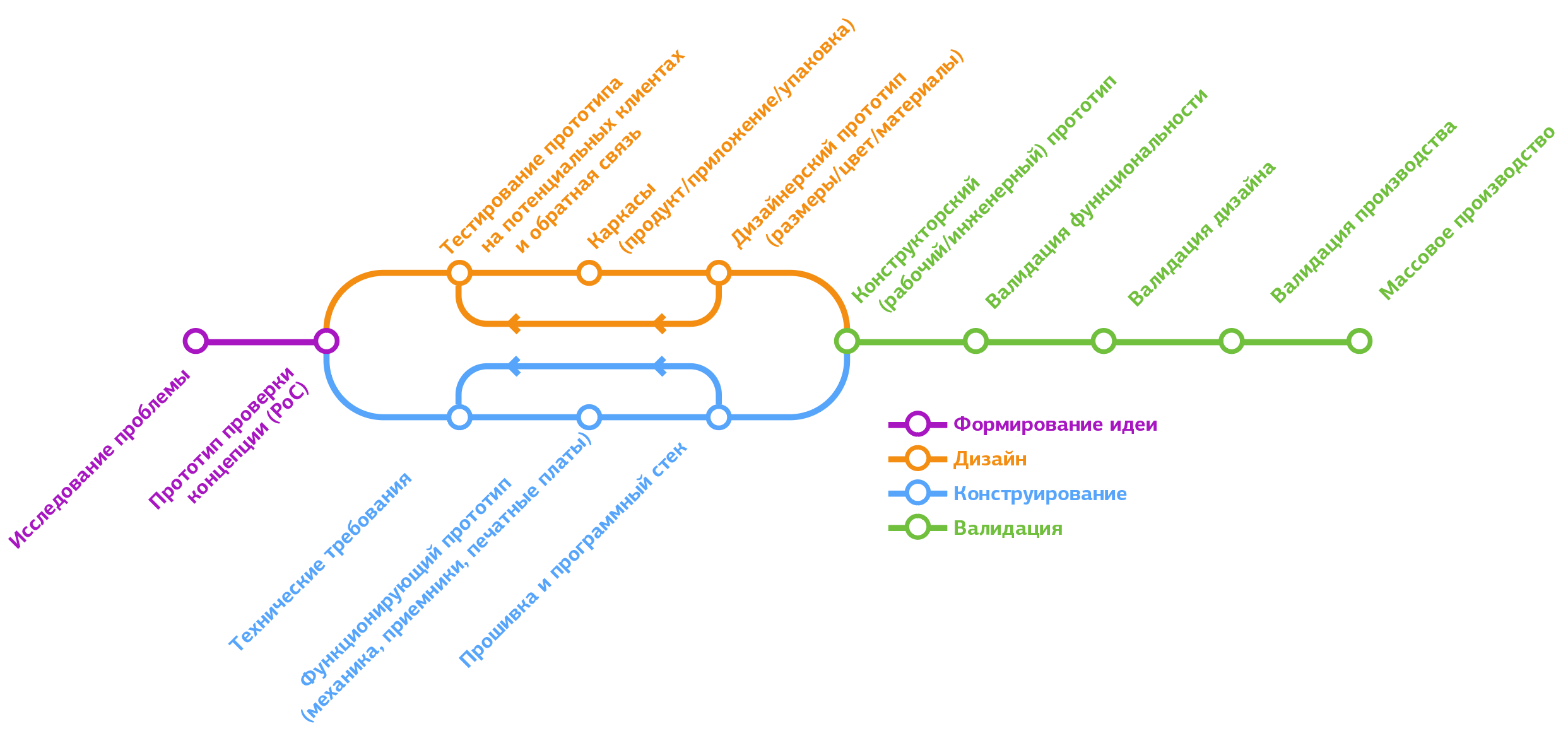

Product Development Visual Aid: Forming an Idea

This is a translation of the first part of a cycle of four articles on the development and production of physical products. Author, source: Ben Einstein .

Often, the difference between a company that brings billions and a bankrupt company is the ability to create a product that customers will love . But given the cost and time costs in the industrial sector, start-ups by and large have only one chance to bring the goods to the market. They do not have the opportunity to engage in iterative development or afford to release an unfinished product, unlike software startups.

')

But if creating a truly good product is so important, then why do most industrial start-ups neglect to build the right processes when developing a product?

This series of articles will talk about the qualitative processes of developing physical products.

Fig. 1. Typical software development process

Yes, processes are important!

It seems that startups have an allergic reaction to everything that is related to order. However, most software startups support the implementation of the Lean Startup concept, popularized by Eric Rees.

This “create-evaluate-learn” cycle is rooted in a start-up software culture, but not exhaustive for grocery ones. Most of them understand something like the product development process:

Fig. 2. Typical physical product development process

Most startups believe that the “we are on all dates” approach is faster because it is less expensive, but in the long run this is far from the case.

