As in Leroy Merlin, you can buy goods from the supplier's warehouse, which is not in the assortment of the store.

We in Leroy have a lot of products that I would like to put on the shelves. For example, more types of wallpaper. Or professional equipment. We have materials for finishing the bedrooms, but there are no beds or bed linen. And so on. 16 million people visit the site monthly with a population of Russia of 146.8 million people. Believe me, our customers want a lot of things, except for 40 thousand products of the main range.

So, marketing comes to us and says: listen, dear developers, you are so cool and fast that you can probably sip a platform for us to let different suppliers sell their goods through the site. And we completed it in delivery to our usual goods.

')

This is space. It’s almost like buying a product and selling it to a customer, but without purchasing it. In the sense of: what the customer wants, we immediately show him the supplier, he buys, the transport company carries with our documents directly (as if it was bought from us), and if you suddenly need to return under warranty or exchange - this is done through any our store.

If successful, this is such a dramatic change in the business model that one can be proud of for another three years. And implement all a couple of months. As we initially thought.

How does all this work?

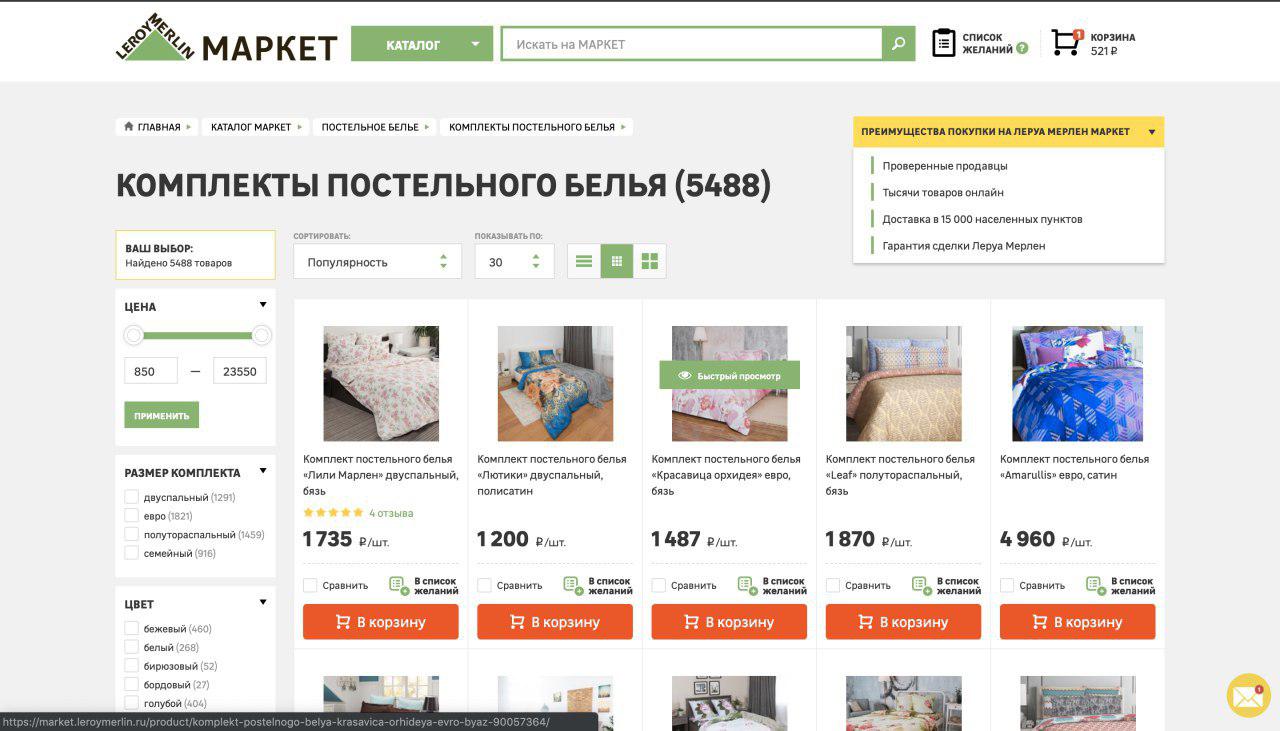

You buy something for us from the bedroom and you want to buy unusual clothes for it:

