3D printing as part of the revolutionary Shipyard 4.0 concept

Shipbuilding is one of the many industries in which 3D printing technologies are being used more and more often: we have already seen a wide variety of solutions, starting with a certified propeller that is printed on a 3D printer, to regulating the use of high technology and intellectual property in maritime shipping. The Spanish state-owned company Navantia is a leading technology company specializing in the design and manufacture of high-tech civilian and military vessels, control systems and combat systems, as well as diesel engines and turbines.

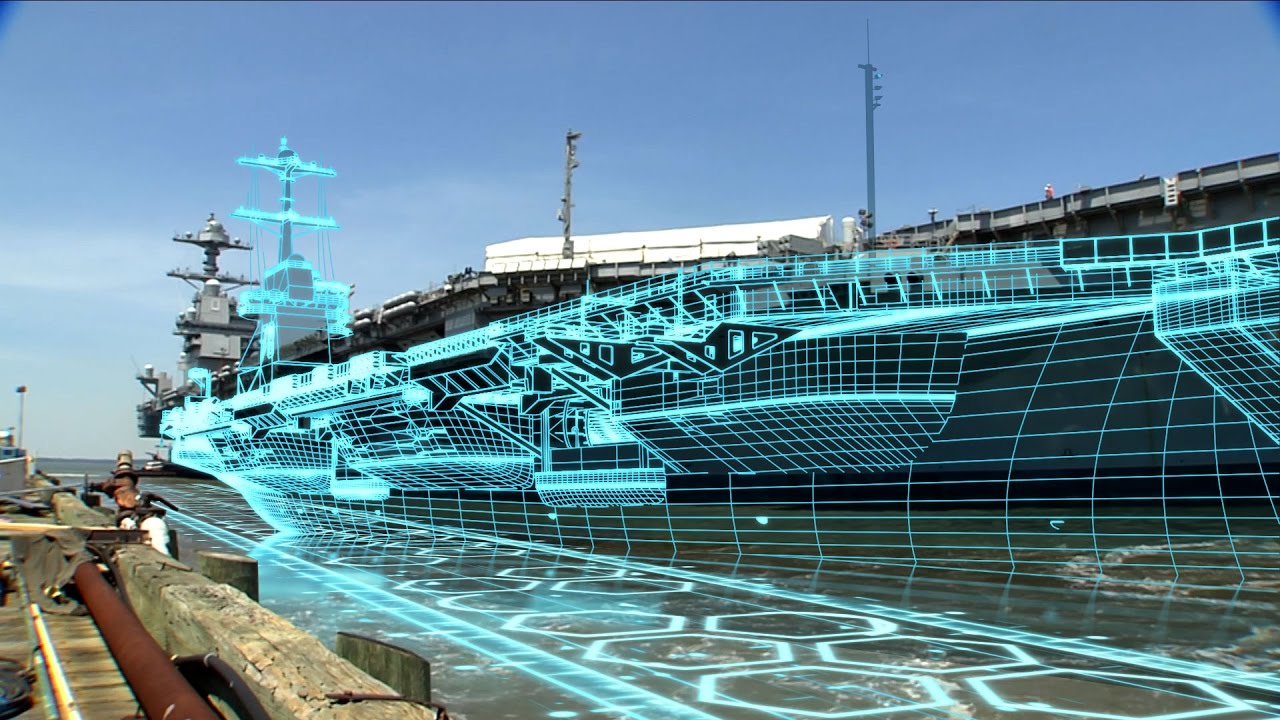

The company aims to use innovation to improve performance in the so-called fourth industrial revolution. This collective concept implies a digital revolution, which is accomplished through the development of automation, the exchange of information and production technologies, including 3D printing. According to Forbes magazine, “there is a blurring of the boundaries between the real world and the world of technology.”

To reduce production costs and increase productivity in accordance with the concept of Industry 4.0, Navantia implemented the Shipyard 4.0 model, which involves the use and optimization of these technologies in shipbuilding. The model was applied at the shipyard of the company in the Spanish city of Ferrol in the construction of frigates of the new generation F110 commissioned by the Spanish Navy. Shipyard 4.0 will also be implemented by Navantia Australia after adapting to the special conditions of the Australian continent.

')

According to the director of the Ferrol shipyard, Pablo Lopez, “the main task of Navantia is sustainable development in the naval and strategic sectors, in the global industry thanks to the development of competitive programs for shipbuilding. This task is served by the strategy we have created called Shipyard 4.0, which consists in introducing into our production processes the advanced technologies of the fourth industrial revolution in which we are involved. The Shipyard 4.0 model has clear goals for reducing costs and timing, improving the quality of our products and technologies to achieve sustainable competitiveness. ”

The new model will improve the results of the Navantia Australia SEA 5000 program and the Continuous Build Program. Shipyard 4.0 will help the development of competitive shipbuilding for the navy, the formation of new skilled labor and the creation of modern equipment - both for the shipyard and for the network of suppliers. This concept will also contribute to the development of modern infrastructure of information and communication technologies to support the digital twin (ship zero) at the shipyard and on the ship. The concept of the digital twin will allow you to model and develop new products and processes on virtual workstations.

