TSAT: Industrial 3D-printing and 3D-scanning in Russia

We continue to talk about the topics of the upcoming conference Top 3D Expo 2019 .

From this issue you will learn about the Center for Additive Technologies in Voronezh - how it appeared, what it does and what is interesting, and about the topic of the speech by its head Alexei Mazalov.

')

A small spoiler: TsAT provides enterprises with services from the sphere of additive technologies and digital production - 3D printing, including metal, 3D scanning and model development, and much more. Read more further.

Alexey Mazalov

Alexey Mazalov graduated from the Aerospace Department of the Moscow State Technical University. N. E. Bauman in 2013 and the Economics Department of RosNOU in 2018. Since 2013, he has led and developed the project of the Voronezh Center for Additive Technologies in the position of General Director.

Subject

The topic of the report: "The use of additive technologies for solving problems of industrial enterprises . "

It will be about 3D-printing systems for industry, which are used by JSC "Center for Additive Technologies". First of all, these are SLS, SLM, vacuum casting and 3D scanning for preliminary assessment and post-verification of parts.

Come to Top 3D Expo and find out more.

About TsAT Company

JSC Center for Technological Competence of Additive Technologies, also known as Center for Additive Technologies, is a project of public-private partnership, the implementation of which began in 2013.

In DAC is represented and works for the benefit of customers equipment of such famous manufacturers as 3D Systems , Stratasys , SLM , EOS and many others.

Now it is one of the largest operators of industrial 3D printers in Russia. The company has more than 12 systems, and more than ten of them are 3D printers that print all sorts of materials. There is also an industrial 3D scanner and a vacuum casting system.

The company has two production units, one of them is a service delivery unit.

CAT Services

The range of services provided by the Voronezh TsAT is quite wide, and it includes 3D printing by most of the materials used for it, including photopolymers and metal.

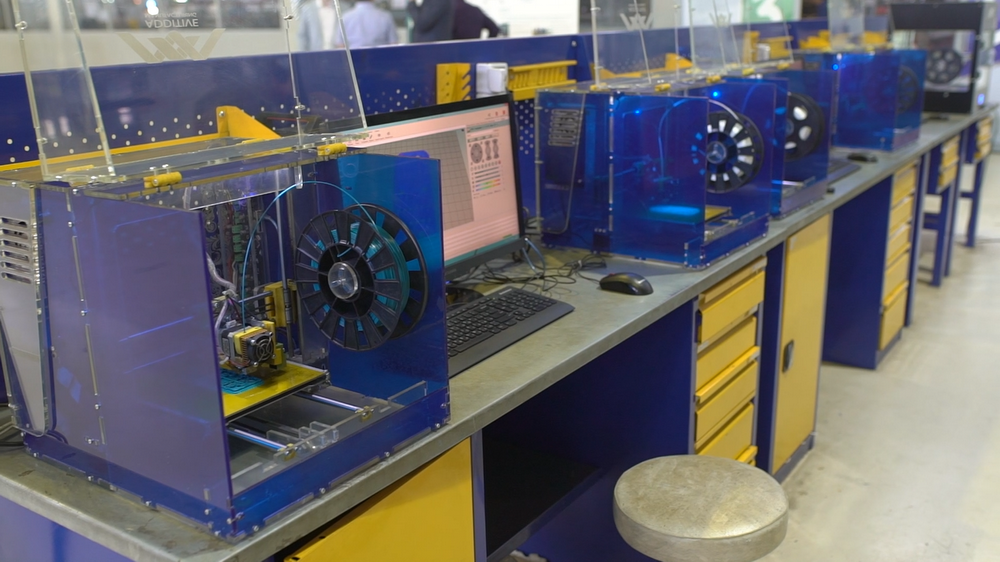

The second production block TsAT collects desktop 3D-printers of its own design.

