windwalking on which to take off gloves to tap an explosion-proof smartphone on the touch screen, do not want to. No Even under the threat of filling out paper acts and wasting time. But fingers at you.

Therefore, we changed the work process a bit - first, we sewed a series of actions on the hardware side buttons of the smartphone, which are perfectly pressed in gloves, and secondly, pumped the gloves themselves: our colleagues who are engaged in providing personnel with personal protective equipment found us gloves that meet all the necessary standards, while also with the ability to work with touch screens.

Here is a little in the video about them.

Another feedback came about the tags themselves at the samplers. The thing is that the samplers are different - plastic, glass, curved, in general, in the range. It is inconvenient to stick a QR code on curved ones, the paper is bent and may not be scanned as well as you would like. Plus, under the tape, too, scanned worse, and if the tape is wound from the heart - not scanned at all.

We replaced all this with NFC tags. This is much more convenient, but we have not yet made it very convenient - we want to switch to flexible NFC tags, but so far we have come up against agreement on explosion protection, so the labels are large, but explosion-proof. But we will work it out with our colleagues from industrial safety, so everything is still ahead.

LIMS as a system itself provides for printing barcodes for such needs, but they have one significant disadvantage - they are disposable. That is, I pasted it on the sampler, finished with the work, and it is necessary to tear it off, throw it out, and then paste a new one. Firstly, it’s not that all this is eco-friendly (the paper goes a lot more than it seems at first glance). Secondly, long. Our tags are reusable, with overwriting. When a sampler is sent to the laboratory, it is sufficient to scan it. Then the sampler is carefully cleaned and returned to take the next sample. An employee in production again scans it and writes down already new data on the label.

This approach also proved to be quite successful, and we thoroughly tested it and tried to work out all the difficult places. As a result, we are now at the stage of developing MVP in the industrial circuit with full integration into corporate systems and accounts. It helps that in time much was transferred to microservices, so there were no problems in terms of work with accounting. Unlike all the same LIMS - for her, no one did anything. Here we had certain rough edges in order to integrate it normally with our development environment, but we mastered them and in the summer we will launch everything into battle.

But what kind of case was born from a rather ordinary problem - once there was an assumption that sometimes a test of tests shows different results from the norm, because samples are corny taken badly. The hypotheses of what was happening were as follows.

We criticized the first option at the start, but just in case we also began to check.

Here I will note one important thing. We are actively teaching the company to restructure the way of thinking towards a culture of developing digital products. Previously, the thinking model was such that there is a vendor, he only needs to write a clear TK with solutions once, give it away, and let him do everything. That is, it turned out that people were de facto repelled immediately from potential ready-made solutions that had to be entered into the TK as a given, instead of starting from the existing problems that I wanted to solve.

And we are now shifting the focus from such an “idea generator” to the formulation of clear problems.

Therefore, having heard the description of these problems, we began to invent ways to test these hypotheses.

It is easiest to check the quality of work of samplers using video surveillance. It is clear that to test a new hypothesis, to take and equip an entire overpass with explosion-proof chambers is not so easy, the knee-length calculation immediately gave us many millions of rubles, and we refused it. It was decided to go to our guys from industry 4.0, who are now piloting the use of the only explosion-proof wifi camera in the Russian Federation. According to the description, this should resemble something the size of an electric kettle, but in reality this thing is not more than a marker for boards.

We took this baby and came to the overpass, telling the staff as much as possible what we are giving here, for how long and for what reason. It was important to immediately make it clear that this is in fact to test the experiment and temporary.

A couple of weeks, people worked normally, no violations were detected, and we decided to test the second hypothesis.

For quick and detailed training, we chose the format of video instructions, suspecting that an adequate video tutorial, which takes you a few minutes to watch, will show everything and everything more clearly than a 15-page job description. Moreover, they already had such an instruction.

No sooner said than done. I went to Tobolsk, looked at how they took samples, and it turned out that the fence mechanics were the same there for the last 20 years. Yes, this is a rather routine process that can be brought to automatism with frequent repetition, but this does not mean that it cannot be automated and simplified. But the original idea with the video instruction staff was rejected, they say, why should these videos be shot, if we have been doing the same thing for 20 years?

We agreed with our PR, equipped the right guy for shooting in the video, gave him an excellent shiny wrench and recorded the sampling process in ideal conditions. Such an exemplary version has been released. Then I also voiced the video for clarity.

