How to make a watch for Ilona Mask

I first learned about the Russian watch manufactory of Konstantin Chaikin several years ago, when I accidentally met information about the Lunokhod watch, which showed lunar phases. Later, about a year ago, I was invited to the presentation of his new development - hours for Mars Conqueror Mars Conqueror, they show the Earth and Martian time and the relative position of our planets. On the eve of the Day of Cosmonautics, I ended up in the workshop of Konstantin, and saw how mechanical watches are made today.

Watches under the brand Konstantin Chaykin are created on a small production in Moscow. They have a fairly high price - tens of thousands of dollars, which is determined by the need to ensure the full production cycle, and the willingness of customers to pay for such hours.

')

Konstantin himself invents and develops mechanisms that add additional functions to a wristwatch, and even implement the standard task of deriving information about the time of day nonbanal, for example, as in the Joker model.

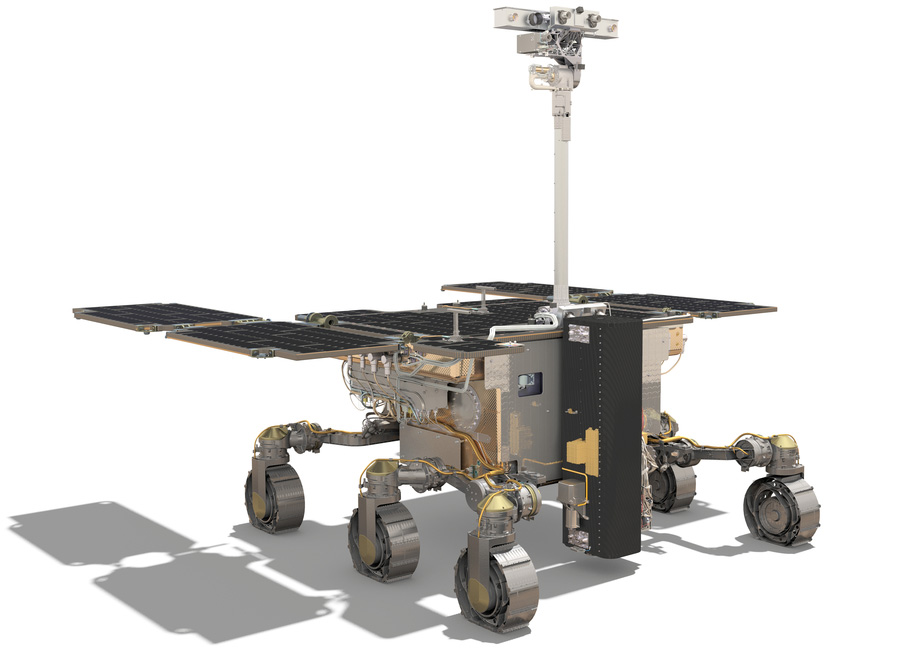

New development on the space theme Mars Conqueror has two dials with Earth and Martian time. The length of the Martian days is longer than the Earth's time by about 39 minutes, therefore, its own watch design is required. In a separate circle, the mutual position of our planets relative to the sun is displayed and periods suitable for a flight to Mars are marked. The strap used material that is used to manufacture the outer layer of the Russian space suit "Falcon".

In the office of the watchmaker of the XXI century there is everything necessary for the invention of a space watch, the development and quality control of workmanship.

Designing is carried out using SolidWorks, and production is done using lasers and modern milling machines, but manual labor is still important and because this plant is in miniature, which produces most of the components of the body and mechanism and is called manufacture.

The manufacturing part of the manufactory repeats familiar sections that are known to virtually anyone who somehow came across factory production: machining, grinding and polishing, electroplating, painting, assembling, quality control ... Only it’s unusual that the whole “plant” is placed in several rooms on two floors , and some "shops" occupy one desktop.

Acquaintance with the production of watches began with mechanical processing.

Now you will not surprise anyone with “smart” cutters, but for the first time I saw a turner with a microscope.

This is really a full-fledged lathe that allows you to produce watch parts with micron precision.

The hardening of steel watch parts is carried out in a special watch furnace, which is produced in Switzerland for the watch manufactories distributed there.

The next stage: grinding and polishing.

The galvanic “workshop” is more like a school experiment in a chemistry class, but the tasks of coating the watch parts with various metals using the electrochemical method are performed successfully.

Nearby is a painting, where colored coatings are applied in a cabinet with an exhaust hood.