3D printers TsAT

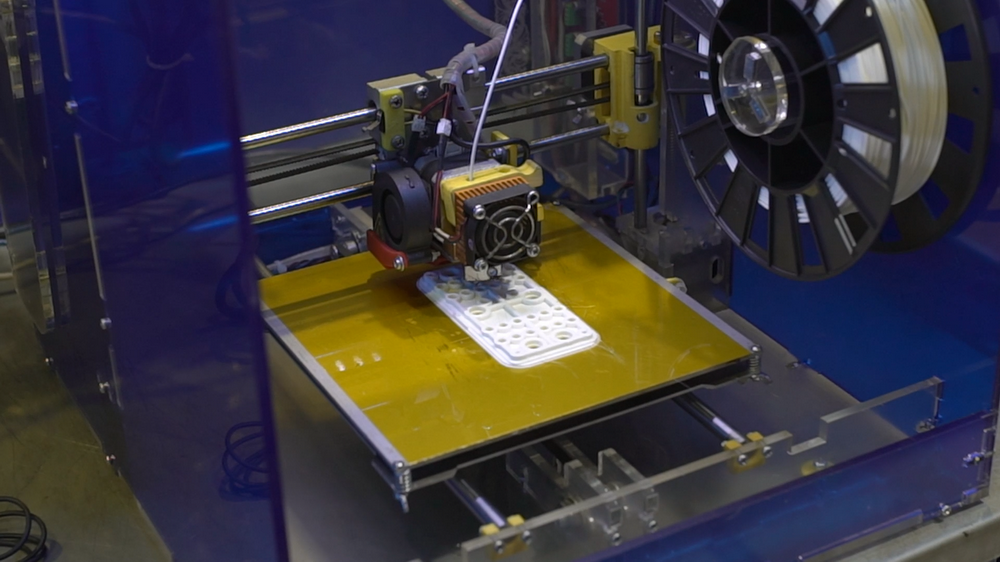

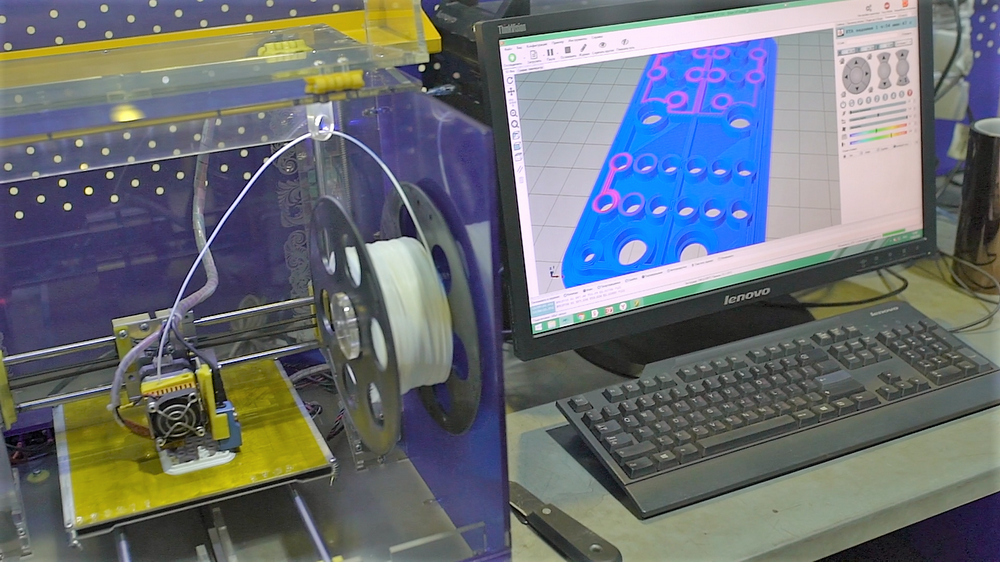

The company develops, manufactures and supplies homemade FDM printers.

These printers are the easiest to learn and use. Alpha 1 is an entry level printer.

Alpha 1

- Closed acrylic case

- Heated table

- Print speed: 50 mm / s

- Minimum layer thickness: 0.03 mm

- Maximum layer thickness: 0.3 mm

- X / Y positioning accuracy: 4 microns

- Z positioning accuracy: 10 microns

- Printing area: 190x190x150 mm

- Auto-calibration by 9 points

- Price: 65 000 rubles

Structurally simple and easy to learn 3D printer designed for teaching and hobby printing.

