Work permit: why it is needed and why electronic is better than paper

Hello!

My name is Igor Gromov, and I work in SIBUR in the function “Digital technologies”, in the direction of digitalization of processes. Now we are actively engaged in the translation into electronic form of our work orders.

')

Work Admission is a safety instruction that is issued to personnel to work with increased danger at industrial sites. Such works include work at heights, earthworks, fire and gas hazardous work. Fire and gas hazardous at SIBUR enterprises account for the largest share of all works of heightened danger. Firing is dangerous because during their holding there is a possibility of heating the structure or tool, and it is necessary to take safety measures against fire and burns. During gas hazardous work, gases may be emitted from tanks or pipelines, some of which are explosive and may cause poisoning.

To avoid injuries and accidents, a work permit is created. It describes in detail what safety measures should be observed during each type of such work - for example, be sure to wear a helmet, cover your eyes with a protective mask, check the air at the work site for the maximum permissible concentration of hydrocarbons.

In this post I will tell you why it is important to transfer the huge document flow associated with tolerance outfits into digital format.

SIBUR is tens of thousands of units of complex equipment that are constantly in need of repair. Here, as with a private car - you know that after 10-15 thousand kilometers you need to change the oil, then with time - pads and stuff. And we have a lot of pumps, compressors, heat exchangers and other complex iron. Each unit has a scheduled operation time without interruption for repairs or maintenance. During many repairs can not do without the work of increased danger. Therefore, there are a lot of orders-tolerances within one enterprise during the year - the bill goes to thousands, and in some places tens of thousands.

