Building a custom computer, part 1

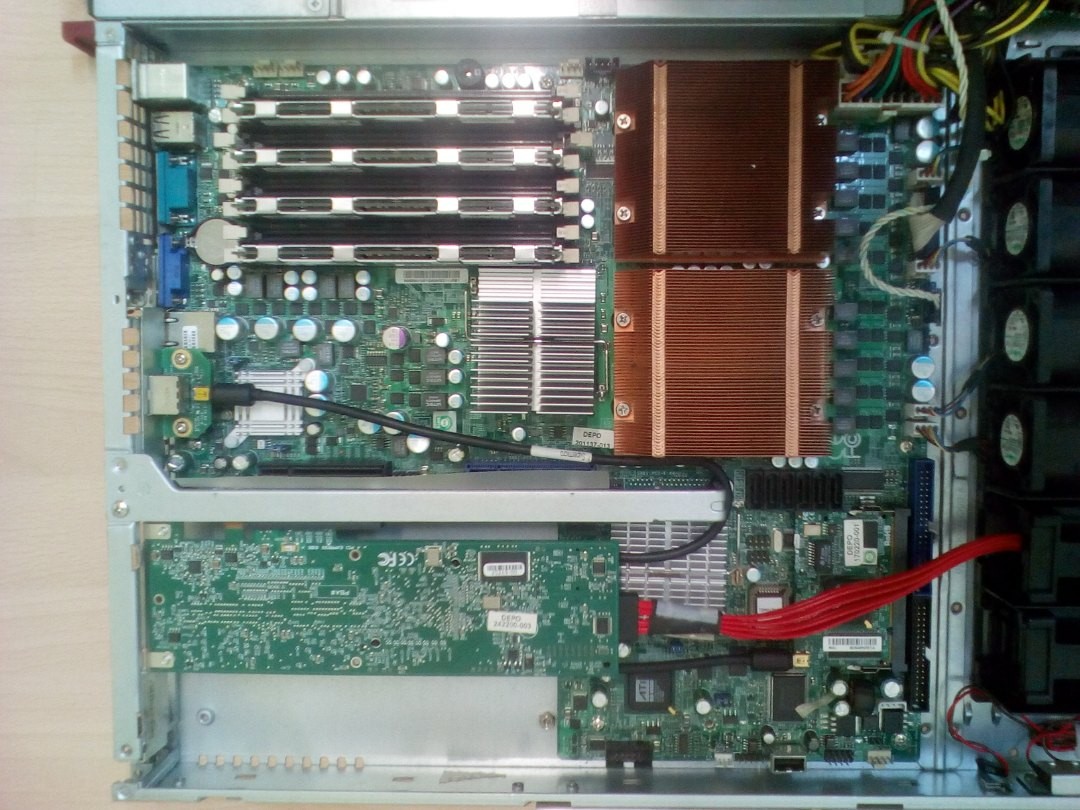

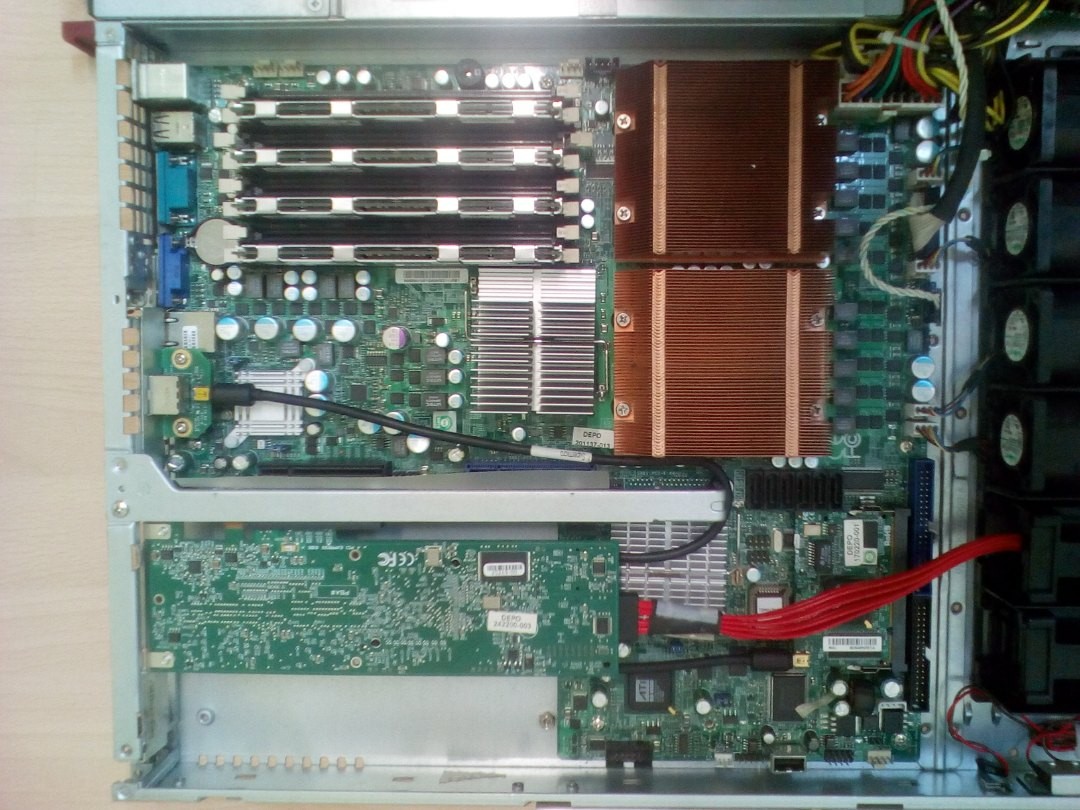

For the third year, I have been running my own small IT school in my city. Since I don’t have permanent funding (yes, I don’t count on it), I basically have to rely on myself and on the help of students. Periodically, it turns out to get help from different people, for example, from one person in Moscow, I managed to get a large number of very good working hardware, especially servers. And once again, I decided to upgrade the class - I begged the district administration for a certain amount of money to purchase components (mainly SSD), and set to work. From the existing computers, we collected 7, typing 6-8 GB of RAM in them and putting the SSD, and for the complete set we decided to assemble about 6 more machines using server platforms, which we have about 8 (not used). So the idea was born to make a beautiful custom workstation, with glass and lighting. I am quietly fixing the manufacturing process ;-) especially if one of my students does modding.

So,

In view of the presence of a large number of server components, it was decided to assemble a custom computer — a workstation. With a successful outcome, these computers need 6 - to replenish the computer class. For our purposes, this is a good option. In the game it is not really, but the work is likely to be quite comfortable.

Since the server's motherboard has an EATX shape that is unusual for a regular PC, which is not rectangular in shape, after some thought, we decided to make our modding case with non-standard dimensions, we will experiment with materials and layout along the way.

The configuration of the iron is assumed as follows:

')

Motherboard: Supermicro X7DWU

Processors: 2 Xeon E5405

RAM: 8 x 2Gb DDR2 ECC FB-DIMM

Hard disk: SSD 240Gb Patriot, + perhaps in addition one more, normal disk HDD. Although due to the fact that the workstations will be located in the AD domain Gigabit network, where there is a basket for 15Tb under the file storage, it doesn’t mean much to put something other than SSD.