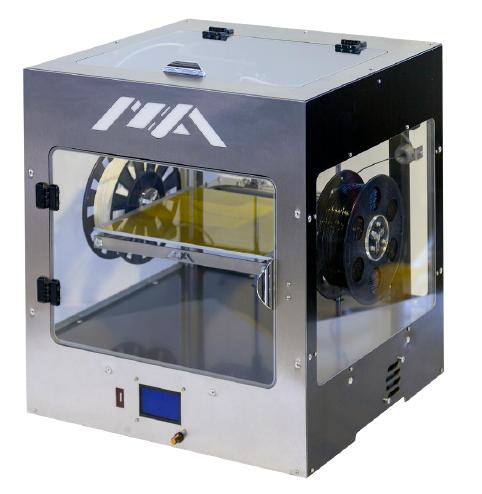

Alpha 2

- Closed aluminum hard case

- Two extruders

- Auto-calibration by 9 points

- X / Y positioning accuracy: 4 microns

- Z positioning accuracy: 10 microns

- Layer thickness: 30-300 microns

- The diameter of the nozzle: 0.2-1.0 mm

- Table working temperature: 0 - 105 °; nozzles 0 - 280 °

- Print resolution: 30-300 microns

- Construction area: 250x250x250 mm

- Price: 160 000 rubles

Used equipment

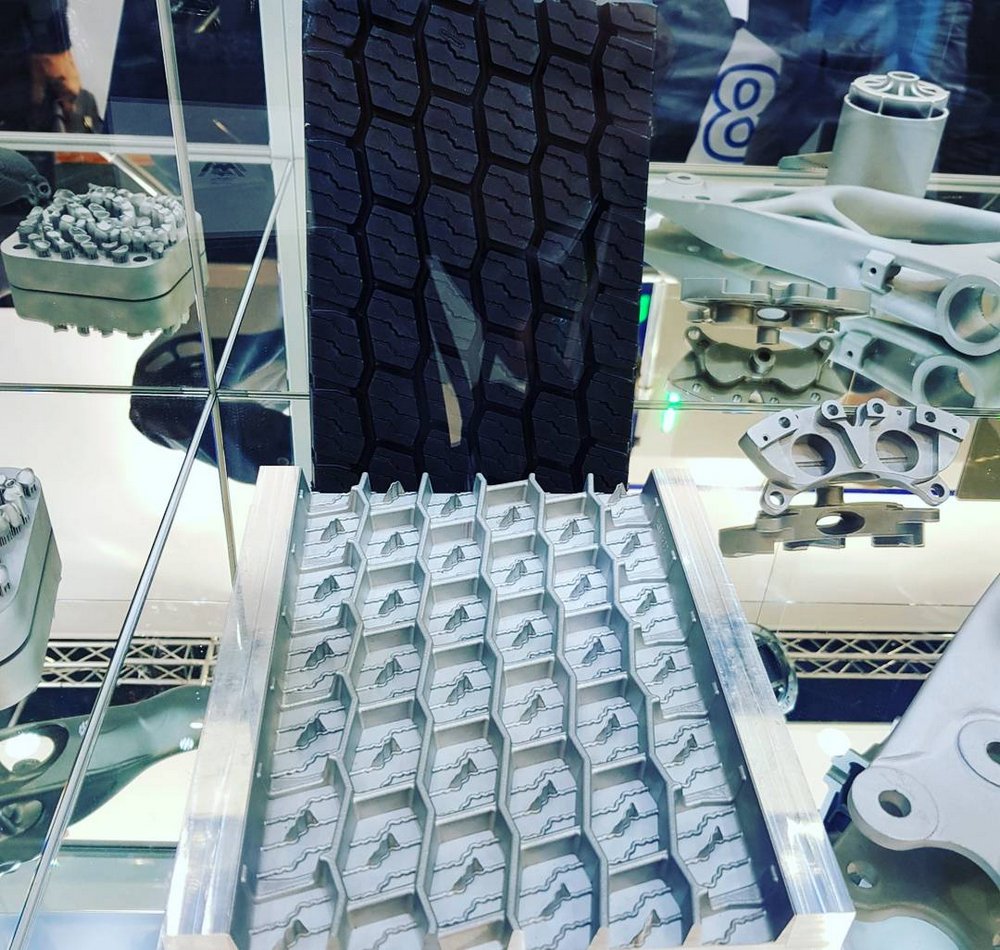

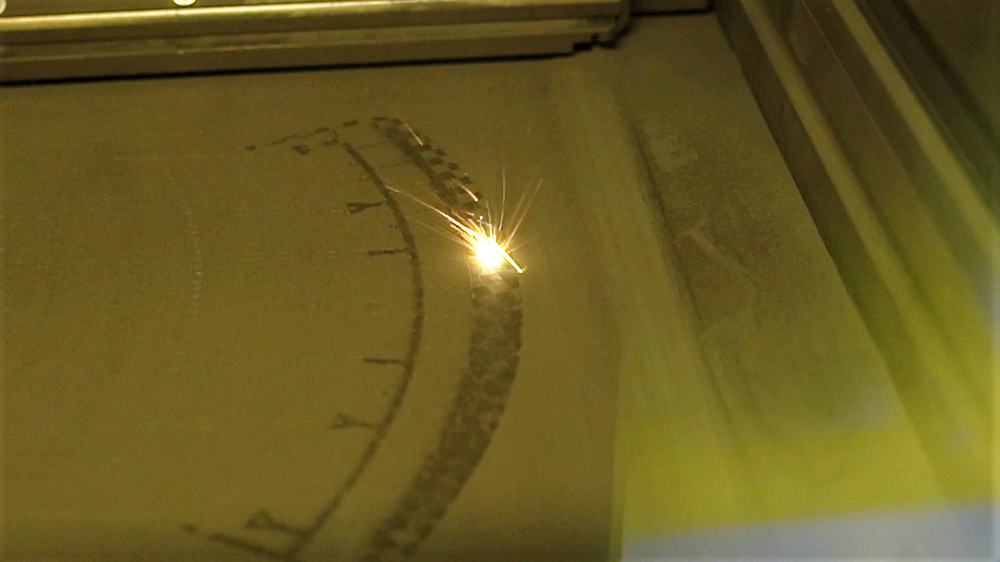

SLM

3D digital printers are printed using SLM technology — selective laser fusion technology, such as 3D Systems ProX 100 with a 100 x 100 x 80 mm working chamber.

The systems of the SLM company also work - two copies of the 280HL model.