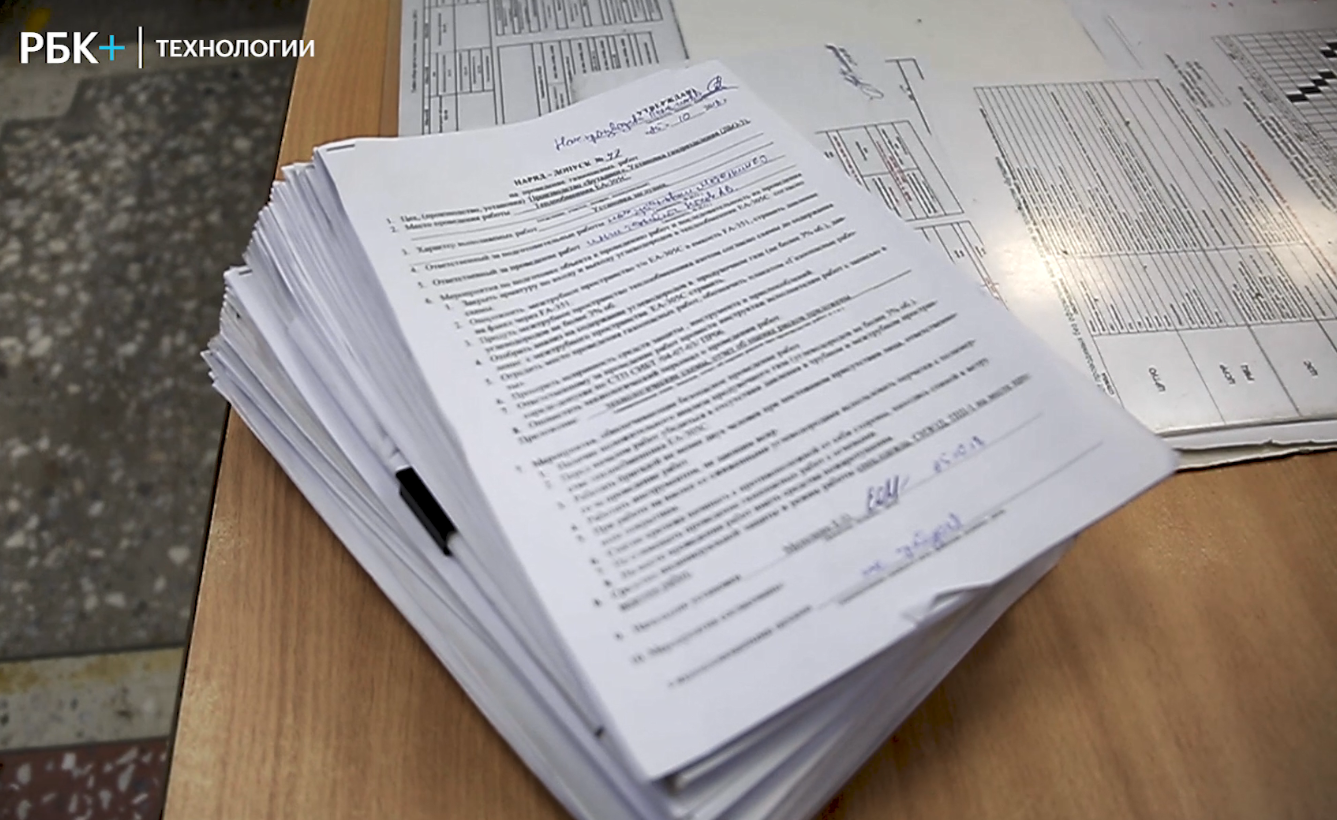

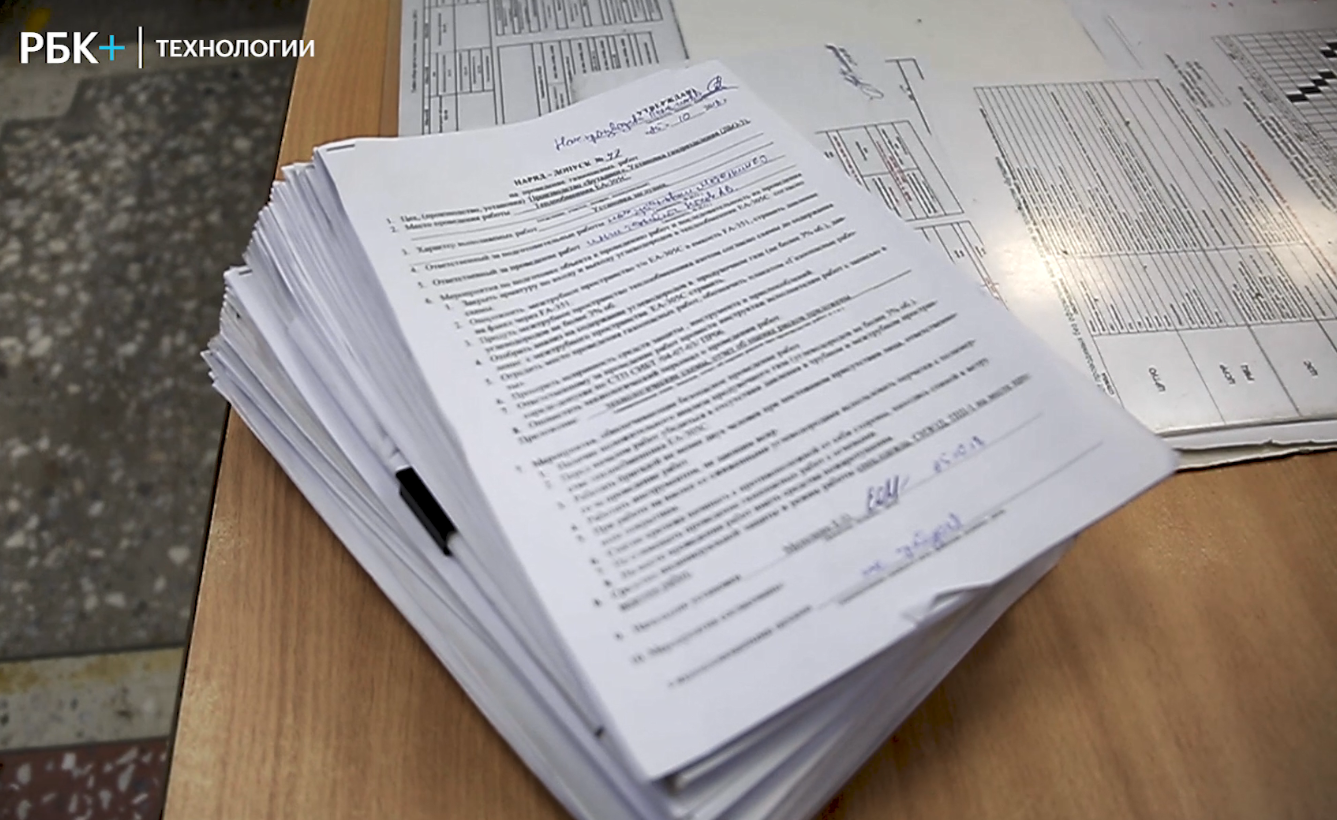

As a result, production engineers draw up a huge number of documents (according to the law, every work permit is made in 2 copies). To understand - a day at the SIBUR Tobolsk plant a stack of paper one meter high is formed.

Of course, paper saving and environmental issues are important. But she is not the only one here, there are other important reasons for digitizing tolerance outfits.

Each work permit contains a lot of useful information, not only for the personnel conducting the repair, but also for the analyst - the crew, location, time. Sometimes it happens that some work is performed by a brigade of 3 people, somewhere 5-7 is already required, somewhere in general 10. All this data, if collected and analyzed, can be useful in planning the next work that is similar to the rules.

