Production of plasma engines in Russia

Giant starships with ghostly luminous engines have become one of the permanent attributes of space fiction. At the same time, plasma engines have been successfully used in real astronautics for half a century, and Russian developers are among the world leaders. I was able to visit the OKB Torch enterprise in Kaliningrad and see how stationary plasma engines are created.

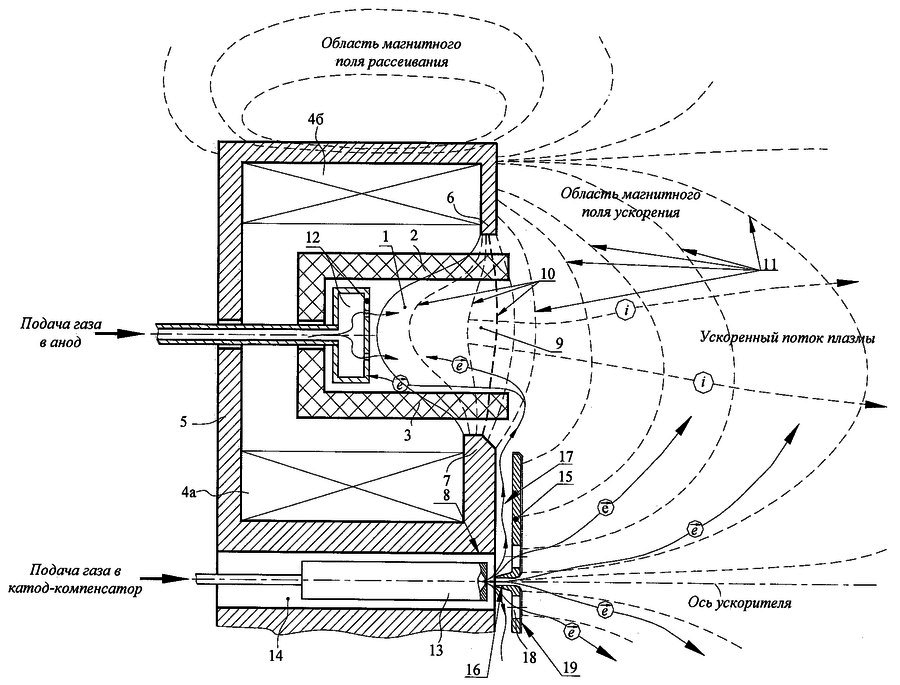

The stationary plasma engine (SPD) is one of the types of the electric propulsion engine, where electrical energy is used to ionize the gas and make the resulting plasma a high flow rate from the "nozzle".

')

This engine has no fuel in the usual sense, i.e. combustible and oxidizing agent necessary for chemical reaction with heat release. SPD fits almost any gas, but it is better to use chemically inactive and with a high atomic mass, such as argon or xenon. Plasma engines provide a very high velocity of the ejected gas jet, for example, for xenon it is about 30 km / s. For comparison, the gas emission rate of one of the most efficient chemical rocket engines, oxygen-hydrogen, is about 4.5 km / s. The advantage of chemical engines is the ability to emit a lot of gas at once, which gives more traction. SPD, on the other hand, requires a powerful source of electrical energy, and even with it is able to emit only a small mass of gas at a time, that is, it has very little cravings and takes a lot of time to accelerate and decelerate. Plasma engines are used only in space: the spacecraft equipped with them have a relatively small supply of working fluid and a large range of solar cells.

The possibilities of using electric rocket engines were conceived as early as the beginning of the 20th century, but they passed to the first tests in space only in the 1960s. In 1972, two electrojet engines were used in the orientation system of the Soviet satellite Meteor: ion and stationary plasma. SPD performed better, and Soviet specialists concentrated on this variety. Specialists from OKB Torch took part in the creation of experimental samples, and since then the company began to specialize in the production of engines of this type, to develop and improve technology.