Video card: x16, low profile, with separate VGA. GT 730 2GB, DDR3

Power supply: ATX 500W SVEN PU-500

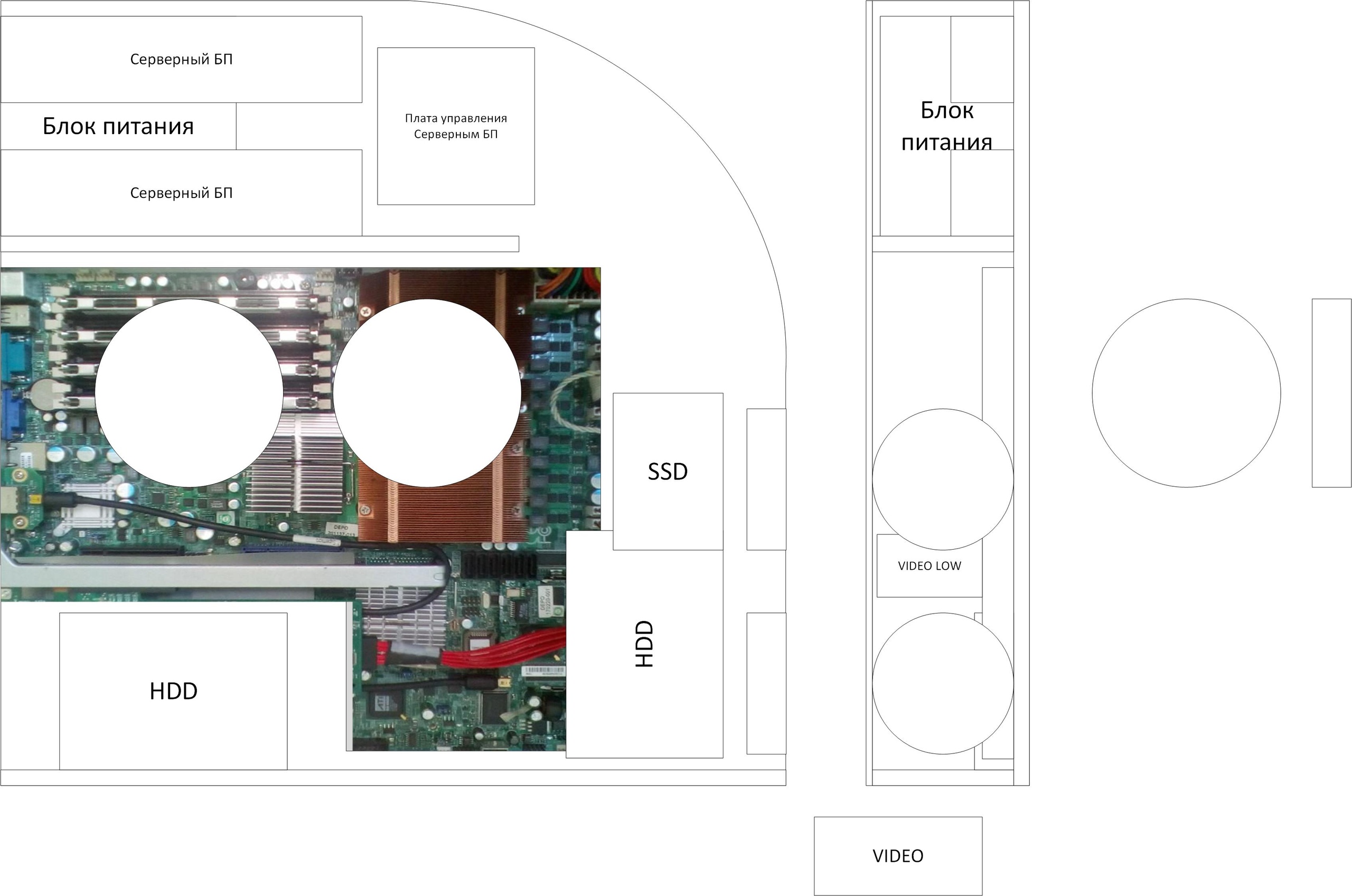

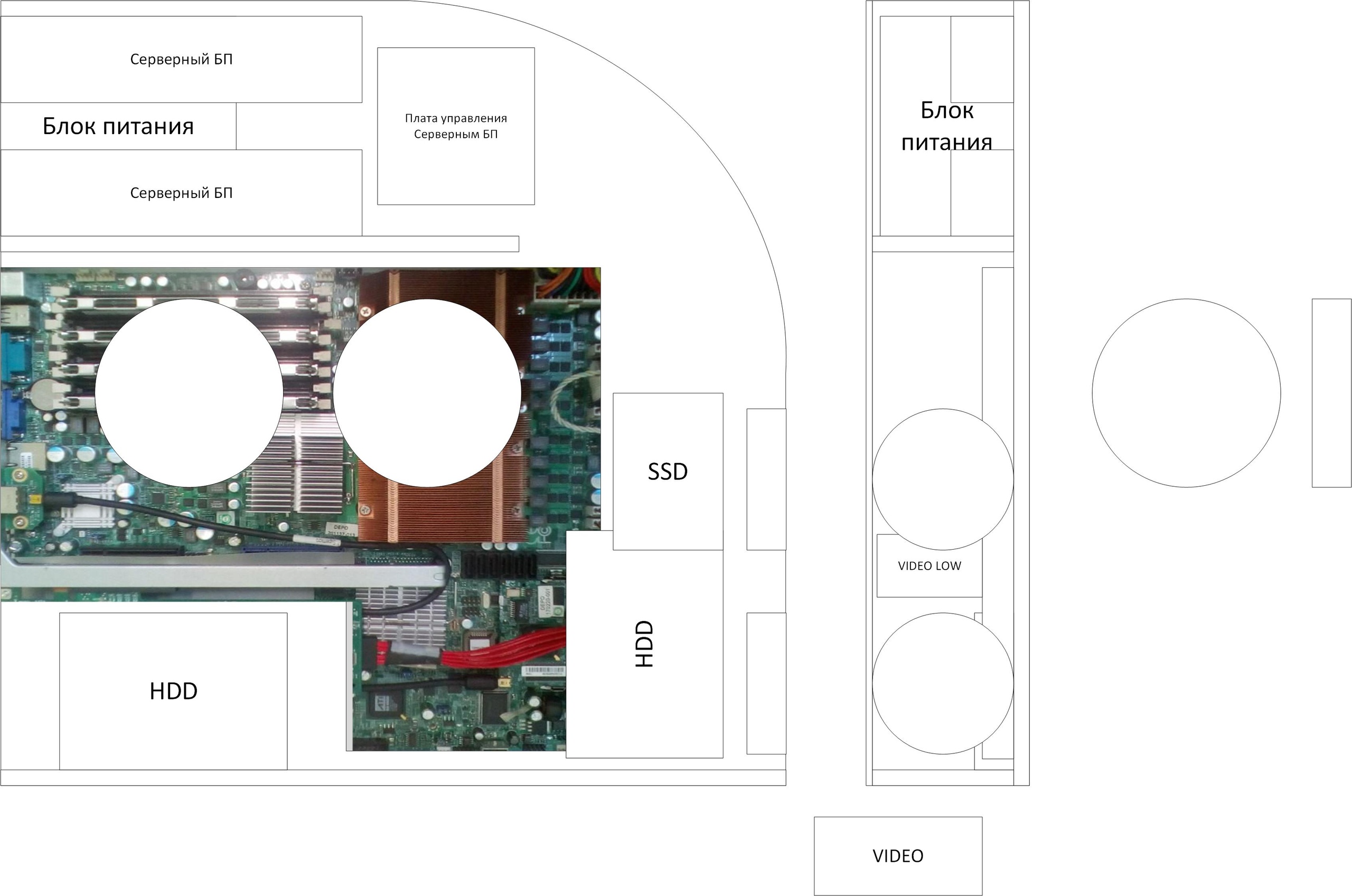

The first sketch of the body:

The idea is to make a thin standing case, with one transparent wall and illuminated fans mounted on a transparent wall. A housing with a large radius of rounding and “open” at the end (or closed by a grid). All components are supposed to be fixed to the second, opaque wall. Also, the ability to install server-side power supplies should be maintained, cables should be as compact as possible, dimensions should be sufficient for installing various fans, etc.

