How I bought a fiber laser marker in Russia + the nuances of choosing devices for engraving and marking in 2018

Hello! I want to tell a little about my experience of choosing a fiber laser engraver-marker for the needs of my engraving business.

I will begin with the fact that in machine tools, especially laser, I did not understand anything until 2018. All the orders that I received from clients were carried out by several printing houses, they have a large fleet of equipment, including laser markers, diode-pumped engravers. In September 2018, I realized that it was time to expand the business (especially the tariffs at these printing houses grew significantly) and having fined money, I decided it was time to buy my own machine for engraving.

Own accumulated funds were 400 thousand rubles. Another loan was approved by the bank for 150 thousand rubles. but planned to use them only as a last resort.

Comparing prices on the market - I realized that everything is not so simple and the difference in prices among suppliers reaches up to 1 million rubles!

')

Machines manufactured in Russia, Austria, USA - an average of 1.5 million rubles.

Aliexpress Chinese counterparts - About 300 thousand rubles. The Russian suppliers of Chinese machine tools - about 500-600 thousand rubles. From the main differences of all the options - work resource, quality of engraving, software convenience, technical support, training in work and a guarantee. It is clear that all the advantages were at the machines for 1.5 million rubles, but first things first.

I decided to reject the idea of buying a machine for Aliexpress or buying directly in China, because there are so many risks. 100% prepayment, and 300 thousand rubles. money for me and for Russia in general is not small. On the forums I read that the marriage will fall among such machines 50%. That is, it may be lucky and maybe not. This manifests itself as an engraving - for defective machines already for 2 months - there is no non-burning when engraving on metal, the power drops, and the accuracy of the laser deteriorates dramatically. Replacing the machine in this case is possible, but it’s still a story, you need to prepare the documents and send the machine back to the factory for diagnosis, you need to arrange a lot of documentation and wait for it + pay everything at your own expense (according to the members of the forum, it can take up to six months!) . Every day of idle time in my business is a loss of money, so I decided to look for a supplier in Russia, preferably in Moscow - the benefit is a great choice.

Money on the machine for 1.5 million rubles. I did not have, therefore, having studied the forums on the subject of lasers, I decided that I needed to go and watch the machines live. Fortunately, I geographically in Serpukhov, near Moscow.

Having visited several addresses of suppliers, I realized that Chinese lasers are also different and sometimes differ in price several times. Having visited the manufacturers of American lasers SharpMark - I realized that there is still such an interesting function as 3D engraving on metal (this can be made straight into the face of a person in metal). Very nice and impressive, to make a good 3D can take up to several days! Otherwise, for my purposes, namely engraving on souvenirs, occasionally rings and pendants of precious metals - I have nowhere to apply 3D.

Therefore, the option with an expensive laser has disappeared by itself, such a laser will pay off more than one year and not three (although I must pay tribute to the sellers of American lasers, I was offered a machine no longer for 1.5 million rubles, but for 990 thousand rubles, supposedly the model in which 3D is already gone).

In general, and 990 thousand rubles. - This is not within my budget, so I decided that I needed a good Chinese machine and always with a guarantee of 2-3 years in Russia so that I could quickly fix it.

Went to several other Chinese laser supplier companies. For myself, I realized that such companies also share those who:

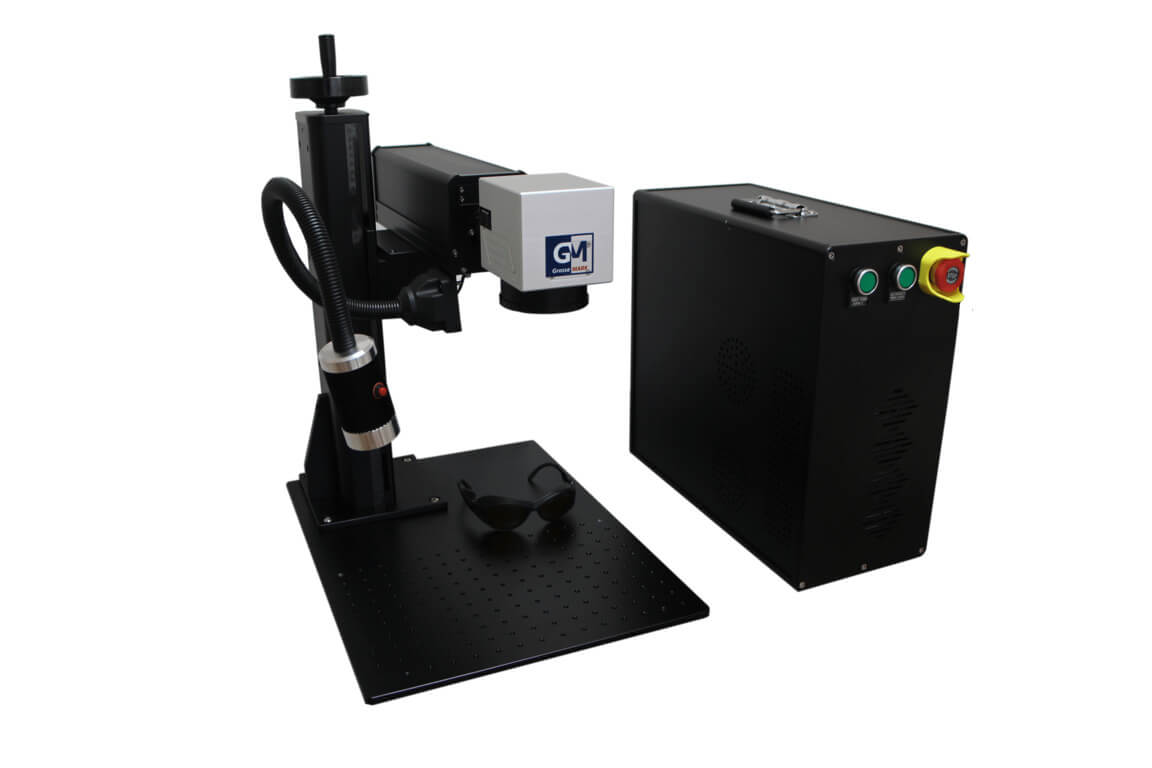

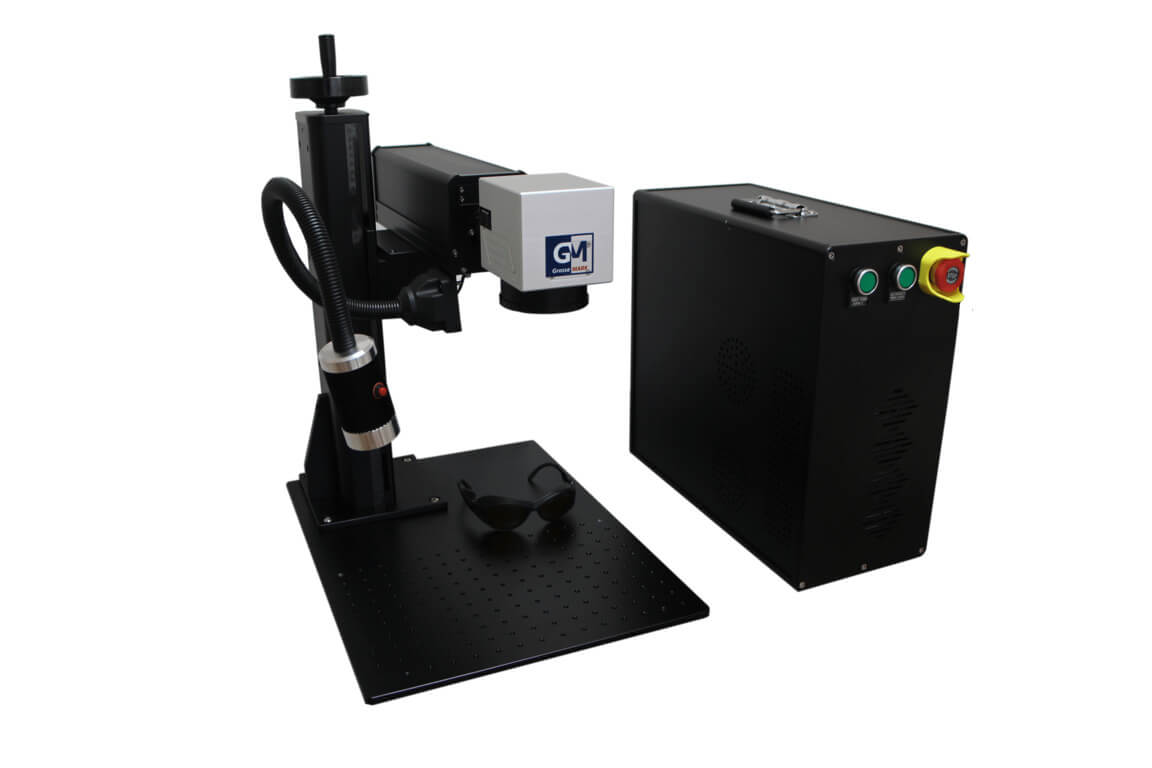

The choice fell on the second category, the technical specialists at such companies competently communicate, they know lasers at a good level, as a rule, many engraving samples and extensive experience in working on a laser.