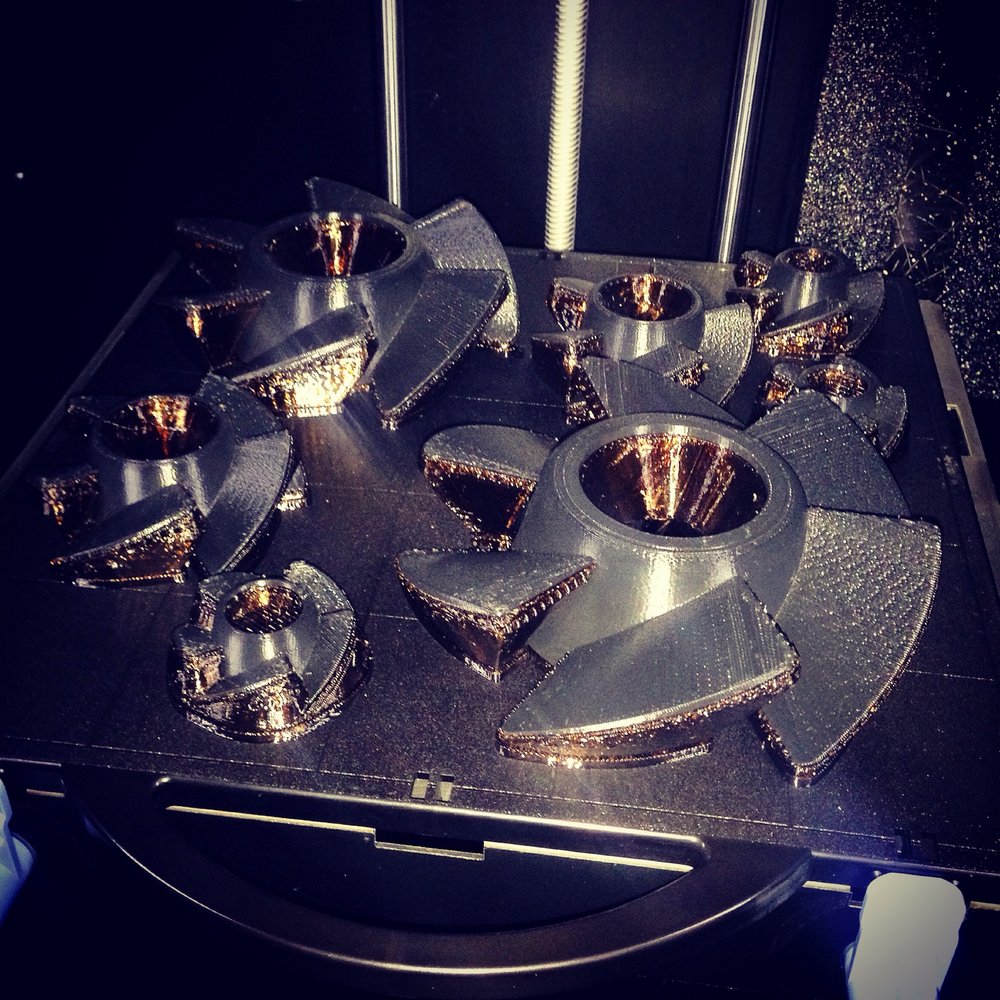

Samples of metal prints made from domestic powders. This seriously saves money in operation, as domestic materials are much more affordable and at the cost, and the possibility of rapid procurement and delivery.

Metal powders for 3D printing are supplied by Polema JSC, VILS OJSC, VIAM Research Institute, MISiS and Rusal NITU.

The main customers of TsAT in this profile are large enterprises from state corporations, such as Rostec or Roskosmos.

In addition to domestic steels and alloys, imported from Germany, England and China are also used at TsAT.

SLM is valued for the ability to produce products of complex configuration with high mechanical characteristics quickly and without creating an equipment, and many SLM-printed parts cannot be created by traditional methods.

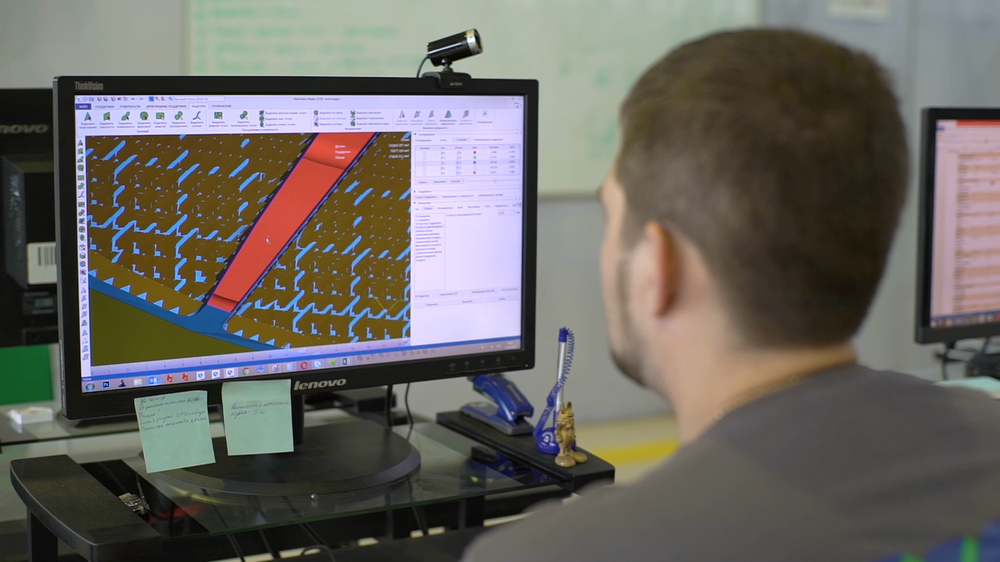

Design and Technology Service

The enterprise has a design and technological service, where engineers, designers and operators of production systems are based.

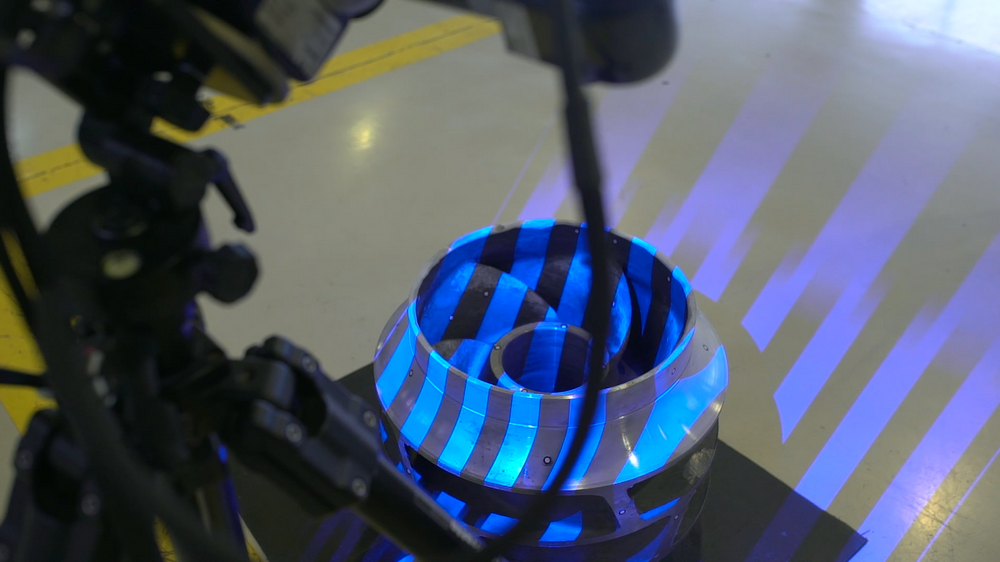

Casting scanning process.