Inspired, among other things, by this picture:

Calculation by power supply. For this motherboard, a PSU of 550 W is recommended, which is logical - 2 processors, 4 hards, 8 memory bars and a bunch of cooling turbines. Our configuration is somewhat weaker - we will only have an SSD, so I assumed that 500 watts would be enough.

But still count:

2 x Xeon E5405 = 2 x 80 W = 160 W

8 x 2GB DDR2 ECC = 8 x 5 = 40 W

Motherboard = 30 W

GT 730 video card = 50 W

SSD = 5 W

In total, a 500 watt unit should suffice with a good margin. You can estimate here .

Important note - the unit must be suitable for the number of power connectors on the board. In other words, the connectors should be enough. However, due to the fact that we will not install a powerful video card, many BPs are suitable (except for the cheapest).

One of the most important issues that immediately appeared is cooling. The server 1U package contains 6 turbines for this purpose, which create a powerful stream that blows processor radiators and memory. The thing is good, no doubt, but if this car is somewhere far away, outside the door. It is desirable away. The noise level for the machine room is not the most critical thing, but somehow we don’t want to sit near the fighter taking off. It was decided to put two 120 mm fans on processors and memory, and to monitor their heating during operation. If this is not enough, either add another stream or change the configuration of the radiators. There was a thought to leave the server power supply units (they are doubled), but it turned out not to be a fountain either, they also each had 1 turbine installed ... well, in general, there could be a backup.

Several 120-mm fan models with green lighting were chosen as decorations and cooling systems; a 90-mm fan can also be installed on the front of the case. The cables will be laid in a beautiful plastic sheath.

With the choice of material, everything is also not very simple - plastic was originally intended, but for experiments I did not find where to buy nearby, but there is plywood ... In general, we took plywood and a board, we’ll try something with them. After assembling the prototype, we will order one wall of glass (it is possible and plexiglas, but I would like to present). By the way, then I found a place in Kaluga where you can order parts from anything - sandwiches, plastics, etc., with sawing out on a coordinate machine.

But the plywood here, next, well, then, still need to ponder - the size, docking.

Fans went to order, something from China, ordered an SSD, video card and something else on the little things. The financial assistance of the district administration and the RONO through our TAC came in very handy.

To work on the body, you also need a tool - a Bulgarian, a grinder, a jigsaw, a drill, and a bunch of all sorts of hardware, which were already purchased during the process.