Collecting and evaluating such data normally in the previous process is to dig into paper with a head, write everything down manually into some kind of sign and try to work with it. On the scale of SIBUR, this approach is difficult to make effective.

Work on clearance orders governs federal legislation - “Rules for the safe conduct of fire, gas hazard and repair work,” for which the work permit must be stored for 30 days. This is necessary in the event that an emergency situation occurs during repair, causing damage to the employee. Then the supervisory authorities will have 30 days to come and carry out an inspection, including data from the work permit.

Starting from 2017, regulations permit the issuance of work permit for the execution of gas hazardous, fire and repair work in electronic form, instead of the work permit with paperwork. When working with the electronic form, we also need to focus on the federal law "On electronic signature".

The work process with the work permit consists of the following steps:

It looks easy. In fact, in terms of digitalization and improvement of business processes, there is an abyss of opportunities inside. So far we have begun to work at the first level, which is dedicated to the formation of work orders.

The main task that we solve at this stage is to relieve the participants of the process from the necessity of forced creation. Previously, engineers had to enter a list of necessary security measures at the stages of preparation and work, keep it all in mind or edit word-templates, remember where and what security measures we have. A person in such conditions may miss something or vice versa - to be safe and write in too much. In each of the units, dozens of work orders must be drawn up every day, people can simply get tired.

