Production of printed circuit boards LUT'om from A to Z

Good day! Among my friends there is an opinion that it is useless to manufacture printed circuit boards (PCBs) independently. Considering that modern components have gone far from the DIP cases, then it’s not even worth trying to stifle motherboards for them. Nevertheless, there is always a need for a quick assessment of a component, and there is no time to wait for a few days ordered payment. And this is taking into account that an order for “several days” is expensive for a one-time task.

In this article, I want to outline the order of actions that will allow you to quickly make PP for components in cases of similar TQFP-100, that is, with legs of 0.2 mm and the same gap, and at the same time to reduce defects to a minimum.

Of course, this is a way to manufacture boards for prototypes only, but it reduces the risks of making a mistake when creating an end device.

')

There are a lot of articles and videos with similar tips, but as a rule, all the nuances of certain actions are not covered there. Here I want to show the whole process, which at home will allow for an hour and a half to produce an acceptable copy of the PP.

Under the cut details and traffic.

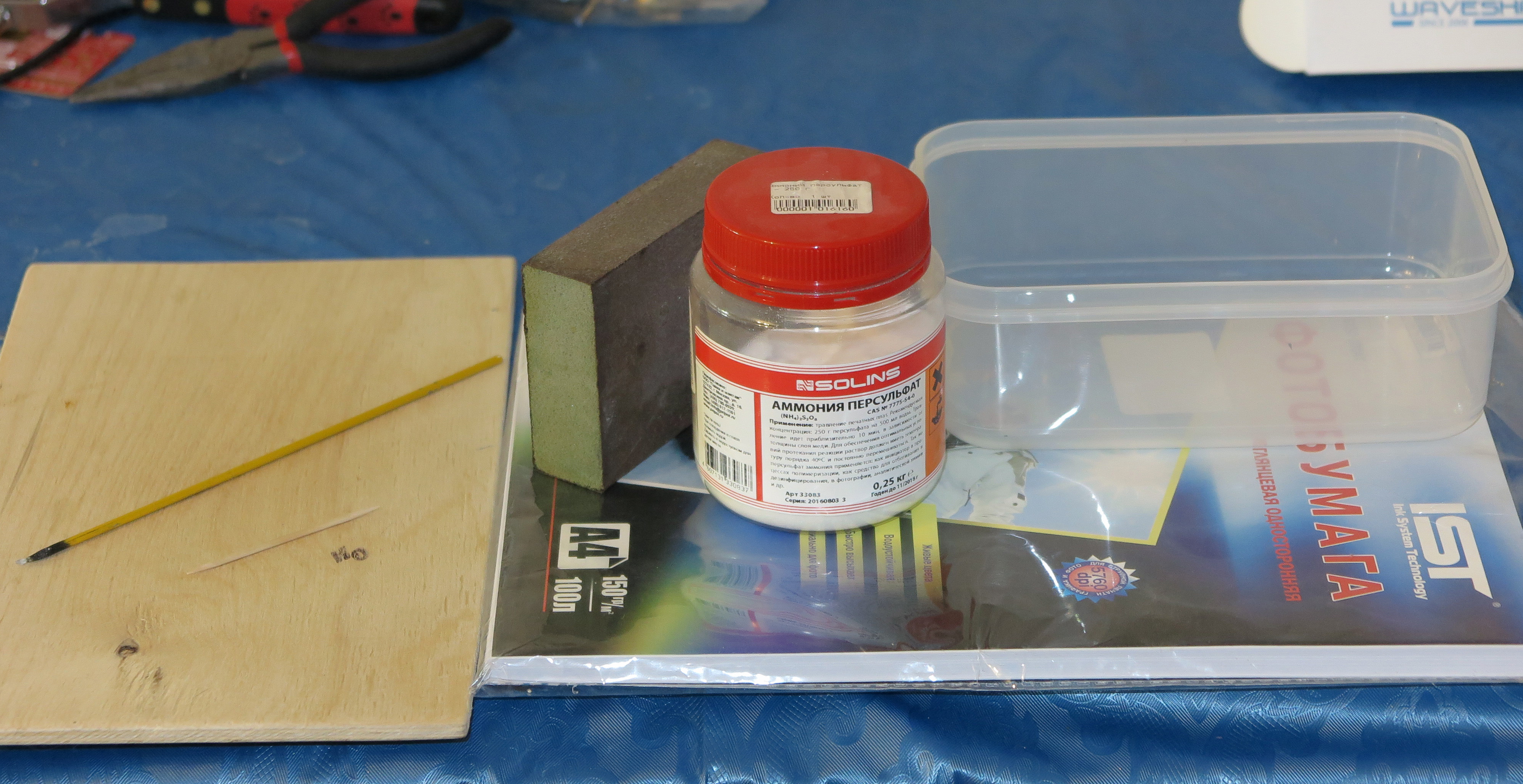

Minimum set of materials:

And, of course, a laser printer and an iron.

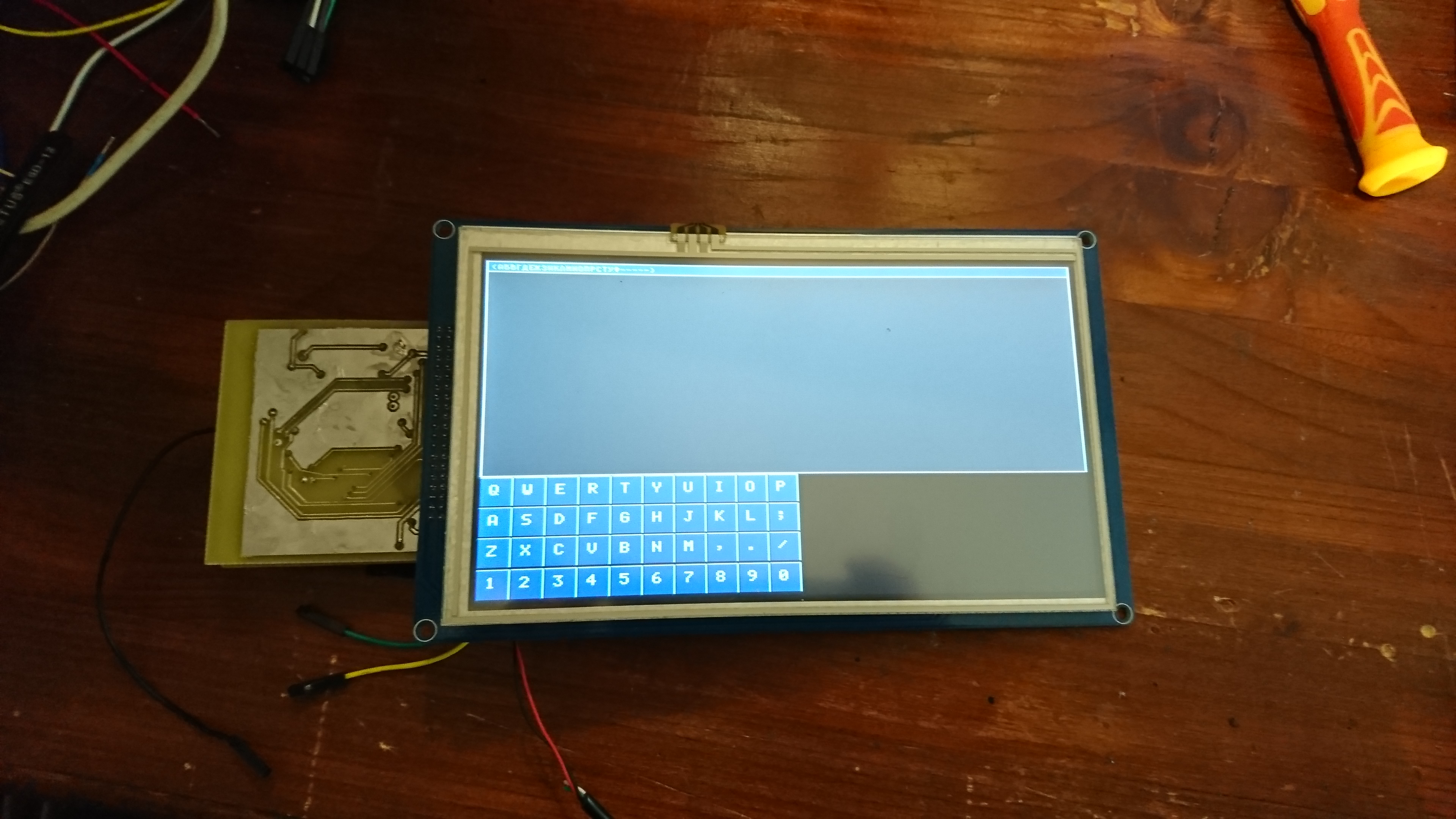

I will show the process on the manufacture of PP for the evaluation of the ATxmega128A1U-AU chip (evaluation of the declared hardware crypto module, EBI and in general), and the board for connecting a 7 inch display to the STM32F407VE

For evaluation boards I try to do the wiring only on one side, where intersections cannot be avoided, I put a resistor with resistance = 0 and case 0805, passing the road under it. If there are a lot of intersections and exactly two layers are needed, then I’m harassing each layer on a separate textolite (then I join it via VIA).

PCB preparation.

One-sided PCB with a copper thickness of 17-35 microns is washed from dirt with dishware under warm water, then a drop of washing agent is applied to the skin with P800 grain or less and the future board is polished to form roughness over the entire area. Moment with sandpaper required! In this way, the copper will not shut up to the holes, but we will ensure good adhesion of the toner. After polishing, the surface is washed with clean water, wiped dry and set aside to dry.

By the time of transfer of the layout, the textolite should be dry, free of oxides, oily stains and noticeable roughness.

In one of the articles I saw a recommendation that the copper layer should be held in the sun, before the appearance of a gray oxide film, in our case it is not necessary.

Preparing the layout.