We gathered staff from eight shifts, gave them a cinema show and asked how it was. It turned out that as when watching the first "Avengers" for the third time: cool, beautiful, but nothing new. Like, we're doing this all the time.

Then we asked the guys directly what they didn’t like in the process and what was causing inconvenience. And here already the dam broke through - after such an improvised design session with production workers, we brought the management a fairly large-scale backlog aimed at changing operating processes. Because it was necessary to first make a number of edits to the processes themselves, and then to make a digital product, which in the new conditions will be correctly perceived.

Well, seriously, if a person has a big uncomfortable sampler without a handle, you have to carry it with both hands, and you say: “You, mobile phone, scan it there, Vanya” - this is somehow not very inspiring.

People for whom you are making a product should understand that you hear them, and not just get ready to roll out some fashionable thing that they don’t need right now.

If you are making a digital product and you have a curved process - no need to implement the product yet, you need to fix this process in the first place. The concern of our direction now is to seize such processes; we continue to collect backlog during design sessions not only for a digital product, but also for global operational improvements that sometimes even happen to be implemented before the product itself. And this in itself gives an excellent effect.

It is also important that part of the team is located directly in the enterprise. We have guys from different departments who have decided to build a career in digital and help us with product introduction and learning processes. Such operational changes are prompted by them.

And it's easier for employees, they understand that we are not just gathered here to sit, but in fact we will discuss how to cancel unnecessary pieces of paper, or to make 1 paper (and then also cancel it) out of 16 necessary papers for the process, how to make EDS and optimize work with government agencies, and so on.

And if we talk about the process itself, we have found this.

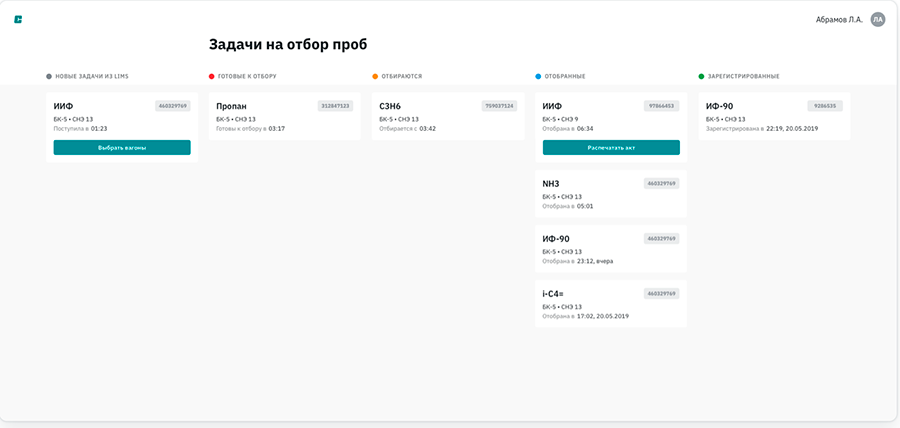

Sampling on average takes about 3 hours. And in this process there are people who act as a coordinator, and all these three hours their phone is broken and they constantly report statuses - where to send the car, how to distribute orders to laboratories, and the like. And this is on the laboratory side.

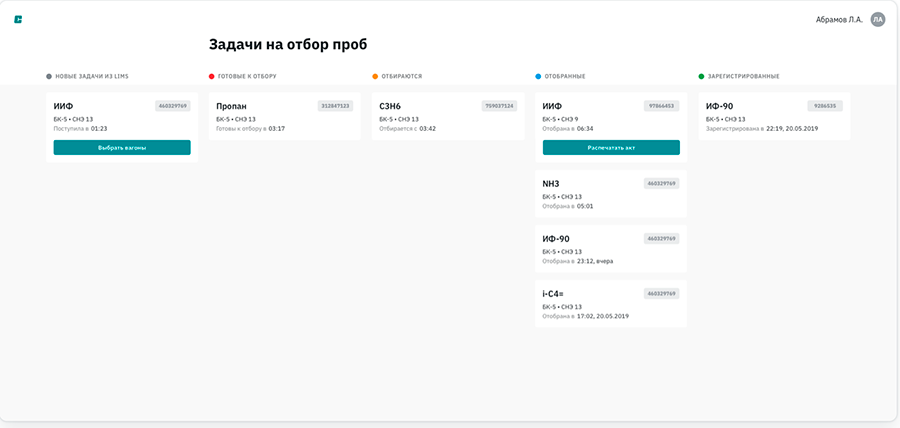

And on the production side sits the same person with the same red-hot phone. And we decided that it would be good to make them a visual dashboard, which will help to see the status of the process, from applications for sampling to issuing results in the laboratory, with the necessary notifications and other things. Then we think to connect it with the order of transport and to optimize the activities of the laboratories themselves - to distribute the work among the employees.