This is a small-scale order of one of the industrial enterprises of Voronezh.

The casting delivered from the customer was machined, scanned and compared with the digital model - this is how the quality of the part is checked. After that, a deviation map is created and transferred to the customer to take them into account when producing a new part.

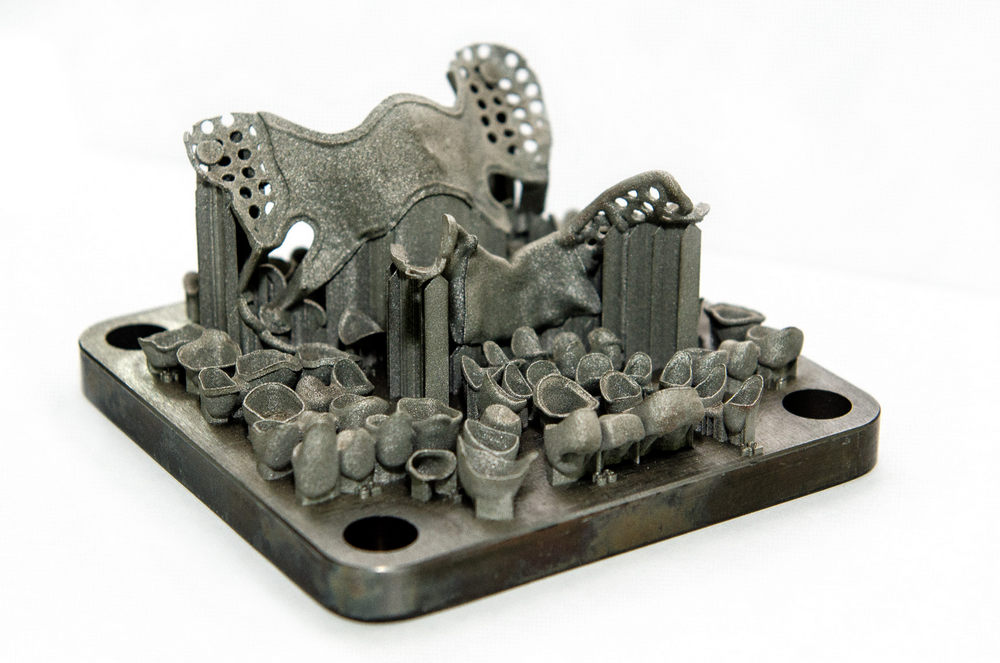

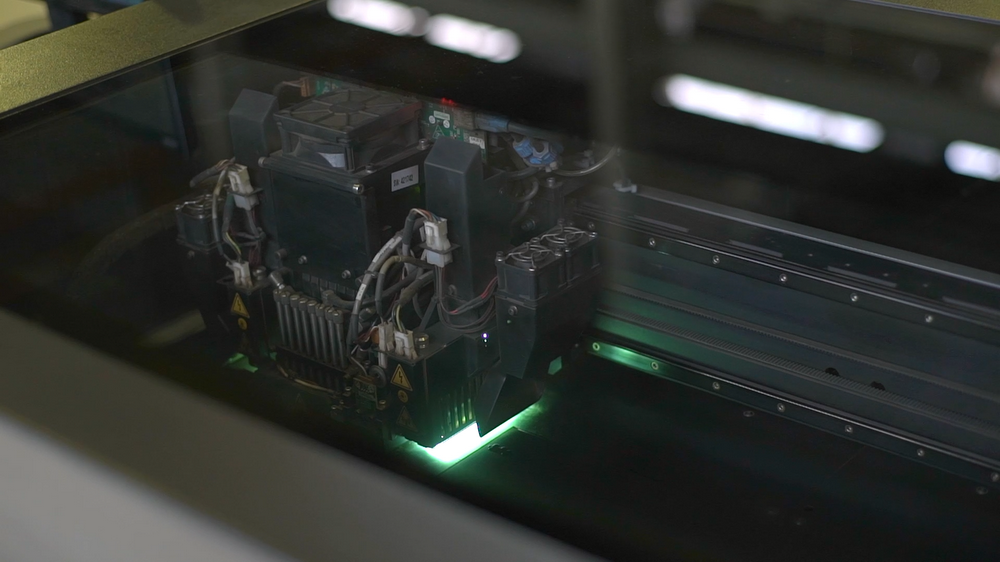

EOS polyamide machine

A polyamide 3D printer produces laser sintering parts. The part under construction, in the process of 3D printing, is in a volume filled with raw materials, that is, not sintered powder, which makes it possible to print models of complex geometry without supports and in all available working volume, regardless of the size and location of each part.

The printer prints as pure PA 12, and mixed with reinforcing or coloring fillers - pigment, aluminum, glass, carbon.

The use of filled polyamides allows you to create parts from sintered dispersed composites, which gives them enhanced physical characteristics.

For printing burnable models for casting materials based on polystyrene are used.

ProJet 660Pro

There are two ProJet 660Pro equipment in the TsAT equipment park, using 3DP full-color 3D printing technology.

