SLM technology breaks records: the biggest rocket engine is printed

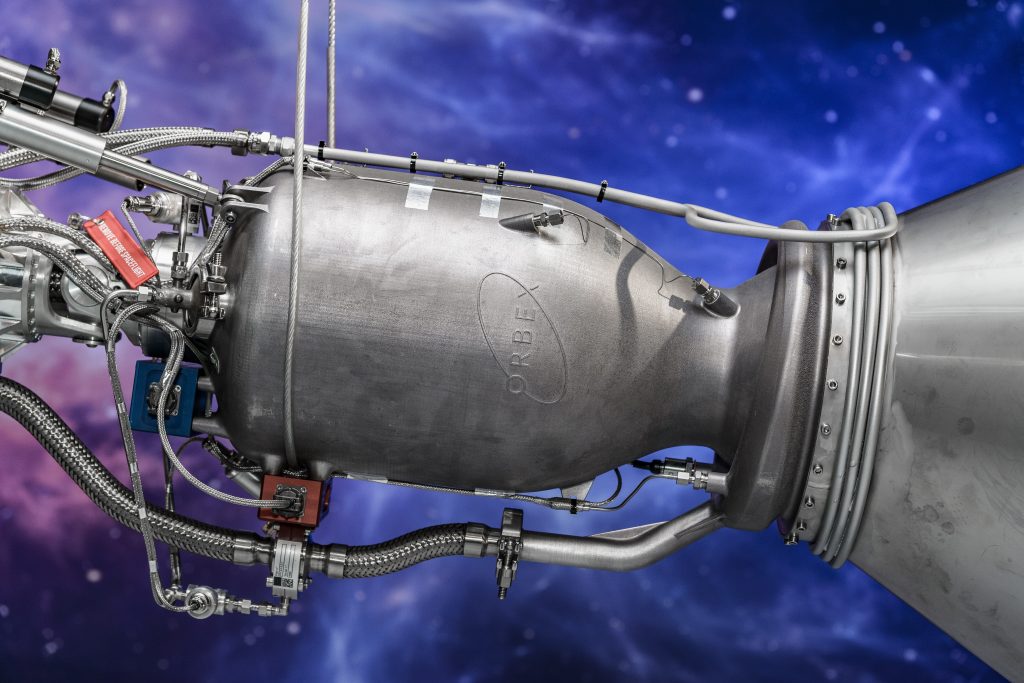

Rocket Prime Orbex. Photo: Orbex

The manufacturer of metal additive plants, SLM Solutions, manufactured an engine for the British aerospace company Orbex, which is named the world's largest rocket engine created using 3D printing. ”

The Prime commercial orbital rocket engine was printed on a 3D printer as an all-metal product and will be used to deliver small satellites to orbit. Prime rocket was recently officially unveiled during the opening ceremony of the new Orbex head office in Forres, Scotland, created with the support of the European Commission Horizon 2020, the UK Space Agency (UKSA) and other private and public organizations.

')

At the solemn ceremony, Graham Turnok, Executive Director of UKSA, said: “The new Orbex project complex is another UK step towards independent commercial rocket launches. It is the strengthening of its leadership in Europe in the eyes of those who fix their eyes on the orbit of the Earth and beyond its limits in the search for new opportunities. ”

Graham Ternok, Executive Director of the Space Agency of Great Britain, speaks at the official launch of the Prime rocket. Photo: Orbex

From an unknown startup to an investment of $ 40 million

Orbex was founded in 2015 with the aim of bringing commercially available kubsat-formatted satellites into Earth orbit — small satellites with a mass of several kilograms. The company operated “in stealth mode” until July 2018, when it announced it was raising private and public funding in the amount of £ 30 million ($ 40 million). At the same time, information was officially confirmed that UKSA would provide Orbex with the opportunity to launch launches from the Sutherland space center, using it together with its American competitor, Rocket Lab.

Thanks to 3D printing, Prime has become 30% lighter and 20% more efficient than any other launch vehicle in this category.

Orbex Prime Prime Booster is refueled with liquid oxygen and propane, a gas that is a non-toxic and cheaper alternative to hydrogen. Like many other modern missiles, Prime booster is designed for multiple use, which reduces the amount of waste generated during the launch process.

Prime rocket with a height of 19 m and a diameter of 1.3 m is capable of delivering a payload of 150 kg to an altitude of up to 500 km. In this regard, it is comparable to the rocket Lab's Electron rocket, whose payload ranges from 150 to 225 kg, but it should be noted that these two missiles use different types of fuel.

3D printing engine for Prime rocket

The Prime rocket engine was printed by SLM Solutions on a large-format 3D printer SLM 800. The SLM 800 build camera has a size of 260x500 mm and allows parts up to 800 mm in height to be printed, which is what the Orbex engine needs.

Close-up of Prime rocket engine, printed as one. Photo: Orbex

The engine was made of nickel alloy, and the additive production method allowed Orbex to spend 90% less time and reduce costs by more than 50% compared with traditional CNC machining. In addition, according to experts, this method of manufacturing the engine made it possible to make the Prime rocket “30% lighter and 20% more efficient than any other carrier rocket in this category.” At the concept development stage, a strategic investor, Orbex, Elecnor Deimos Space, demonstrated that the Prime rocket has a mass of only 18 tons.

One of the key factors in the production process of the engine is 3D metal printing as a solid product, which significantly increases its overall reliability due to the absence of any joints and seams. Speaking about the engine creation process, Lukas Pankevich, SLM Solutions specialist on the use of 3D printing, notes: “We tried to meet Orbex’s expectations regarding quality and make the engine suitable for additive manufacturing without compromising its functionality. In preparing the data, each supporting structure was individually configured to ensure the best quality in each engine section, taking into account, among other things, the post-processing process. ”

We are waiting for launch in 2021!

In the industry of private space launches, there are more and more competitors who are in a hurry to take the lead in the commercial market. In an effort to reduce costs and develop new, lightweight designs , many manufacturers in this area have resorted to the use of 3D printers for the production of engines. For example, 3D printing was used to create the Superdraco engine from Space X, the AR1 engine (Aerojet Rocketdyne), the Rutherford engine (Rocket Lab), and individual parts of the BE series engines from Blue Origin.

The first launch of the Orbex Prime rocket with an engine printed on a 3D printer is scheduled for 2021 - this will be the conclusion of an experimental payload for Surrey Satellite Technology, a leader in 3D printing.

Speaking at Prime Prime Minister's ceremony, Chris Larmor, Orbex CEO, said: “Today, Orbex has taken several big steps forward, creating something unique for Europe — a well-funded, private microsatellite launch project, behind which are excellent manufacturing capabilities and close cooperation. with industrial enterprises and the rapid growth in the number of commercial clients. ”

Translation from English. The original of this material on the website 3dprintingindustry.com

Source: https://habr.com/ru/post/448152/

All Articles