Opus about His Majesty Clay. Part Four - Silicones

Dedicated to Andrei A., whom I still haven’t apologized so far for the thing spoiled by silicone ...

We continue to slowly ourstories about fishing opuses about adhesives. Our today's hero cannot boast the title of a popular construction adhesive for any spacecraft, but is a sign of the absolute majority of readers. Because silicones are the main adhesives for various stickers, labels and adhesive tapes of the consumer (as opposed to professional scotch) segment. Well, everything else, namely, silicone is most often used for sealing everything and everyone. Under the cut - an explanation of why he can do it and how to help him do it even better. About "silicone - the worker imperceptible".

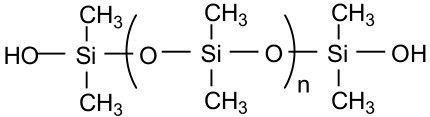

RU Wikipedia broadcasts to us that silicones (polyorganosiloxanes, polysiloxanes) are oxygen-containing silicon polymers, whose structure is represented by the main inorganic silicon-oxygen chain —Si-O-Si-O-Si-O- with attached organic side groups (they are attached to silicon atoms). Sometimes these side functional groups can join together two or more silicone chains, forming cross-links. By varying a) the length of the main silicone chain, b) the side functional groups, and c) the number and type of crosslinks, it is possible to synthesize silicones with different properties.

')

The first studies in chemistry of silicones were conducted at the end of the 19th century by the English chemist Frederick Kipping (= “father of silicones”), and it was he who, by the way, proposed the term silicone in 1901. Due to this, many “translators” (mainly the journalistic fraternity) still confuse silicones and silicon. Silicon is an inorganic material, a semiconductor, which is used to make integrated circuits and solar cells. Silicones are organic compounds that contain silicon, carbon, hydrogen, oxygen, and sometimes other atoms, and are most often used as sealants, label glues and ... for example, breast implants. So, I hope, the habr-reader will never confuse silicon (silicon) and silicone (silicone). Including when the conversation goes to the " Silicon Valley ".

Departing from historical parallels, we can say that the first business potential in silicones was considered by businessmen from chemistry, represented by Corning Glassworks (now Dow Corning) and General Electric, and it was thanks to them that hundreds and thousands of different modifications, compositions, etc. were developed.

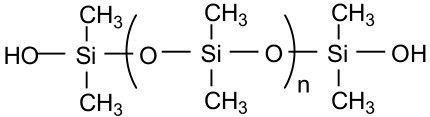

Most silicone sealants are based on polydimethylsiloxanes with terminal silanol groups, which are often called silanols, for example: where n is usually from 300 to 1600:

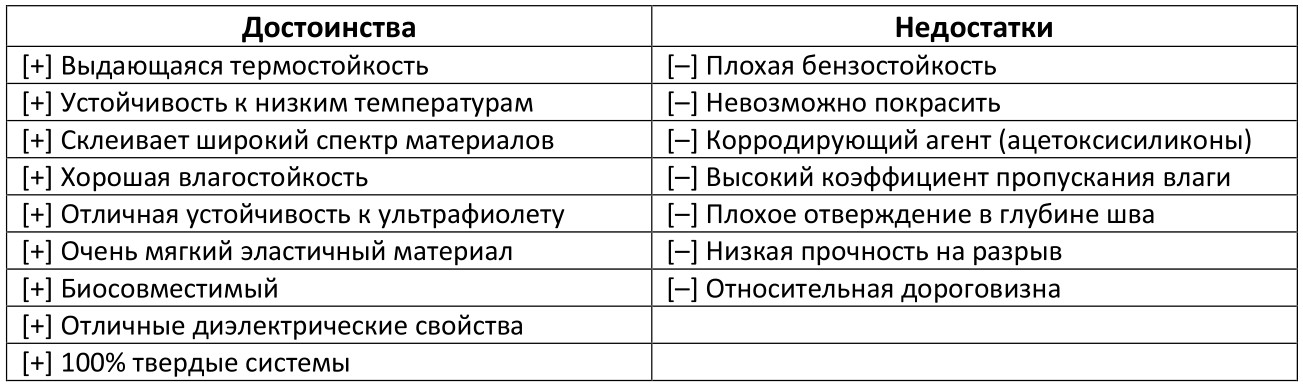

Due to its structure, these compounds occupy a unique intermediate position between inorganic and organic materials. Saturated inorganic backbone Si-O-Si provides superior elasticity, flexibility and resistance to sunlight (mainly to UV radiation), while organic functional groups are responsible for intermolecular forces. The following key features may be noted that determine the flexibility and durability of this class of materials:

- Low surface tension

- High water repellency

- Low glass transition temperature

- High gas permeability

- High thermal resistance and resistance to oxidizing agents

- Insoluble in water

- High silicon-oxygen bond energy

Silicone adhesives are not characterized by high strength (including tearing), they are mainly valued for their elasticity and ability to work in a wide range of temperatures (from cryotechnics from -115 ° C to over 265 ° C with a plus sign, by the way, if need even higher, use supplements based on iron oxide). In simple terms, silicone adhesives are very sticky (so much so that, due to low surface energy, they can bind with polyethylene / polypropylene and fluorocarbons - hello sappience with a question about Duty Free sachets ).