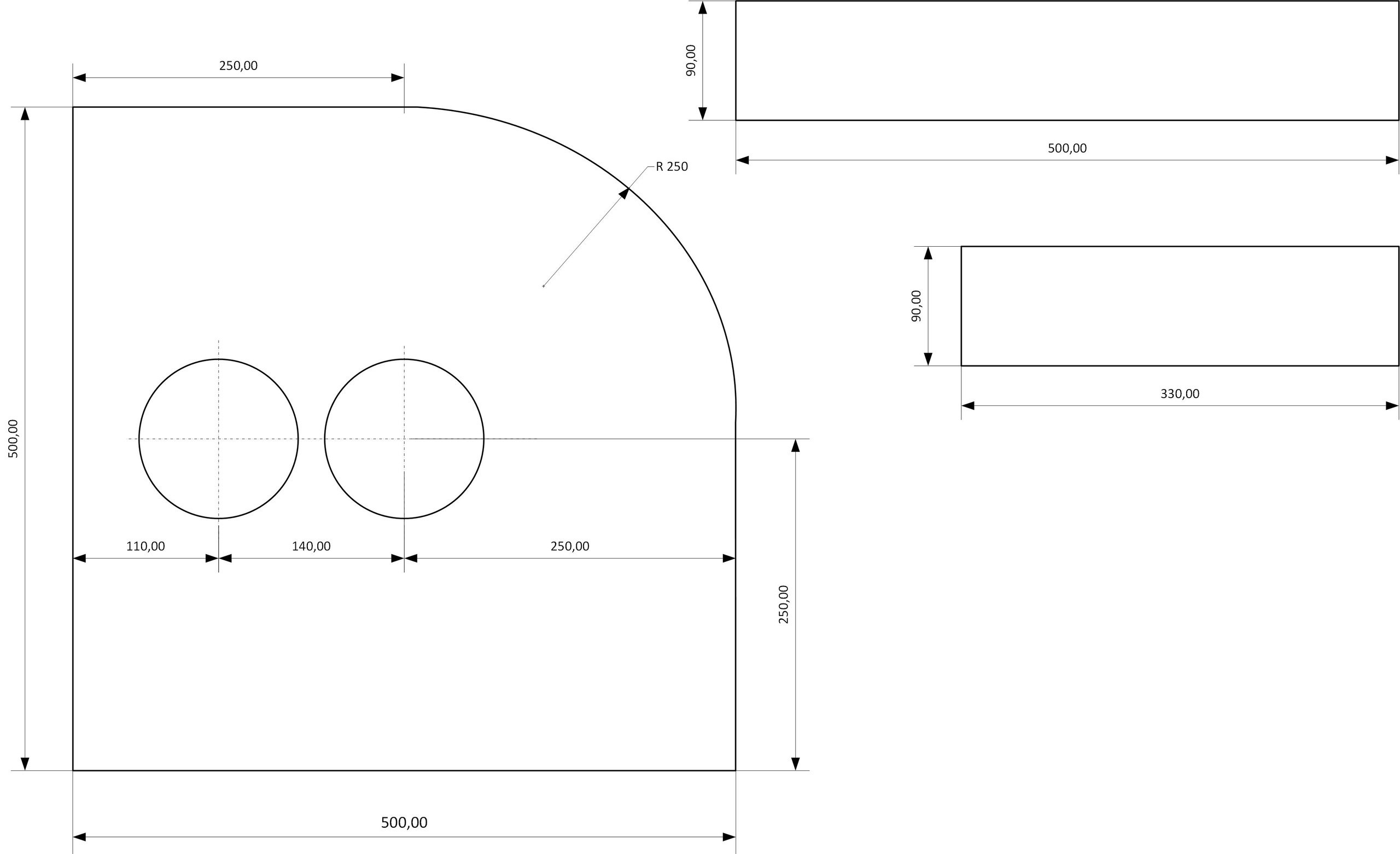

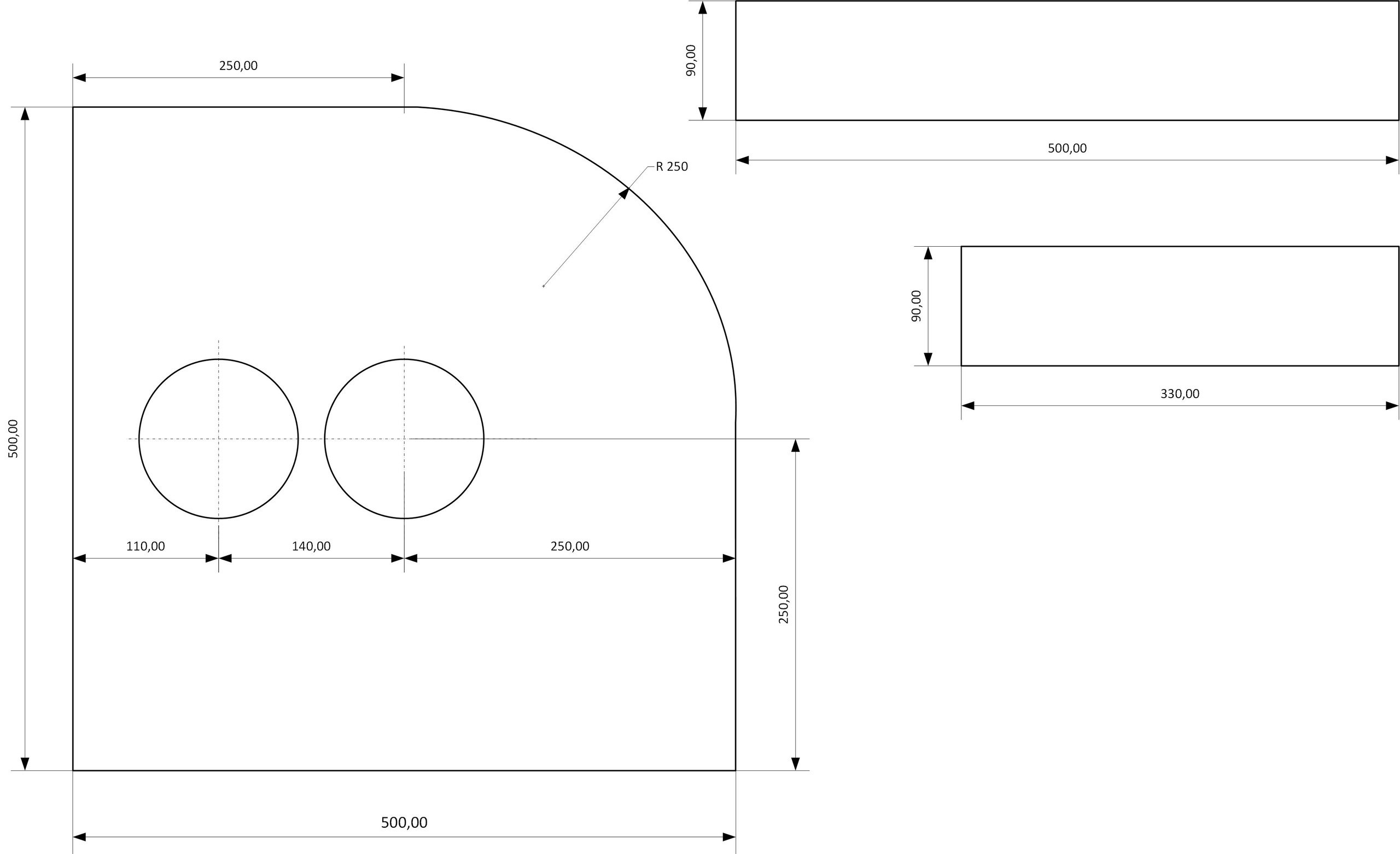

A drawing for cutting the wall and the bottom shelf (still the top one, but then it was decided to refuse it):

We cut it out with a jigsaw, we decided to cut the whole sheet at once to get identical walls (9 pieces).

After cutting the walls, we first align the grinder, then grind it with a machine so that they are the same. One wall fell out - too curve, we leave for experiments. As for the rest, they flew a little in size, after leveling they got something about 496x496 mm. Not scary, but we consider for the future.

We cut off the bottom shelf from the board, while leaving a width of 130 mm (like a board), then see how real it can be reduced (ideally to 100 mm).

We fill one wall at once, dry and grind - we try to get a smooth, smooth surface for painting. As for painting, I have already agreed with the master, he will do it in the best possible way (side wall and lower shelf).

For now - we will assemble a prototype case, so that everything will work and at the same time we will think over the fasteners and specify the dimensions.

So,

Part 1

In view of the presence of a large number of server components, it was decided to assemble a custom computer — a workstation. With a successful outcome, these computers need 6 - to replenish the computer class. For our purposes, this is a good option. In the game it is not really, but the work is likely to be quite comfortable.

Since the server's motherboard has an EATX shape that is unusual for a regular PC, which is not rectangular in shape, after some thought, we decided to make our modding case with non-standard dimensions, we will experiment with materials and layout along the way.

The configuration of the iron is assumed as follows:

')

Motherboard: Supermicro X7DWU

Processors: 2 Xeon E5405

RAM: 8 x 2Gb DDR2 ECC FB-DIMM

Hard disk: SSD 240Gb Patriot, + perhaps in addition one more, normal disk HDD. Although due to the fact that the workstations will be located in the AD domain Gigabit network, where there is a basket for 15Tb under the file storage, it doesn’t mean much to put something other than SSD.