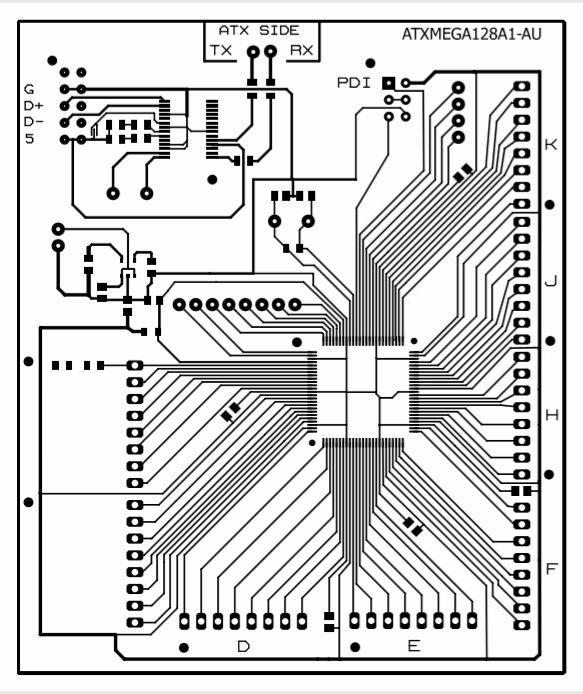

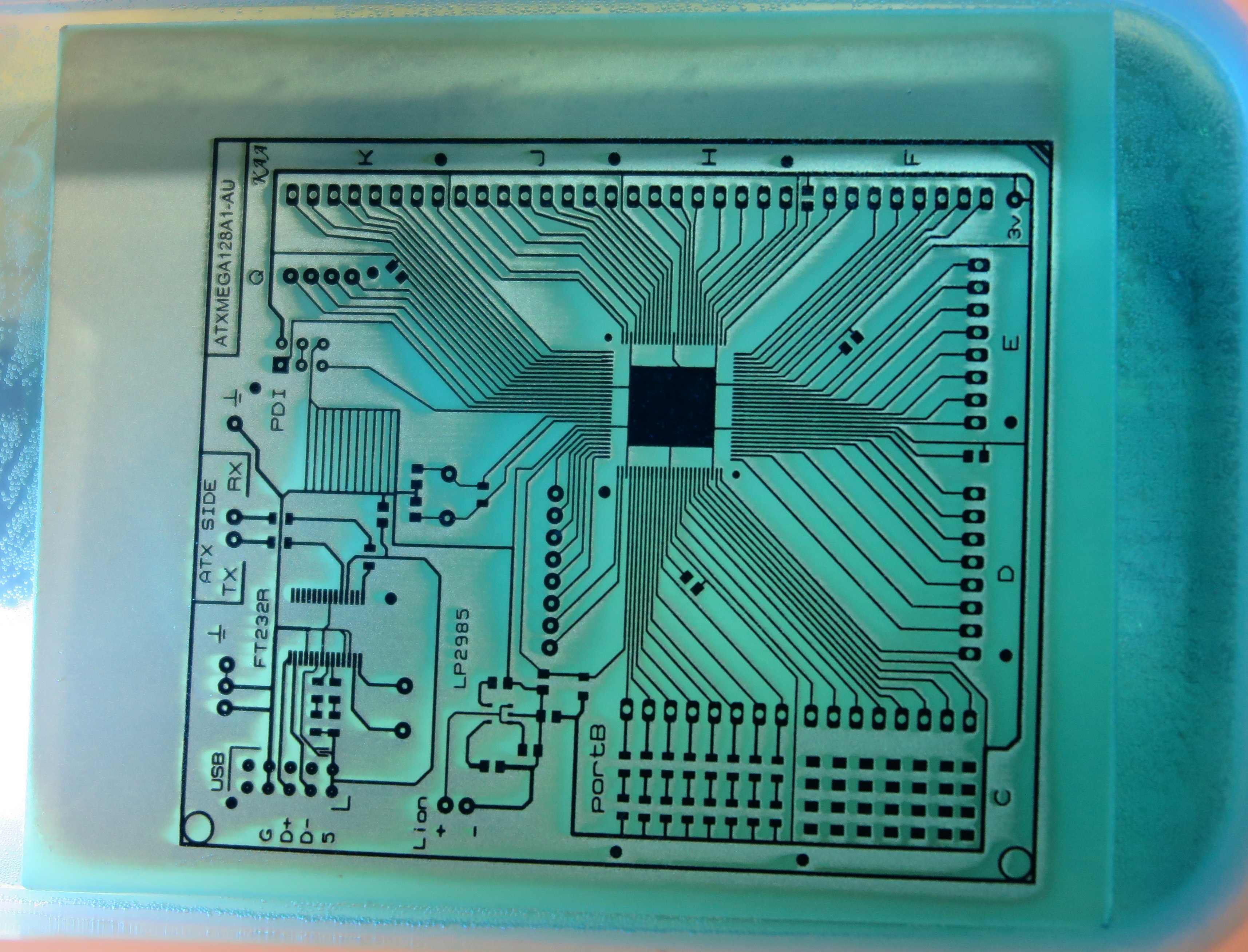

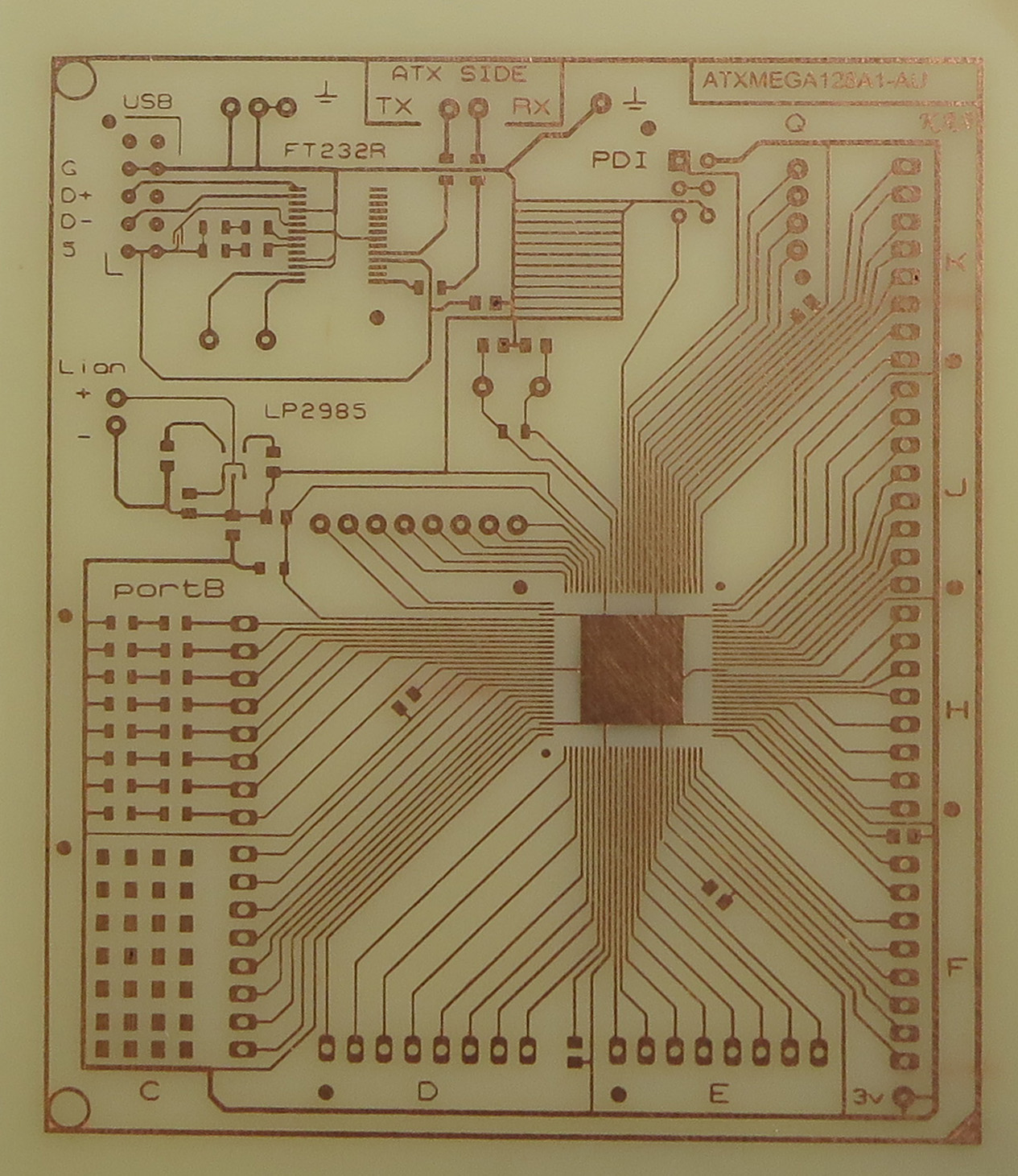

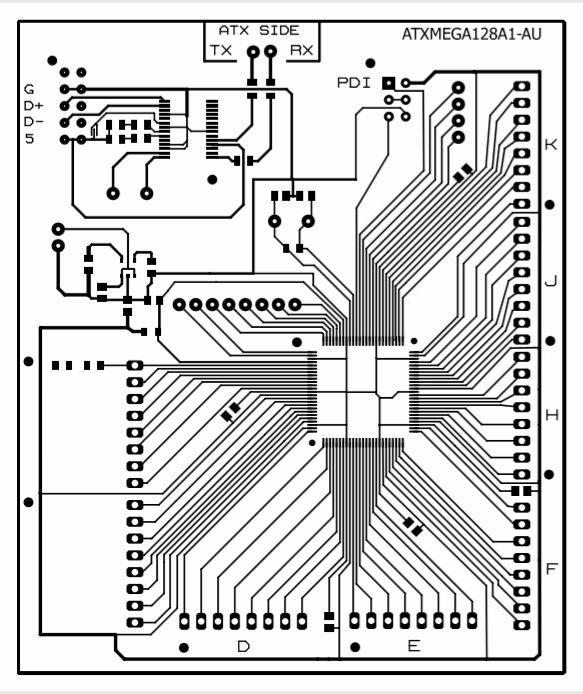

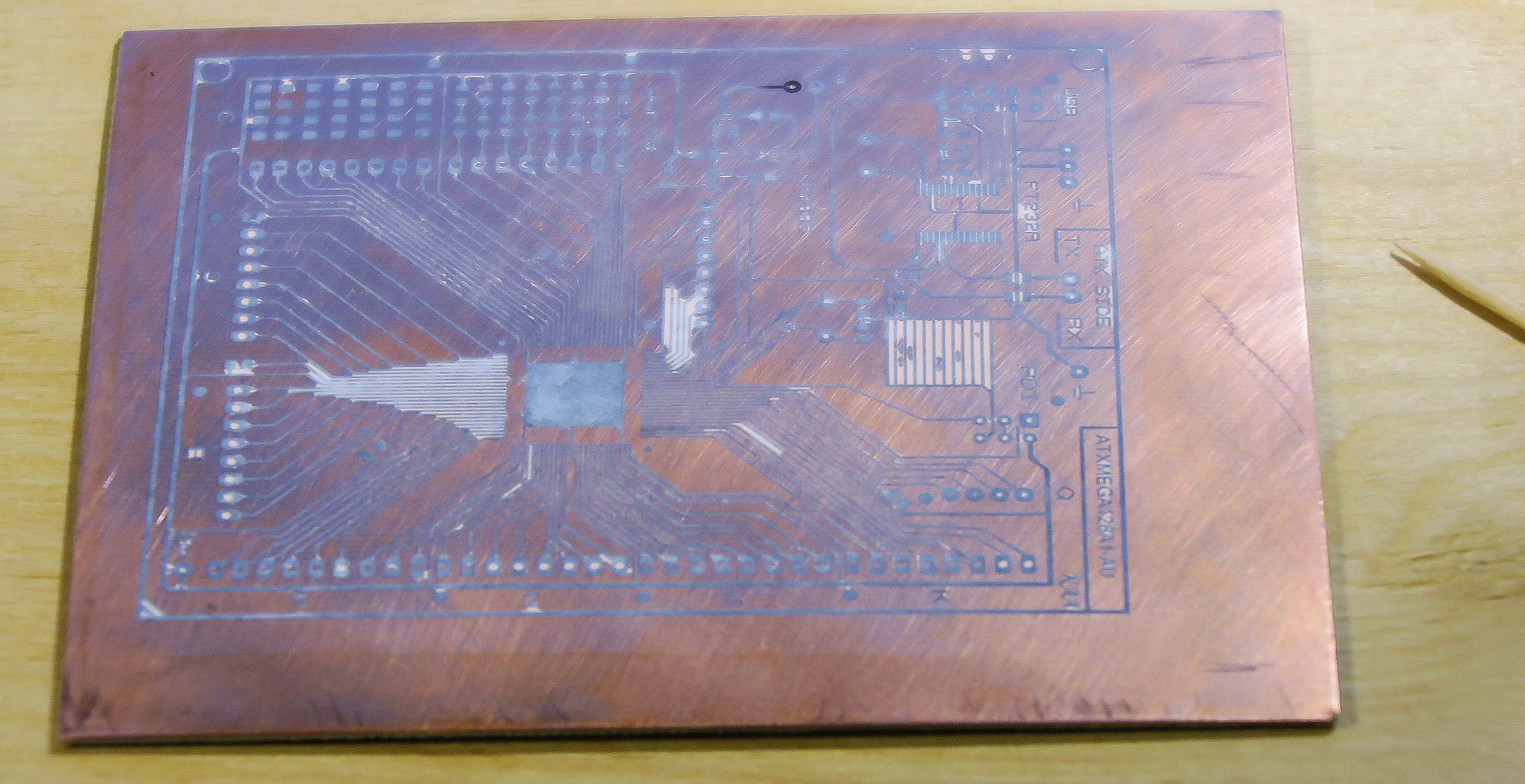

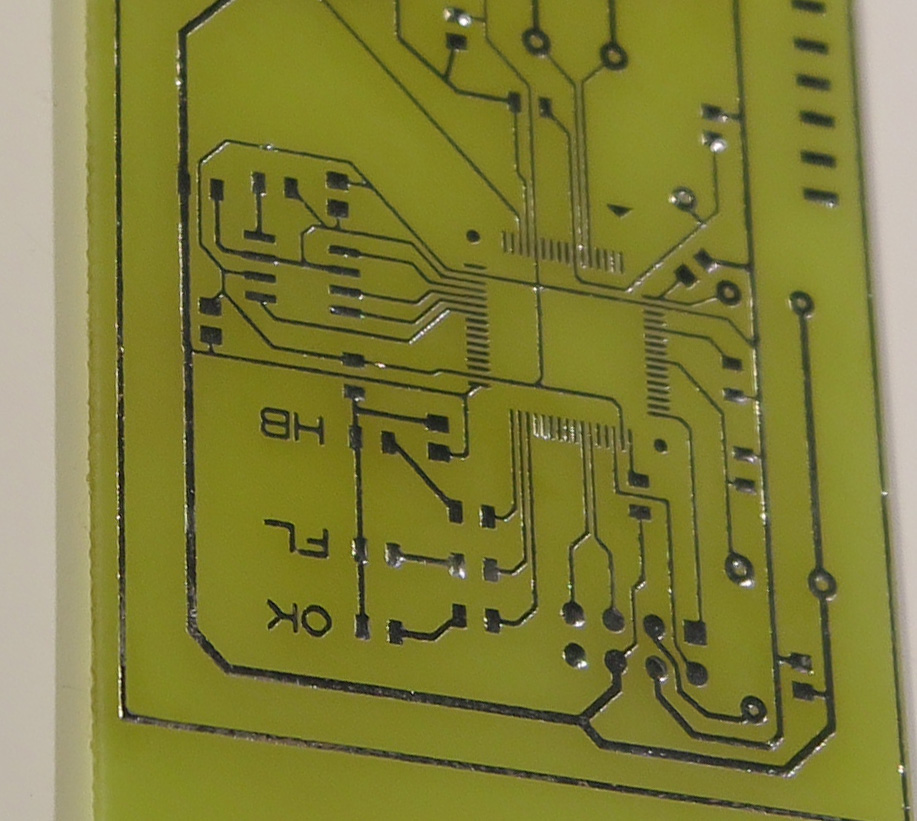

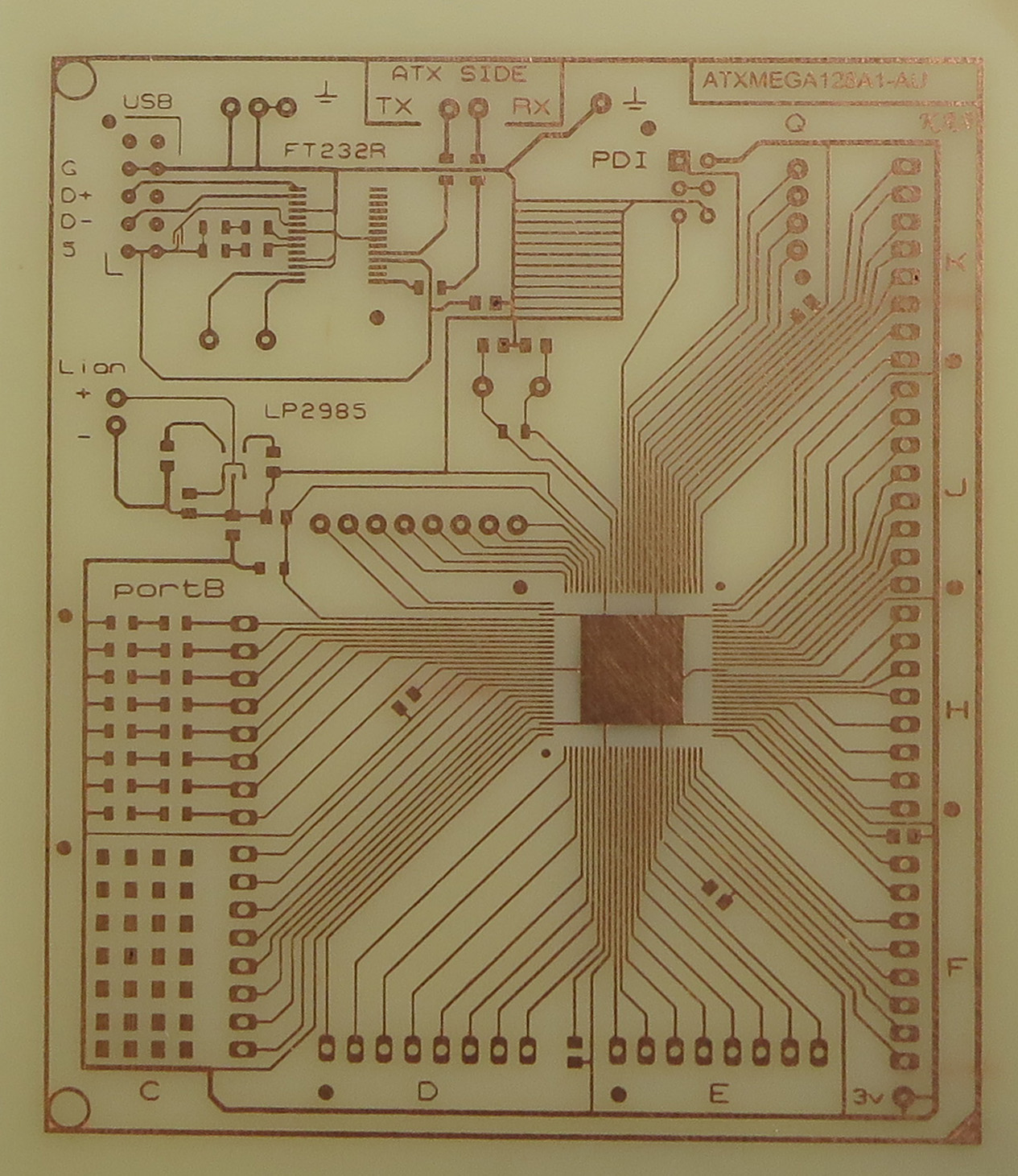

For ATxmega128 did this layout:

if necessary, there is a PDF .