In addition, low shrinkage and the ability to easily fill surface irregularities and gaps (due to low surface tension) make these materials ideal sealants in kitchens and bathrooms. Silicone is ideal when tensile strength is more important than tensile or shear.

The low polarity of silicone elastomers gives these compounds excellent electrical insulating properties, which makes them highly resistant to high-voltage ionization and the formation of a corona discharge. Moreover, silicone adhesives and sealants retain their beneficial insulating properties at elevated temperatures due to the lack of thermal degradation.

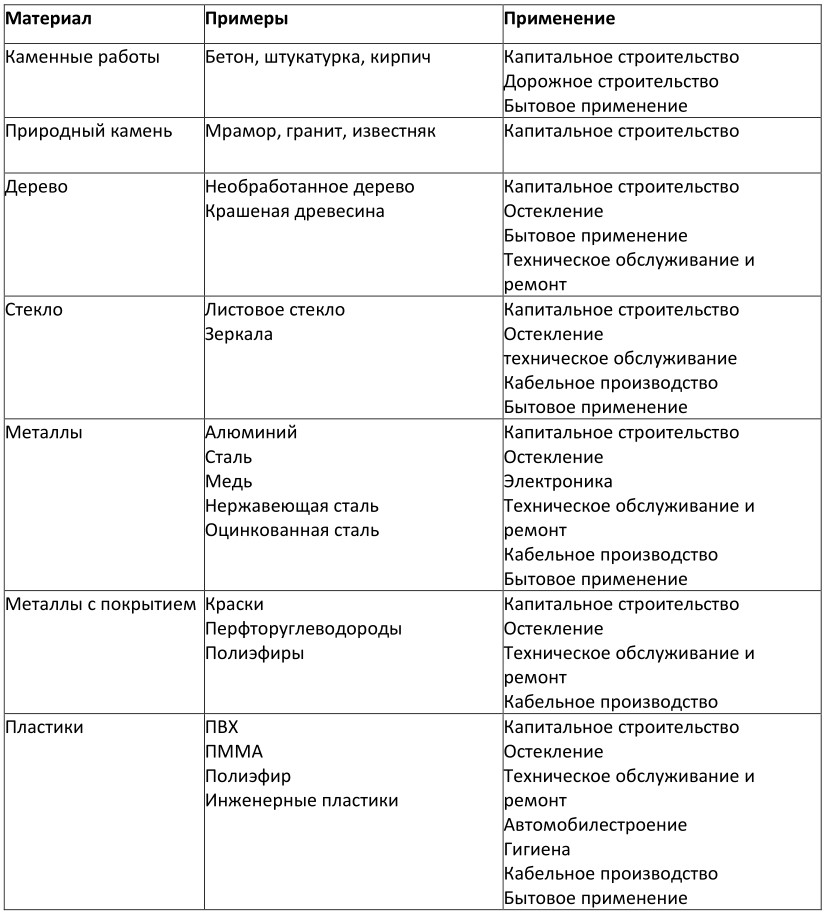

Excellent resistance to ozone and ultraviolet radiation inherent in silicone polymers, makes the use of specialized additives and additives unnecessary. Silicone elastomers can work for a long time without cracking and shrinkage in the open air in all climatic conditions. This is due to the fact that silicones are commonly used for bonding glass when glazing buildings (that is, where significant values of thermal expansion of materials can be expected) or for the manufacture of tanks.

The high initial cost is more than compensated for by the high durability and the absence of the need for frequent repairs.

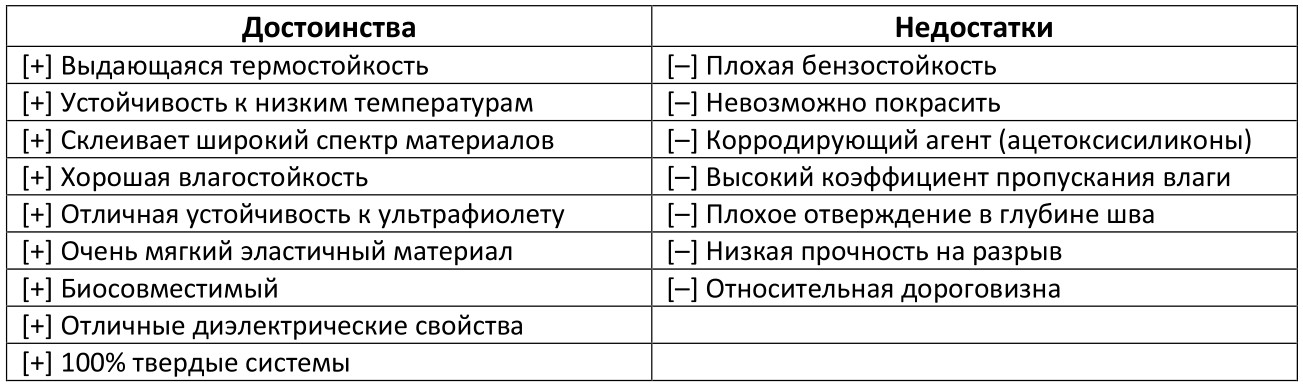

Among the shortcomings, it is possible to note the low resistance to gasoline, which somewhat limits the use of silicones in the car / aircraft industry. And the fact that this adhesive cures for a very long time in deep layers (it is not recommended to use a layer thicker than 12–13 mm) due to the nature of crosslinking by means of air humidity (= diffusion of moist air into the material slows down with increasing thickness of the adhesive layer, etc. and etc.). Low surface energy does not allow paints to form good adhesion to the silicone coating (therefore, it is difficult to paint over the sealant with ordinary paint), which is sometimes vital when you want to hide the glue line. Finally, depending on the type of silicone used (see below), acetic acid can be released during the curing process, acting as a corrosive agent (especially in the case of contact with metals like copper and brass).

