Measure cast parts of complex shape? MetraSCAN 3D to the rescue

The leading Czech company in the field of production, modernization and repair of molding machines uses in its work a 3D scanner from Creaform, which significantly speeds up the process of measuring parts of complex shape.

Šmeral Brno (“Shmeral Brno”) is a joint-stock company with a long tradition, which began in 1861. Over its long history, the company has gradually expanded the scope of its activities. Starting from the foundry industry and then adding engineering to it, in 1925 the company began to produce molding equipment of its own brand.

At present, Šmeral manufactures and supplies turn-key molding lines, including automated using robots or transfers, autonomous molding machines and other equipment for forging workshops, such as presses and punching hammers for hot forging or forging rolls. Šmeral Brno is the world leader in the supply of machines for the cross-wedge rolling of steel and aluminum alloys . An important part of the company's production program is the overhaul and modernization of the molding equipment of any brand, type or year of manufacture.

Why use a 3D scanner?

Having already managed to acquire such advanced equipment as a laser tracker and a CMM, Šmeral wanted to supplement its monitoring and measuring equipment park with a portable scanning device so that it was easy to carry out a comparison with the CAD model, modernization and reverse engineering .

')

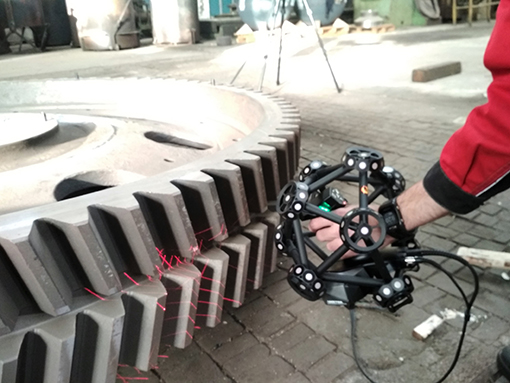

After some searches, Šmeral contacted Creaform to obtain detailed information about the MetraSCAN 3D 3D scanner, a flexible portable solution for 3D measurements in production environments.

MetraSCAN 3D is a portable 3D scanning device based on the C-Track optical tracker, which provides dynamic binding, automatic alignment and continuous tracking of parameters. This 3D scanner is insensitive to external fluctuations in production conditions and is ideal for measuring parts that cannot be transferred to a granite or cast-iron table.

During the field demonstration held by SolidVision, the official distributor of Creaform in the Czech Republic, representatives of Šmeral Brno were greatly impressed by the capabilities of the MetraSCAN 3D 3D scanner , especially in terms of measuring and scanning shiny and rough surfaces. Moreover, such results can be obtained without any preliminary preparation, in contrast to similar solutions that require applying spray to the objects or performing other preliminary operations. Other advantages were the speed and available range of measurements, as well as the portability of the system, which can be used directly at the factory and at the customer's site.

Šmeral specialists quickly made the decision to purchase the MetraSCAN 750-Elite 3D scanner. Although they already had other measuring equipment, this device did not allow for 3D scanning. The MetraSCAN 3D 3D scanner has provided wider measurement possibilities: this is extremely important for the company because it seeks to provide the most efficient measurement methods when designing equipment for cross-wedge rolling. Creaform scanner was a great help, allowing to measure products of complex shape much faster.