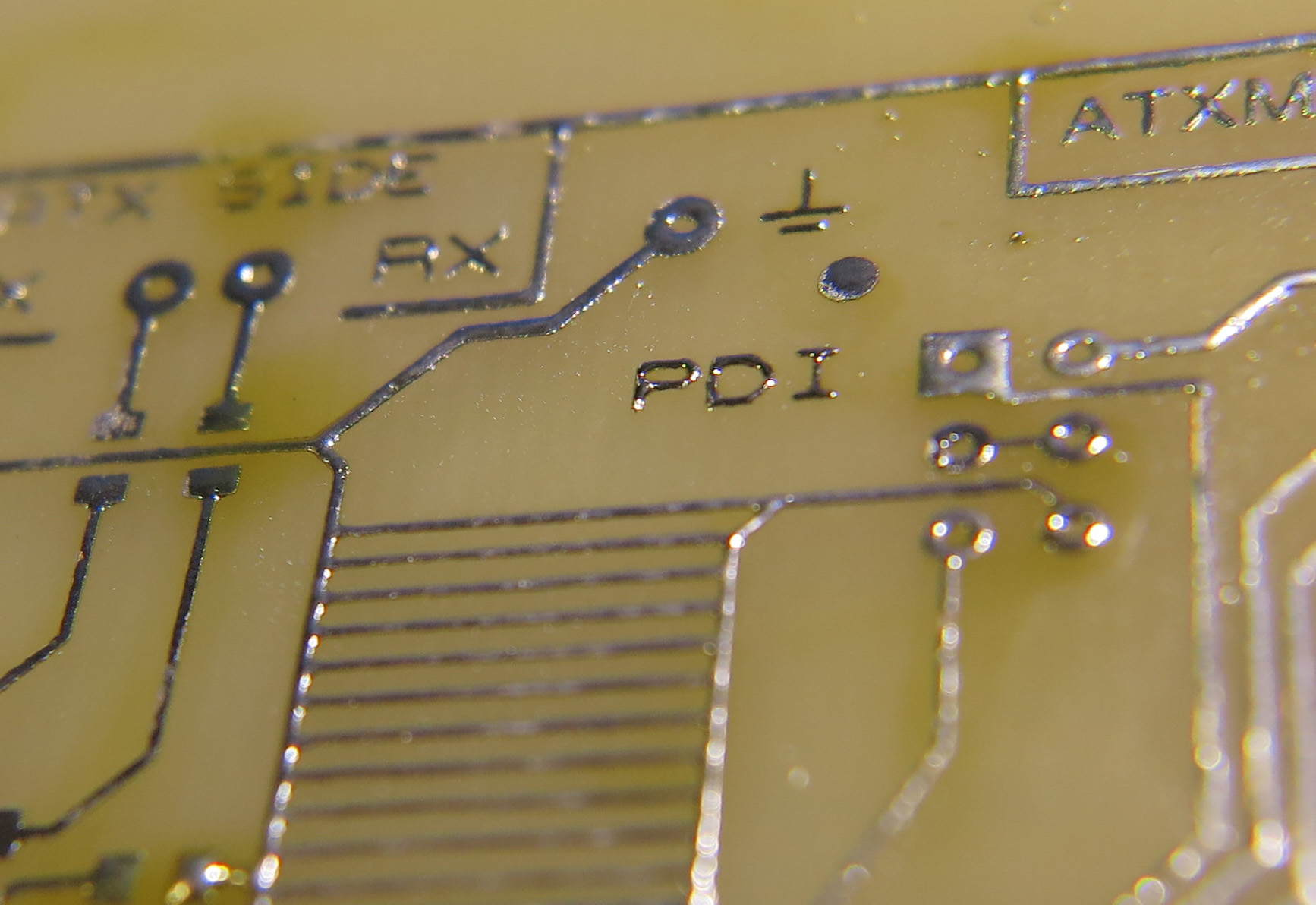

The board itself has xmega, ft232 interface converter and lp2985 stabilizer, as well as small things - a PDI, USB connector, LEDs for the entire port “B”. The drawing of the board is a little different from what I’ll poison. Before printing added inscriptions and trivia to complicate.

All roads are on the top layer (TOP), therefore we print the model in mirrored form.

The presence in the printer of "uneconomic" mode for bold printing is optional. I printed on different printers with “default” printing and there were no problems, except for one thing: Brother printers (specifically, HL-l2340 and HL-l2250) are very disrespectful of translating DPI to real size, so the picture can float in size , and this is critical, when on 1mm two roads must fit.

Now paper.

No glossy magazines and substrates from self-bonding!

And even from Chinese paper for LUT I also refused (too thin and crumpled when printed)

The paper must be dense - at least 150g per square centimeter, it must adhere quickly when heated and not wiggle under the iron, it is good to swell in water.

The best option is glossy photo paper, not too good quality. Not “too good quality,” which means neither premium nor LOMOND. That is cheap glossy photo paper. In the photo above, one of these is shown, there is also “Glossy Photo Paper”, produced under the brand of a large computer equipment store, a clone of the one on the photo (it seems that they are from the same factory, but in different packages).

This paper immediately sticks to the copper under the iron and does not move when ironing (matte paper does not contain a glossy layer and therefore does not stick, and hot toner is easy to lubricate), it easily leaves in warm water (unlike LOMOND and paper with a premium prefix ).

So it's time to type. We print the layout, then, without touching the front side with your fingers, cut off the edges. and prepare the iron.

Translation layout.

You must first prepare a container with water in which the board will be soaked. I have the role of this capacity performs the usual basin. Hot water is poured in (50 degrees, that is, so that the hand no longer suffers), five liters, and a little detergent dissolves in it (a little, this is a tablespoon).

And we go to the iron.

We place the prepared textolite on a flat surface and cover it with a printed layout, iron it up to the maximum temperature, iron it along the center line, and then from the center to the sides. When you first press the printout is better to hold, so as not to move. After the first ironing, the sheet of photo paper sticks to the copper and you can no longer be afraid to move it with an iron. Now you can walk the tip of the iron on all edges and places where the paper looks like it is moving away. Then thirty seconds just warming up the entire volume.

I could not resist not to show the main actor in the article about LUT:

After proglazhivaniya, without cooling, throw the board water. That is, without removing the paper, pick up the hot tweezers and put in a prepared container of water. 10 minutes break for soaking.

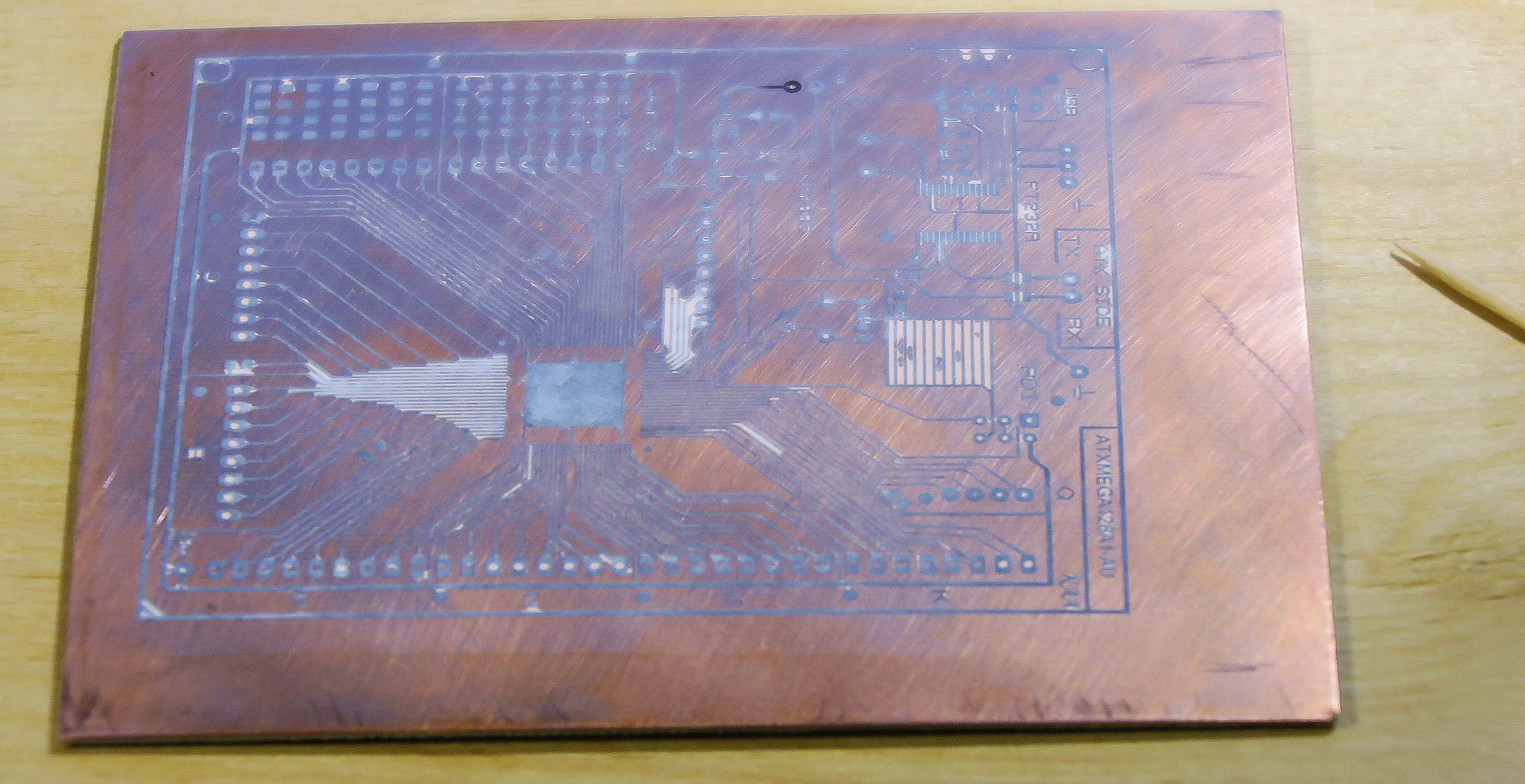

Paper cleaning.

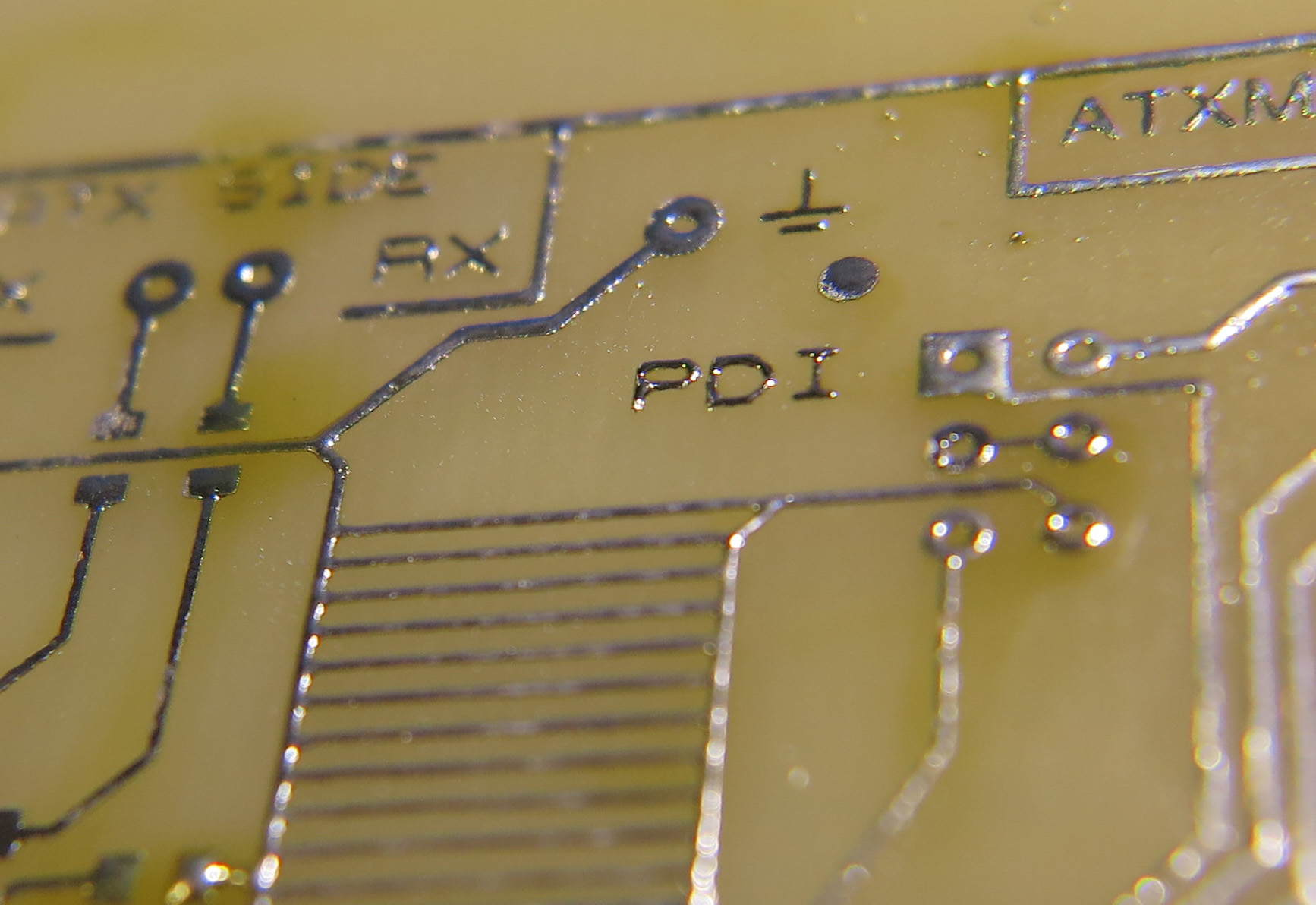

After 10 minutes, remove the board from the water and remove the paper. No matter how long the board is in the water, all paper will not lag behind. More precisely, the paper itself is without problems, but the glossy layer that provided us with good adhesion will remain in narrow places.