Silicone adhesives are divided into two main groups:

- Single component

-Two-component

Single-component silicones contain -OH groups polyorganosiloxane and a crosslinking agent (for example methyltriacetoxysilane), which is sensitive to hydrolysis, that is, reacts with water (when the material comes in contact with air moisture) as a result of condensation at room temperature. Therefore, this type is often referred to as RTV-1 (= vulcanization at room temperature, one-component). Acetic acid is a by-product of condensation (when methyltriacetoxysilane is used as a hardener, although alcohol can be released for so-called RTV-1 with neutral curing). The cheapest, and therefore most common (the basis of the absolute majority of construction and household sealants) option of silicone is acetoxysilicone. The initial setting of the glue occurs within 15–20 minutes and reaches full depth within 24–48 hours, depending on the relative humidity during curing (the picture below shows the curing schedule for the most common acetoxysilicone in an environment with a humidity of 50%).

On average, it is believed that curing occurs at an average rate of about 2 mm per day. Since the process depends on the air humidity, temperature and thickness of the glue line, it is logical to mention that in order to accelerate curing, a) silicone should not be applied with a very thick layer (6 mm maximum), b) maximum air contact of the glue line with moist air should be provided (ventilate the room actively, do not use seams with a complex geometry (spiral / broken, etc.), or seams inside objects without air access. Since acetic acid is released during the condensation process, the addition of components with an alkaline reaction (for example, alkaline pipe cleaning agent ala “Mole” or hydrated lime) will accelerate the curing process. The acid reacts with alkali, neutralizes and produces water, which in turn reacts with silicone (in addition to diffusion water taken from the air). it will obviously be weaker to stink of vinegar (by the way, if you need to wash off such silicone - “knock it out with a wedge” - to make it more productive with acetic acid in a more concentrated way, at least 70% of the essence).

In addition to the unpleasant odor, as I mentioned, the exiting acetic acid can stimulate metal corrosion processes. For this reason, RTV-1 sealants have been developed using other hardeners.