As a result, for one sampling cumulatively from digital and operational changes, we will be able to save about 2 hours of human labor and an hour of inactivity of the train, compared to how they worked before us. And this is only for one selection, there may be several of them per day.

Of the effects, about a quarter of the sampling is now being done this way. It turned out that we are releasing approximately 11 units of personnel for more useful work. A reduction in car-hours (and compositional-hours) opens up spaces for monetization.

Of course, not everyone fully understands what the digital team has forgotten here at all and why it is engaged in operational improvements, people have this not quite right perception, when you think that you have developed, you have done an application for you in a day and solved all the problems. But operating personnel, of course, is happy with this approach, albeit with a little skepticism.

But it is important to remember that there are no magic boxes. This is all work, research, hypothesis and testing.

Hello!

In production, it is important to monitor the quality of products, both coming from suppliers and the one that we issue at the outlet. To do this, we often carry out sampling - specially trained staff take samplers and collect the samples according to the available instructions, which are then transferred to the laboratory, where they are checked for quality.

')

My name is Katya, I am the owner of the product of one of the teams in SIBUR, and today I will tell you how we improved the life (at least during working hours) of the samplers and other participants in this fascinating process. Under the cut - about the hypotheses and their testing, about the attitude to the users of your digital product and a little bit about how we have everything.

Hypotheses

It’s worth starting with the fact that our team is quite young, we have been working since September 2018, and one of our first challenges in the process of digitization of processes is production control. De facto, this is a check of everything at the stage between the receipt of raw materials to us and before the output from our production of the final product. We decided to eat the elephant piece by piece and started with sampling. After all, in order to put laboratory tests on samples on digital rails, these samples must first be collected and brought by someone. Usually with arms and legs.

The first hypotheses concerned the avoidance of paper and manual labor. Previously, the process looked like this - the person had to write on a piece of paper that he was preparing to collect in the sampler, identify himself (read - write his full name on the piece of paper and the time of sampling), stick this piece of paper on the test tube. Then go to the overpass, take a sample from several cars and return to the control room. In the control room, the person had to score the same data in the second round in the sampling report, with which the sample was sent to the laboratory. And then also to write a magazine just for myself, so that in case something happens, check it out who and when took the specific sample. A chemist, registering the sample in the laboratory, then transferred records from the papers to a special laboratory software (LIMS).

The problems are obvious. First, it takes a long time, plus we see duplication of the same operation. Secondly, low accuracy - the sampling time was written partly by the eye, because one thing that you wrote on paper was an approximate selection time, and another thing - until you reached the carriage and began to collect samples, it would be a little different time. For data analytics and process tracking, this is more important than it seems.

As you can see, the field for optimizing the process is truly unplowed.

We had little time, and we needed to do everything quickly, and within the corporate circuit. To do something in the cloud at work is a so-called undertaking, because you work with a lot of data, some of which are trade secrets or contain personal data. To create a prototype, we only needed the carriage number and the name of the product — this data was approved by the security personnel, and we started.

My team now has 2 external developers, 4 internal, designer, scrum master, and junior product. By the way, what vacancies we currently have in general .

Over the week, we gathered an admin panel for the team and an uncomplicated mobile application for users on Django. Then they finished and set up another week, and then gave them to users, trained them and started testing.

Prototype

It's simple. There is a web part that allows you to create a task for sampling, and there is a mobile application for employees, where everything is clear, say, go to that overpass and collect samples from that car. At the samplers we first stuck QR codes in order not to reinvent the wheel, because we would have to coordinate a more serious sampler tuning, and then everything was harmless, glued a piece of paper and went to work. The employee only had to select the task in the application and scan the tag, after which the system recorded data that he (a particular employee) at such an exact time took samples from the car with such and such number. Figuratively speaking, "Ivan took the sample from the car number 5 at 13.44." Upon returning to the control room, he could only print out the already finished act with the same data and just put his signature on it.