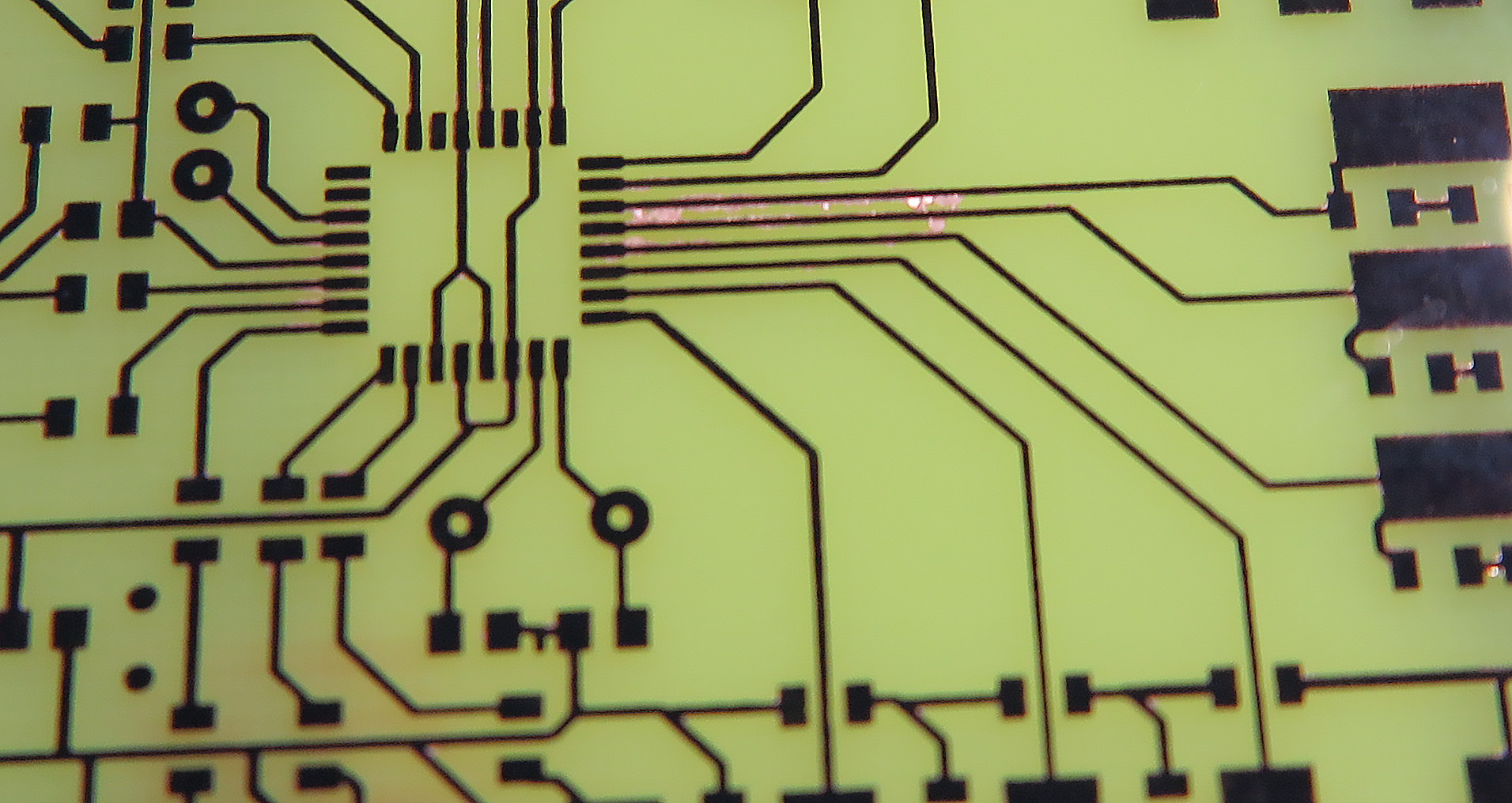

something like this:

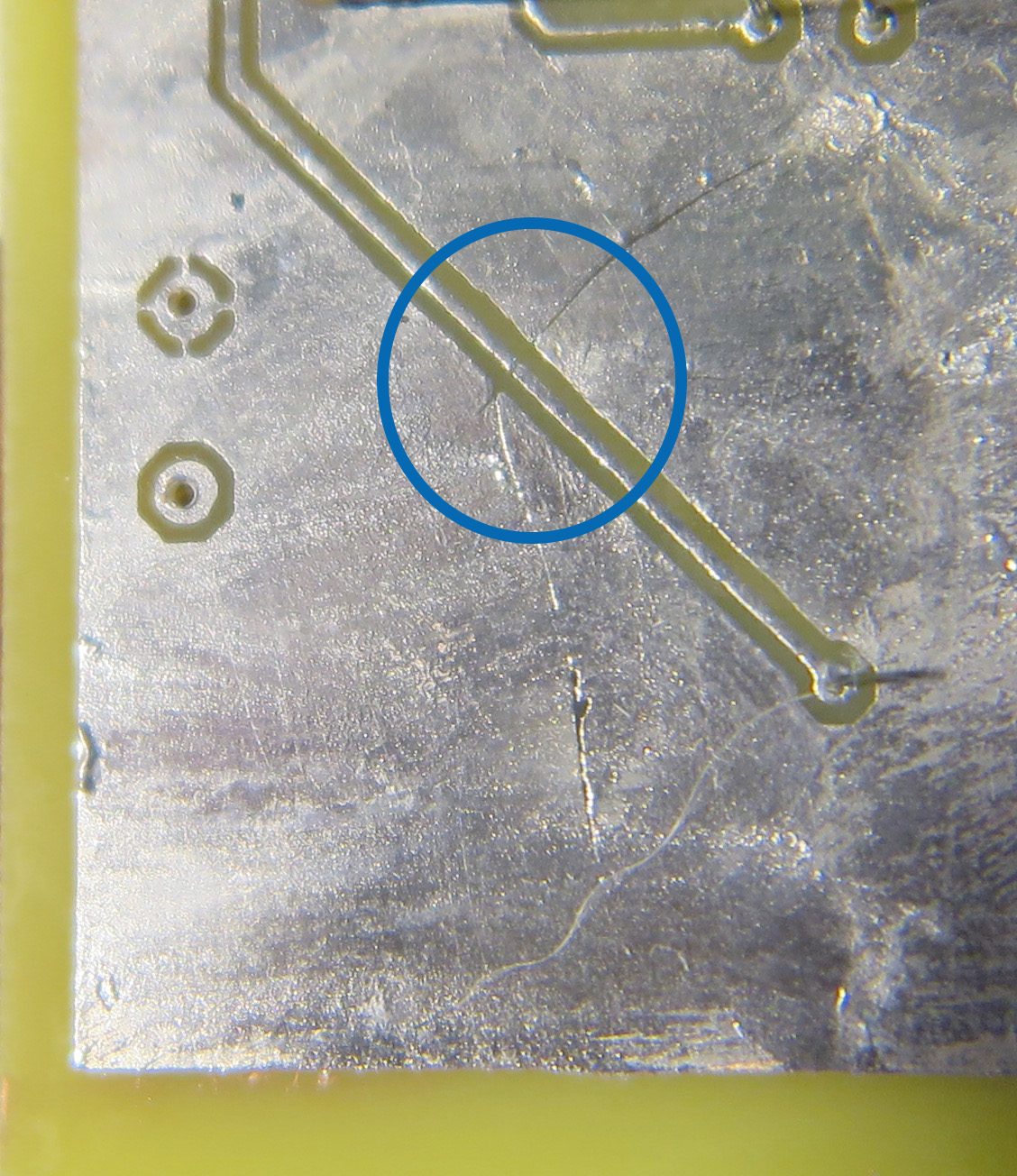

In general, the toner is kept very securely, you can rub it with your fingers, an eraser, or a sponge for washing dishes, but it is difficult to pull out the gloss between the tracks, just let the board dry, such places will be visible.

There are three ways.

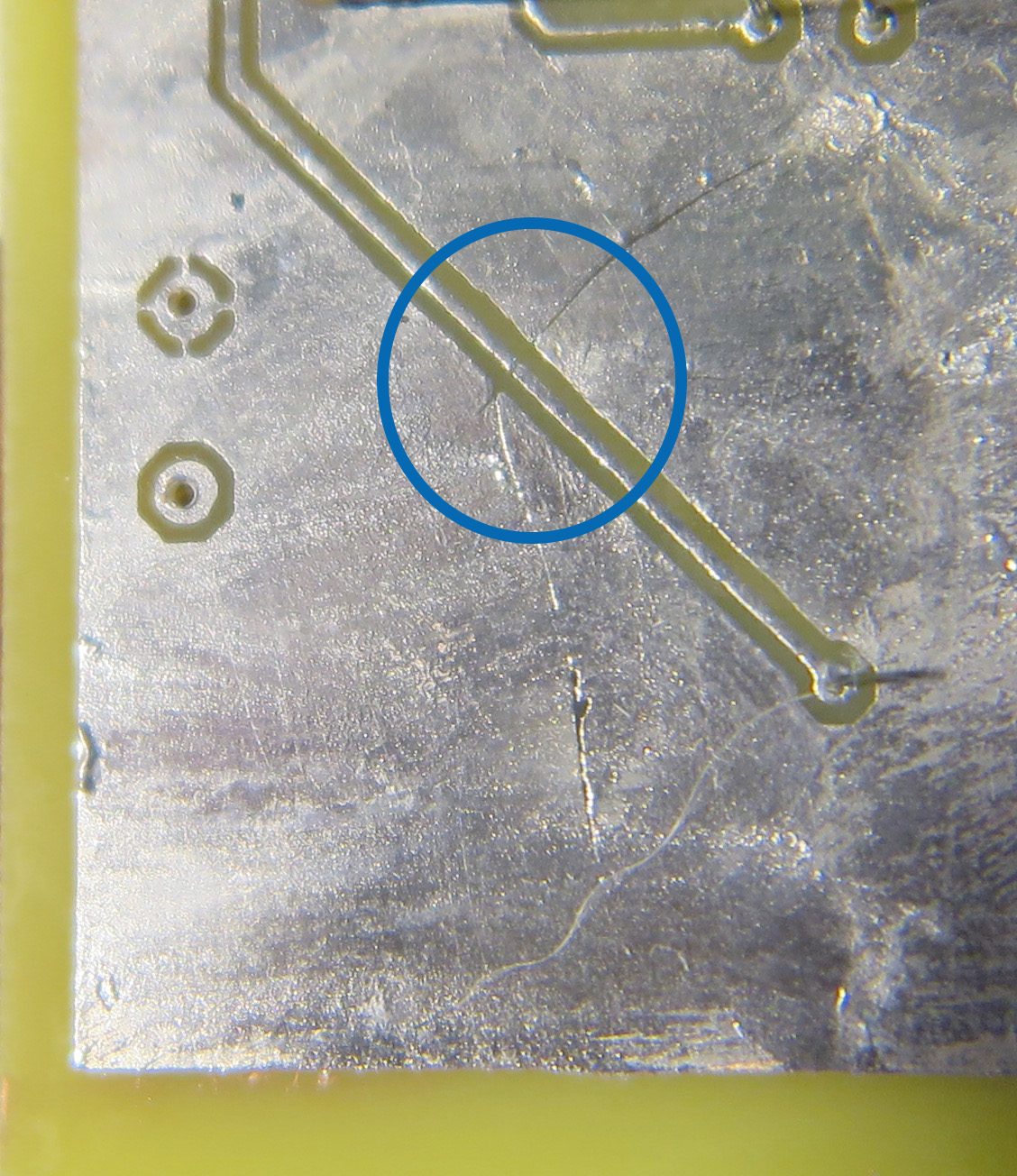

To do this, wet the board back and remove the excess with a sharp object. It is best to use a sharp toothpick. Wet gloss is removed without problems, and the toothpick tree does not tear down the toner. I note especially that you can not use needles! Not because you can remove the toner (it is stuck well), but because the iron leaves traces on the copper. Yes! I myself am in shock, I know that copper is softer than iron, especially stainless steel. But the fact is the place to be. Where the needle drove the copper is poisoned very slowly.

A practical example:

After removing the residues of the glossy layer, wash the board with detergent, removing the "fingers". Leave to dry.

Almost deliberately left a few places where the gloss is not removed (then we will see that all is not so scary).

Etching.

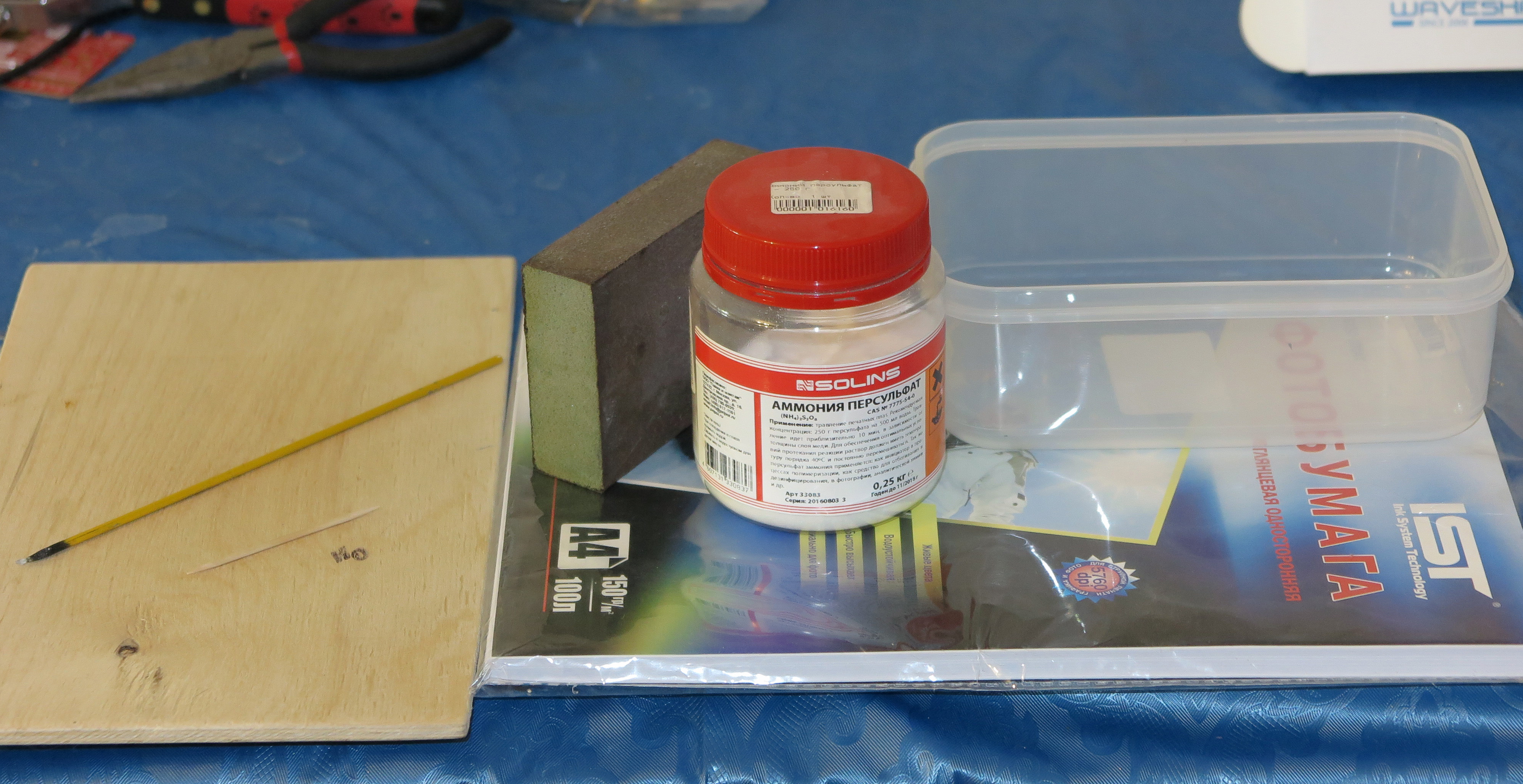

I am poisoning ammonium persulphate, not to say that it is better than ferric chloride, iron is just more dirt (well, yes, ammonium persulphate is the same bleach, what mud is there) and ferric chloride is harder to store - hygroscopic and as a result fused into large pieces that need to be crushed .