Before, we had no such linen. And now not. But you can buy it. The same applies to the same machines or professional vacuum cleaners. Here is the equipment that rarely gets on the shelves:

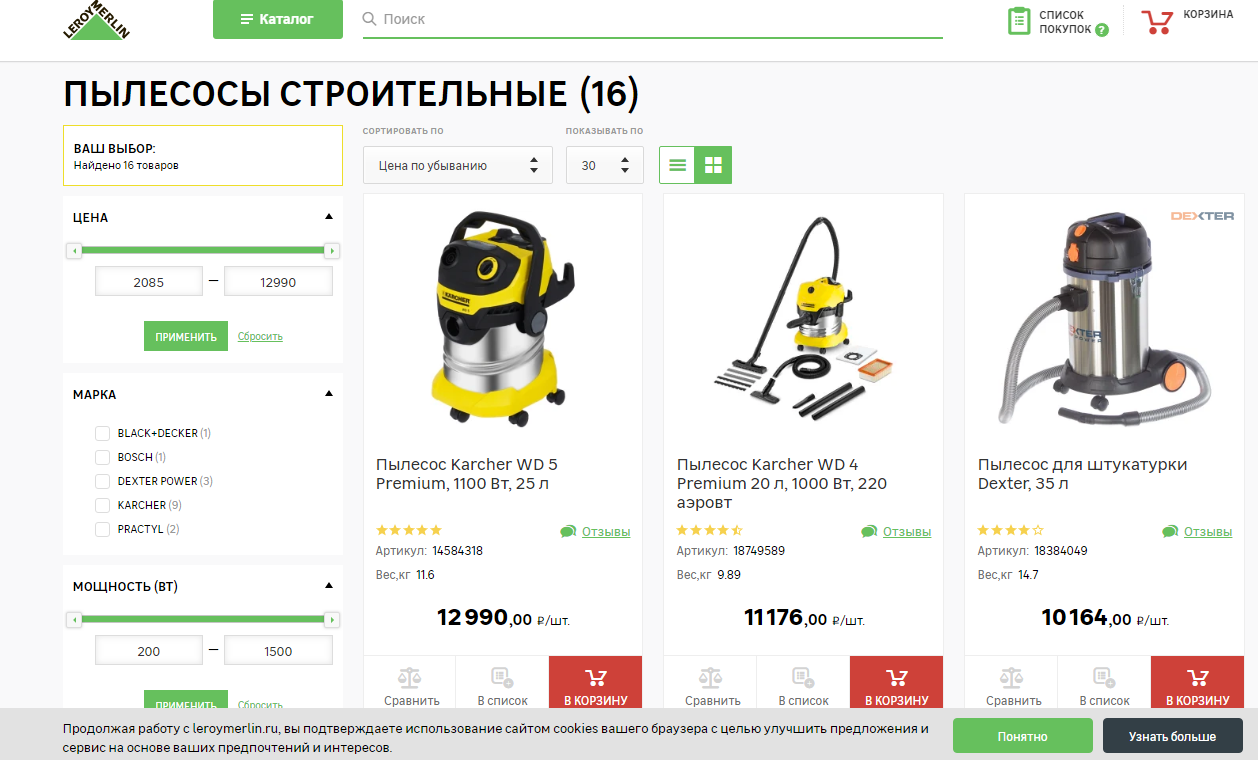

But construction vacuum cleaners:

We don’t put professional tools on the shelves, because the demand is low. Yet these are single items for many cities. But small business has this demand, and you still want to sell it. Moreover, they come to us in search of such.