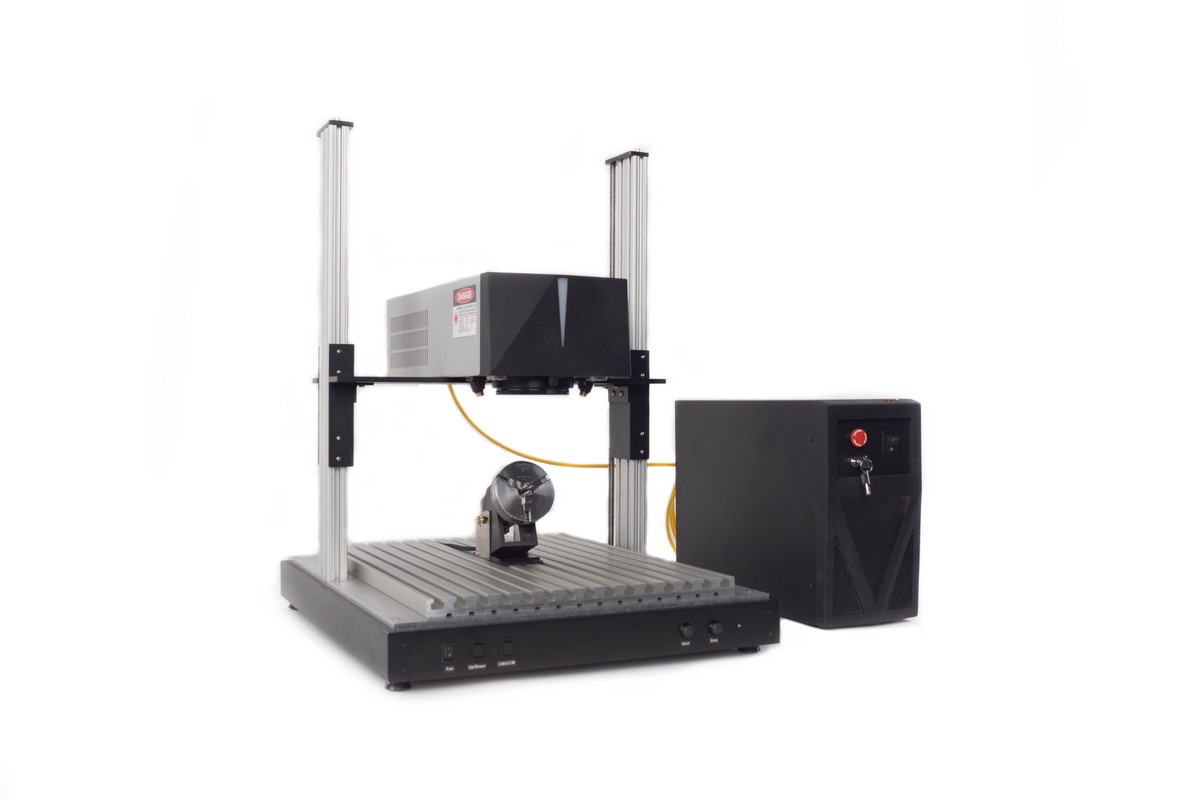

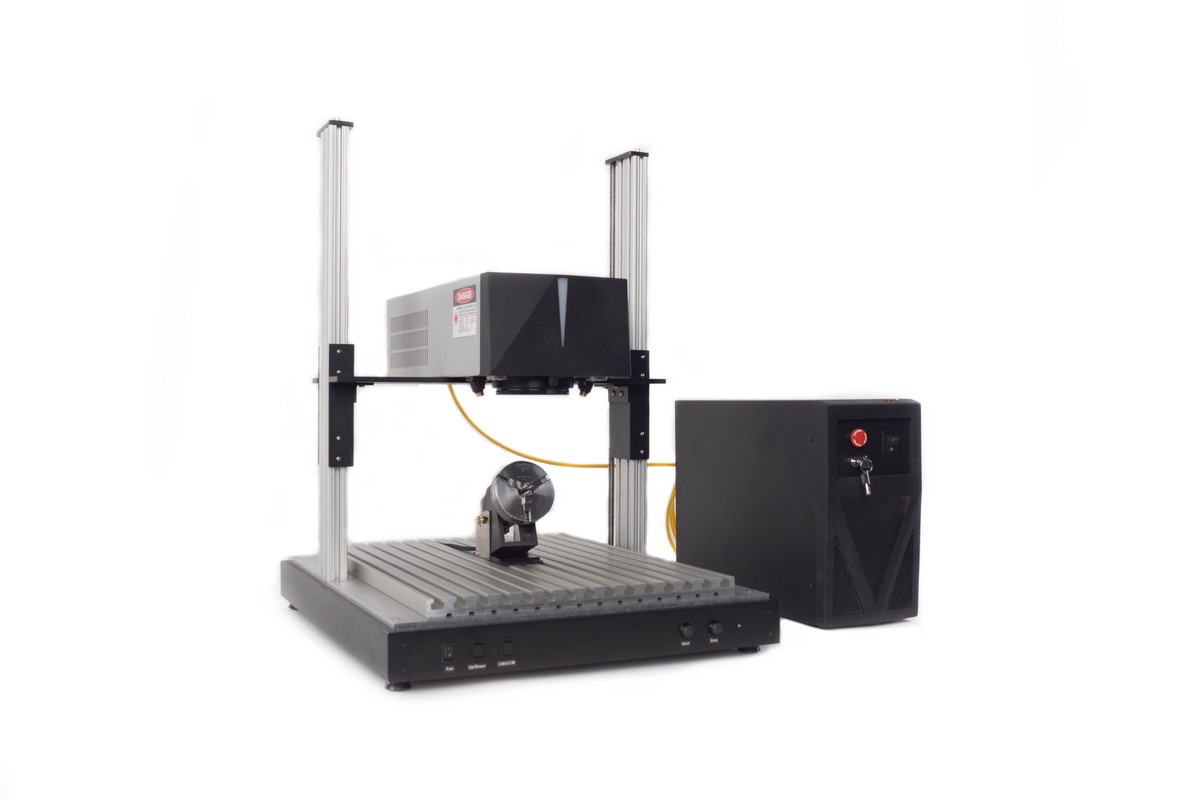

After talking with technical experts, I realized that a laser with a power of 30 W would be optimal for me (there is still 20 W - not enough for deep engraving, and 50 W - the price is already under 1 million). From the special stages I decided to take another turning device (for rings and thermo jacks) and a lens with a field of 220x220 mm (in the standard 110x110 mm - the field size is not always enough).

