Launched production of the Federation spacecraft

In Russia, the production of the hull of the first copy of the new generation Federation spacecraft began.

At the Samara-based enterprise Arkonik SMZ, they began to fulfill an order from the Experimental Machine-Building Plant, which is part of the Energia Rocket and Space Corporation (RSC), for the manufacture of an aluminum hull for the first Federation ship.

At the first stage of the fulfillment of this order, the chassis of the aggregate compartment and the returned apparatus will be manufactured.

')

The Arkonik SMZ enterprise has been cooperating with RSC Energia for a long time and possesses all the necessary industrial capacities to fulfill the order, it is the largest Russian enterprise for the production of aluminum semi-finished products.

The Samara Metallurgical Plant employs about 3,000 people, the quality management system at the plant is certified according to ISO 9001, and the company's environmental management system is certified according to ISO 14001.

According to the contract between RSC Energia and Roskosmos, the manufacture of the Federation ship for the first flight was to begin in 2016 and last until 2023.

After several years of delays, Roskosmos finally began making a new body of the Federation spacecraft.

The Roskosmos state corporation is now fully engaged in monitoring the manufacture of the elements of a manned transport ship, and comprehensive measures are being carried out to support and monitor the stages of its production.

The aggregate compartment and the returned apparatus of the Federation will be made of aluminum, although it was previously assumed that the new ship would be 80% composite.

In 2015, Roscosmos demonstrated a composite carbon fiber capsule of a prototype ship at the MAKS air show.

It turns out that the capsule for this presentation was made in Germany at the facilities of Aerospace Composites GmbH, specially commissioned by RSC Energia.

However, due to the sanctions for the delivery of finished composite products to Russia, the order of carbon capsules for spacecraft has now become impossible.

Several years ago, RSC Energia made a decision to deploy a plant for the production of composite products on its territory. Currently, there is no data on the readiness of the workshop and equipment for the production of the necessary units.

It is possible that the development and launch of this plant was preventively stopped when the composite hull of the Federation ship did not pass a toxicological check.

It turned out that during a long flight into the atmosphere of the ship can be released harmful and toxic substances.

In addition, a number of experts previously expressed concerns about the use of a composite body instead of aluminum due to the possible insufficient strength of the new material.

Currently, all foreign spacecraft are also made from aluminum - American Orion, Starliner and Dragon.

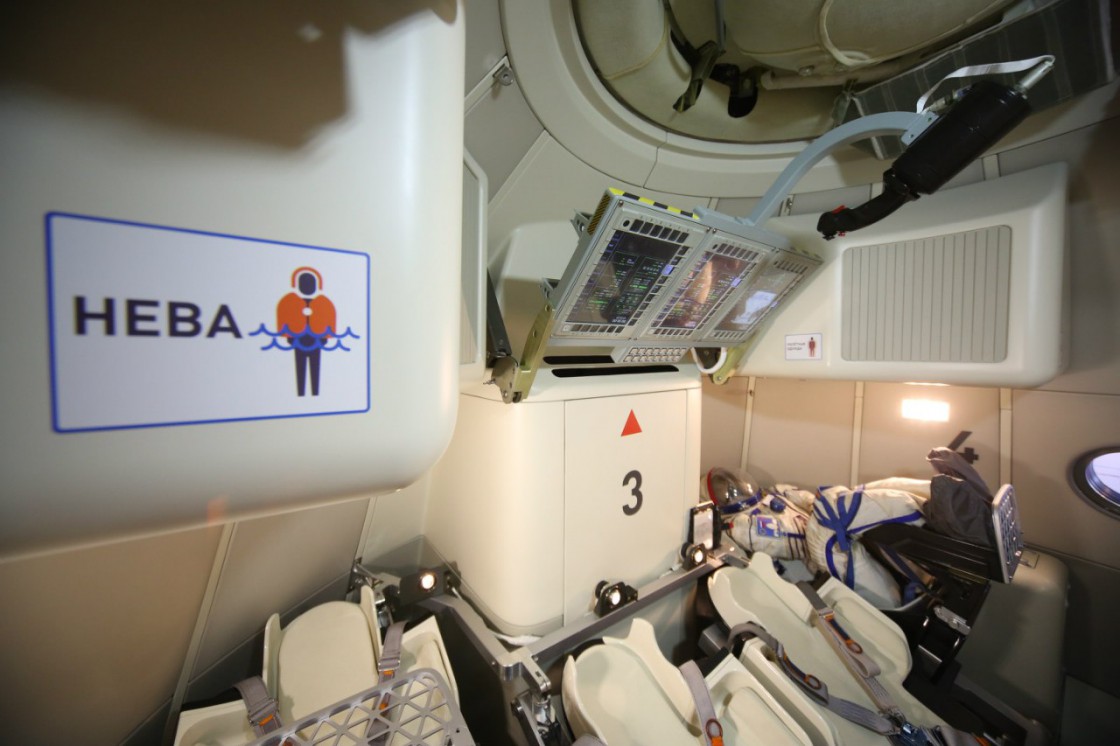

The Federation project is a reusable manned spacecraft of a new generation. The device should replace the Soyuz series ships.

It is assumed that the Federation will be put into orbit with the help of the Irtysh launch vehicle (the Soyuz-5 project).

In addition to problems with the material of the capsule and the delay in production, questions have arisen even about the name of the launched vehicles - new spacecraft, now called the Federation, can be renamed in honor of the first Russian ships built by Peter I.

In the "Roscosmos" as a new name offer: "Eagle", "Flag" or "Aist". It is emphasized that this is only an idea, and the final decision on this issue has not been made.

The first test flight of the Federation spacecraft is scheduled for 2022, and in 2023 it is planned to send it to the ISS in unmanned mode, in 2024 the spacecraft must go to the ISS with the crew on board.

Source: https://habr.com/ru/post/451646/

All Articles