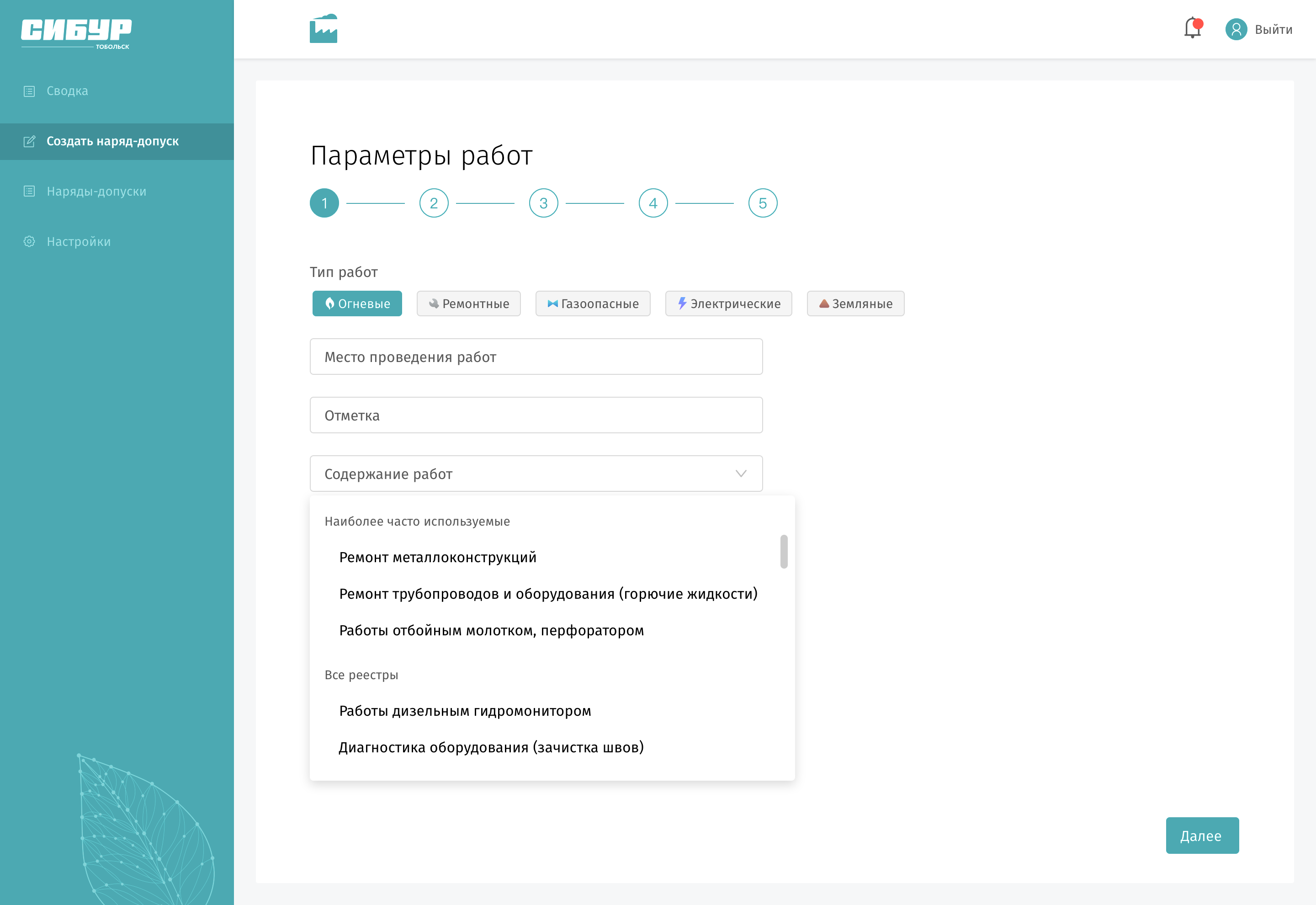

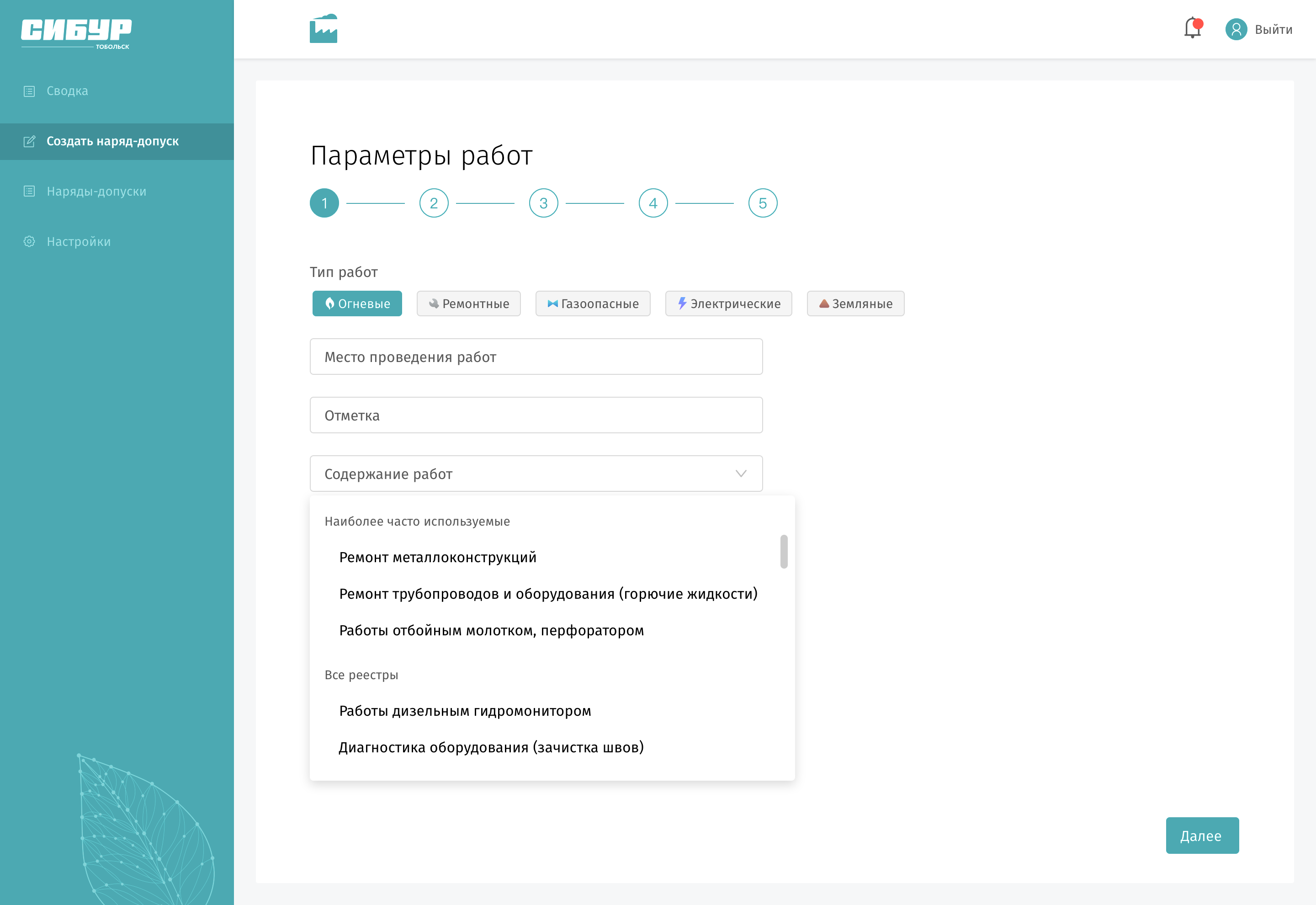

For the first stage, we have created a database that corresponds with each type of work and with the units of equipment on which these works should be carried out. In the database there is a list of all equipment, and technological maps, and security measures. Using an uncomplicated interface and database, the employee selects the necessary conditions and creates a work permit. Everything about everything now takes one or two minutes, and the output is a finished document, which can already be used.