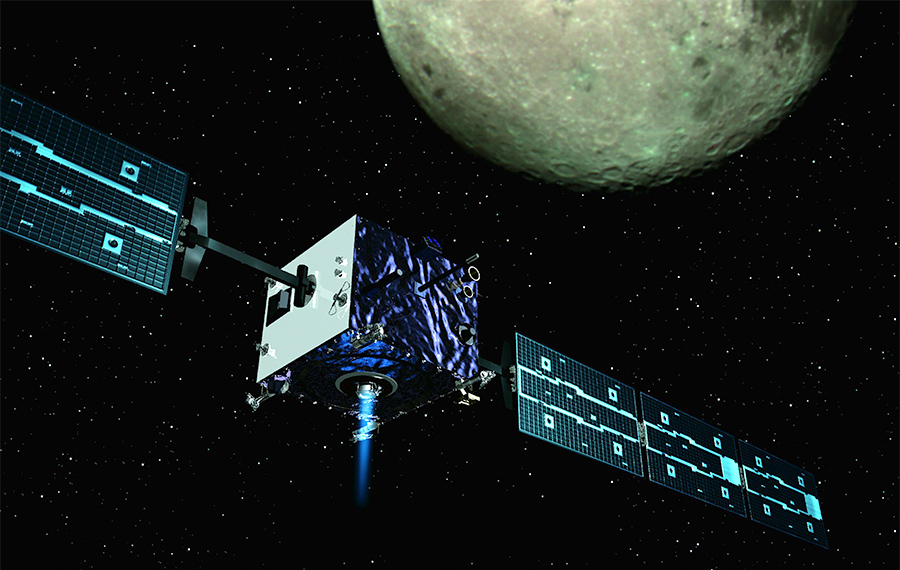

At the beginning of the 21st century, the Kaliningrad SPD-100 was successfully tested on the lunar satellite of the European Space Agency Smart-1 .

After a successful flight to the moon, European manufacturers of commercial geostationary satellites began to buy Russian engines and create new generations of satellites. Previously, chemical engines based on toxic hydrazine were used on repeater satellites. The use of Russian SPD has opened up the possibility of creating a so-called. "All-electric satellites", on which there was no chemical traction.

Kaliningrad SPD have a rather small size, but the cycle of their production still requires considerable production areas.

The developers of OKB Torch actively cooperate with European manufacturers and even helped the French to make their own engine. However, the company has the strictest safety standards. Photographing on the excursion was banned by security officers, and the personnel used in the report were later taken by the press service at my request.

On the "OKB Torch" clearly visible continuity of generations.

Young people work alongside experienced specialists.

Kulmans have long been replaced by CAD " Compass-3D " for the development of three-dimensional models and the release of design documentation.

Shop machining opens modern CNC machines.

“In some cases, we have turners write the programs themselves,” says Yevgeny Kosmodemyansky, General Designer of the enterprise. And I understand that the time has come to throw out my certificate as a turner of the second category.

However, in the depths of the hall, work goes on universal machines, where the role of manual labor retains its value, and my hopes for a space career are revived.

The necessary stage in creating a space engine is testing. To check SPD, it is necessary to simulate the conditions of space, first of all the vacuum.

Vacuum chambers seem huge for such small engines. They are suitable for testing the entire range of engines that produce on the "OKB Torch".

In Soviet times, the most powerful engine in its class was developed here - the SPD-290. Now creates a comparable power SPD-230.

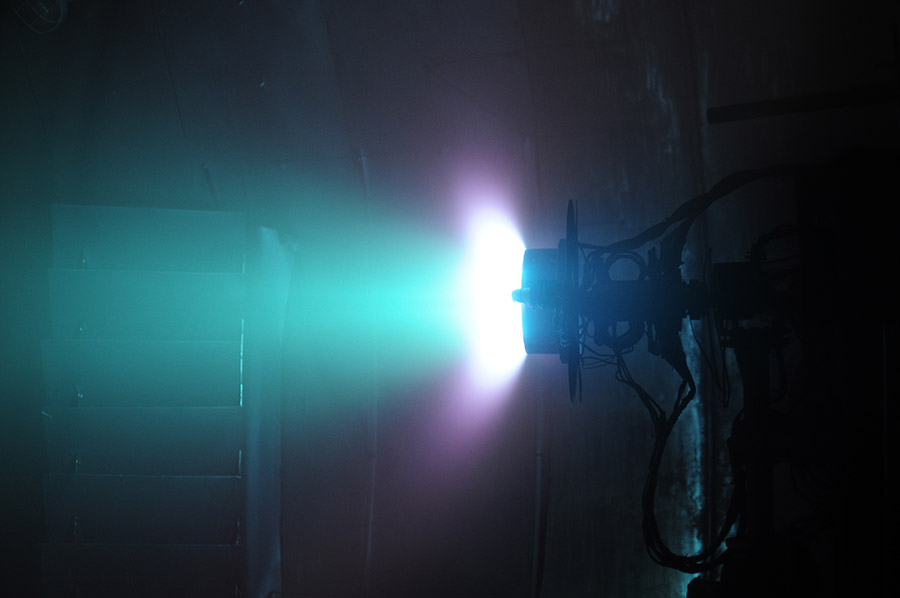

With my own eyes, unfortunately, the plasma engine failed to be seen, but we were provided with photos.