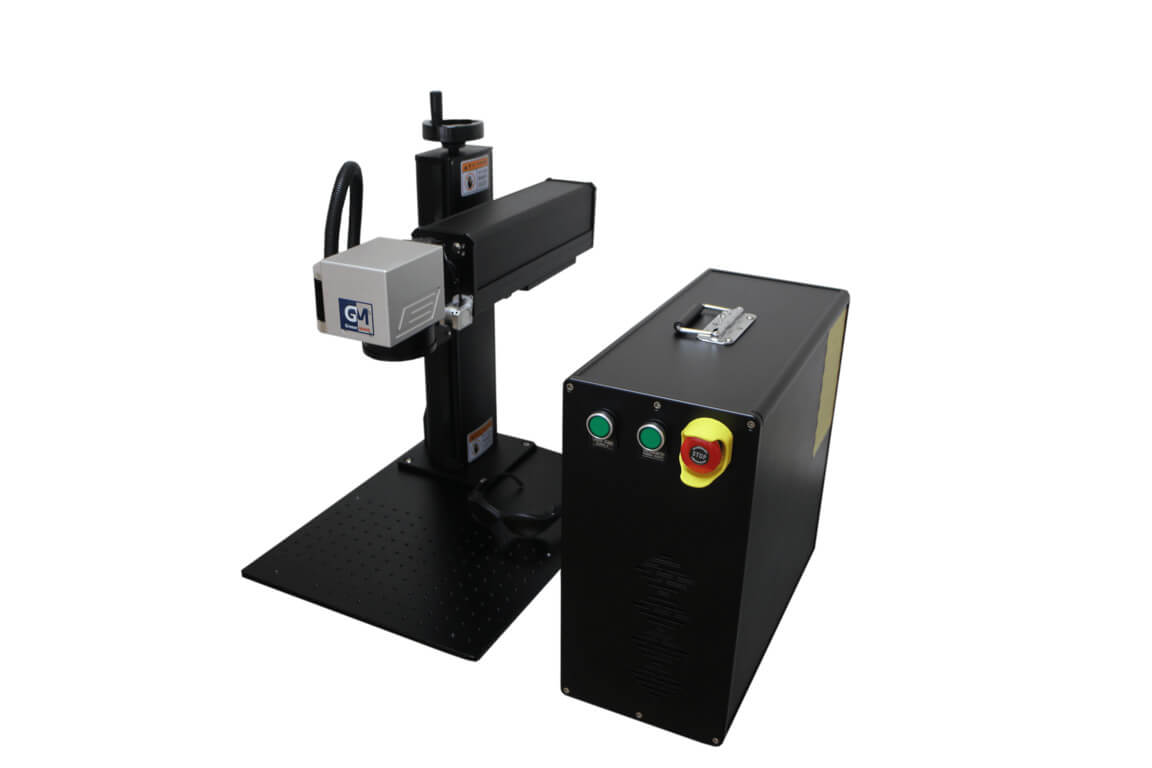

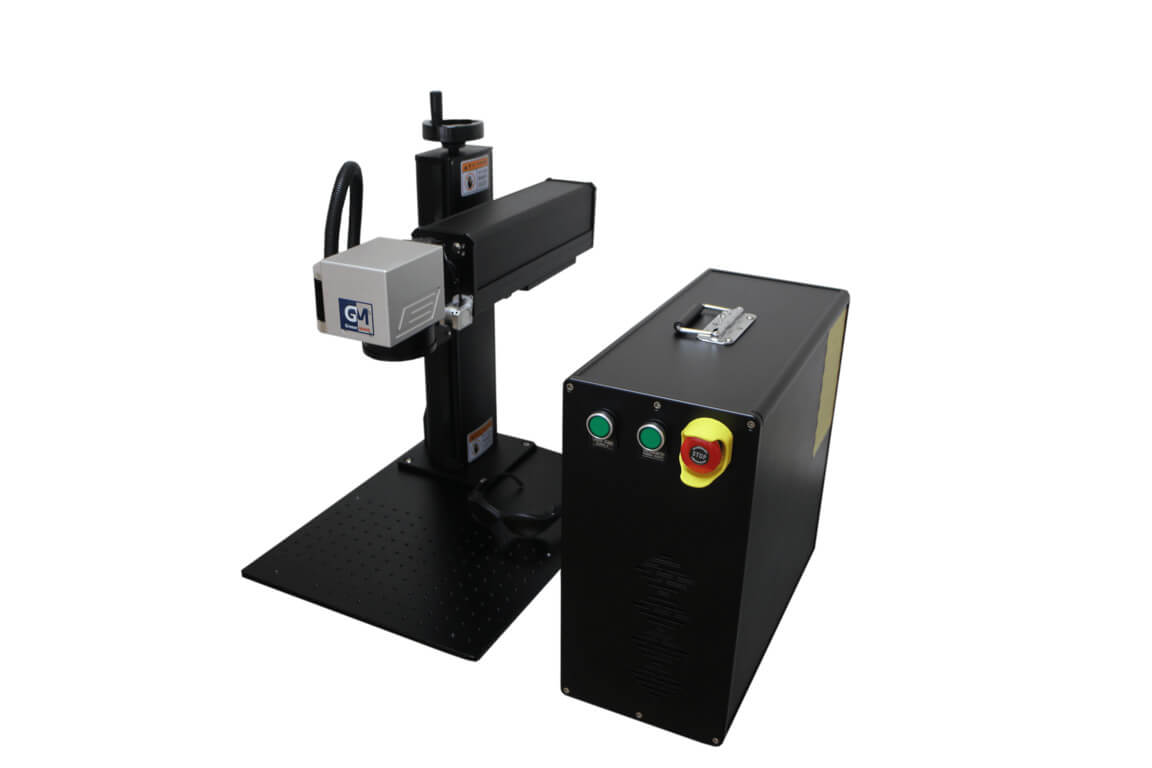

According to the results, I chose two companies, which had approximately the same prices and started bargaining. I had money in cash + credit = 550 thousand rubles. I also knocked out an additional 3 year guarantee for myself (2 years by default from both suppliers) and a discount for 100% prepayment of 50 thousand rubles.