Harassment at a temperature of 40 degrees. On a board with copper 35µm - 15 minutes, With copper 17µm - 5 dashes 7 minutes. It is possible and at room temperature of 17 microns it is poisoned about 20 minutes, 35 microns in theory 40 minutes, but I don’t remember it anymore.

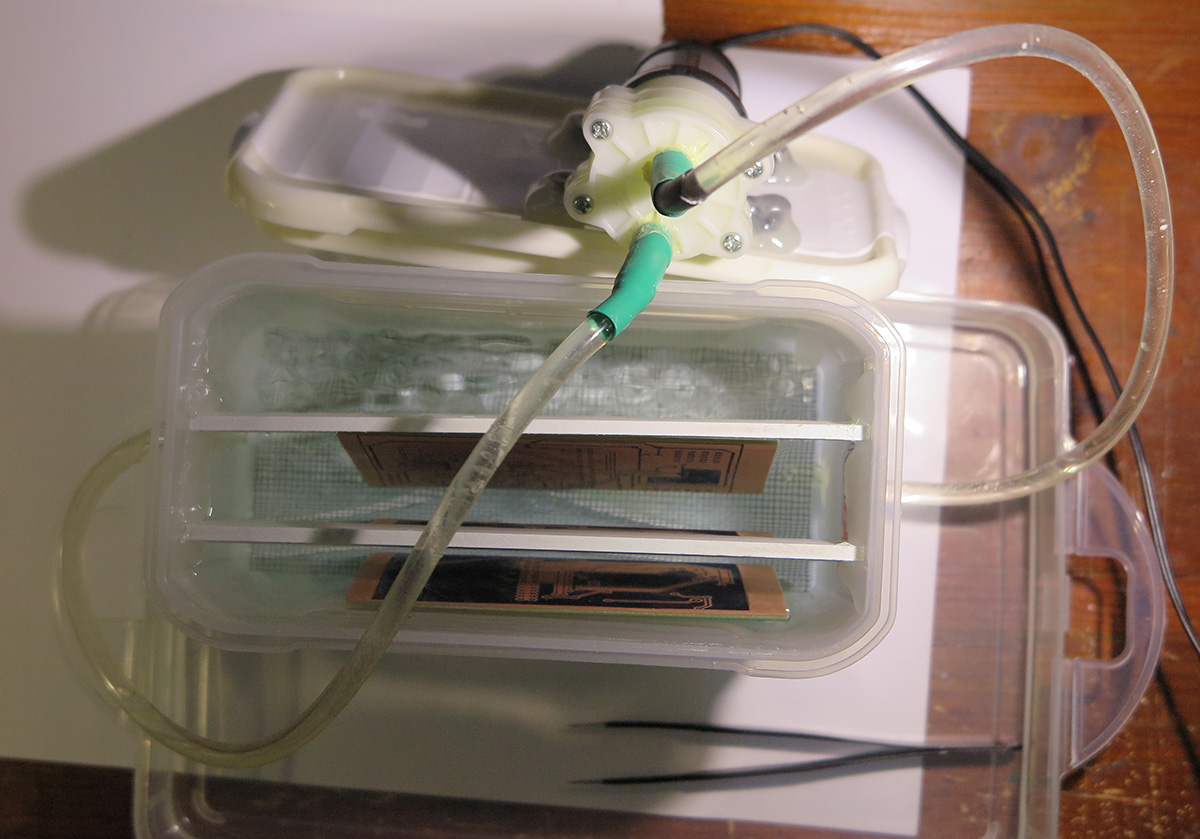

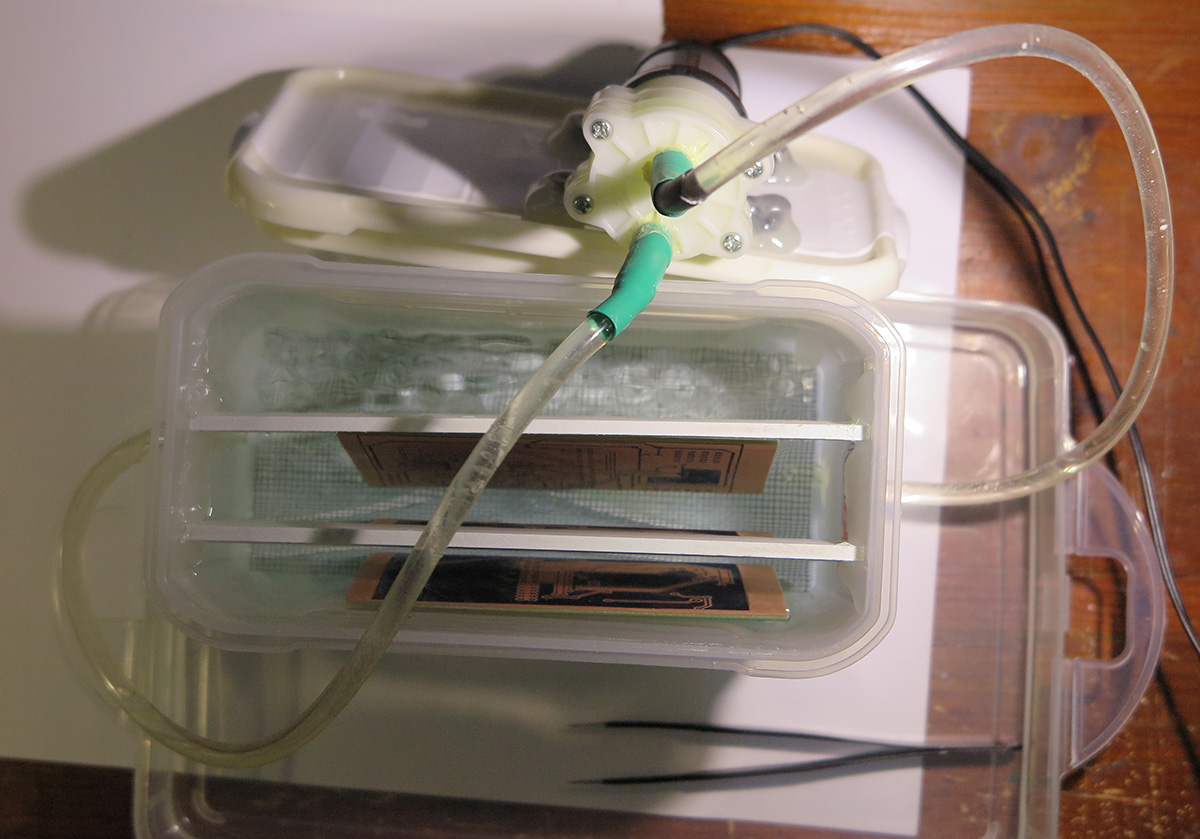

At home, you can poison in any container, for this article specifically poisoned in a conventional plastic container, which imposes certain additional actions from the artist. But if the PP is made often, then you can seal yourself a bath for etching:

the main addition of which is the pump for mixing the solution, it exempts from "certain additional actions". The pump needs a membrane, with a plastic membrane.

The one on the picture, bought in the online store for robokrafterov.

Inside the bulkhead, to accommodate several PP.

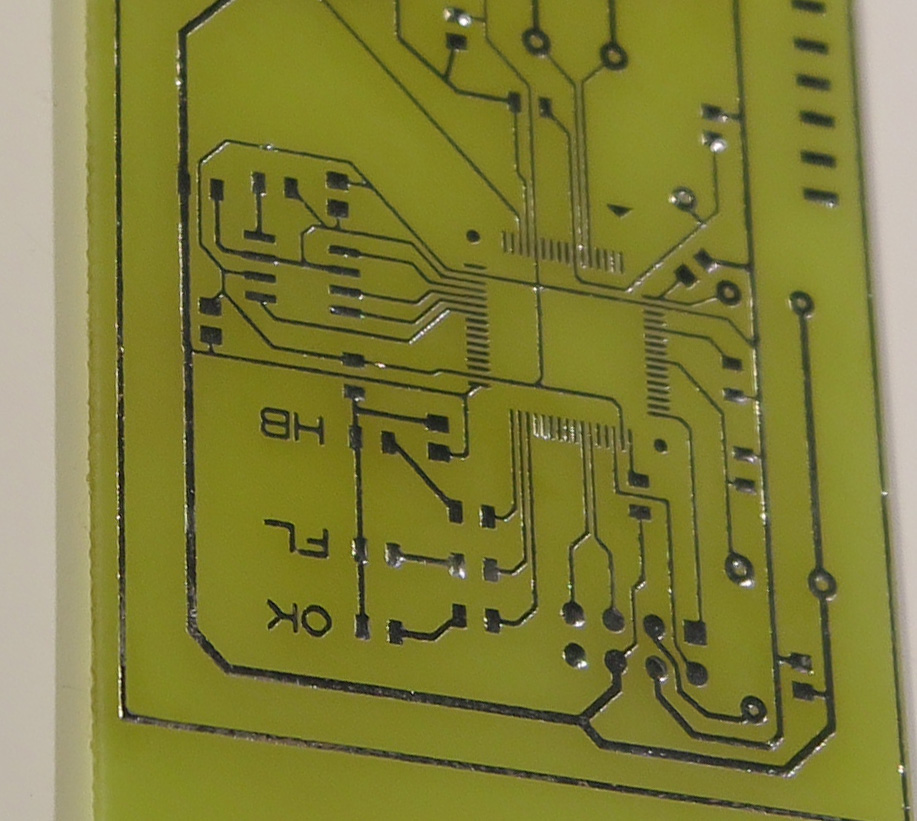

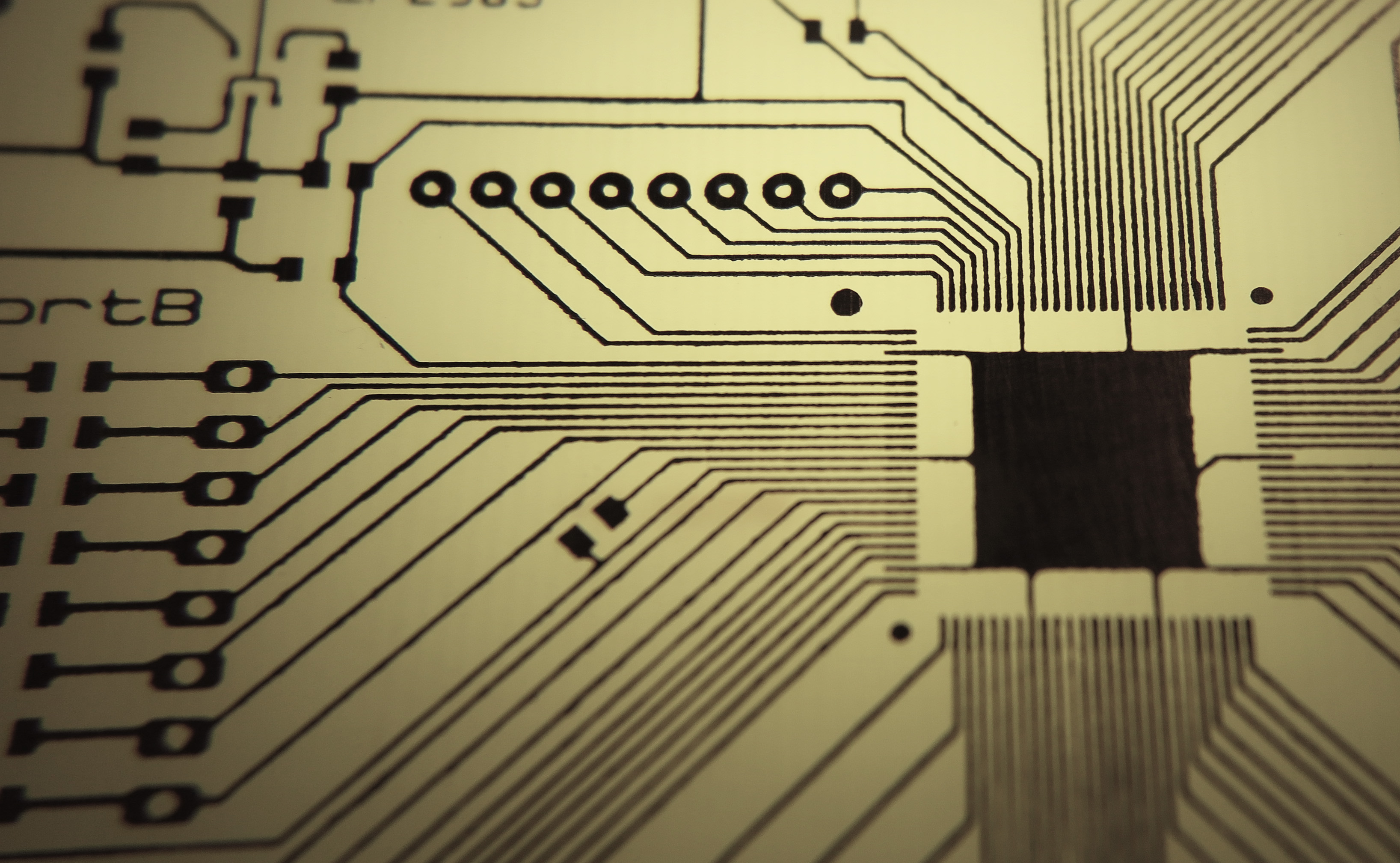

The photo shows two sides of the board under the STM32F407VE connected to a seven-inch display.

Under xmega I will corrode in the open plastic.

We make a solution - half a liter of water plus 100-150g of ammonium persulfate. In general, 250 grams per half liter is recommended, but in artisanal conditions when the solution is cooled and the water evaporates, crystals fall out and firmly stick to the copper, as a result of the non-etched points.