Old admin version

Creating a task in the new admin panel

The girls in the laboratory at this stage also became simpler - now you can not disassemble the inscriptions on the piece of paper, but simply scan the code and immediately understand what is in the sampler.

And here we stumbled upon a similar problem already on the laboratory side. The girls here also have their own sophisticated software, LIMS (Laboratory Information Management System), in which they had to interrupt everything from the received acts of sampling with handles. And at this stage of their pain, our prototype did not solve it in any way.

Therefore, we decided to do the integration. The ideal situation seems to be when all the stuffing that we made to integrate these opposite ends, from sampling to laboratory analysis, will help get rid of the paper altogether. The web application will replace paper logs, the selection report will be filled out automatically using an electronic signature. Thanks to the prototype, we realized that the concept can be applied, and we started the development of MVP.

Prototype of the previous version of the mobile application

MVP new mobile app

Fingers and gloves

Here it is necessary to take into account the fact that work in production is not +20 and a light breeze rattling the straw hat fields, and at times -40 and outright windwalking on which to take off gloves to tap an explosion-proof smartphone on the touch screen, do not want to. No Even under the threat of filling out paper acts and wasting time. But fingers at you.

Therefore, we changed the work process a bit - first, we sewed a series of actions on the hardware side buttons of the smartphone, which are perfectly pressed in gloves, and secondly, pumped the gloves themselves: our colleagues who are engaged in providing personnel with personal protective equipment found us gloves that meet all the necessary standards, while also with the ability to work with touch screens.

Here is a little in the video about them.

Another feedback came about the tags themselves at the samplers. The thing is that the samplers are different - plastic, glass, curved, in general, in the range. It is inconvenient to stick a QR code on curved ones, the paper is bent and may not be scanned as well as you would like. Plus, under the tape, too, scanned worse, and if the tape is wound from the heart - not scanned at all.

We replaced all this with NFC tags. This is much more convenient, but we have not yet made it very convenient - we want to switch to flexible NFC tags, but so far we have come up against agreement on explosion protection, so the labels are large, but explosion-proof. But we will work it out with our colleagues from industrial safety, so everything is still ahead.

More about tags

LIMS as a system itself provides for printing barcodes for such needs, but they have one significant disadvantage - they are disposable. That is, I pasted it on the sampler, finished with the work, and it is necessary to tear it off, throw it out, and then paste a new one. Firstly, it’s not that all this is eco-friendly (the paper goes a lot more than it seems at first glance). Secondly, long. Our tags are reusable, with overwriting. When a sampler is sent to the laboratory, it is sufficient to scan it. Then the sampler is carefully cleaned and returned to take the next sample. An employee in production again scans it and writes down already new data on the label.

This approach also proved to be quite successful, and we thoroughly tested it and tried to work out all the difficult places. As a result, we are now at the stage of developing MVP in the industrial circuit with full integration into corporate systems and accounts. It helps that in time much was transferred to microservices, so there were no problems in terms of work with accounting. Unlike all the same LIMS - for her, no one did anything. Here we had certain rough edges in order to integrate it normally with our development environment, but we mastered them and in the summer we will launch everything into battle.

Checks and training

But what kind of case was born from a rather ordinary problem - once there was an assumption that sometimes a test of tests shows different results from the norm, because samples are corny taken badly. The hypotheses of what was happening were as follows.

- Samples are simply incorrectly taken due to non-compliance by the field staff of the technological process.

- Many newcomers come to production, they may not be able to explain everything in detail, hence the not entirely correct sampling of samples.

We criticized the first option at the start, but just in case we also began to check.

Here I will note one important thing. We are actively teaching the company to restructure the way of thinking towards a culture of developing digital products. Previously, the thinking model was such that there is a vendor, he only needs to write a clear TK with solutions once, give it away, and let him do everything. That is, it turned out that people were de facto repelled immediately from potential ready-made solutions that had to be entered into the TK as a given, instead of starting from the existing problems that I wanted to solve.

And we are now shifting the focus from such an “idea generator” to the formulation of clear problems.

Therefore, having heard the description of these problems, we began to invent ways to test these hypotheses.