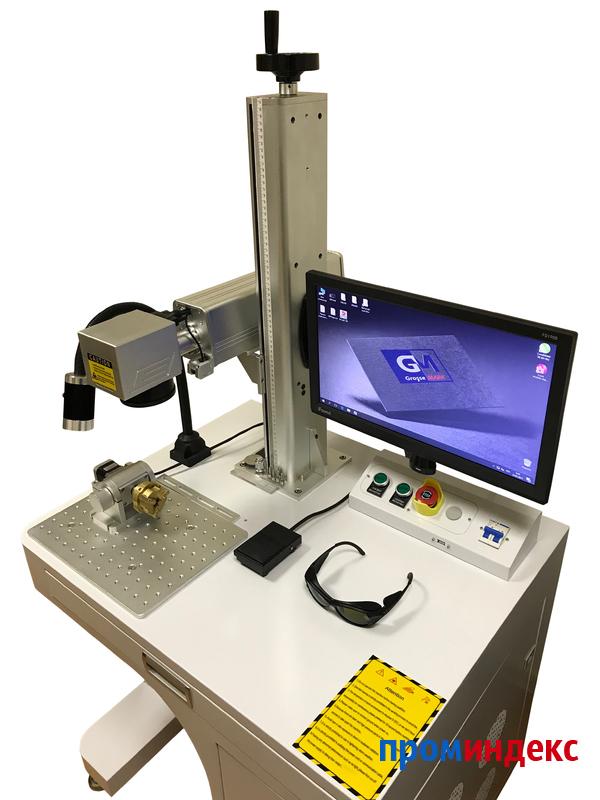

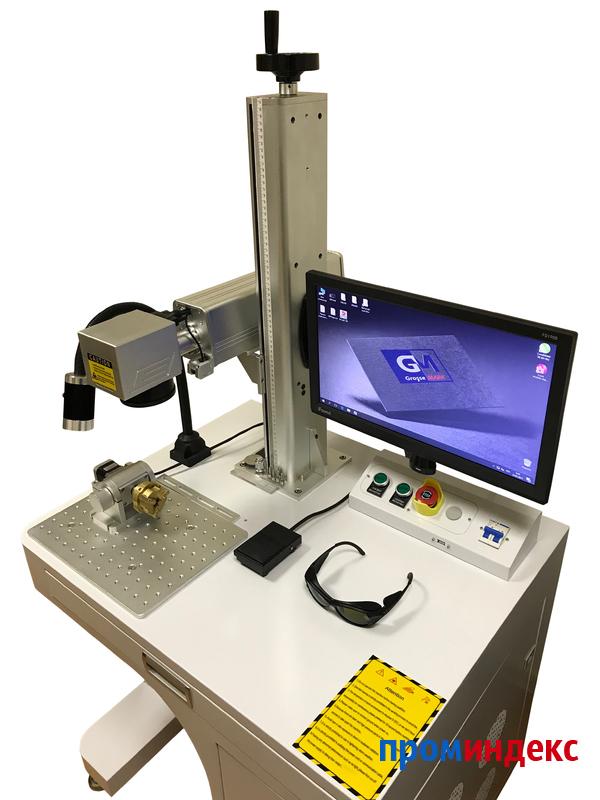

I work for the seventh month, normal flight. He went to the training himself personally to the office. After the machine took the car (took the desktop version). A couple of times the software crashed, updated the drivers for Win10 while everything works without failures. There were problems with plastic engraving, it was decided to adjust the layout in CorelDraw (there were overlapping lines on each other and plastic foamed where the lines overlapped).

I hope it was useful, write questions in the comments.