Our suppliers in the line all the goods from the examples there. Most likely, we take from such suppliers of pieces 50 best products, despite the fact that he has a total range of 300-2000 positions. And we also deliver from other marketplace suppliers that do not work with us in retail.

That is, we can offer the supplier to put his goods in our online store, but not ship to our warehouse.

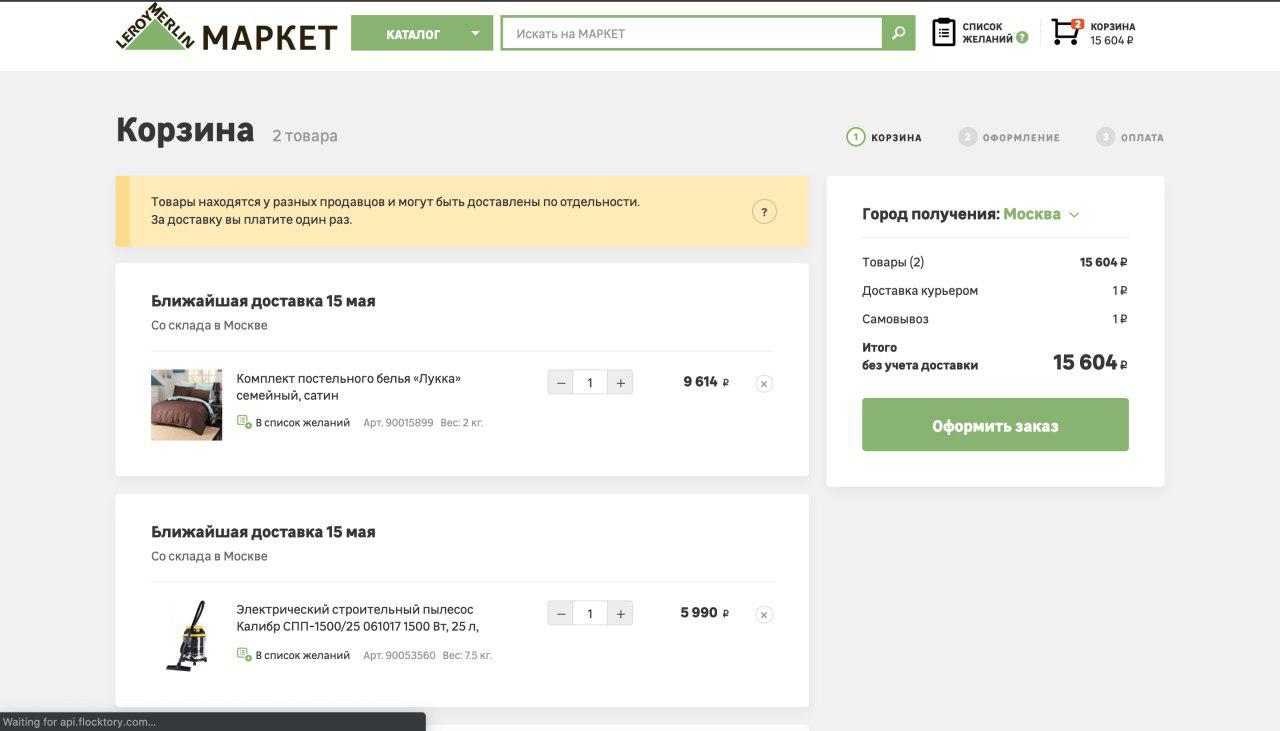

When you buy bed linen or something else that is not off the shelf, you will receive a separate delivery from the supplier’s warehouse. We pay off with the supplier - as if we buy this product from him, give our documents to him and send to you. But physically the goods travels directly from the supplier.

You receive the goods with documents from us.

In case of problems with the goods (damage or exchange) return to us.