The technology allows you to quickly and accurately create color layouts and individual details.

Stratasys Connex500

Industrial SLA printer. The system works with UV-curable liquid photopolymers. It has two powerful UV lamps. One of the most accurate systems.

Layer thickness - up to 16 microns. An extensive list of materials used, including, for example, mechanically similar rubber and ABS. In one operation, you can make a functional prototype for testing ergonomics, constructive, assembly.

Helps to determine the feasibility of ordering an expensive metal prototype. Also used for the manufacture of high-precision master models for casting in silicone.

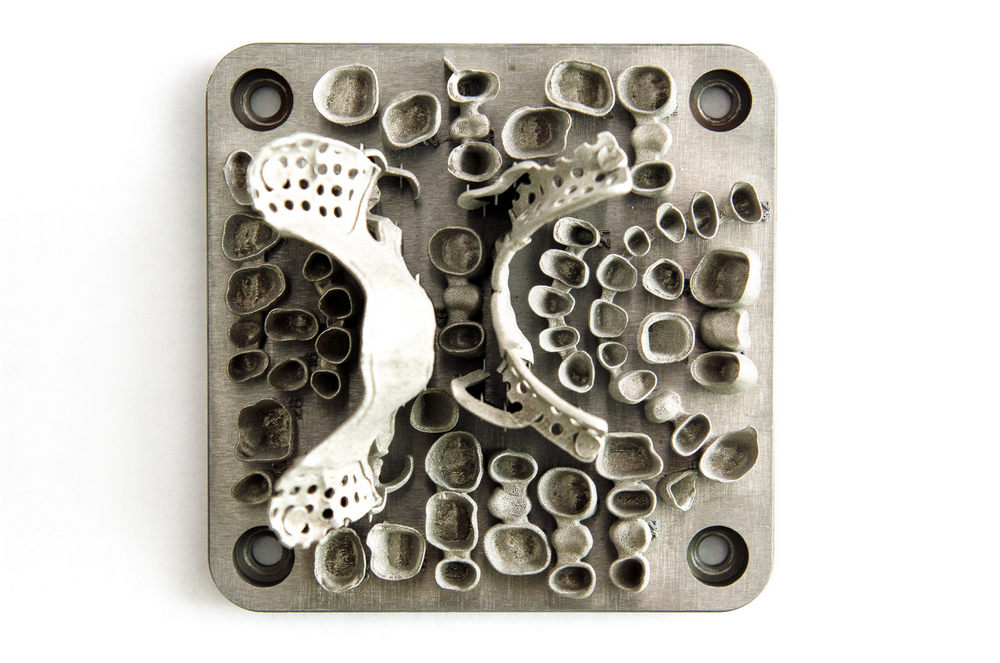

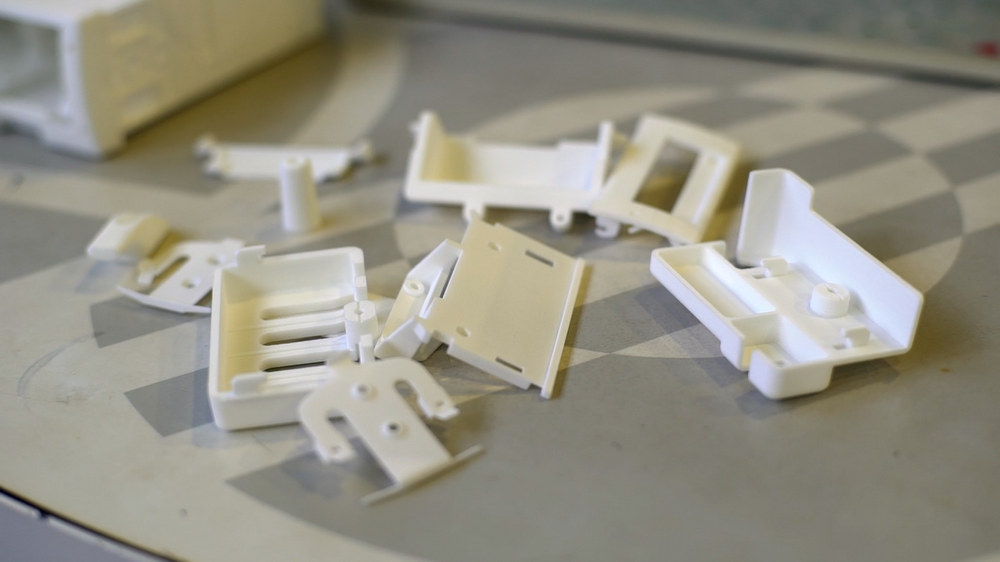

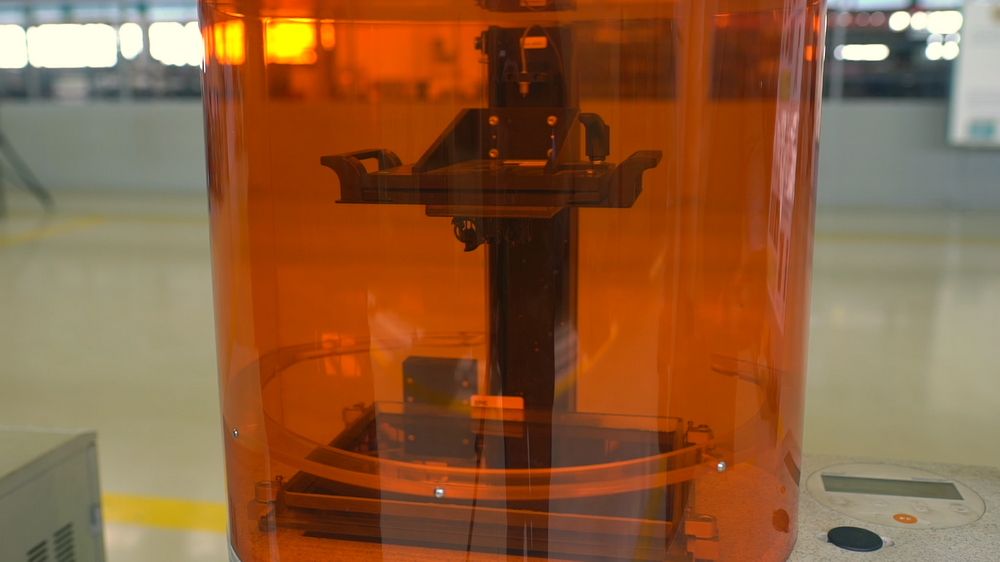