I will begin with the fact that in machine tools, especially laser, I did not understand anything until 2018. All the orders that I received from clients were carried out by several printing houses, they have a large fleet of equipment, including laser markers, diode-pumped engravers. In September 2018, I realized that it was time to expand the business (especially the tariffs at these printing houses grew significantly) and having fined money, I decided it was time to buy my own machine for engraving.

Budget

Own accumulated funds were 400 thousand rubles. Another loan was approved by the bank for 150 thousand rubles. but planned to use them only as a last resort.

Supplier selection:

Comparing prices on the market - I realized that everything is not so simple and the difference in prices among suppliers reaches up to 1 million rubles!

')

Machines manufactured in Russia, Austria, USA - an average of 1.5 million rubles.

Aliexpress Chinese counterparts - About 300 thousand rubles. The Russian suppliers of Chinese machine tools - about 500-600 thousand rubles. From the main differences of all the options - work resource, quality of engraving, software convenience, technical support, training in work and a guarantee. It is clear that all the advantages were at the machines for 1.5 million rubles, but first things first.

I decided to reject the idea of buying a machine for Aliexpress or buying directly in China, because there are so many risks. 100% prepayment, and 300 thousand rubles. money for me and for Russia in general is not small. On the forums I read that the marriage will fall among such machines 50%. That is, it may be lucky and maybe not. This manifests itself as an engraving - for defective machines already for 2 months - there is no non-burning when engraving on metal, the power drops, and the accuracy of the laser deteriorates dramatically. Replacing the machine in this case is possible, but it’s still a story, you need to prepare the documents and send the machine back to the factory for diagnosis, you need to arrange a lot of documentation and wait for it + pay everything at your own expense (according to the members of the forum, it can take up to six months!) . Every day of idle time in my business is a loss of money, so I decided to look for a supplier in Russia, preferably in Moscow - the benefit is a great choice.

Money on the machine for 1.5 million rubles. I did not have, therefore, having studied the forums on the subject of lasers, I decided that I needed to go and watch the machines live. Fortunately, I geographically in Serpukhov, near Moscow.

Having visited several addresses of suppliers, I realized that Chinese lasers are also different and sometimes differ in price several times. Having visited the manufacturers of American lasers SharpMark - I realized that there is still such an interesting function as 3D engraving on metal (this can be made straight into the face of a person in metal). Very nice and impressive, to make a good 3D can take up to several days! Otherwise, for my purposes, namely engraving on souvenirs, occasionally rings and pendants of precious metals - I have nowhere to apply 3D.

Therefore, the option with an expensive laser has disappeared by itself, such a laser will pay off more than one year and not three (although I must pay tribute to the sellers of American lasers, I was offered a machine no longer for 1.5 million rubles, but for 990 thousand rubles, supposedly the model in which 3D is already gone).

In general, and 990 thousand rubles. - This is not within my budget, so I decided that I needed a good Chinese machine and always with a guarantee of 2-3 years in Russia so that I could quickly fix it.

Went to several other Chinese laser supplier companies. For myself, I realized that such companies also share those who:

- Many different machines (milling, plasma cutters, sheet bending machines, 3D printers, etc.)

- Only laser machines (markers, engravers, welding, CO2 engravers)

The choice fell on the second category, the technical specialists at such companies competently communicate, they know lasers at a good level, as a rule, many engraving samples and extensive experience in working on a laser.

After talking with technical experts, I realized that a laser with a power of 30 W would be optimal for me (there is still 20 W - not enough for deep engraving, and 50 W - the price is already under 1 million). From the special stages I decided to take another turning device (for rings and thermo jacks) and a lens with a field of 220x220 mm (in the standard 110x110 mm - the field size is not always enough).

Purchase

According to the results, I chose two companies, which had approximately the same prices and started bargaining. I had money in cash + credit = 550 thousand rubles. I also knocked out an additional 3 year guarantee for myself (2 years by default from both suppliers) and a discount for 100% prepayment of 50 thousand rubles.

I work for the seventh month, normal flight. He went to the training himself personally to the office. After the machine took the car (took the desktop version). A couple of times the software crashed, updated the drivers for Win10 while everything works without failures. There were problems with plastic engraving, it was decided to adjust the layout in CorelDraw (there were overlapping lines on each other and plastic foamed where the lines overlapped).

I hope it was useful, write questions in the comments.

Source: https://habr.com/ru/post/451434/

All Articles