SLA technology concept car: how it is done in China

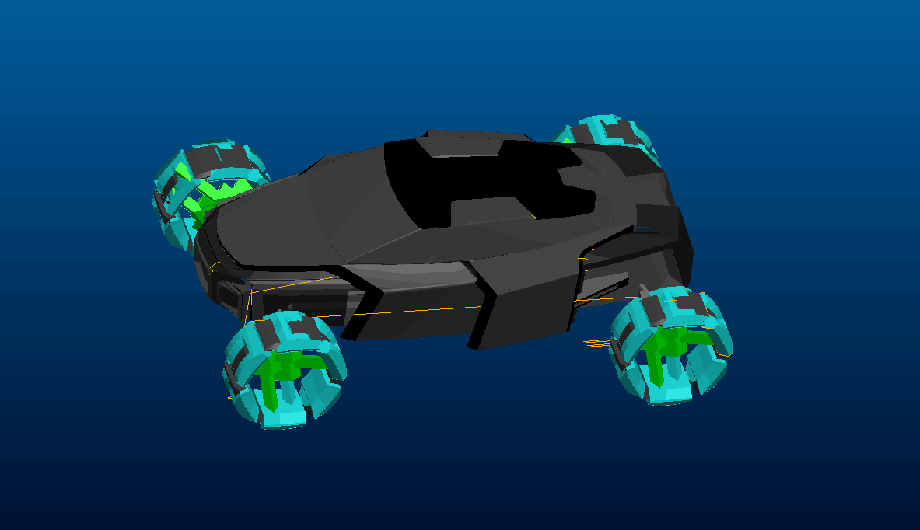

The Tension concept car printed on a 3D printer (designed by Peter Lin)

iQB Technologies has become the exclusive distributor of ProtoFab , a major player in the Chinese 3D printing market. ProtoFab manufactures powerful and economical industrial SLA printers and unique materials for solving the most complex production problems, and also provides a wide range of 3D printing services. We open the series of publications devoted to ProtoFab solutions with the history of an interesting project on creating a concept car using a photopolymer 3D printer .

- Project name: SKANDA concept car model, designer - Liu Yakhsin.

- Model size: about 1.2 meters in length.

- Material: photopolymer ProtoFab Formula L1.

- Manufacturing technology: stereolithographic 3D printing .

- Equipment: ProtoFab SLA600.

- Accuracy: 0.01 mm.

- Order date of performance: 10 days.

- Requirements: exact observance of the sizes; smooth, well-defined lines; impressive overall appearance.

Prototype - for 10 days!

The design team of the Faculty of Industrial Design of the University of Huafan is a dedicated group of young professionals with multilateral experience. In the project about which we want to tell, the team led by its scientific director, director of the transport design group Shaun Lee, needed the help of ProtoFab in the manufacture of high-quality models of sports cars for display at exhibitions.

')

Below is a picture of a 4x4 vehicle for business customers. The designer decided to use elements of traditional Chinese architecture, and the intersecting lines characteristic of this style provided the car with an extremely spectacular look. Here is one of the sketches that the customer submitted to ProtoFab:

Design sketch of a prototype sports car

Problems

- The model was quite large - 1.2 meters in length, which required its assembly from several parts.

- Post-processing specialists required special care when performing complex and labor-intensive polishing and painting operations.

- The assembly stage was also extremely difficult due to the need to glue together several parts by hand. This task has become a serious challenge for the assembly team.

Solutions

1. Considering that the SLA600 3D printer can print objects up to 600 x 600 x 400 mm in size, the model needed to be divided into eight parts. Using the software , we evaluated the possibility of manufacturing each individual section of the model and optimized their design for 3D printing. These eight parts are shown in the illustration below, where each is highlighted in its own color. Having completed the modeling of each of the eight individual elements using software, we modeled the final design to ensure that the assembly operation proceeds exactly as it should.

Full size prototype scan

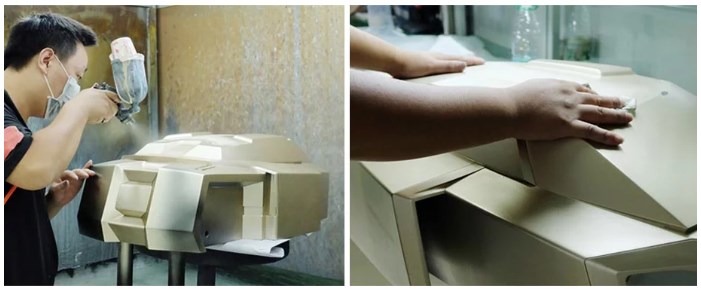

2. After printing, we carefully removed the model from the 3D printer, washed it with alcohol and removed the support . After a painstaking post-processing, no traces of supporting structures remained, and the surface of the model became absolutely smooth. The initially printed object may be slightly rough, with some noticeable surface defects.

Polishing parts just come from a 3D printer

We polished the model, starting with coarse sandpaper, and then gradually moving to the finest grain. ProtoFab is renowned for its attention to detail, which was confirmed by the polishing phase. Polishing was carried out in shifts and took longer than usual due to the large size and complexity of the model, as well as due to strict requirements. High demands were made at this stage and to the qualifications of the whole team. As it was planned, we painted each of the eight parts with our own color and tried to make the finish coat as shiny as possible. So that the coating does not lose its luster over time, paint of very high quality was used.

After applying the paint, additional polishing is performed to ensure the best surface quality.

3. The most difficult part of the project was the assembly phase. All eight printed parts of the model had to be glued together, in accordance with the high requirements of the customer to the quality of the finish. We used gluing, interlacing and other methods to connect the parts. We also filled the model from the inside with foam material , as a result of which it slightly increased in volume. This allowed to emphasize the design features and gave a more realistic look to the model as a whole.

Final assembly

Finished model

Below is a concept car printed on a 3D printer, as well as several other models made by ProtoFab for the design team of the University of Huafan.

Concept car created on the ProtoFab SLA600 printer

Alpine (designers - Lin Li, Peter Lin, Ricky Tin, Huan Yuanvey)

Metamorphosis - X Evolution (designer - Tsai Chigi)

Gravity (designer - Ricky Tin)

Pursue (designer - Wan Huaiji)

Maserati Frenesia Concept (designer - Yuan Chen)

Samurai (designer - Huan Yuanvey)

All the models that we made for students from Huafan University were well received by both the designers themselves and the visitors to the exhibitions. The creation of a concept car model for this project was completed in 10 days and became a real test for all the specialists involved, especially at the final stage. It was very nice to see that the results of our hard work are put on display and receive such a positive response.

Material provided by ProtoFab

Want to learn more about 3D printing solutions offered by ProtoFab? Visit the iQB Technologies booth at Metalwork 2019

Source: https://habr.com/ru/post/449534/

All Articles