EnvisionTec Perfactory 4 Mini

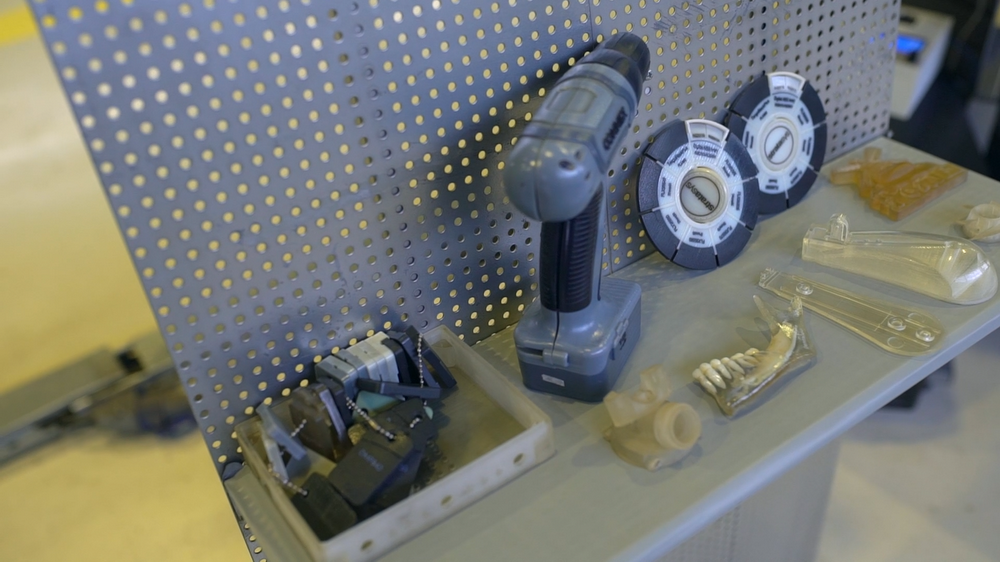

A small high-precision photopolymernik with DLP technology. Here you see the made set of burned-out master models for the subsequent creation of molds and metal casting.

EnvisionTec Ultra 3SP

Another photopolymer machine. It has a larger construction area, allowing to produce more different prototypes and models for casting. The output is a smooth soft-touch surface. Often used for the manufacture of equipment for forming aligners - corrective cap used in orthodontics to correct the bite. Also, the apparatus is used for the manufacture of master models for vacuum casting.

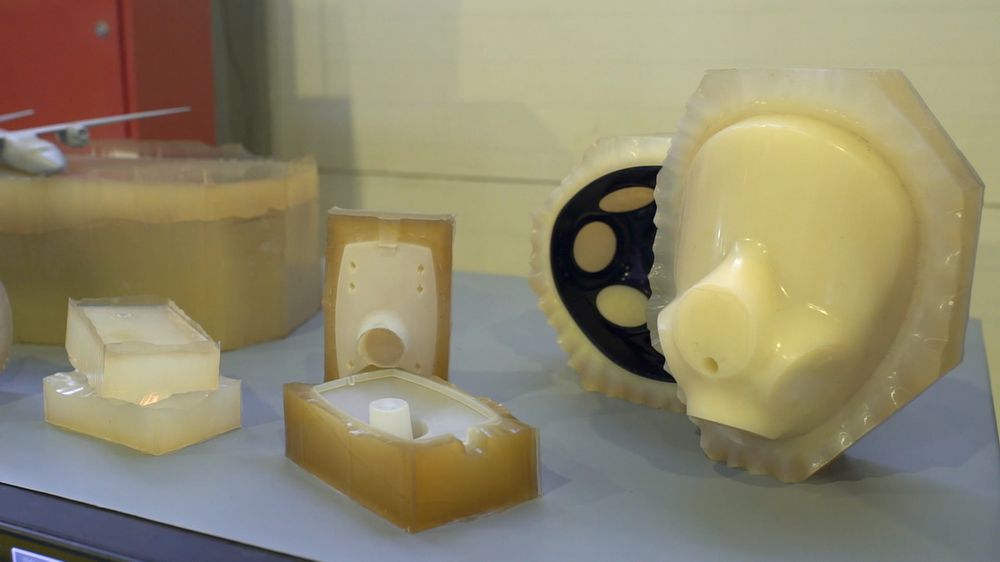

Vacuum casting

The TsAT equipment park has equipment for vacuum casting into silicone.