Recently, Roscosmos showed a cool video from on-board cameras of the satellite Egyptsat-A, created at RSC Energia.

These frames, perhaps, for the first time in the world, are shown the operation of SPD-70 plasma engines in space.

Perhaps my phrase about world leadership of the OKB Torch may seem overly pathetic, but practice shows the correctness of these words. Space System / Loral, Airbus are one of the largest manufacturers of commercial communication satellites in the world, and they take Kaliningrad SPD. And most recently, probably the largest contract in the history of world satellite construction was concluded - for several hundred modernized engines SPD-50M.

When my tour took place, employees of the company did not recognize who the customer was referring to a non-disclosure agreement. Later the information got into the media and now we know that this is OneWeb. The project of low-orbit satellite Internet involves the launch of nearly a thousand spacecraft within three to four years. And each satellite will have a Russian plasma engine.

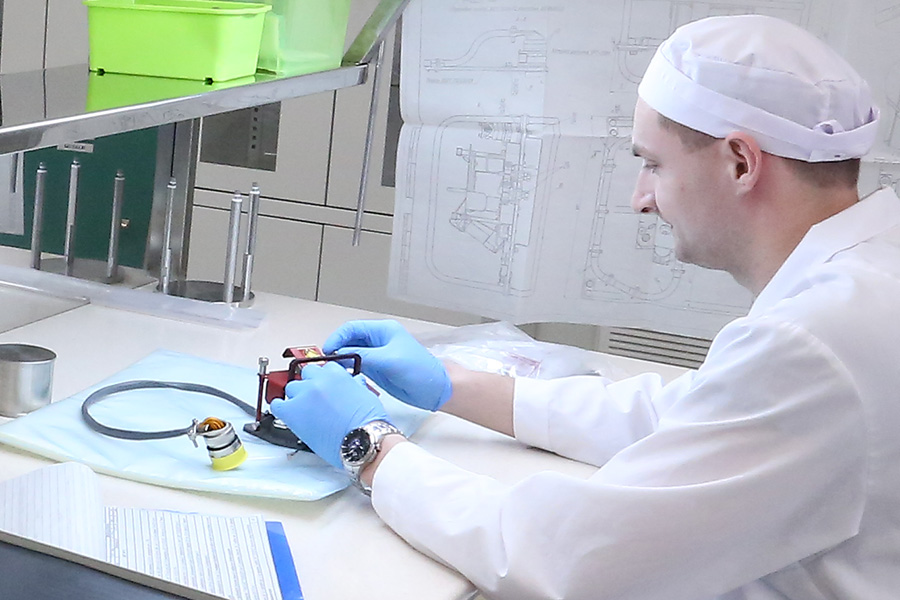

New order requires the restructuring of the entire production, because you need to create almost on the engine a day. Specialists are recruited even from other cities. Such a load was never, therefore, for the OneWeb project, we upgraded the new CNC machines and equipped a new, modern, clean room for assembly.

At each table is going to the engine.

Finished products are locked in a special cabinet, where a certain temperature and humidity conditions are maintained.

The work is almost a jeweler and an unprepared look is perceived unusually. Usually under the assembly of space engines is understood something more ambitious.