Then the same model was expanded to suppliers whose goods are not yet on our shelves: for example, in the regions there are a lot of individual entrepreneurs and small LLCs selling a related range, but with them there is simply no time and opportunity to bother to enter into supply contracts. This is a huge task for big retailers: in order to properly comply with the contract when working with the network, you need to have your own department that monitors only such an agreement.

This same story is also needed to quickly test new products. Sometimes the supplier comes to us and says: but take the XXX product, it is new and wonderful. We need to evaluate it (this time), purchase, describe, arrange, and so on, and if it turns out to be not very remarkable, then we will spend a lot of time and money on it.

Now these products can be tested on the marketplace. And if they are in great demand - immediately put in the network. That is, we got a test site.

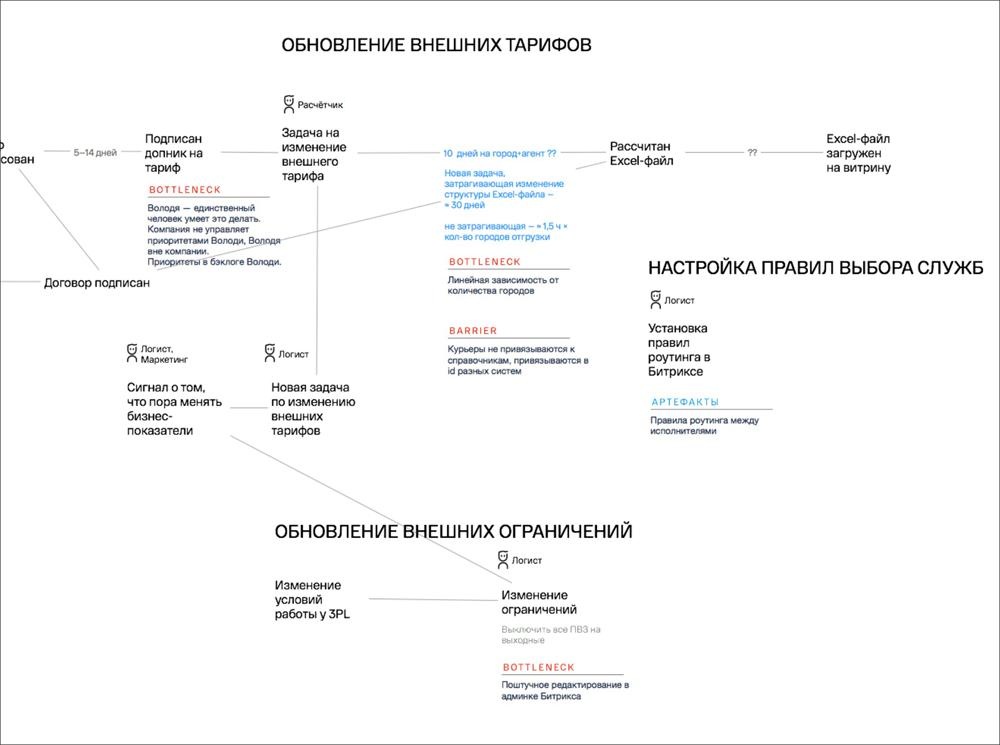

The third feature is that our purchasing process is largely tied to manual processes and has a pair of fairly narrow bottlenecks. Creating a new process architecture from scratch is a task that is close to impossible, you can only slowly move towards improvement. Because the burden on purchases is very large. Marketplace, on the other hand, makes it possible to build a parallel process of very fast automated procurement alongside it - the way it should be in the future. After a couple of years of parallel work, it will be possible to simply switch all purchases to this corridor (with some modifications) and save an incredible amount of resources.

In general, all this had to be done. Our eyes were burning.

It was the tip of the iceberg

For the third reason from the list above, we decided to isolate the marketplace from the rest of the business logic of Leroy Merlin to reduce business costs through automation. After all, it is for this that the IT department in the company is needed - to be able to solve tasks that require flexibility.