As I wrote above - the temperature is 40 degrees.

We throw a board into the solution and begin to mix the solution with a brush so that the etching proceeds evenly. Also, a brush can remove the glossy flakes from the board, if not all are removed during the preparation.

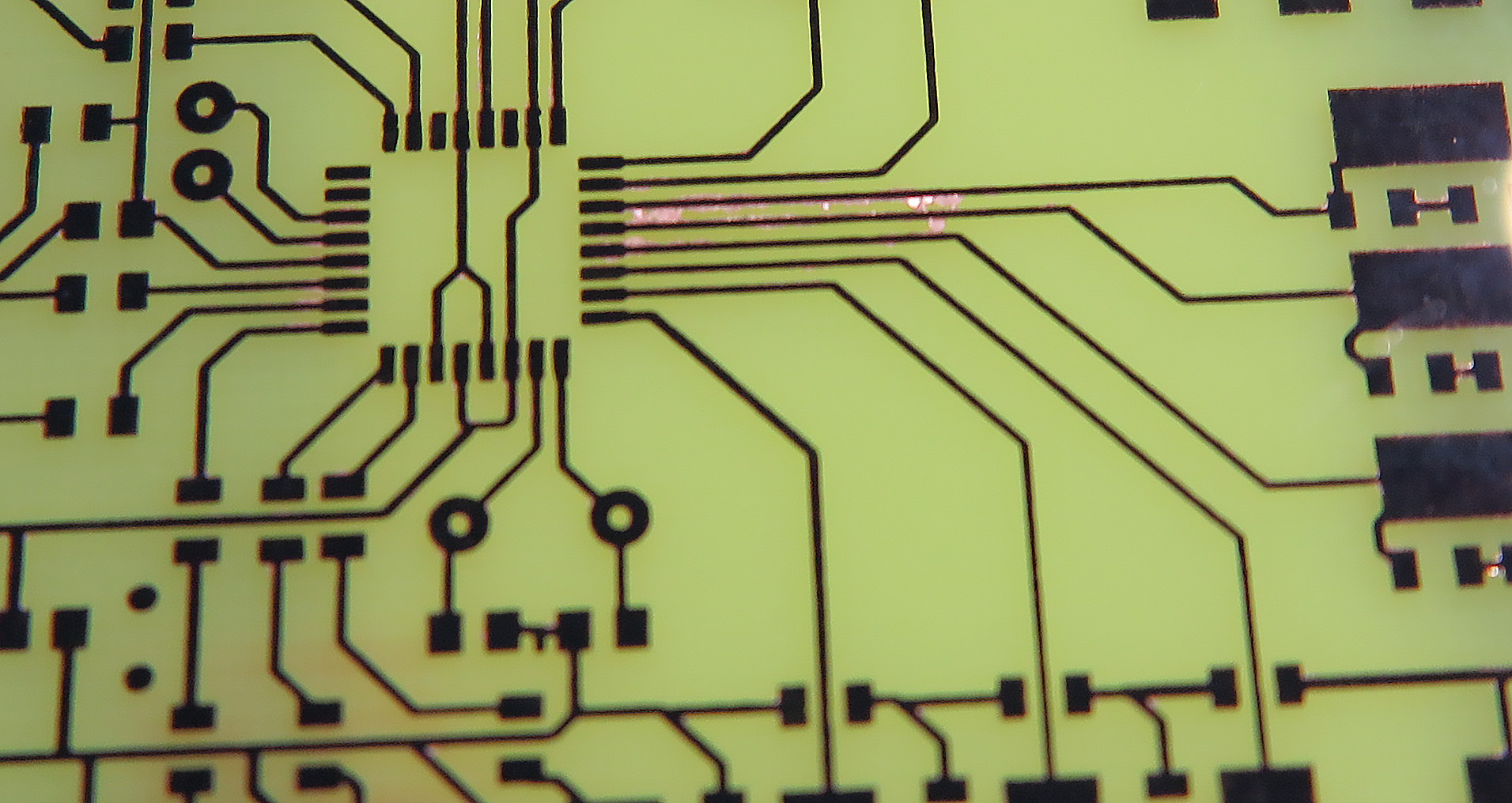

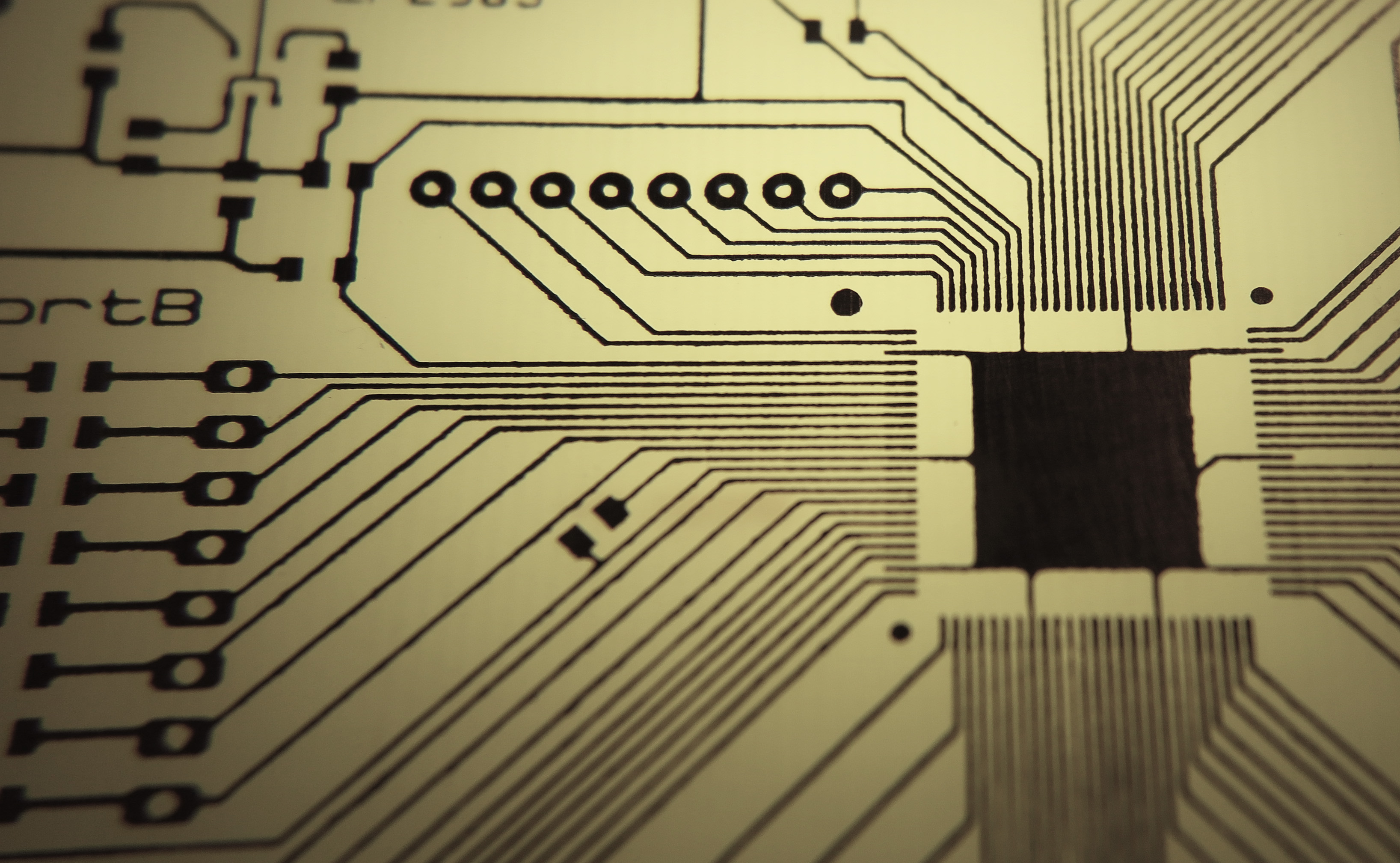

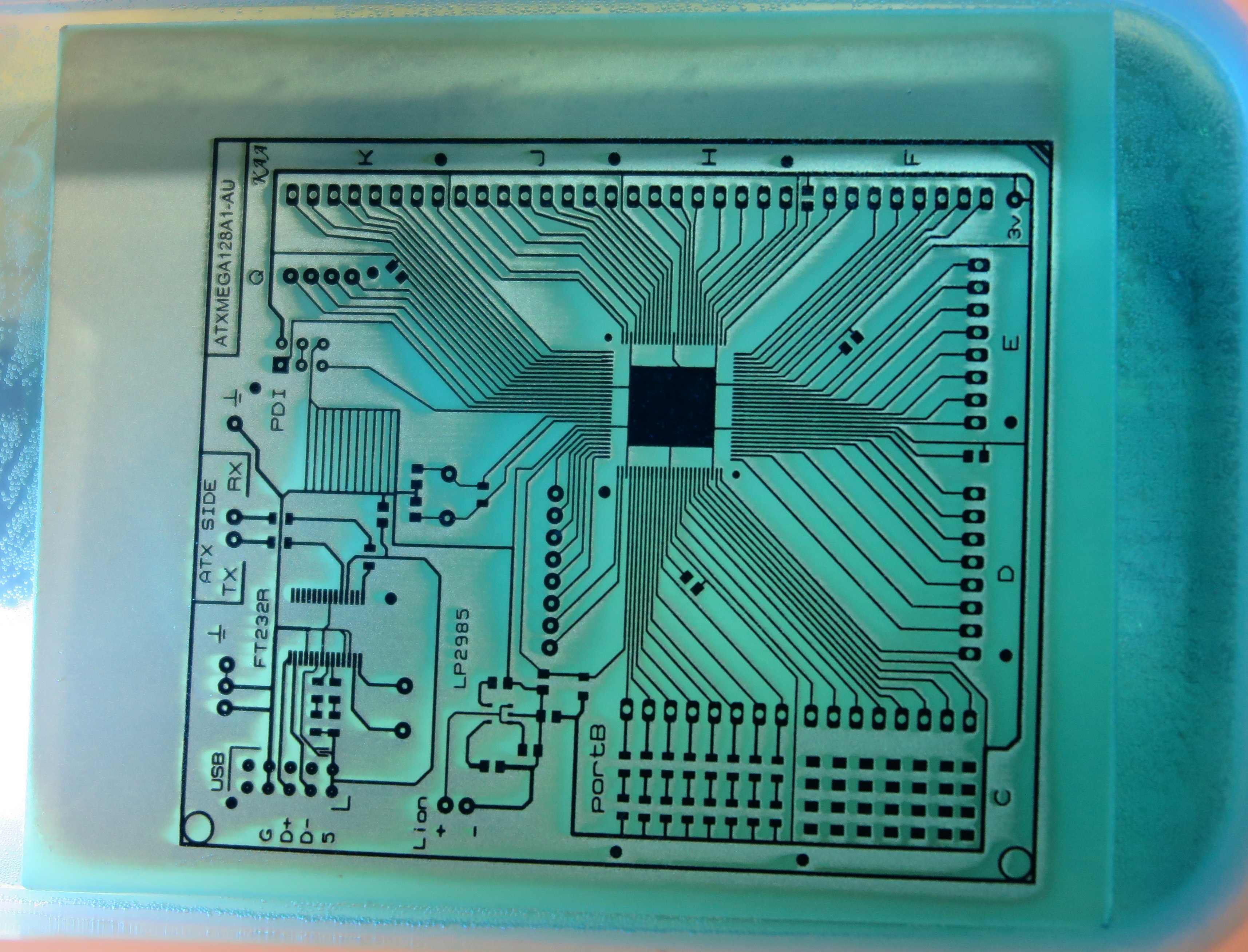

I have a board with copper of 35 microns, in 10 minutes textolite is already visible:

I wait another 5 minutes and everything is ready.

It must be said that in the etching process it is better to over-charge the board than to underexpose. And the extra time can be quite large. One time I saw an unfinished training ground threw the handkerchief back and forgot about it for about three hours, when I remembered, I thought that it had been torn through. However, not a single undercut was noticed:

Here is this peredelanets (already derelict):

So, we pulled out our board, washed it and looked at the light:

If you find excess copper, then you can throw back into the solution.

If all is well, then LUT is over!

We wash off the toner with acetone and maintain it, if in the near future maintenance is not provided, then the board can be stored without washing the toner, it will be a protective sheath.

Total:

Above, I marked the places on the board where the glossy finish remained. Those places that the gloss closed hermetically (a corner on the board) were not etched there, where there is a small overlap between the lanes - everything is fine, the solution got there. If you use a container with a pump, then the glossy coating can generally not be completely rubbed off, just the pickling time doubles.

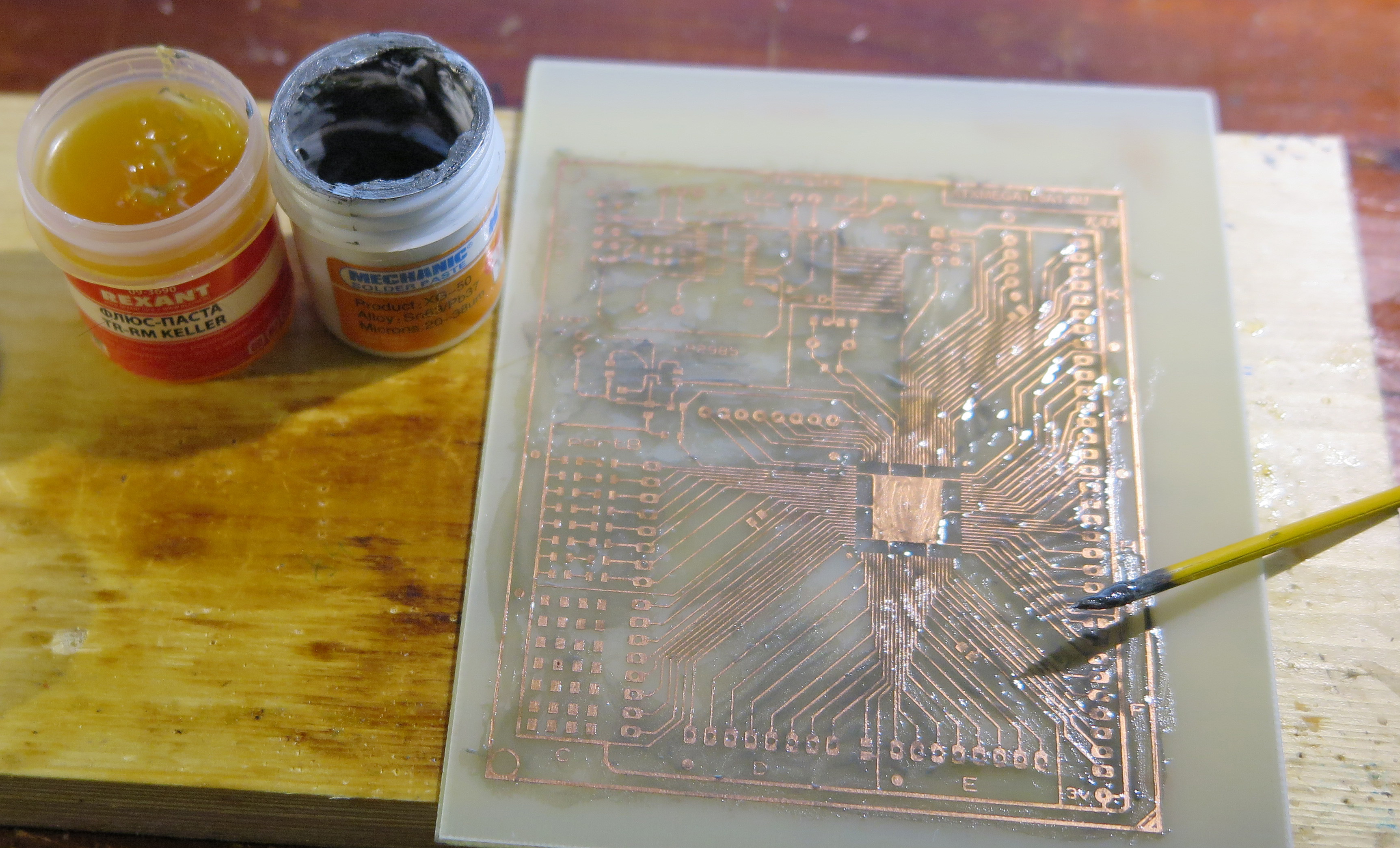

A couple of phrases about tinning. Since LUT makes temporary fees or for yourself, you shouldn’t pay too much attention to maintenance (IMHO), you can simply go for a soldering iron to the places where there will be soldering, and then cover everything with varnish.