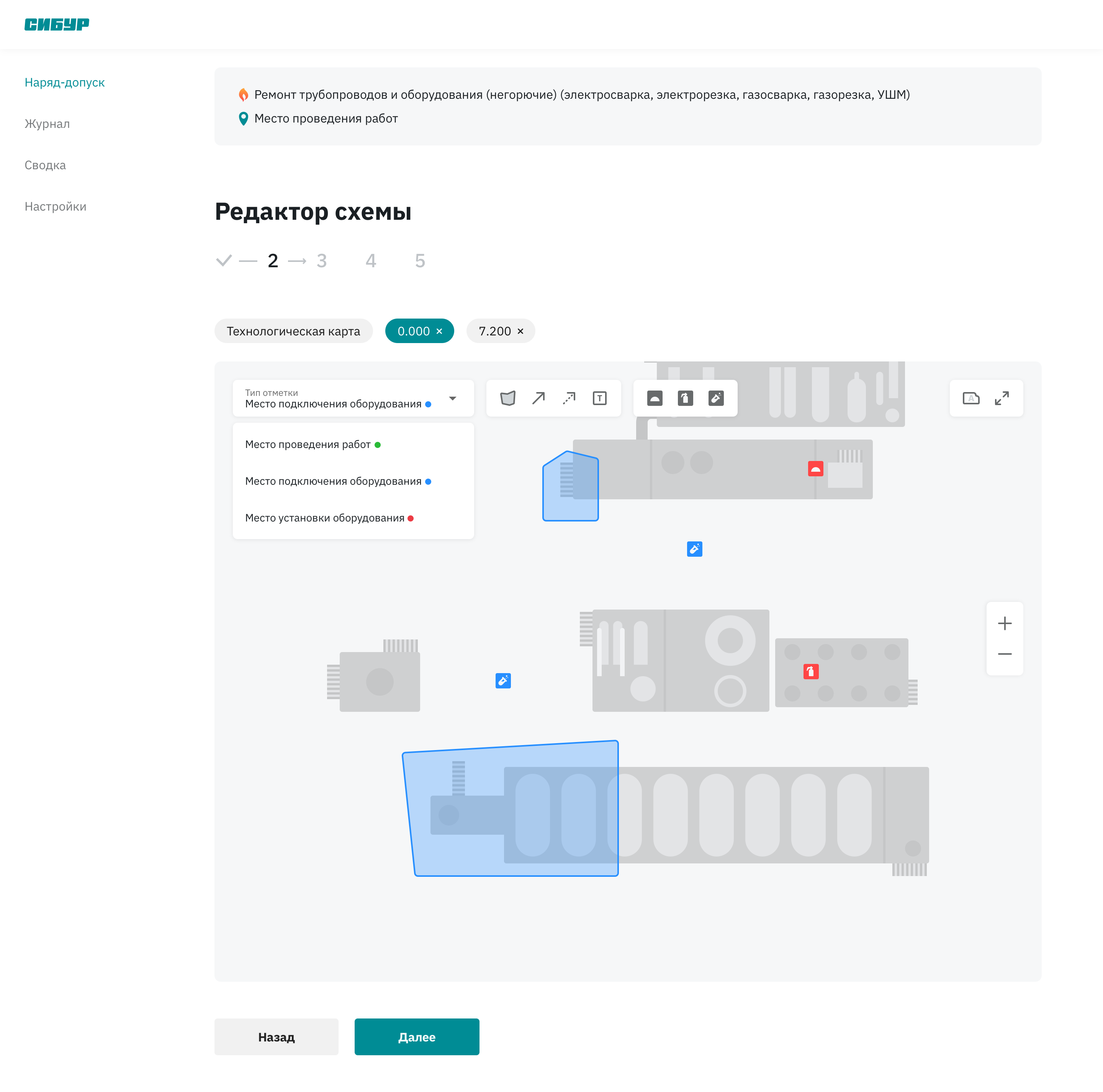

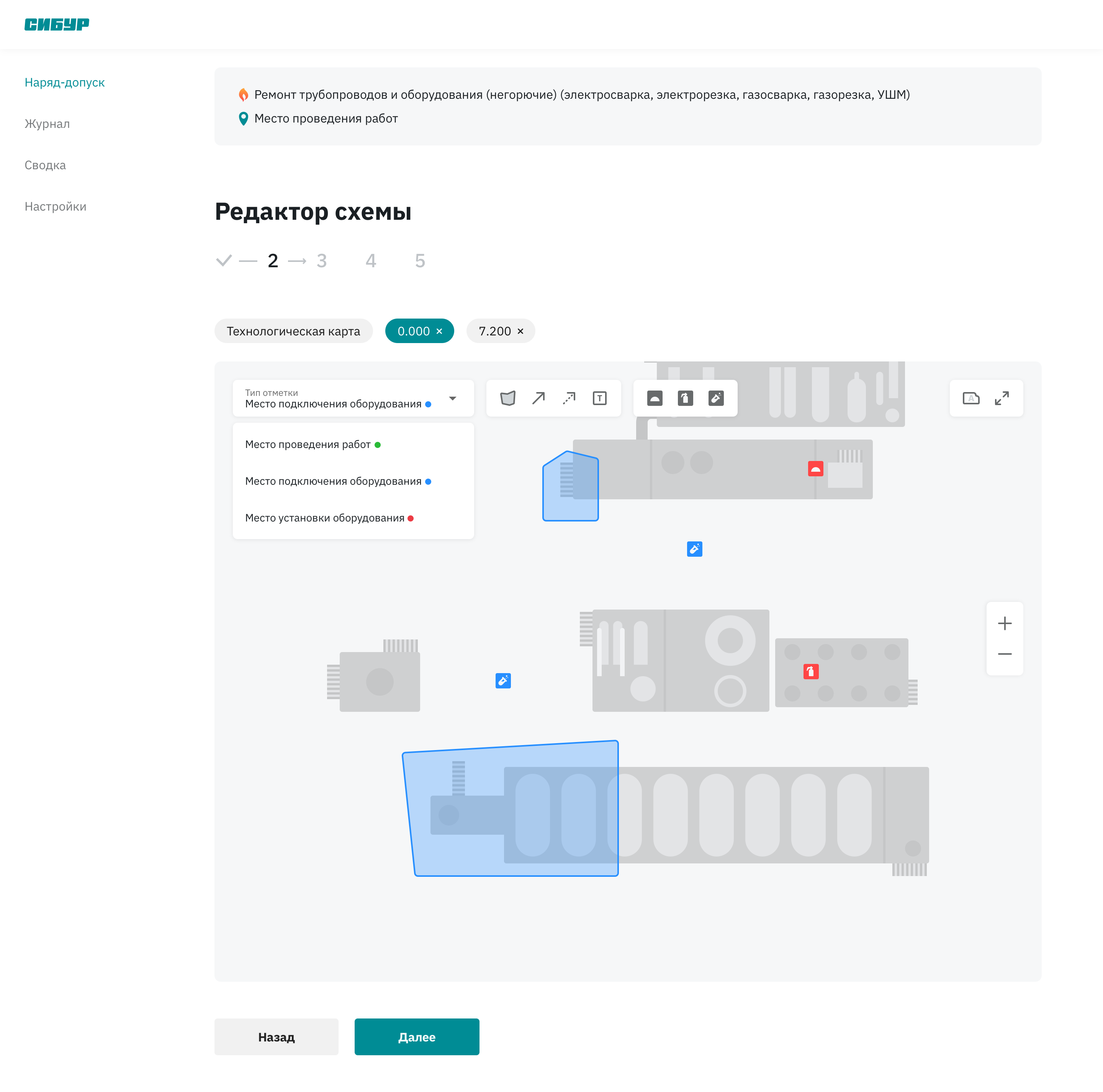

The second important step was the issue of navigation - in the work permit, you must also indicate the location of the work during hot work. A person should know exactly where to carry out work, where fire extinguishing agents are located and the like. We also simplified this by taking schemes from process regulations. We wrote a simple browser-based image editor, which allows a person to quickly put the necessary marks on the scheme and get a ready-made map for specific works.

Previously, employees had to disassemble in a pile of folders, look for schemes there, draw layouts in Visio, outlining the necessary objects. Now you just get the scheme of the place of work and note everything important.

As a result, the time of the formation of a dress, we have reduced by 5 times.

It sounds cool, but it's not an end in itself. In our case, it is 2 minutes now versus 10 minutes before. But if you sit down and translate this effect into real money for the enterprise, the effect will not be very large. And if you even bring the cost of maintaining your own development unit for this purpose under these figures (reducing the time of formation of the order), the economy will hardly converge.

The main thing that was achieved was to reduce the time loss of the working teams, which carry out work on the work permit.

Each clearance is always time. And before we started, this time was 1.5-2 hours. That is, a team of 10 people fully armed could sit for a couple of hours and wait for the work permit to go through all the bureaucratic steps, and you could go to work. Let me remind you that the outfits - tens of thousands. And if already here such temporary losses for the downtime of the brigade to transfer into money are tens of millions of rubles a year.

The next important point will be the full implementation of the electronic signature in the product. Now to get a signature on the dress and its approval have to move a lot around the plant. You need to take outfit, go to the head of the unit, so that he put the signature. And he has a lot of other things besides the signature, and he may not be in place, which means you have to wait until he returns from the meeting and signs.

Therefore, we completely translate this into an electronic format, so that the person who has created a work permit in the web just sends it for approval in electronic form. There it will receive, sign and agree remotely.