We have created a separate business unit next to traditional retail and e-commerce. We started with the materials for decoration - there are really millions of SKUs, and they are always lacking in the spirit of clients: “Is there the same, only more polished?”

Appeared as a start-up inside the company, they started rolling out MVP. For three months, we collected requirements for the process and thought about how quickly to show that this was possible at all.

It turned out that almost everything needs to be redone. Almost none of the traditional processes suited us. We needed a separate web showcase, a separate logistics management system, and separate suppliers. There were a lot of conflicts of interests at the choice of the range - for example, if you bought everything for the hallway, then it seems clear that the cat house in the hallway also needs to be sold "after" on the marketplace. But the cat itself? Cat food? It seems not. But how to find the border?

Then it turned out that in the regions there are a lot of local suppliers who, in order to sell well on the new channel, where it is very simple to sell quite a lot of goods, by their standards, began to lower prices. More precisely, to lower the prices of analogues of our products, which are mainly in the assortment. And since our policy is the most affordable prices, we had to make a model for recalculating prices for retail goods, if a player with a similar product appears in the marketplace.

In general, we worked at MVP for about half a year and did almost everything with Excel macros (in fact, no, but there was a lot on crutches and blue electrical tape). The task was to complete the requirements.

After six months, we realized that we had known almost all the problems of this world and sat down to collect a new release - not as a startup, but as an internal priority project. A normal technological stack appeared, a thought about a highload appeared, the team increased, processes appeared.

Reality and pitfalls

Firstly, we try to connect three parts of communication (retail, traditional e-commerce and our platform) into one common sales channel. This is called omnikanal, it looks like an extended application online. For example, as a terminal in a store where you can order the wallpaper of the desired pattern, if it is not in the main assortment.

The sales assistant, of course, must know and understand this. And the problem is that he gets a bonus for selling in his store (whether offline or online with delivery from his store), and he has absolutely no motivation to do something in the marketplace. Therefore, we had to sort out the business process of the formation of salaries so that this product was also taken into account in the turnover and bonus.

Secondly, we needed a distributed external logistics. These are some services that, on our instructions, go to the supplier to the warehouse, pick up the goods there, take him to the customer. We do not trust delivery to the partner, because in case of possible problems there should be a second company that will pick up the order. All logisticians must meet our requirements for service, that is, at least be punctual, polite and leave the necessary documents. After all, the customer does not distinguish our products from the marketplace.

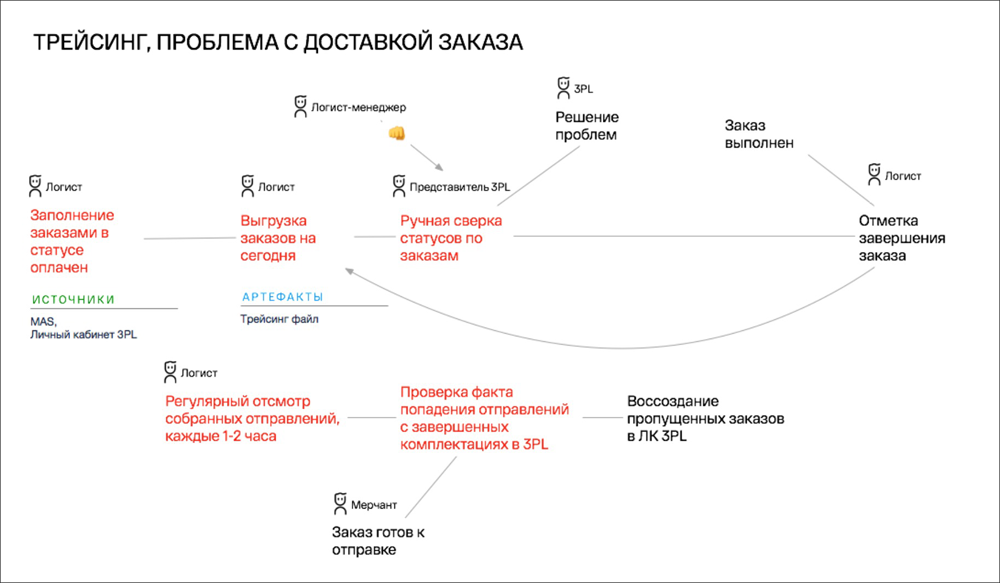

The operational part - tracking and management, distribution to partners, preparation of the document for the incoming service, tracing and control of deviations.