Navantia works in a very competitive environment, using for its solutions implementation 12 basic advanced technologies that are used in conjunction with shipbuilding technologies in the Shipbuilding 4.0 model:

- 3D printing ,

- Artificial Intelligence,

- autonomous vehicles

- large data sets and their analysis,

- cyber security

- health, safety and environmental protection,

- new materials

- robotic process automation,

- secure cloud services

- ubiquitous communication and the internet of things

- virtual and augmented reality

- virtual modeling (including simulation).

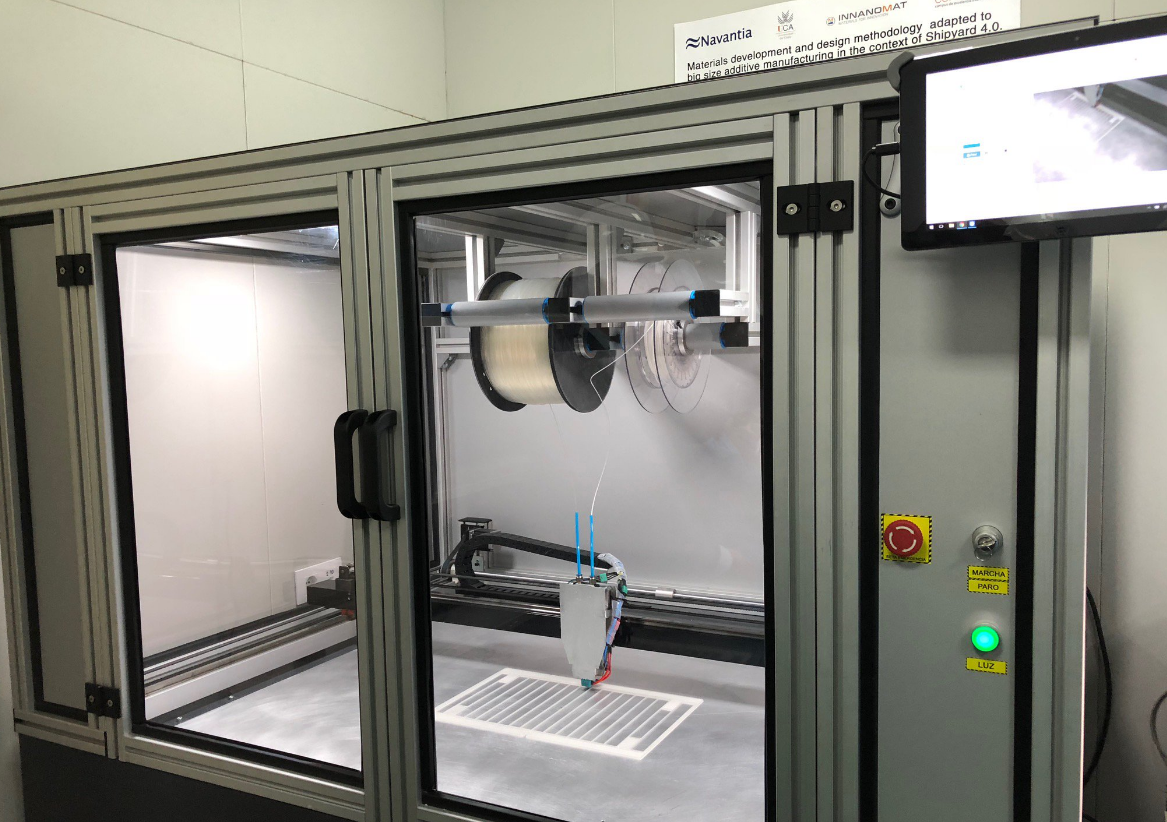

The R & D + i project, conducted by Navantia with the support of the INNANOMAT research group at the University of Cadiz, uses 3D printing technology. In January 2018, the company presented one of its projects for the transition to the Shipbuilding 4.0 model.

“At the end of last year, we received the first practical results when the first Navantia R & D project for additive manufacturing called 3DCABINS was completed. It consisted of integrated 3D printing of a modular toilet and installation of ventilation grids, also grown on a 3D printer, on board, ”explained Lopez.

The 3DCABINS project is an undoubted success, since its implementation allowed the company to manufacture two prototypes of a toilet for a naval vessel at a much lower price, while the weight of the products was reduced by almost 50%. Such a result would be impossible without the use of 3D printing.

“This year we launched the second draft of the R & D + i program called ADIBUQUE, with which we aim to unify the practice of using this technology on our ships,” says Lopez.

Within the framework of this project, parts that can be manufactured in an additive manner will be analyzed after installation on ships. In addition, large-scale three-dimensional printing will be used for the production of vessel elements. The 3DCABINS and ADIBUQUE projects enable Navantia to clearly follow the course of introducing additive manufacturing and confirm its commitment to the Shipbuilding 4.0 model and the fourth industrial revolution.

Author: Sarah Saunders Translation from English. The original of this material is on the website 3dprint.com .

Source: https://habr.com/ru/post/448290/

All Articles