Here a good help is 63-FZ about a digital signature, one type of which is a simple electronic signature. On a corporate scale, if simplified for understanding, an electronic signature is a “login-password” pair in the corporate system. If a person is logged in to the system, then it is considered that all documents that he sends from his account to colleagues are signed with a simple electronic signature.

A simple electronic signature meets the requirements of supervisory authorities and, in comparison with a reinforced electronic signature, is easily scalable. It does not need certification centers, enhanced signatures, tokens and certificates.

The main difficulty with a simple electronic signature is that not all employees have accounts in information systems. Mechanics who are directly involved in repairs do not need a working computer. Now we are designing a system that will allow us to collect simple electronic signatures from people without familiar accounts. I will tell you about the decision when it will be ready.

To get a product that works in a work environment, an excellent team of designers and developers is not enough. Yes, now the industry has a lot of tools that allow you to create fast prototypes and collect feedback from users. But our experience shows that between the prototype, which everyone likes, and the really working product that everyone is ready to use is an impressive distance. And at this distance is the development of infrastructure, the formation and alignment of those processes that should fit into it.

A couple of years ago, German Oskarovich Gref lamented the fact that Sberbank units were slowly rolling out software updates, compared to Silicon Valley companies. Sberbank then entered the phase of building DevOps ...

At the very beginning, the situation with the speed of appearance of changes in the working environment was unbearable - neither hardware, nor DevOps-experts, nor software, which was already coordinated with colleagues from information security. From 12 months, we spent about 70% of the time on building a continuous integration process (CI), and we will get to continuous delivery (CD) in the next couple of months. Our team consists of a designer, 6 developers, a scrum master and a product owner, and we are also looking for a QA specialist. So far I like how everything works, especially the realization that the software development system, which is beginning to produce results, appeared in such a conservative environment as the petrochemical industry.

My name is Igor Gromov, and I work in SIBUR in the function “Digital technologies”, in the direction of digitalization of processes. Now we are actively engaged in the translation into electronic form of our work orders.

')

Work Admission is a safety instruction that is issued to personnel to work with increased danger at industrial sites. Such works include work at heights, earthworks, fire and gas hazardous work. Fire and gas hazardous at SIBUR enterprises account for the largest share of all works of heightened danger. Firing is dangerous because during their holding there is a possibility of heating the structure or tool, and it is necessary to take safety measures against fire and burns. During gas hazardous work, gases may be emitted from tanks or pipelines, some of which are explosive and may cause poisoning.

To avoid injuries and accidents, a work permit is created. It describes in detail what safety measures should be observed during each type of such work - for example, be sure to wear a helmet, cover your eyes with a protective mask, check the air at the work site for the maximum permissible concentration of hydrocarbons.

In this post I will tell you why it is important to transfer the huge document flow associated with tolerance outfits into digital format.

SIBUR is tens of thousands of units of complex equipment that are constantly in need of repair. Here, as with a private car - you know that after 10-15 thousand kilometers you need to change the oil, then with time - pads and stuff. And we have a lot of pumps, compressors, heat exchangers and other complex iron. Each unit has a scheduled operation time without interruption for repairs or maintenance. During many repairs can not do without the work of increased danger. Therefore, there are a lot of orders-tolerances within one enterprise during the year - the bill goes to thousands, and in some places tens of thousands.

As a result, production engineers draw up a huge number of documents (according to the law, every work permit is made in 2 copies). To understand - a day at the SIBUR Tobolsk plant a stack of paper one meter high is formed.

Of course, paper saving and environmental issues are important. But she is not the only one here, there are other important reasons for digitizing tolerance outfits.

Data

Each work permit contains a lot of useful information, not only for the personnel conducting the repair, but also for the analyst - the crew, location, time. Sometimes it happens that some work is performed by a brigade of 3 people, somewhere 5-7 is already required, somewhere in general 10. All this data, if collected and analyzed, can be useful in planning the next work that is similar to the rules.

Collecting and evaluating such data normally in the previous process is to dig into paper with a head, write everything down manually into some kind of sign and try to work with it. On the scale of SIBUR, this approach is difficult to make effective.

Work on clearance orders governs federal legislation - “Rules for the safe conduct of fire, gas hazard and repair work,” for which the work permit must be stored for 30 days. This is necessary in the event that an emergency situation occurs during repair, causing damage to the employee. Then the supervisory authorities will have 30 days to come and carry out an inspection, including data from the work permit.

Starting from 2017, regulations permit the issuance of work permit for the execution of gas hazardous, fire and repair work in electronic form, instead of the work permit with paperwork. When working with the electronic form, we also need to focus on the federal law "On electronic signature".

How it all happened

The work process with the work permit consists of the following steps:

- To form a work permit.