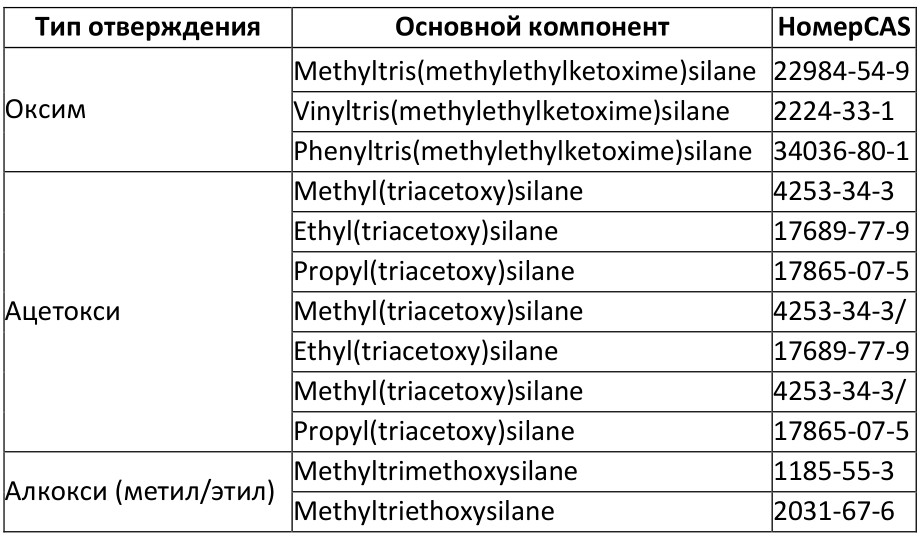

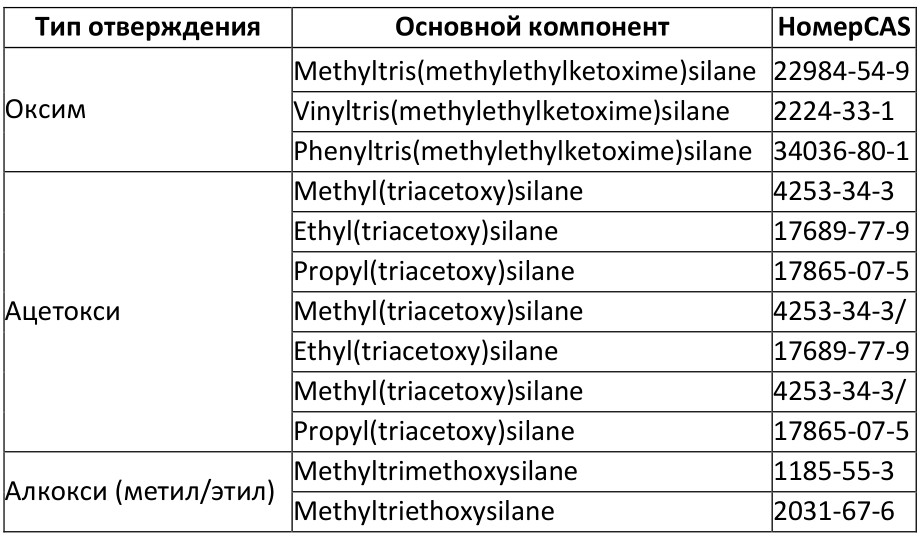

Examples of the most frequently used compounds with their CAS numbers can be seen in the table below:

True, such silicones are a bit more expensive, less common, and the curing process is slower. Comparison of various RTV-1 under the spoiler

If for some reason one-component silicones are not suitable, you can try two-component silicones, or RTV-2 (= vulcanization at room temperature, two-component). Such adhesives:

- cure much faster than the first group

- do not require high humidity

- cures evenly over the entire depth of the glue line (regardless of width)

- do not emit questionable by-products during curing

A typical RTV-2 silicone consists of a silanol + hardener with a catalyst. Organic compounds of tin (tin octoate or dibutyl tin dilaurate, which, by the way, will work as “neutral” RTV-1) as catalysts for curing, act as a catalyst. Increased temperature accelerates the curing process. An example is the well-known silicone sealant SYLGARD 184 , which is actively used to seal solar cell modules.

Cured two-component silicones shrink slightly and provide better heat resistance among all silicone adhesives.

The performance of silicone adhesive seam (RTV-2, although some items apply to RTV-1) is generally influenced by the following factors:

- Precursor structure

- Dosage of the hardener: too high a dose may make the glue line too rigid, unstable, or generally uncured (see my ps)

- pH of the medium: pH accelerates the rate of hydrolysis and condensation.

- Many substances can act as catalysts: mineral acids, alkoxide salts, tin compounds, titanium esters, zirconium salts, phosphorus compounds and amines.

- System temperature: at elevated temperatures, the molecule moves faster / the number of collisions increases => curing occurs faster.