Fig. 3. The process of developing hardware products is more complicated.

Development of physical products requires more detailed planning than software development. This is due to the huge number of operations that need to be performed before launching the product to the market. Most of them have a long run time and high cost of error. A tiny flaw in the design or a defective part that bypasses quality control can lead to your bankruptcy.

Processes

The process that we use in our company BOLT is a combination of rigid processes of manufacturing companies and light processes used by professional designers. It is divided into 4 main stages: the formation of ideas, design, construction and validation.

Fig. 4. Full product development cycle

For illustration, we will follow the development of the DipJar product using this methodology.

Fig. 5. The first version of DipJar

DipJar is a young company with a simple product for collecting donations and tips from a bank card. DipJar customers pay a fixed amount every month, and the company receives a small percentage of each transaction.

Ryder Kessler and Jordan Bar Am founded the company in New York and raised relatively small investments. At the same time, they successfully shipped many products to customers and showed a good product / market fit. Most of their quick success is directly related to the iterative development focus and consumer interests in product development.

PART 1: IDEA FORMATION

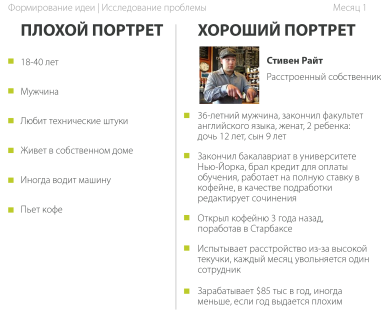

Fig. 6. The first stage of product development

Forming an idea begins with a clear definition of the problem that the product solves (problem research) and ends with a prototype of the proof-of-concept prototype. Having allocated enough time for this stage, you will be able to lay a solid foundation for further product development.

Fig. 7. Research problem

Each illustration shows where we are regarding product development (top left) and elapsed time (top right).

Very often, founding engineers immediately begin to create a product without defining the problem they are working on. Understand the problem through a survey of future customers.

During communication with potential customers:

- Do not try to direct the conversation in any direction. Let communication develops naturally.

- Do not talk about your product or solution.

- Record what you hear in writing or on a voice recorder to create a database.

- Create at least three images of the target audience (customer personas).

- Pay attention not only to what people say, but also to how they speak.

Fig. 8. Find your moment of insight

Virtually every company starts from the moment of “insight” - a story that connects the life experience of the company's founders with the problem they solve. For DipJar, that moment happened in a coffee shop. As a student, Ryder often visited Starbucks and became friends with the barista. One day, the day at the coffee shop turned out to be particularly crowded, which they were not happy about. “At least you get more tips,” Rider said. But what answer did he get: “In fact, no one leaves them anymore because of credit cards. It would be better if nobody came at all. ”

While communicating more and more with people, Ryder realized that not only the barista suffered because of a decrease in cash turnover. He spoke with street musicians, hairdressers and charitable organizations (including the Salvation Army and the Children's Miracle Network, who were among the first buyers of DipJar).

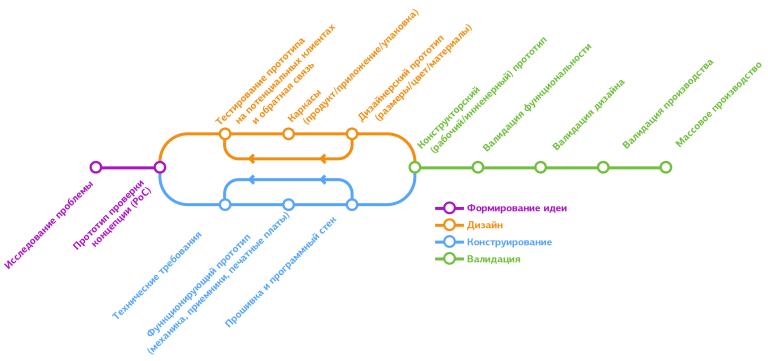

Fig. 9. Think of a customer portrait

Such communication is the basis for creating portraits of customers (customer personas), generalized, invented images of your ideal users. Frequent communication will provide you with data useful to use when developing a product.

Fig. 10. The portrait on the right is better, as it shows the depth of the problem analysis.

Usually a good study of the problem in completing this checklist:

- If they are B2B customers: you know which people in the company make decisions, how they buy products like yours, and why the problem you want to solve is the “top 3” problem in their business.

- If it's B2C: you know what brands they identify with, what “marketing territory” they live in, understand their habits.

- You have learned how much they are willing to pay for your product.

- You have determined the size of the target audience.

- If you plan to attract venture capital, you can show how these numbers will bring 100 million profits in 5 years.

- If you have solved all these problems, you are ready to start looking for a solution to the problem.