Third, I needed a shipping price calculator. The calculator should answer the question how much it costs to deliver each item. To be more precise - how much does it cost to deliver a composition of several products of a known size and a known weight. The number of requests for a calculator is two orders of magnitude greater than the number of actual orders, since these data are used in different informers. In particular, the customer must immediately see on the item card how much it will cost with delivery.

Just the fact that there is no consolidation of orders on our side from several suppliers. The difficult thing is that there are several logistic stories with the SLA, which are abutting against each other, and they always “sparkle” at the places of these joints. Our function is to orchestrate the order and delivery automatically. The next step is consolidation at the intermediate hub, but this is in the plans.

The system was designed in two priorities:

- Ideal on time delivered order.

- Orders processed for the number of partners (flow rate).

An example of a problem: they counted one shipment, the logisticians arrived behind the box, and it was a different size. Changed the characteristics of the order on the fly.

Fourth, the range. Question: if there are two similar products in our range and in the range of the supplier - is it necessary to drop in price to a minimum? Yes, in terms of price policy, Leroy Merlin in the same city is necessary. And if this is another city? Then, probably, no: someone is ready to change the 8% discount for four days of waiting.

Another question: two suppliers brought working mittens to the marketplace. We have them in the range of 40 species, they added another 50 each. 10 of them are intersections, and their prices are different. Leave both? Maybe yes. The client is interested in the speed of delivery, and here she will go from different places and at different prices.

Fifth, the exchange of current stock and prices. Suppliers should unload it all regularly, or send requests to us when they change. We decided to use automatic modules for their ERP - most often it is 1C, and there are many solutions. And the difficulty is this: in order for a supplier to correctly account in 1C, it is necessary that it be more or less large. And when it is more or less large, its 1C is sometimes a mess of crutches. In the end, it turns out that every connection must be maintained. A little, but necessary. Therefore, for the time being, we have decided to limit ourselves to medium-sized business in the list of suppliers in Moscow and experiment with large individual entrepreneurs in the regions.

The exchange of descriptions and photographs is also available through the supplier portal: sometimes, they have a product changed within the same article number. Then you need to go and change the parameters, or unload the correct ones. We are still separately take away the price and availability and separately - characteristics and photos.