It is easiest to check the quality of work of samplers using video surveillance. It is clear that to test a new hypothesis, to take and equip an entire overpass with explosion-proof chambers is not so easy, the knee-length calculation immediately gave us many millions of rubles, and we refused it. It was decided to go to our guys from industry 4.0, who are now piloting the use of the only explosion-proof wifi camera in the Russian Federation. According to the description, this should resemble something the size of an electric kettle, but in reality this thing is not more than a marker for boards.

We took this baby and came to the overpass, telling the staff as much as possible what we are giving here, for how long and for what reason. It was important to immediately make it clear that this is in fact to test the experiment and temporary.

A couple of weeks, people worked normally, no violations were detected, and we decided to test the second hypothesis.

For quick and detailed training, we chose the format of video instructions, suspecting that an adequate video tutorial, which takes you a few minutes to watch, will show everything and everything more clearly than a 15-page job description. Moreover, they already had such an instruction.

No sooner said than done. I went to Tobolsk, looked at how they took samples, and it turned out that the fence mechanics were the same there for the last 20 years. Yes, this is a rather routine process that can be brought to automatism with frequent repetition, but this does not mean that it cannot be automated and simplified. But the original idea with the video instruction staff was rejected, they say, why should these videos be shot, if we have been doing the same thing for 20 years?

We agreed with our PR, equipped the right guy for shooting in the video, gave him an excellent shiny wrench and recorded the sampling process in ideal conditions. Such an exemplary version has been released. Then I also voiced the video for clarity.

We gathered staff from eight shifts, gave them a cinema show and asked how it was. It turned out that as when watching the first "Avengers" for the third time: cool, beautiful, but nothing new. Like, we're doing this all the time.

Then we asked the guys directly what they didn’t like in the process and what was causing inconvenience. And here already the dam broke through - after such an improvised design session with production workers, we brought the management a fairly large-scale backlog aimed at changing operating processes. Because it was necessary to first make a number of edits to the processes themselves, and then to make a digital product, which in the new conditions will be correctly perceived.

Well, seriously, if a person has a big uncomfortable sampler without a handle, you have to carry it with both hands, and you say: “You, mobile phone, scan it there, Vanya” - this is somehow not very inspiring.

People for whom you are making a product should understand that you hear them, and not just get ready to roll out some fashionable thing that they don’t need right now.

Pro processes and effects

If you are making a digital product and you have a curved process - no need to implement the product yet, you need to fix this process in the first place. The concern of our direction now is to seize such processes; we continue to collect backlog during design sessions not only for a digital product, but also for global operational improvements that sometimes even happen to be implemented before the product itself. And this in itself gives an excellent effect.

It is also important that part of the team is located directly in the enterprise. We have guys from different departments who have decided to build a career in digital and help us with product introduction and learning processes. Such operational changes are prompted by them.

And it's easier for employees, they understand that we are not just gathered here to sit, but in fact we will discuss how to cancel unnecessary pieces of paper, or to make 1 paper (and then also cancel it) out of 16 necessary papers for the process, how to make EDS and optimize work with government agencies, and so on.

And if we talk about the process itself, we have found this.

Sampling on average takes about 3 hours. And in this process there are people who act as a coordinator, and all these three hours their phone is broken and they constantly report statuses - where to send the car, how to distribute orders to laboratories, and the like. And this is on the laboratory side.

And on the production side sits the same person with the same red-hot phone. And we decided that it would be good to make them a visual dashboard, which will help to see the status of the process, from applications for sampling to issuing results in the laboratory, with the necessary notifications and other things. Then we think to connect it with the order of transport and to optimize the activities of the laboratories themselves - to distribute the work among the employees.

As a result, for one sampling cumulatively from digital and operational changes, we will be able to save about 2 hours of human labor and an hour of inactivity of the train, compared to how they worked before us. And this is only for one selection, there may be several of them per day.

Of the effects, about a quarter of the sampling is now being done this way. It turned out that we are releasing approximately 11 units of personnel for more useful work. A reduction in car-hours (and compositional-hours) opens up spaces for monetization.

Of course, not everyone fully understands what the digital team has forgotten here at all and why it is engaged in operational improvements, people have this not quite right perception, when you think that you have developed, you have done an application for you in a day and solved all the problems. But operating personnel, of course, is happy with this approach, albeit with a little skepticism.

But it is important to remember that there are no magic boxes. This is all work, research, hypothesis and testing.

Source: https://habr.com/ru/post/454982/

All Articles