- Agree on a work permit.

- Approve outfit admission.

- Perform security measures in its preparation and report it.

- Implement safety measures when carrying out outfits directly.

It looks easy. In fact, in terms of digitalization and improvement of business processes, there is an abyss of opportunities inside. So far we have begun to work at the first level, which is dedicated to the formation of work orders.

The main task that we solve at this stage is to relieve the participants of the process from the necessity of forced creation. Previously, engineers had to enter a list of necessary security measures at the stages of preparation and work, keep it all in mind or edit word-templates, remember where and what security measures we have. A person in such conditions may miss something or vice versa - to be safe and write in too much. In each of the units, dozens of work orders must be drawn up every day, people can simply get tired.

What we have now

For the first stage, we have created a database that corresponds with each type of work and with the units of equipment on which these works should be carried out. In the database there is a list of all equipment, and technological maps, and security measures. Using an uncomplicated interface and database, the employee selects the necessary conditions and creates a work permit. Everything about everything now takes one or two minutes, and the output is a finished document, which can already be used.

The second important step was the issue of navigation - in the work permit, you must also indicate the location of the work during hot work. A person should know exactly where to carry out work, where fire extinguishing agents are located and the like. We also simplified this by taking schemes from process regulations. We wrote a simple browser-based image editor, which allows a person to quickly put the necessary marks on the scheme and get a ready-made map for specific works.

Previously, employees had to disassemble in a pile of folders, look for schemes there, draw layouts in Visio, outlining the necessary objects. Now you just get the scheme of the place of work and note everything important.

As a result, the time of the formation of a dress, we have reduced by 5 times.

It sounds cool, but it's not an end in itself. In our case, it is 2 minutes now versus 10 minutes before. But if you sit down and translate this effect into real money for the enterprise, the effect will not be very large. And if you even bring the cost of maintaining your own development unit for this purpose under these figures (reducing the time of formation of the order), the economy will hardly converge.

The main thing that was achieved was to reduce the time loss of the working teams, which carry out work on the work permit.

Each clearance is always time. And before we started, this time was 1.5-2 hours. That is, a team of 10 people fully armed could sit for a couple of hours and wait for the work permit to go through all the bureaucratic steps, and you could go to work. Let me remind you that the outfits - tens of thousands. And if already here such temporary losses for the downtime of the brigade to transfer into money are tens of millions of rubles a year.

Second phase

The next important point will be the full implementation of the electronic signature in the product. Now to get a signature on the dress and its approval have to move a lot around the plant. You need to take outfit, go to the head of the unit, so that he put the signature. And he has a lot of other things besides the signature, and he may not be in place, which means you have to wait until he returns from the meeting and signs.

Therefore, we completely translate this into an electronic format, so that the person who has created a work permit in the web just sends it for approval in electronic form. There it will receive, sign and agree remotely.

Here a good help is 63-FZ about a digital signature, one type of which is a simple electronic signature. On a corporate scale, if simplified for understanding, an electronic signature is a “login-password” pair in the corporate system. If a person is logged in to the system, then it is considered that all documents that he sends from his account to colleagues are signed with a simple electronic signature.

A simple electronic signature meets the requirements of supervisory authorities and, in comparison with a reinforced electronic signature, is easily scalable. It does not need certification centers, enhanced signatures, tokens and certificates.

The main difficulty with a simple electronic signature is that not all employees have accounts in information systems. Mechanics who are directly involved in repairs do not need a working computer. Now we are designing a system that will allow us to collect simple electronic signatures from people without familiar accounts. I will tell you about the decision when it will be ready.

Important about infrastructure and development practices

To get a product that works in a work environment, an excellent team of designers and developers is not enough. Yes, now the industry has a lot of tools that allow you to create fast prototypes and collect feedback from users. But our experience shows that between the prototype, which everyone likes, and the really working product that everyone is ready to use is an impressive distance. And at this distance is the development of infrastructure, the formation and alignment of those processes that should fit into it.

A couple of years ago, German Oskarovich Gref lamented the fact that Sberbank units were slowly rolling out software updates, compared to Silicon Valley companies. Sberbank then entered the phase of building DevOps ...

At the very beginning, the situation with the speed of appearance of changes in the working environment was unbearable - neither hardware, nor DevOps-experts, nor software, which was already coordinated with colleagues from information security. From 12 months, we spent about 70% of the time on building a continuous integration process (CI), and we will get to continuous delivery (CD) in the next couple of months. Our team consists of a designer, 6 developers, a scrum master and a product owner, and we are also looking for a QA specialist. So far I like how everything works, especially the realization that the software development system, which is beginning to produce results, appeared in such a conservative environment as the petrochemical industry.

Source: https://habr.com/ru/post/453020/

All Articles