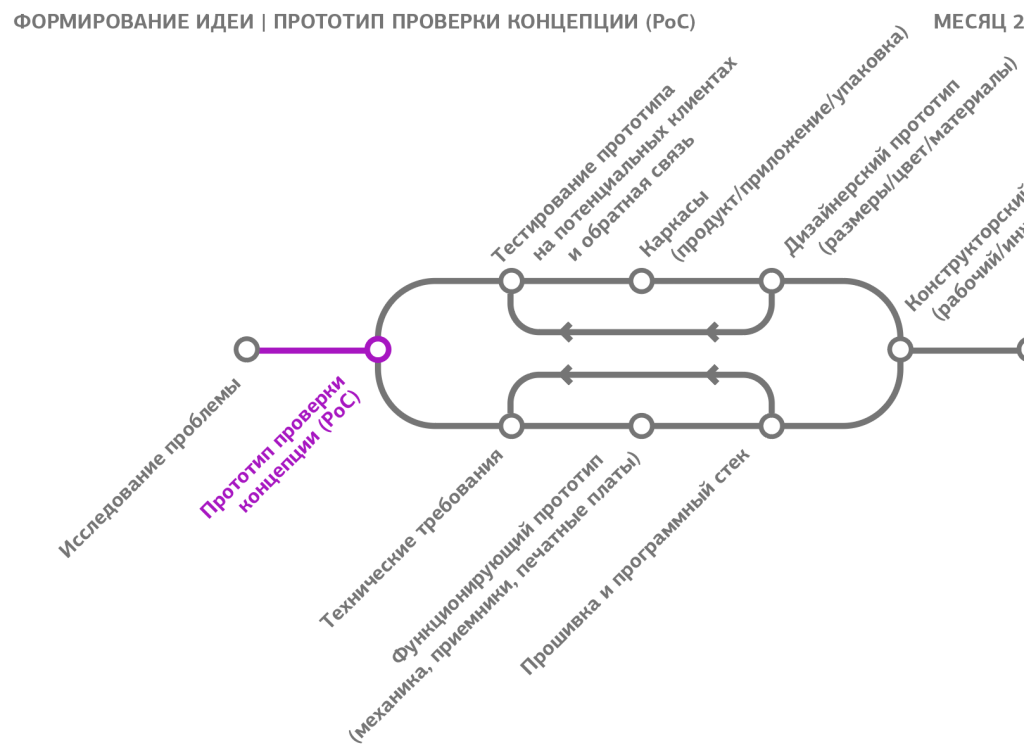

Prototype Test Concept (PoC, Proof-of-Concept)

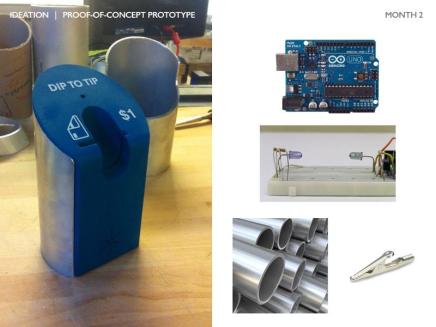

Fig. 11. Prototype of Concept Verification Prototype

The essence of prototypes of concept verification is in confirming the main hypotheses that your research has revealed. In the case of DipJar, the team had to answer the following questions:

- Can people figure out in 5 seconds while they are paying at the checkout how to use DipJar?

- Is it important to also collect cash?

- Do store owners / employees agree to place a DipJar at the cash desk?

Fig. 12. First product prototypes

These questions are crucial for assessing the viability of DipJar as a business. The team quickly created several prototypes to test these hypotheses. Three prototypes (pictured above) were created in a few days from finished parts (Arduino, infrared sensors, a piece of aluminum pipe and a plastic part painted with a can)

Despite the fact that the main goal of DipJar is to debit money from a bank card, the team did not have time to implement this functionality (and this was not important for testing working hypotheses). Therefore, these prototypes did not even have a card reader. They simply had sensors counting the number of times people inserted a bank card.

Fig. 13. Prototyping

The team took the prototypes to several target customers and left them for one day. And then took them back to assess the effectiveness.

Evaluation findings:

- People immediately understood what DipJar is and how to use it;

- In most places, cash was collected in existing containers - therefore, the cash collection section was abandoned at the prototype stage;

- Owners and employees were not against allocating a little space at the cash register in order to get more tips.

Any prototyping process is iterative . A few tips on how to make it more efficient:

- Before you design something, generate a lot of ideas and choose the best to create a prototype. For this, some people prefer to use formal approaches: mental maps, brainstorming, etc. In my experience, they are inferior in efficiency to informal ones: communication with people, modeling, searching for similar technical solutions.

- Concentrate on hypothesis testing.

- Give priority to speed, not quality (this is difficult for engineers, but at this step, speed is much more important).

- Use prefabricated parts, not create them from a sketch .

Now you have a good understanding of the problem, and you know how to solve it. Time to optimize your product for use by customers.

This is a translation made by the FABLKA team of fab lab , the first part of a cycle of four articles on the development and production of physical products. Author, source: Ben Einstein .

Source: https://habr.com/ru/post/448250/

All Articles