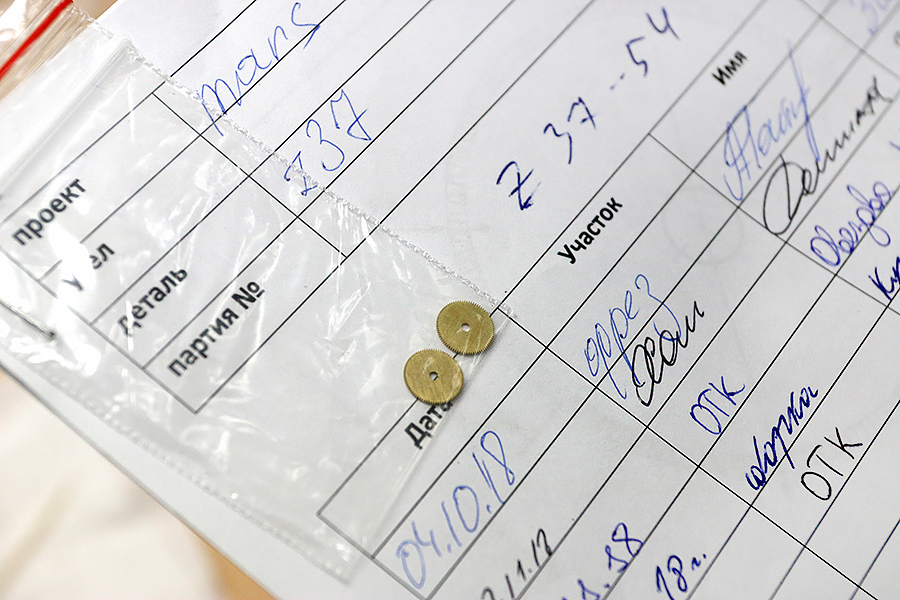

Each stage of the creation of parts passes quality control. In the accompanying sheet notes are made about the operations with the signature of the responsible.

Please note that in the photo there are not disks, they are cogwheels, but the teeth are so small that they cannot be distinguished in the picture.

And here the collector does not have afternoon crumbs on the table, but parts ready for installation into the product.

It is curious that the theme of space is accompanied by a tour of the watch manufactory. It is evident that the interest is not only the founder.

The assembly section of the watch reminded me of another factory site I visited recently - the production of plasma engines at the OKB Torch in Kaliningrad. The engines assembled there are not many more than wristwatches and the work is almost jewelry.

Compare:

Konstantin Chaykin notes that watchmaking with a jewelry has an important difference - jewelry art allows artistic freedom of creativity, but watches require strict adherence to technology and high accuracy of each product. However, due to the manual nature of labor, errors in manufacturing occur and in order to promptly identify them and the Quality Control Department works.

Z.

- Tried to somehow automate production?

K.C.

- At the stage of machining is obtained. Manufacturing products, control sizes. But for the rest - it is necessary with hands and eyes. Tried to somehow automate quality control, optical means, but the machine can not cope. Here, look, these are all defective parts. Take a magnifying glass, can you see the marriage?

Z.

- No, they seem flawless.

K.C.

- And he is.

Z.

- Do you use 3D printers?

K.C.

- For prototyping, yes, but for finished products they do not provide the required accuracy. We have partners who print well with plastic and metal, have tried them, but the printer is not yet comparable to traditional processing methods.

Z.

- For parts in production, I see that the main series is Joker?

K.C.

- Yes, our record holder. Orders for the year ahead. Steady demand, and even fakes began to fall on the Internet. We study, we look, but they are far from us.

Z.

- Didn’t think to expand production?

K.C.

- For the time being it is unprofitable: to recruit and train people, to increase the area, to install equipment ... It is more comfortable to work with a stable order.

Z.

- What is close to the theme of space?

K.C.

- This is a childhood dream. I want to touch in my work at least that way.

Z.

- Probably another PR, won Omega since the 60s launches its clocks into orbit and the moon. Not so long ago, our cosmonauts all flew without fail with the clock of this brand.

K.C.

- This is not just PR. Mechanical watches in astronautics are really in demand. They are not afraid of heavy charged particles, are resistant to induced radiation and temperature changes, work in a vacuum, do not require the replacement of batteries. This is especially true in flight to Mars. Even self-winding in weightlessness works better, and the whole mechanism, due to the reduction of friction. And the accuracy of modern mechanics is close to quartz.

Z.

- Have you already launched your watch into space, experienced in zero gravity?

K.C.

- Not yet, but there are such plans.

Z.

- Speaking of the Red Planet, until Ilon Mask built his giant rocket, your Martian clock will really come in handy for the drivers of rovers. A laboratory at the Space Research Institute works in Moscow, they have instruments on Mars, and knowing the local time would be useful. Soon the ExoMars rover will fly. True, I'm afraid the salary of scientists will not allow ...

K.C.

- We are preparing a simplified version, in the price range up to $ 10K, and with our Martian scientists I am ready to meet and separately support their work.

Z.

- I will try to help contact them. You can also test for zero gravity in a suborbital launch of an ultra-low rocket along a ballistic trajectory. In Russia, there are private owners: "Cosmocourse", "NSTR rocket technologies", I think he will be happy with the order for a test launch. NSTR already promises a rocket this year, although it will not reach space yet.

K.C.

- Still interesting, you need to contact them.

Z.

- Thanks for the tour and the story!

Source: https://habr.com/ru/post/448390/

All Articles