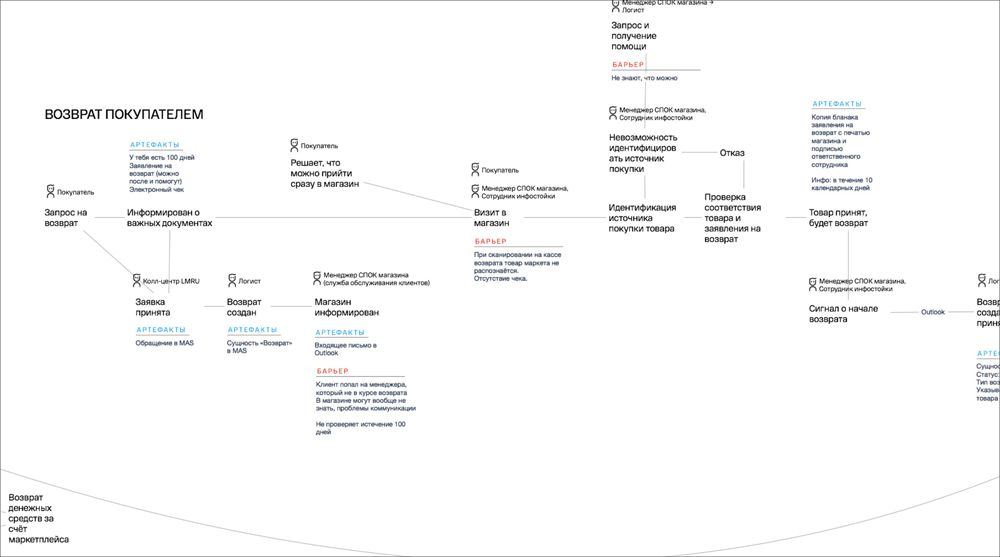

Sixth, return. To return goods to the store, you need:

- Arrange with the store that they accept returns. This means changing the seller’s training system, because, of course, not all of them understand what it is and how to work with it.

- Make verification procedures in IT-systems of sellers: at first they did not know where to look for checks, and did not check the dates of returns.

- Set up a financial return process (it was relatively fast).

- Repacking the shipping container, because often a return is made without a box.

- Make a replacement service (another loop for delivery): we do not repair the goods in the service, but simply give them back to the supplier and send a new one when exchanging. In fact, any incident on the goods ends in return.

Treaties. At first, we thought that we would have to look for local suppliers, but the situation was reversed. Everyone is climbing into the world and they want to go to the marketplace, because they consider it as an outlet for distribution (which is a victory for many) or as an additional sales channel. There was a difficulty at the input control. Now we have automated everything that is asking for automation, but still there remains a long process of legal verification. Why it is necessary - because if the supplier disappears, then we, of course, will solve the issue with the client, but we will get on the VAT.

Now there are big plans for scoring and rating: for example, if not shipped on time, then degraded in the stars. On the issue will affect the accuracy of the description, price level, speed picking and so on. Rating drops below three - you can refuse the supplier.

Another feature of the marketplace is the war for search promotion. Actually need more content. And content from suppliers is difficult. Therefore, a process was needed for grocery descriptions and images. We outsource photography in studios in the regions: we offer the supplier a photo shoot service for their product. He pays for and receives pictures (often the first in his life for goods) - we load them on the marketplace, in particular. Descriptions of the goods are made in approximately the same way.

Over bringing to the monotony of the attributes of goods to facilitate the search in the marketplace still have to work.

And the last important feature of the project - it was extremely important for us to coordinate in the perimeter of Legacy-systems of the head Leroy Merlin (more precisely, the “parent” group of companies ADEO) in France. Because any change, testing, coordination and implementation are quite lengthy processes. Therefore, in some places we have duplicated the processes in a new way. We chose the API-centric-architecture on microservices, on the proto we describe all the apices of each service, and then Go (for scaling and loads) or Node.js. As a base, MongoDB and PostgreSQL. For a part of the development, outsourcers were attracted, played in the hybrid team method. On this project, outsourcing is located in Chelyabinsk, but we have 30% of the team. With the success of the project we plan to gradually reduce outsourcing resources and increase our own. Nonetheless, outsourcing helped us accomplish a quick start to the project plus showed some features of the API-centic-approach that are not obvious to the team in practice.

Total

A similar marketplace started in Brazil a little later than ours. They are smaller, and there are problems with logistics, which we immediately decided at the stage of thinking through the architecture. In France, the marketplace is older than ours, but there is rather a feature of the “long tail” - that which belongs to Leroy, but is not in a particular store. There, the peculiarity was that the buyers trained the sellers to sell from there, because they were very demanding for the goods.

We made it. It all worked. It is not ideal, but we really like the story, because we rewrote a lot of the old overhead project, made our product, the product has healed better than its counterparts in the world and brings practical benefits. The roadmap is still large, but you can already share the joy of good work. This is the project when you know that something has changed in the world.

Source: https://habr.com/ru/post/452000/

All Articles