But if the components on the board will be re-soldered or the board will be used for a long time, then it is better to do it. Or a soldering iron to go through the entire copper, or if there is a hairdryer, then with a solder paste.

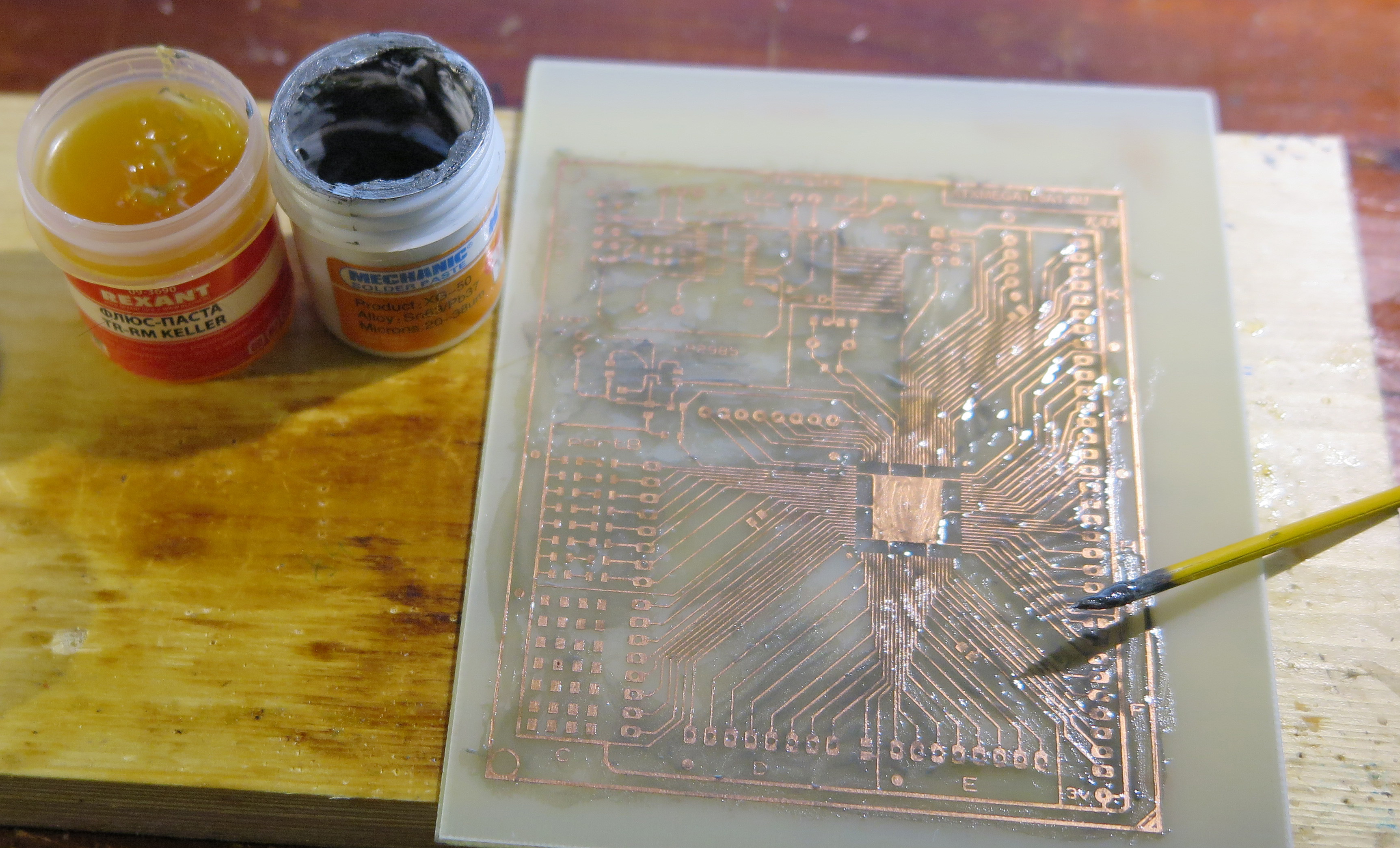

I interfere with the flux paste about 1 part of the paste and 5 parts of the flux, cover the entire board and heat it with a hairdryer:

while warming up, a textolite brush (known as the “eternal brush”) drives the solder to the edges of the board, I do not have too much solder on the tracks with this method, and where there is not enough of it, you can drive it from the edges. Not an air knife, of course, but also pretty neat.

The main problem with the use of solder paste is the extra balls stuck to the board. Here you can see them in the photo:

Therefore, after tinning, the board must be thoroughly washed and wiped off with a cloth moistened with acetone.

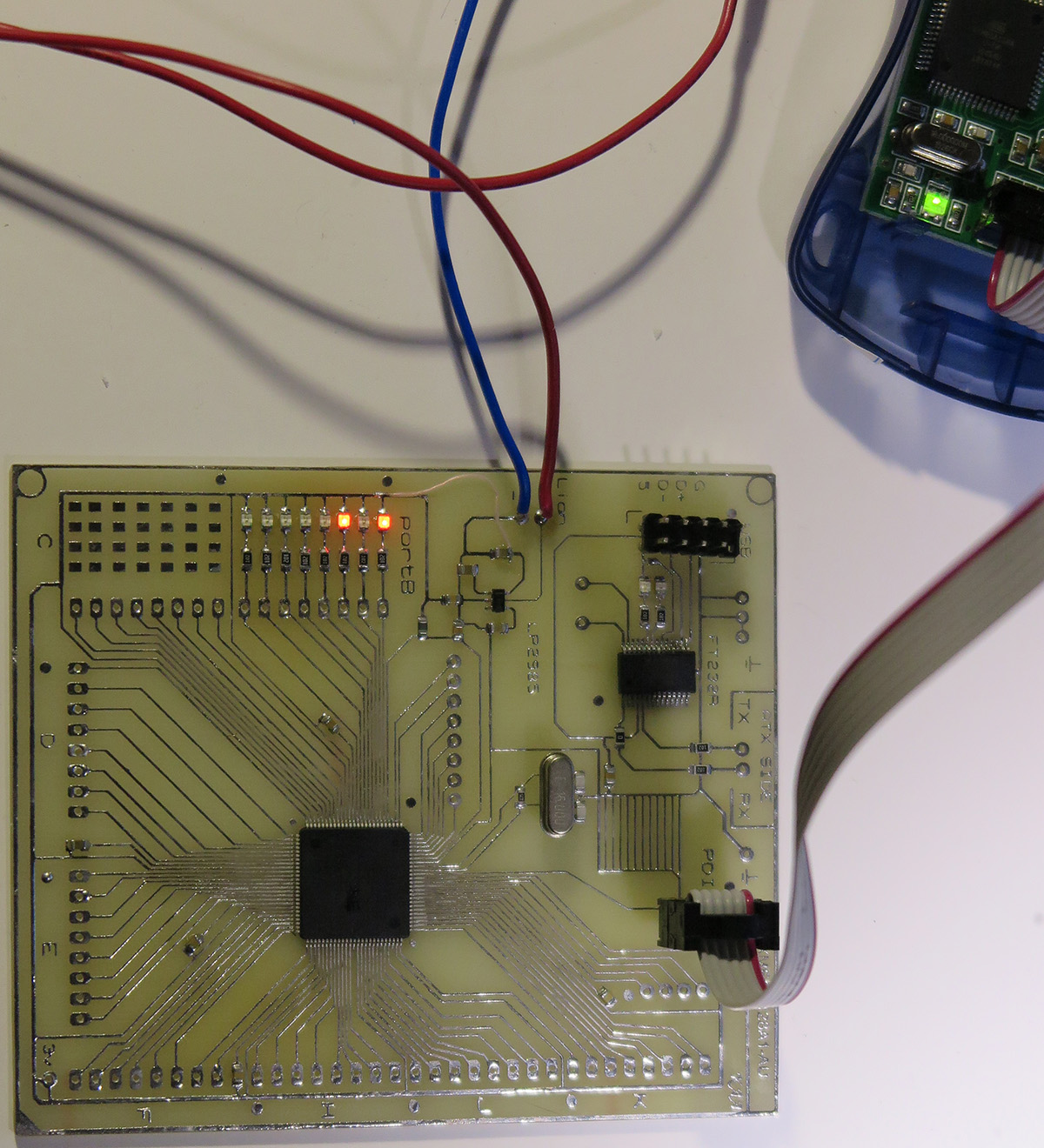

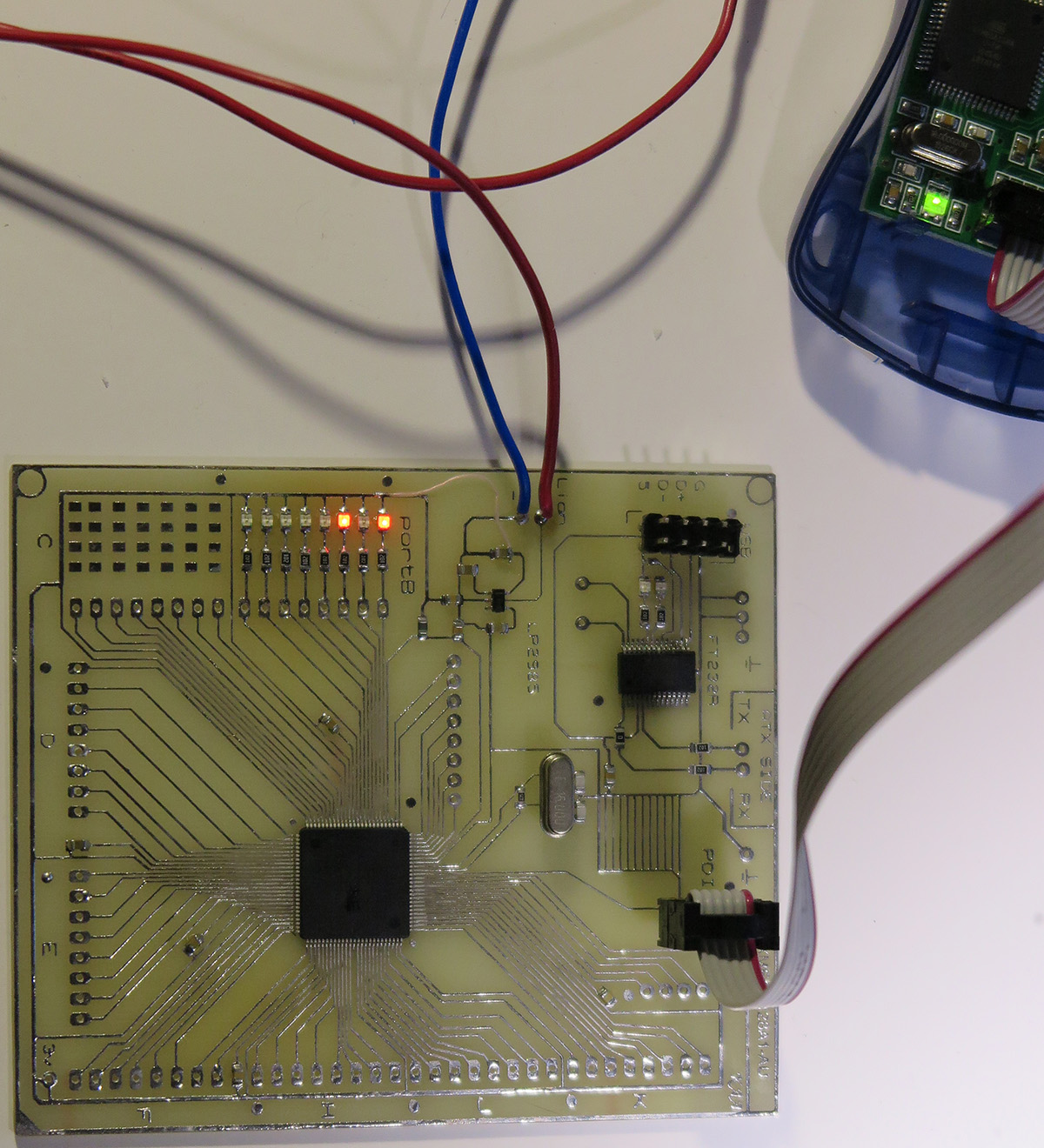

The fee was condemned, now everything is for sure. Installation. Check:

Mission accomplished. On this fee took no more than an hour (taking into account the photographing stages).