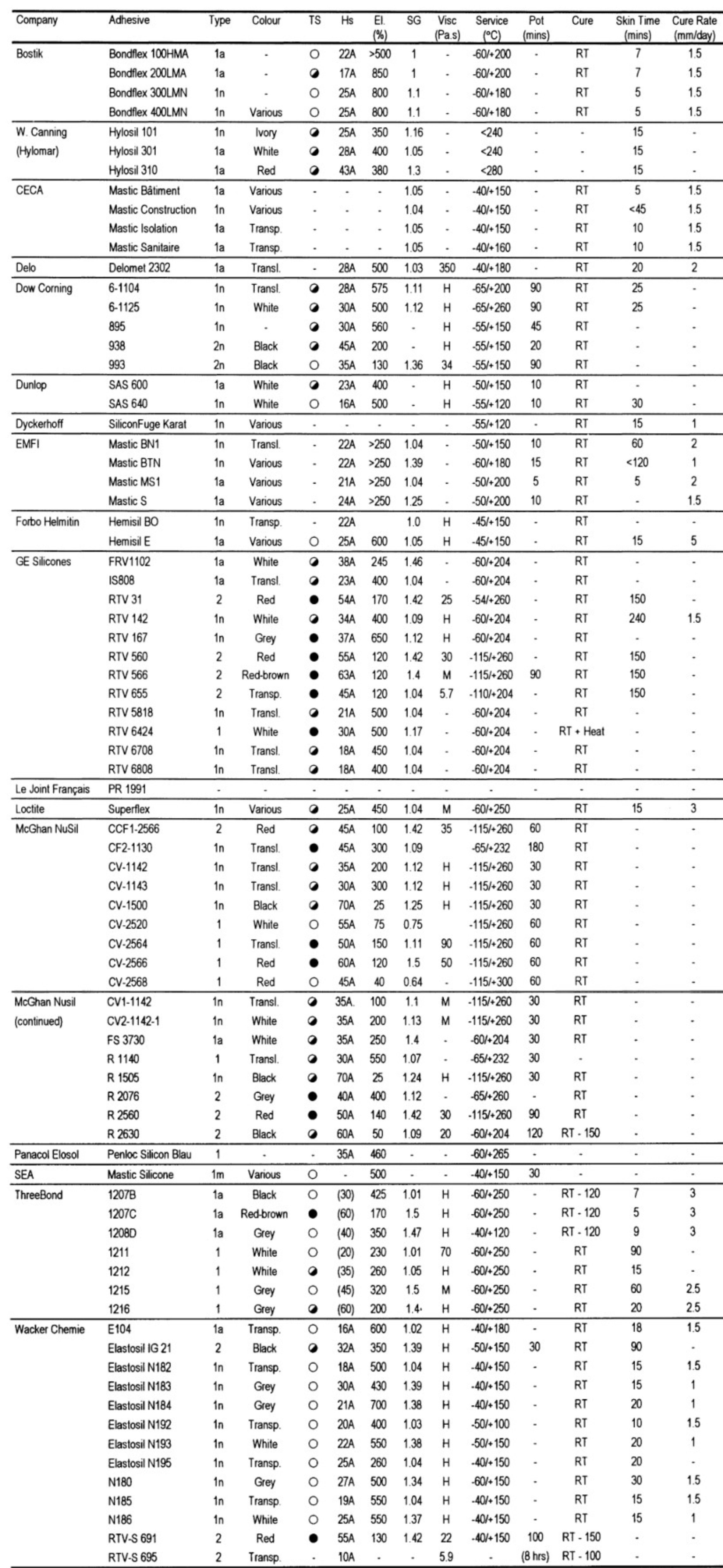

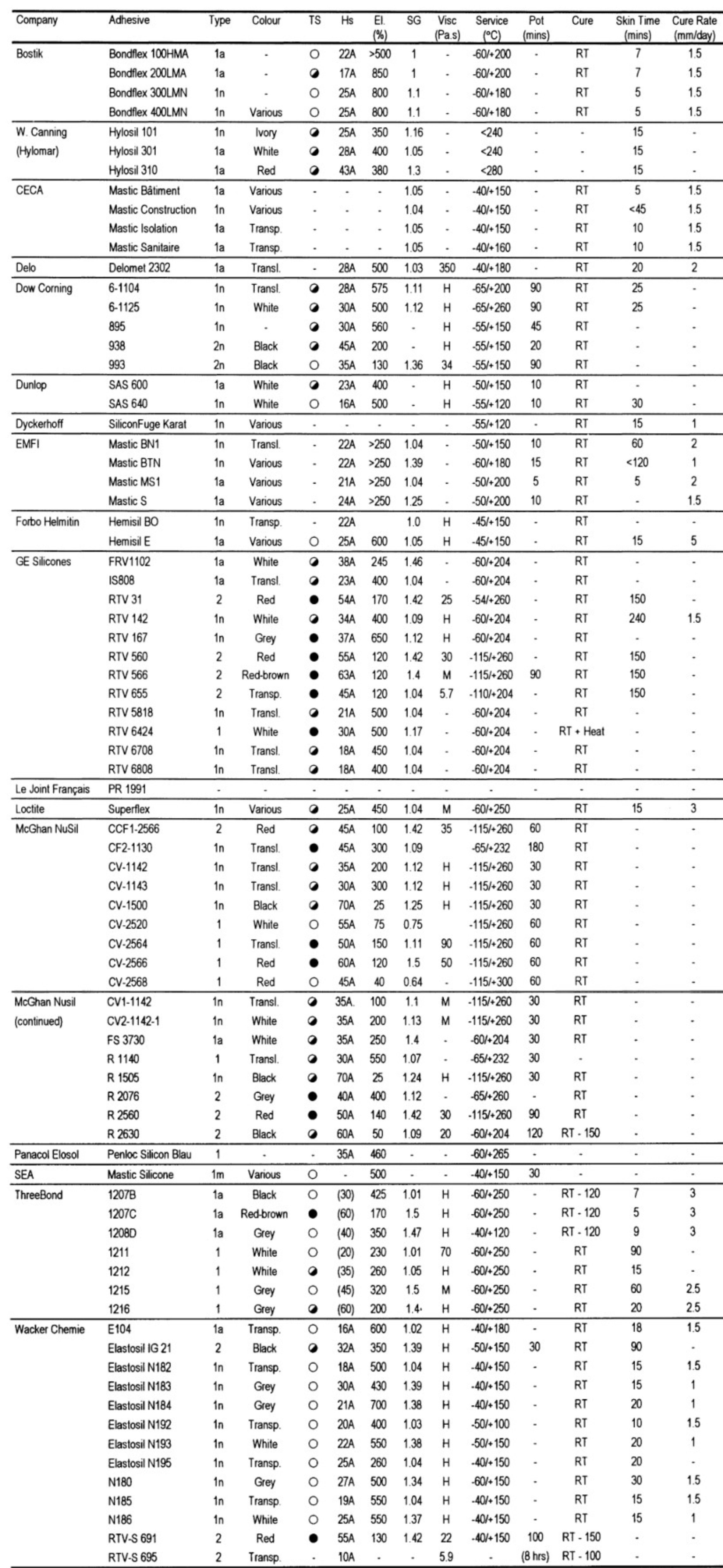

Under the spoiler - a table with well-known representatives of commercial silicones and their properties. Questions, traditionally, ask in the comments :)

Than "tear off the plates":

Industrial washes:

- from the “fathers of silicone” Dow Corning, DS-2025 for hardened silicone - as part of dodecylbenzenesulfonic acid (anionic surfactant), ABSK

- from “fathers of silicone” Dow Corning, DS-1000 for uncured silicone - composed of non-ionic surfactant - ethoxylated alcohol C6-C12, quaternary ammonium compound , propylene glycol methyl ether (= solvent for washing nozzles of inkjet printer cartridges), (2-methoxymethylethoxy) propanol (washing liquid in printing).