Examples of parts measured in Šmeral Brno, with measurement reports

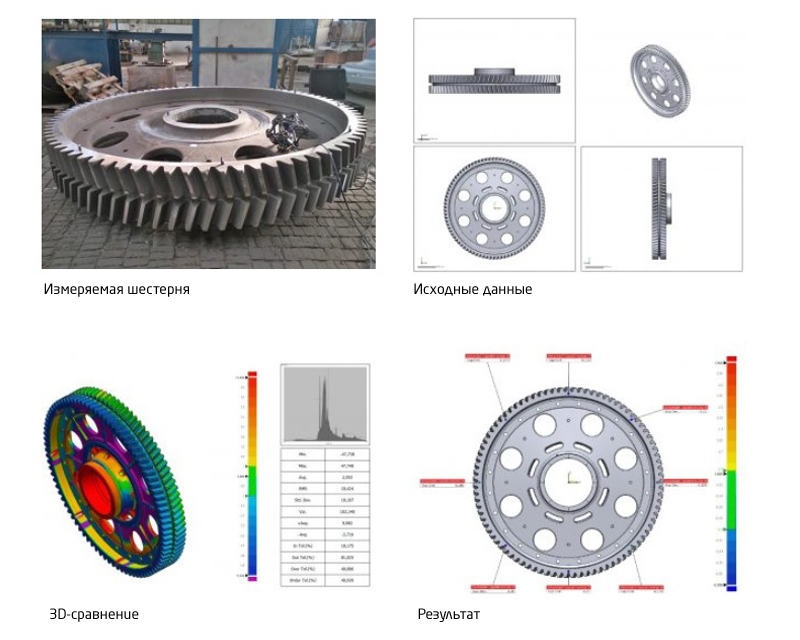

Item 1: Gear

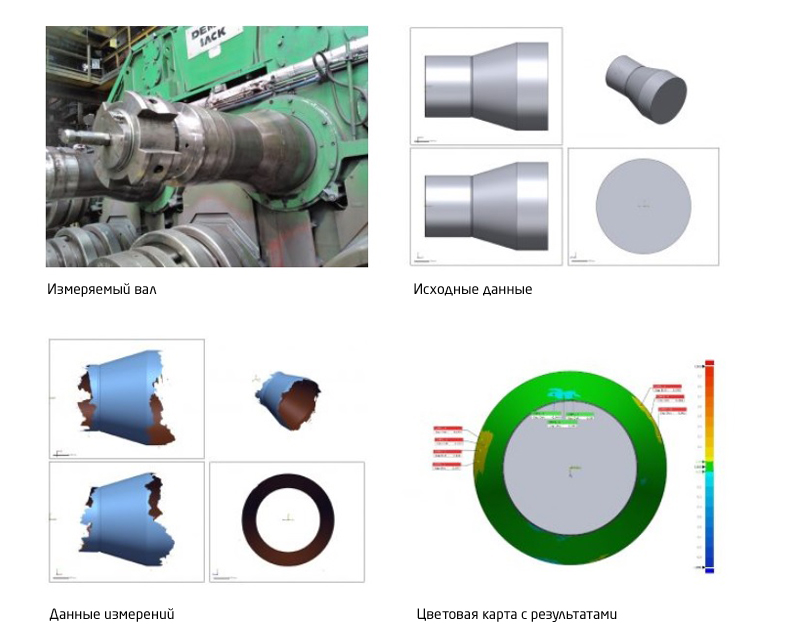

Detail 2: Shaft

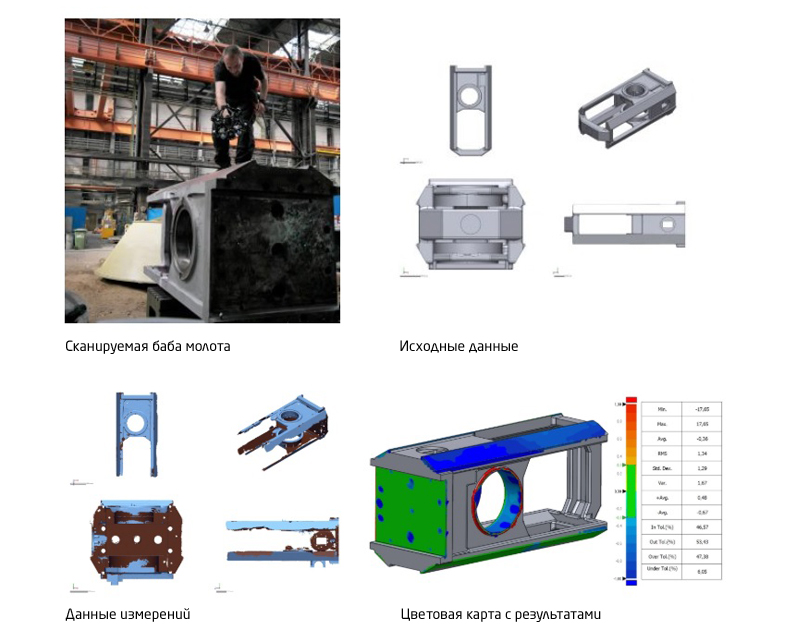

Detail 3: Baba hammer before repair

Material provided by Creaform.

Source: https://habr.com/ru/post/450880/

All Articles