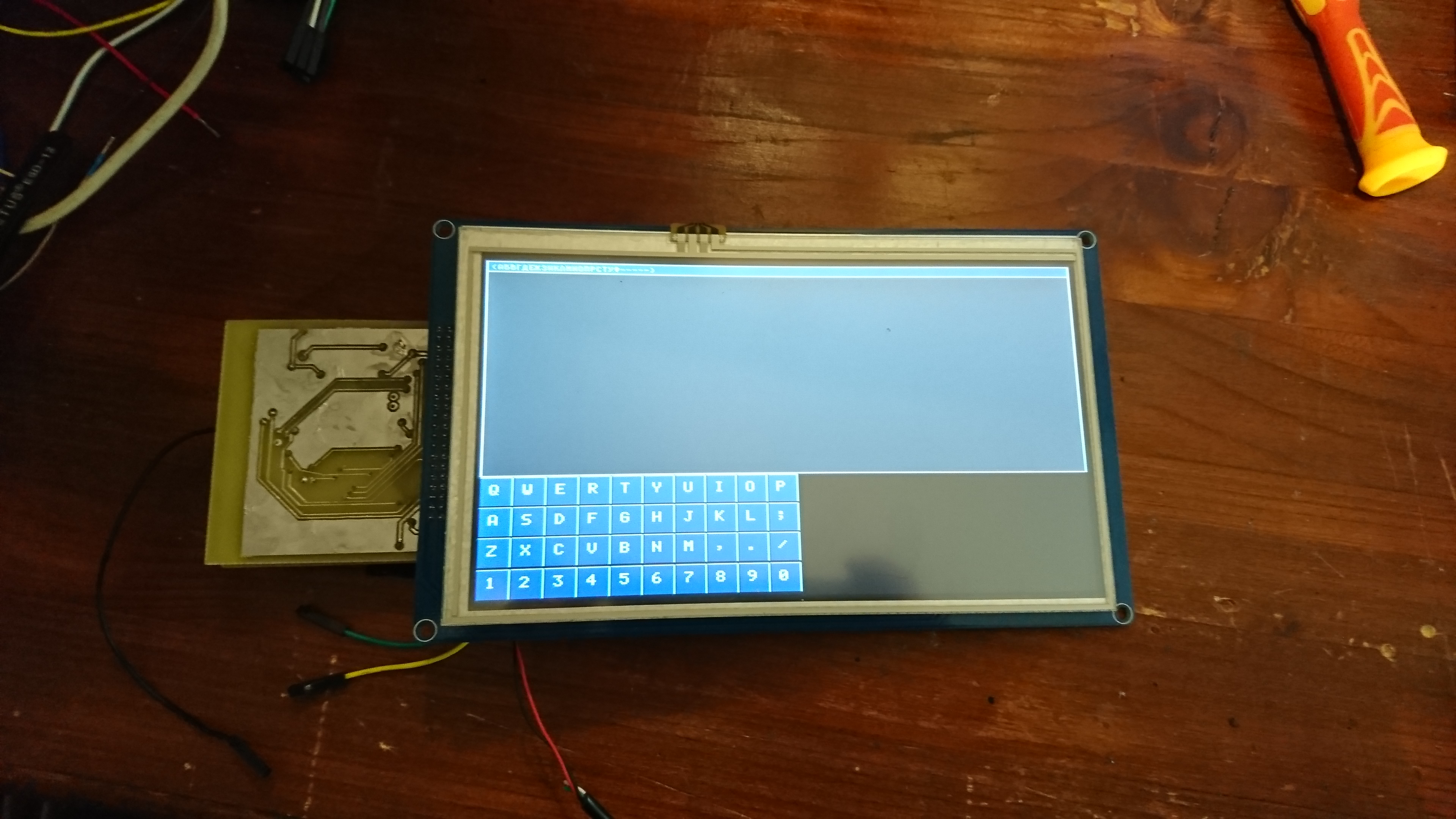

At the same time, I was poisoning the second board, or rather two sides of the same board. And if the first handkerchief was more likely to demonstrate (it was possible to do a DIP adapter, and not to do something like an arduin), then the second was needed for a specific purpose and weaving braids of wires on the adapter is not an option (and it’s not the fact that it doesn’t pick up any interference connection via fsmc)

Two sides:

As you can see, I did not persecute double-sided textolite, going through the deadly procedure of combining two templates at the stage of work with an iron. Better to do it now.

We drill holes on VIA in all boards, take the legs from resistors and 5 pieces are soldered to one side, then we string the other side on them, we solder from both sides. All boards are combined! Now you can solder all the holes.

Something like this:

All is ready!

You must have noticed a strong marriage on one side:

The paper after the printer is electrolyzed and collects everything. Especially the hair, especially the cat! So I did not watch it.

And here is the culprit:

Monitors all running processes.

After the restoration of the track, the PP is ready and the device is assembled:

True, it was just a temporary fee - to check the correctness of the connections, then to dissolve humanly and order.

That's all. Good luck in your endeavors!

In this article, I want to outline the order of actions that will allow you to quickly make PP for components in cases of similar TQFP-100, that is, with legs of 0.2 mm and the same gap, and at the same time to reduce defects to a minimum.

Of course, this is a way to manufacture boards for prototypes only, but it reduces the risks of making a mistake when creating an end device.

')

There are a lot of articles and videos with similar tips, but as a rule, all the nuances of certain actions are not covered there. Here I want to show the whole process, which at home will allow for an hour and a half to produce an acceptable copy of the PP.

Under the cut details and traffic.

Minimum set of materials:

- The right paper (below I will focus on the concept of "correct")

- Ammonium persulfate

- Pickling tank

- Skin "zero"

- Brush (natural or fiberglass)

- Toothpick

And, of course, a laser printer and an iron.

I will show the process on the manufacture of PP for the evaluation of the ATxmega128A1U-AU chip (evaluation of the declared hardware crypto module, EBI and in general), and the board for connecting a 7 inch display to the STM32F407VE

For evaluation boards I try to do the wiring only on one side, where intersections cannot be avoided, I put a resistor with resistance = 0 and case 0805, passing the road under it. If there are a lot of intersections and exactly two layers are needed, then I’m harassing each layer on a separate textolite (then I join it via VIA).

First stage

PCB preparation.

One-sided PCB with a copper thickness of 17-35 microns is washed from dirt with dishware under warm water, then a drop of washing agent is applied to the skin with P800 grain or less and the future board is polished to form roughness over the entire area. Moment with sandpaper required! In this way, the copper will not shut up to the holes, but we will ensure good adhesion of the toner. After polishing, the surface is washed with clean water, wiped dry and set aside to dry.

By the time of transfer of the layout, the textolite should be dry, free of oxides, oily stains and noticeable roughness.

In one of the articles I saw a recommendation that the copper layer should be held in the sun, before the appearance of a gray oxide film, in our case it is not necessary.

Second phase

Preparing the layout.

For ATxmega128 did this layout:

if necessary, there is a PDF .

The board itself has xmega, ft232 interface converter and lp2985 stabilizer, as well as small things - a PDI, USB connector, LEDs for the entire port “B”. The drawing of the board is a little different from what I’ll poison. Before printing added inscriptions and trivia to complicate.

All roads are on the top layer (TOP), therefore we print the model in mirrored form.

The presence in the printer of "uneconomic" mode for bold printing is optional. I printed on different printers with “default” printing and there were no problems, except for one thing: Brother printers (specifically, HL-l2340 and HL-l2250) are very disrespectful of translating DPI to real size, so the picture can float in size , and this is critical, when on 1mm two roads must fit.

Now paper.

No glossy magazines and substrates from self-bonding!

And even from Chinese paper for LUT I also refused (too thin and crumpled when printed)

The paper must be dense - at least 150g per square centimeter, it must adhere quickly when heated and not wiggle under the iron, it is good to swell in water.

The best option is glossy photo paper, not too good quality. Not “too good quality,” which means neither premium nor LOMOND. That is cheap glossy photo paper. In the photo above, one of these is shown, there is also “Glossy Photo Paper”, produced under the brand of a large computer equipment store, a clone of the one on the photo (it seems that they are from the same factory, but in different packages).

This paper immediately sticks to the copper under the iron and does not move when ironing (matte paper does not contain a glossy layer and therefore does not stick, and hot toner is easy to lubricate), it easily leaves in warm water (unlike LOMOND and paper with a premium prefix ).

So it's time to type. We print the layout, then, without touching the front side with your fingers, cut off the edges. and prepare the iron.

Third stage

Translation layout.

You must first prepare a container with water in which the board will be soaked. I have the role of this capacity performs the usual basin. Hot water is poured in (50 degrees, that is, so that the hand no longer suffers), five liters, and a little detergent dissolves in it (a little, this is a tablespoon).

And we go to the iron.

We place the prepared textolite on a flat surface and cover it with a printed layout, iron it up to the maximum temperature, iron it along the center line, and then from the center to the sides. When you first press the printout is better to hold, so as not to move. After the first ironing, the sheet of photo paper sticks to the copper and you can no longer be afraid to move it with an iron. Now you can walk the tip of the iron on all edges and places where the paper looks like it is moving away. Then thirty seconds just warming up the entire volume.

I could not resist not to show the main actor in the article about LUT:

After proglazhivaniya, without cooling, throw the board water. That is, without removing the paper, pick up the hot tweezers and put in a prepared container of water. 10 minutes break for soaking.

Fourth stage

Paper cleaning.

After 10 minutes, remove the board from the water and remove the paper. No matter how long the board is in the water, all paper will not lag behind. More precisely, the paper itself is without problems, but the glossy layer that provided us with good adhesion will remain in narrow places.

something like this:

In general, the toner is kept very securely, you can rub it with your fingers, an eraser, or a sponge for washing dishes, but it is difficult to pull out the gloss between the tracks, just let the board dry, such places will be visible.

There are three ways.

- Soak the board in alcohol for another 10-15 minutes, the glossy layer will swell and wash off with a soft cloth. This is not our way, in view of its blasphemy.

- Soak the board in an “anti-silicone” solvent, which is sold in hardware stores. I do not know what is there as an active substance (it is not written on the bottle), but the glossy layer also swells and is removed, while the toner remains. This is an amateur way, a means rather smelly.

- And the third way is to remove mechanically, which is not very long.

To do this, wet the board back and remove the excess with a sharp object. It is best to use a sharp toothpick. Wet gloss is removed without problems, and the toothpick tree does not tear down the toner. I note especially that you can not use needles! Not because you can remove the toner (it is stuck well), but because the iron leaves traces on the copper. Yes! I myself am in shock, I know that copper is softer than iron, especially stainless steel. But the fact is the place to be. Where the needle drove the copper is poisoned very slowly.

A practical example:

After removing the residues of the glossy layer, wash the board with detergent, removing the "fingers". Leave to dry.

Almost deliberately left a few places where the gloss is not removed (then we will see that all is not so scary).

Fifth stage

Etching.

I am poisoning ammonium persulphate, not to say that it is better than ferric chloride, iron is just more dirt (well, yes, ammonium persulphate is the same bleach, what mud is there) and ferric chloride is harder to store - hygroscopic and as a result fused into large pieces that need to be crushed .

Harassment at a temperature of 40 degrees. On a board with copper 35µm - 15 minutes, With copper 17µm - 5 dashes 7 minutes. It is possible and at room temperature of 17 microns it is poisoned about 20 minutes, 35 microns in theory 40 minutes, but I don’t remember it anymore.

At home, you can poison in any container, for this article specifically poisoned in a conventional plastic container, which imposes certain additional actions from the artist. But if the PP is made often, then you can seal yourself a bath for etching:

the main addition of which is the pump for mixing the solution, it exempts from "certain additional actions". The pump needs a membrane, with a plastic membrane.

The one on the picture, bought in the online store for robokrafterov.

Inside the bulkhead, to accommodate several PP.

The photo shows two sides of the board under the STM32F407VE connected to a seven-inch display.

Under xmega I will corrode in the open plastic.

We make a solution - half a liter of water plus 100-150g of ammonium persulfate. In general, 250 grams per half liter is recommended, but in artisanal conditions when the solution is cooled and the water evaporates, crystals fall out and firmly stick to the copper, as a result of the non-etched points.

As I wrote above - the temperature is 40 degrees.

We throw a board into the solution and begin to mix the solution with a brush so that the etching proceeds evenly. Also, a brush can remove the glossy flakes from the board, if not all are removed during the preparation.

I have a board with copper of 35 microns, in 10 minutes textolite is already visible:

I wait another 5 minutes and everything is ready.

It must be said that in the etching process it is better to over-charge the board than to underexpose. And the extra time can be quite large. One time I saw an unfinished training ground threw the handkerchief back and forgot about it for about three hours, when I remembered, I thought that it had been torn through. However, not a single undercut was noticed:

Here is this peredelanets (already derelict):

So, we pulled out our board, washed it and looked at the light:

If you find excess copper, then you can throw back into the solution.

If all is well, then LUT is over!

We wash off the toner with acetone and maintain it, if in the near future maintenance is not provided, then the board can be stored without washing the toner, it will be a protective sheath.

Total:

Above, I marked the places on the board where the glossy finish remained. Those places that the gloss closed hermetically (a corner on the board) were not etched there, where there is a small overlap between the lanes - everything is fine, the solution got there. If you use a container with a pump, then the glossy coating can generally not be completely rubbed off, just the pickling time doubles.

A couple of phrases about tinning. Since LUT makes temporary fees or for yourself, you shouldn’t pay too much attention to maintenance (IMHO), you can simply go for a soldering iron to the places where there will be soldering, and then cover everything with varnish.

But if the components on the board will be re-soldered or the board will be used for a long time, then it is better to do it. Or a soldering iron to go through the entire copper, or if there is a hairdryer, then with a solder paste.

I interfere with the flux paste about 1 part of the paste and 5 parts of the flux, cover the entire board and heat it with a hairdryer:

while warming up, a textolite brush (known as the “eternal brush”) drives the solder to the edges of the board, I do not have too much solder on the tracks with this method, and where there is not enough of it, you can drive it from the edges. Not an air knife, of course, but also pretty neat.

The main problem with the use of solder paste is the extra balls stuck to the board. Here you can see them in the photo:

Therefore, after tinning, the board must be thoroughly washed and wiped off with a cloth moistened with acetone.

The fee was condemned, now everything is for sure. Installation. Check:

Mission accomplished. On this fee took no more than an hour (taking into account the photographing stages).

At the same time, I was poisoning the second board, or rather two sides of the same board. And if the first handkerchief was more likely to demonstrate (it was possible to do a DIP adapter, and not to do something like an arduin), then the second was needed for a specific purpose and weaving braids of wires on the adapter is not an option (and it’s not the fact that it doesn’t pick up any interference connection via fsmc)

Two sides:

As you can see, I did not persecute double-sided textolite, going through the deadly procedure of combining two templates at the stage of work with an iron. Better to do it now.

We drill holes on VIA in all boards, take the legs from resistors and 5 pieces are soldered to one side, then we string the other side on them, we solder from both sides. All boards are combined! Now you can solder all the holes.

Something like this:

All is ready!

You must have noticed a strong marriage on one side:

The paper after the printer is electrolyzed and collects everything. Especially the hair, especially the cat! So I did not watch it.

And here is the culprit:

Monitors all running processes.

After the restoration of the track, the PP is ready and the device is assembled:

True, it was just a temporary fee - to check the correctness of the connections, then to dissolve humanly and order.

That's all. Good luck in your endeavors!

Source: https://habr.com/ru/post/451314/

All Articles