PS My acquaintance with a two-component silicone was rather sad (see the article’s dedication). The same Sylgard 184 was solicited from friends from an adjacent scientific research institute to create a replica of the diffraction grating (1200 strokes / mm from an old Soviet device, such as MDR-2). From this:

Without feeling a dirty trick, I mixed the components as my colleagues recommended to me (“normally seizes”) and put the grid on this layer with enough liquid silicone. Joyful went home anticipating what beauty I would get in the morning. But in the morning I was met by the same, not frozen silicone, which was spread over the entire grid. My hair stood on end (inside I felt that it was not just a lattice) and I began to try various washes. The situation was complicated by the fact that you cannot rub the diffraction grating - all engraving will be destroyed. Only run the solvent with a stream of nitrogen. What I just did not try, right up to the rarest solvents (because how, the person trusted me, and I, I actually destroyed someone else's thing). In impotence, I decided to cure silicone temperature. He hardened and now firmly buried the idea of preserving the diffraction strips of the grating. But I decided to finish the job. Having tried 30 different solvents, it was possible to dilute the hard mass only with glacial acetic acid. And the gas pressure to blow off the grill. Looking under the microscope at what remained on the glass from the microbouzres engraved on the aluminum substrate of the lattice, I didn’t have the courage ... So the lattice still lies: (Sorry, Andrei, if you read it ...

We continue to slowly our

RU Wikipedia broadcasts to us that silicones (polyorganosiloxanes, polysiloxanes) are oxygen-containing silicon polymers, whose structure is represented by the main inorganic silicon-oxygen chain —Si-O-Si-O-Si-O- with attached organic side groups (they are attached to silicon atoms). Sometimes these side functional groups can join together two or more silicone chains, forming cross-links. By varying a) the length of the main silicone chain, b) the side functional groups, and c) the number and type of crosslinks, it is possible to synthesize silicones with different properties.

')

The first studies in chemistry of silicones were conducted at the end of the 19th century by the English chemist Frederick Kipping (= “father of silicones”), and it was he who, by the way, proposed the term silicone in 1901. Due to this, many “translators” (mainly the journalistic fraternity) still confuse silicones and silicon. Silicon is an inorganic material, a semiconductor, which is used to make integrated circuits and solar cells. Silicones are organic compounds that contain silicon, carbon, hydrogen, oxygen, and sometimes other atoms, and are most often used as sealants, label glues and ... for example, breast implants. So, I hope, the habr-reader will never confuse silicon (silicon) and silicone (silicone). Including when the conversation goes to the " Silicon Valley ".

Departing from historical parallels, we can say that the first business potential in silicones was considered by businessmen from chemistry, represented by Corning Glassworks (now Dow Corning) and General Electric, and it was thanks to them that hundreds and thousands of different modifications, compositions, etc. were developed.

Most silicone sealants are based on polydimethylsiloxanes with terminal silanol groups, which are often called silanols, for example: where n is usually from 300 to 1600:

Due to its structure, these compounds occupy a unique intermediate position between inorganic and organic materials. Saturated inorganic backbone Si-O-Si provides superior elasticity, flexibility and resistance to sunlight (mainly to UV radiation), while organic functional groups are responsible for intermolecular forces. The following key features may be noted that determine the flexibility and durability of this class of materials:

- Low surface tension

- High water repellency

- Low glass transition temperature

- High gas permeability

- High thermal resistance and resistance to oxidizing agents

- Insoluble in water

- High silicon-oxygen bond energy

Silicone adhesives are not characterized by high strength (including tearing), they are mainly valued for their elasticity and ability to work in a wide range of temperatures (from cryotechnics from -115 ° C to over 265 ° C with a plus sign, by the way, if need even higher, use supplements based on iron oxide). In simple terms, silicone adhesives are very sticky (so much so that, due to low surface energy, they can bind with polyethylene / polypropylene and fluorocarbons - hello sappience with a question about Duty Free sachets ).

In addition, low shrinkage and the ability to easily fill surface irregularities and gaps (due to low surface tension) make these materials ideal sealants in kitchens and bathrooms. Silicone is ideal when tensile strength is more important than tensile or shear.