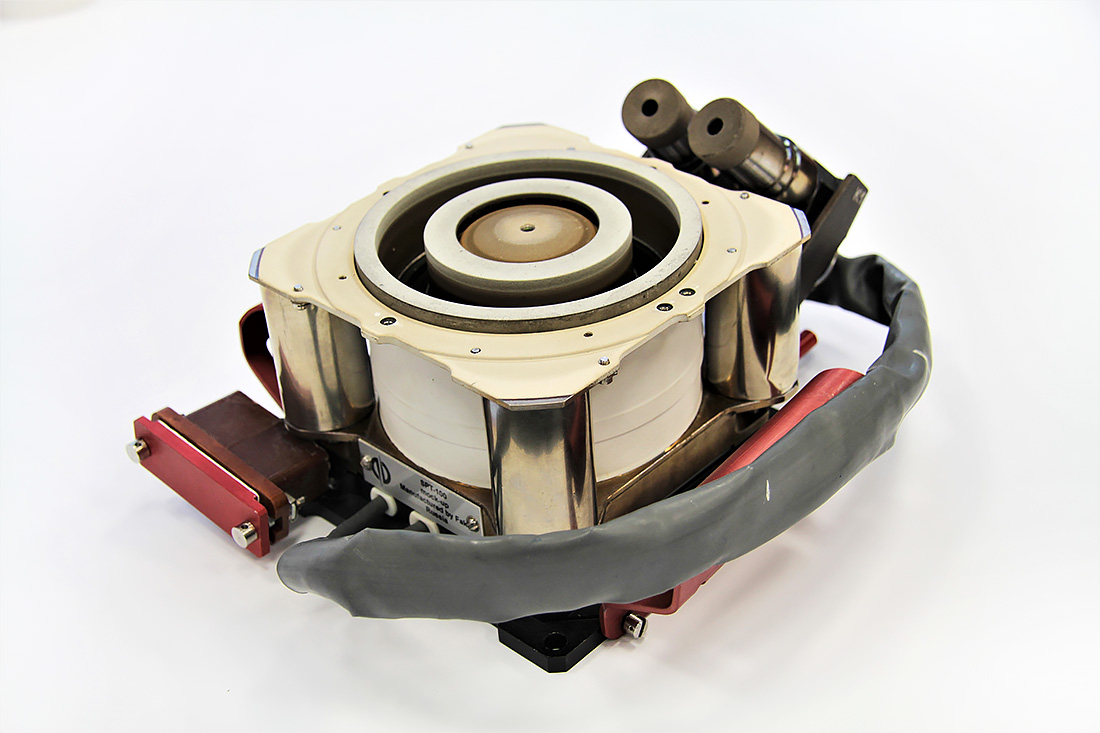

But the result is such handsome men.

The final stage of the tour is the enterprise museum. Here, first of all, they show historical pride, the “lunar fireplace” - a mock-up of a radioisotope heat generator, which was installed on the Soviet “Lunokhod-1” and “Lunokhod-2” and warmed the electronics during cold moon nights.

Of course, the museum sample is not filled with polonium and is not radioactive.

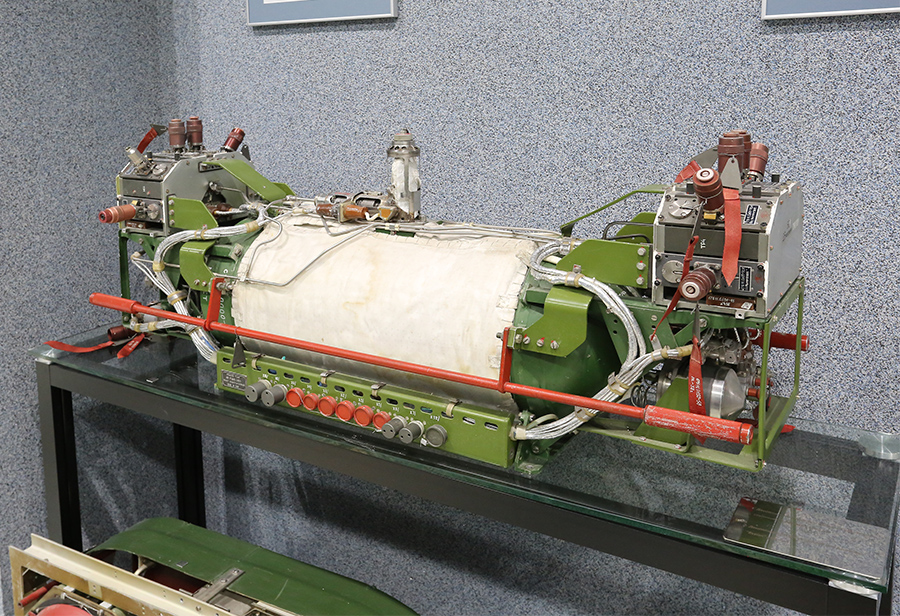

Another direction produced by OKB Torch for spacecraft engines is thermal catalytic. They require a chemical fuel, but its decomposition to gaseous components occurs with the help of a metal catalyst located inside the engine. To increase the intensity of the reaction, the catalyst is heated like a spiral of a hot plate.

Thermocatalytic engines have lower efficiency than plasma or even chemical two-component engines, but they allow you to create a simpler fuel system. Typically, these engines are used to orient the spacecraft and are located in blocks of several pieces.

Of particular interest is one museum sample - a stationary plasma engine that has passed long-term tests in a vacuum chamber. Thousands of hours of operation lead to degradation of the surface of the engine under the influence of plasma.

Such tests allow to increase the engine life. Now SPD provide guaranteed work for several thousand hours. And, according to representatives of OKB Torch, this resource has been repeatedly confirmed by customers, and new orders speak best of all about quality.

I would like to coincide with this publication on the Day of Cosmonautics, so that, not in words, but using the example of the OKB Torch, we can show that we have space, we just need to be able to prepare it.

I express my gratitude to the press service and employees of OKB Torch and Ascon company for their great help in preparing the material .

Source: https://habr.com/ru/post/448088/

All Articles