Video card: x16, low profile, with separate VGA. GT 730 2GB, DDR3

Power supply: ATX 500W SVEN PU-500

The first sketch of the body:

The idea is to make a thin standing case, with one transparent wall and illuminated fans mounted on a transparent wall. A housing with a large radius of rounding and “open” at the end (or closed by a grid). All components are supposed to be fixed to the second, opaque wall. Also, the ability to install server-side power supplies should be maintained, cables should be as compact as possible, dimensions should be sufficient for installing various fans, etc.

Inspired, among other things, by this picture:

Calculation by power supply. For this motherboard, a PSU of 550 W is recommended, which is logical - 2 processors, 4 hards, 8 memory bars and a bunch of cooling turbines. Our configuration is somewhat weaker - we will only have an SSD, so I assumed that 500 watts would be enough.

But still count:

2 x Xeon E5405 = 2 x 80 W = 160 W

8 x 2GB DDR2 ECC = 8 x 5 = 40 W

Motherboard = 30 W

GT 730 video card = 50 W

SSD = 5 W

In total, a 500 watt unit should suffice with a good margin. You can estimate here .

Important note - the unit must be suitable for the number of power connectors on the board. In other words, the connectors should be enough. However, due to the fact that we will not install a powerful video card, many BPs are suitable (except for the cheapest).

One of the most important issues that immediately appeared is cooling. The server 1U package contains 6 turbines for this purpose, which create a powerful stream that blows processor radiators and memory. The thing is good, no doubt, but if this car is somewhere far away, outside the door. It is desirable away. The noise level for the machine room is not the most critical thing, but somehow we don’t want to sit near the fighter taking off. It was decided to put two 120 mm fans on processors and memory, and to monitor their heating during operation. If this is not enough, either add another stream or change the configuration of the radiators. There was a thought to leave the server power supply units (they are doubled), but it turned out not to be a fountain either, they also each had 1 turbine installed ... well, in general, there could be a backup.

Several 120-mm fan models with green lighting were chosen as decorations and cooling systems; a 90-mm fan can also be installed on the front of the case. The cables will be laid in a beautiful plastic sheath.

With the choice of material, everything is also not very simple - plastic was originally intended, but for experiments I did not find where to buy nearby, but there is plywood ... In general, we took plywood and a board, we’ll try something with them. After assembling the prototype, we will order one wall of glass (it is possible and plexiglas, but I would like to present). By the way, then I found a place in Kaluga where you can order parts from anything - sandwiches, plastics, etc., with sawing out on a coordinate machine.

But the plywood here, next, well, then, still need to ponder - the size, docking.

Fans went to order, something from China, ordered an SSD, video card and something else on the little things. The financial assistance of the district administration and the RONO through our TAC came in very handy.

To work on the body, you also need a tool - a Bulgarian, a grinder, a jigsaw, a drill, and a bunch of all sorts of hardware, which were already purchased during the process.

A drawing for cutting the wall and the bottom shelf (still the top one, but then it was decided to refuse it):

We cut it out with a jigsaw, we decided to cut the whole sheet at once to get identical walls (9 pieces).

After cutting the walls, we first align the grinder, then grind it with a machine so that they are the same. One wall fell out - too curve, we leave for experiments. As for the rest, they flew a little in size, after leveling they got something about 496x496 mm. Not scary, but we consider for the future.

We cut off the bottom shelf from the board, while leaving a width of 130 mm (like a board), then see how real it can be reduced (ideally to 100 mm).

We fill one wall at once, dry and grind - we try to get a smooth, smooth surface for painting. As for painting, I have already agreed with the master, he will do it in the best possible way (side wall and lower shelf).

For now - we will assemble a prototype case, so that everything will work and at the same time we will think over the fasteners and specify the dimensions.

Source: https://habr.com/ru/post/451002/

All Articles