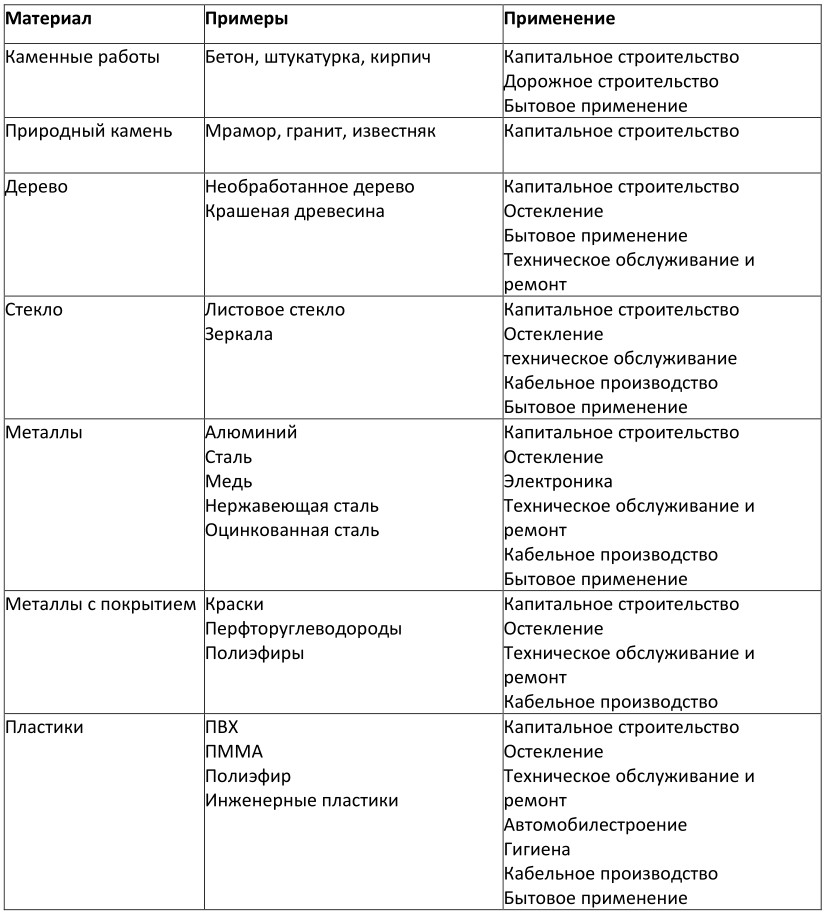

Construction : installation and installation of glazing (wood, metals, plastics, glass), filling gaps and expansion joints on facades and masonry, waterproof seals when creating tanks and aquarium (industrial and domestic), seals in refrigeration and air conditioning systems.

The low polarity of silicone elastomers gives these compounds excellent electrical insulating properties, which makes them highly resistant to high-voltage ionization and the formation of a corona discharge. Moreover, silicone adhesives and sealants retain their beneficial insulating properties at elevated temperatures due to the lack of thermal degradation.

Electronics: low viscosity insulating silicones are used to fill electronic components (compounds). Metal-filled silicones are used as conductive adhesives.

Excellent resistance to ozone and ultraviolet radiation inherent in silicone polymers, makes the use of specialized additives and additives unnecessary. Silicone elastomers can work for a long time without cracking and shrinkage in the open air in all climatic conditions. This is due to the fact that silicones are commonly used for bonding glass when glazing buildings (that is, where significant values of thermal expansion of materials can be expected) or for the manufacture of tanks.

The high initial cost is more than compensated for by the high durability and the absence of the need for frequent repairs.

Rocket science: silicones are used in high vacuum technology (including space), in the construction of nuclear power plants (in laboratory nuclear installations, etc.) because of their radiation resistance.

Among the shortcomings, it is possible to note the low resistance to gasoline, which somewhat limits the use of silicones in the car / aircraft industry. And the fact that this adhesive cures for a very long time in deep layers (it is not recommended to use a layer thicker than 12–13 mm) due to the nature of crosslinking by means of air humidity (= diffusion of moist air into the material slows down with increasing thickness of the adhesive layer, etc. and etc.). Low surface energy does not allow paints to form good adhesion to the silicone coating (therefore, it is difficult to paint over the sealant with ordinary paint), which is sometimes vital when you want to hide the glue line. Finally, depending on the type of silicone used (see below), acetic acid can be released during the curing process, acting as a corrosive agent (especially in the case of contact with metals like copper and brass).

Silicone Adhesives

Silicone adhesives are divided into two main groups:

- Single component

-Two-component

Single-component silicones contain -OH groups polyorganosiloxane and a crosslinking agent (for example methyltriacetoxysilane), which is sensitive to hydrolysis, that is, reacts with water (when the material comes in contact with air moisture) as a result of condensation at room temperature. Therefore, this type is often referred to as RTV-1 (= vulcanization at room temperature, one-component). Acetic acid is a by-product of condensation (when methyltriacetoxysilane is used as a hardener, although alcohol can be released for so-called RTV-1 with neutral curing). The cheapest, and therefore most common (the basis of the absolute majority of construction and household sealants) option of silicone is acetoxysilicone. The initial setting of the glue occurs within 15–20 minutes and reaches full depth within 24–48 hours, depending on the relative humidity during curing (the picture below shows the curing schedule for the most common acetoxysilicone in an environment with a humidity of 50%).

On average, it is believed that curing occurs at an average rate of about 2 mm per day. Since the process depends on the air humidity, temperature and thickness of the glue line, it is logical to mention that in order to accelerate curing, a) silicone should not be applied with a very thick layer (6 mm maximum), b) maximum air contact of the glue line with moist air should be provided (ventilate the room actively, do not use seams with a complex geometry (spiral / broken, etc.), or seams inside objects without air access. Since acetic acid is released during the condensation process, the addition of components with an alkaline reaction (for example, alkaline pipe cleaning agent ala “Mole” or hydrated lime) will accelerate the curing process. The acid reacts with alkali, neutralizes and produces water, which in turn reacts with silicone (in addition to diffusion water taken from the air). it will obviously be weaker to stink of vinegar (by the way, if you need to wash off such silicone - “knock it out with a wedge” - to make it more productive with acetic acid in a more concentrated way, at least 70% of the essence).

In addition to the unpleasant odor, as I mentioned, the exiting acetic acid can stimulate metal corrosion processes. For this reason, RTV-1 sealants have been developed using other hardeners.