The vacuum casting system does not directly relate to additive technologies, but to a large extent it works in conjunction with them, significantly expanding the Centre’s capabilities.

With this system, you can quickly produce small batches of polymer products for end use, including complex configuration.

Used a large number of different materials for casting.

It is possible to create very complex shapes. One of the most interesting orders is the case of an electronic device, a remote control for controlling special equipment, which was molded into this form.

Casting orders a very wide range of customers. We had to open the second shift in vacuum casting. The main customers are small and medium business, instrument makers, the automotive industry, large enterprises.

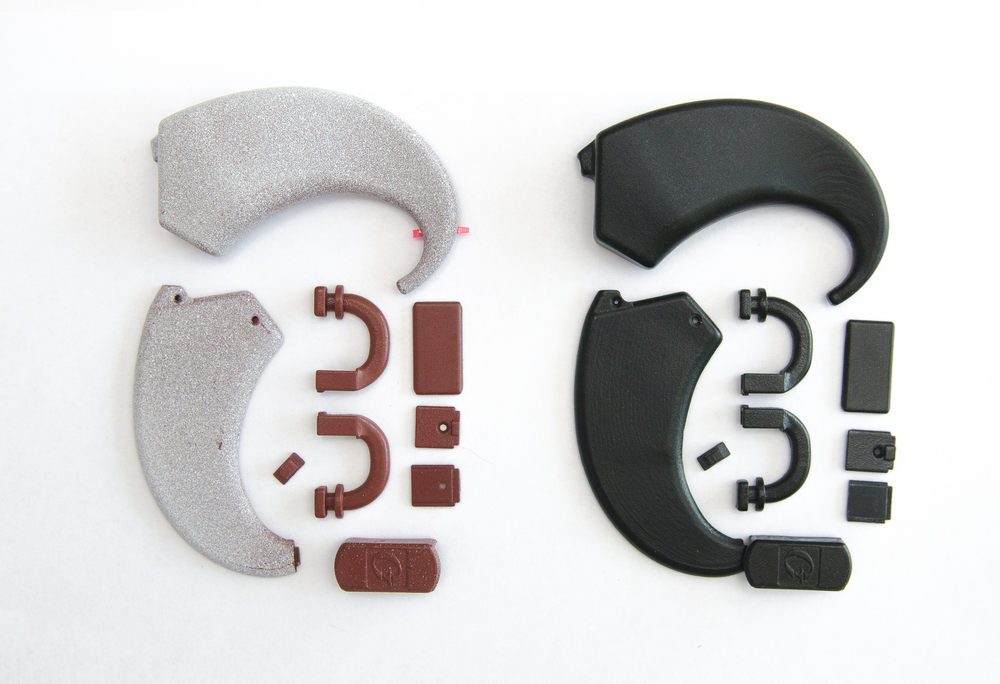

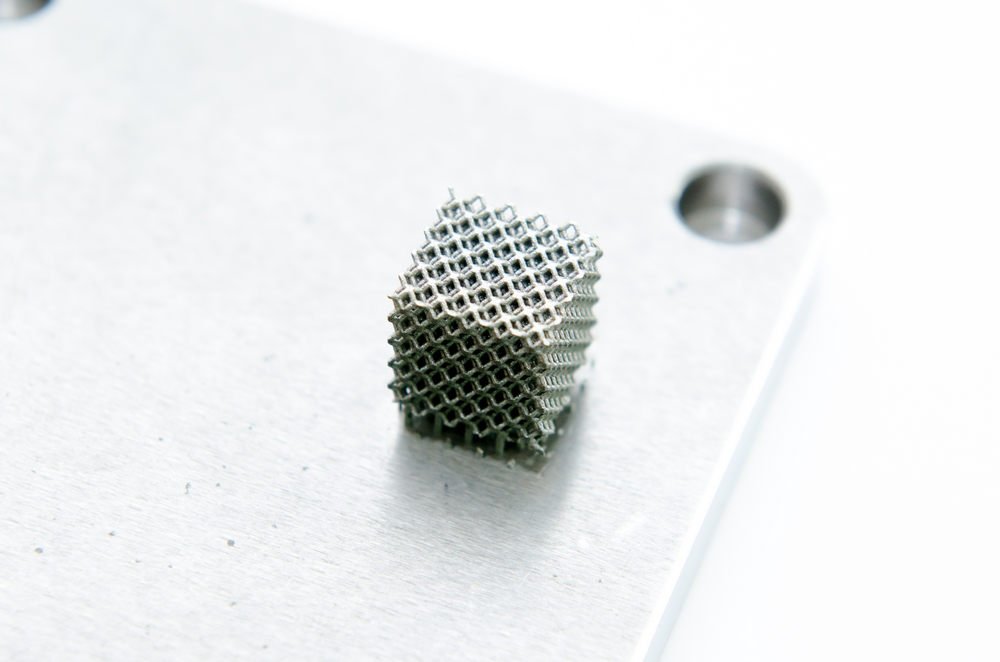

Samples of completed orders

Photos of parts created in the Center for additive manufacturing for customers.

Exhibition Materials

The videos that will be shot at the upcoming Top 3D Expo 2019 conference will be available only to Business and VIP class ticket holders.

Hurry to register and come, there will be many interesting things.

If you are unable to attend the exhibition, but want to keep abreast of the latest developments in additive and digital production, purchase a Business class ticket and receive exclusive Top 3D Expo video footage, including presentations by invited experts.

Through other channels recordings of performances will not be distributed.

Source: https://habr.com/ru/post/448456/

All Articles