Examples of the most frequently used compounds with their CAS numbers can be seen in the table below:

True, such silicones are a bit more expensive, less common, and the curing process is slower. Comparison of various RTV-1 under the spoiler

Comparison of different types of RTV-1

If for some reason one-component silicones are not suitable, you can try two-component silicones, or RTV-2 (= vulcanization at room temperature, two-component). Such adhesives:

- cure much faster than the first group

- do not require high humidity

- cures evenly over the entire depth of the glue line (regardless of width)

- do not emit questionable by-products during curing

A typical RTV-2 silicone consists of a silanol + hardener with a catalyst. Organic compounds of tin (tin octoate or dibutyl tin dilaurate, which, by the way, will work as “neutral” RTV-1) as catalysts for curing, act as a catalyst. Increased temperature accelerates the curing process. An example is the well-known silicone sealant SYLGARD 184 , which is actively used to seal solar cell modules.

Cured two-component silicones shrink slightly and provide better heat resistance among all silicone adhesives.

The performance of silicone adhesive seam (RTV-2, although some items apply to RTV-1) is generally influenced by the following factors:

- Precursor structure

- Dosage of the hardener: too high a dose may make the glue line too rigid, unstable, or generally uncured (see my ps)

- pH of the medium: pH accelerates the rate of hydrolysis and condensation.

- Many substances can act as catalysts: mineral acids, alkoxide salts, tin compounds, titanium esters, zirconium salts, phosphorus compounds and amines.

- System temperature: at elevated temperatures, the molecule moves faster / the number of collisions increases => curing occurs faster.

Under the spoiler - a table with well-known representatives of commercial silicones and their properties. Questions, traditionally, ask in the comments :)

Overseas Commercial Silicone Adhesives

Table legend:

TS : tensile strength

SG : specific gravity (density relative to the density of water).

HS : Shore Scale (A or D)

EL (%) : elongation at break in the tensile test,%.

Visc. (Pa.s) : viscosity index (pascal second)

Service (° C) : cured glue line operating temperature

Cure : A type of cure for obtaining standard seam strength. RT-room temperature (if there is a figure - this is the heating temperature).

Cure Rate (mm / day): cure rate (mm / day)

Skin Time (mins): time required for setting (minimum required strength of glue line)

Legend:

1n = one-component neutral, 1a = one-component acid, 2 - two-component

The circles indicate the properties of a particular adhesive with respect to all adhesives of this class: the black circle is the highest, the black and white circle is moderate, the white circle is weak.

TS : tensile strength

SG : specific gravity (density relative to the density of water).

HS : Shore Scale (A or D)

EL (%) : elongation at break in the tensile test,%.

Visc. (Pa.s) : viscosity index (pascal second)

Service (° C) : cured glue line operating temperature

Cure : A type of cure for obtaining standard seam strength. RT-room temperature (if there is a figure - this is the heating temperature).

Cure Rate (mm / day): cure rate (mm / day)

Skin Time (mins): time required for setting (minimum required strength of glue line)

Legend:

1n = one-component neutral, 1a = one-component acid, 2 - two-component

The circles indicate the properties of a particular adhesive with respect to all adhesives of this class: the black circle is the highest, the black and white circle is moderate, the white circle is weak.

Than "tear off the plates":

By the way, if you need to wash off such a silicone - “knock it out with a wedge” - make it more productive with acetic acid in a more concentrated way, at least 70% of the essence

Industrial washes:

- from the “fathers of silicone” Dow Corning, DS-2025 for hardened silicone - as part of dodecylbenzenesulfonic acid (anionic surfactant), ABSK

- from “fathers of silicone” Dow Corning, DS-1000 for uncured silicone - composed of non-ionic surfactant - ethoxylated alcohol C6-C12, quaternary ammonium compound , propylene glycol methyl ether (= solvent for washing nozzles of inkjet printer cartridges), (2-methoxymethylethoxy) propanol (washing liquid in printing).

PS My acquaintance with a two-component silicone was rather sad (see the article’s dedication). The same Sylgard 184 was solicited from friends from an adjacent scientific research institute to create a replica of the diffraction grating (1200 strokes / mm from an old Soviet device, such as MDR-2). From this:

Without feeling a dirty trick, I mixed the components as my colleagues recommended to me (“normally seizes”) and put the grid on this layer with enough liquid silicone. Joyful went home anticipating what beauty I would get in the morning. But in the morning I was met by the same, not frozen silicone, which was spread over the entire grid. My hair stood on end (inside I felt that it was not just a lattice) and I began to try various washes. The situation was complicated by the fact that you cannot rub the diffraction grating - all engraving will be destroyed. Only run the solvent with a stream of nitrogen. What I just did not try, right up to the rarest solvents (because how, the person trusted me, and I, I actually destroyed someone else's thing). In impotence, I decided to cure silicone temperature. He hardened and now firmly buried the idea of preserving the diffraction strips of the grating. But I decided to finish the job. Having tried 30 different solvents, it was possible to dilute the hard mass only with glacial acetic acid. And the gas pressure to blow off the grill. Looking under the microscope at what remained on the glass from the microbouzres engraved on the aluminum substrate of the lattice, I didn’t have the courage ... So the lattice still lies: (Sorry, Andrei, if you read it ...

Source: https://habr.com/ru/post/453588/

All Articles