Development and assembly of a photo-lamp

In preparation for the next family holiday - the anniversary of the parents decided to implement one great idea - the creation of a unique photo fixture using 3D technology.

The idea did not come to me, I will be honest, I saw the realization of my internet comrade, Nikolai Ralkov (for which I want to express special thanks to him for the idea and help in solving the problems that arise).

')

So let's go through the order.

The first thing to start with is to describe the structure:

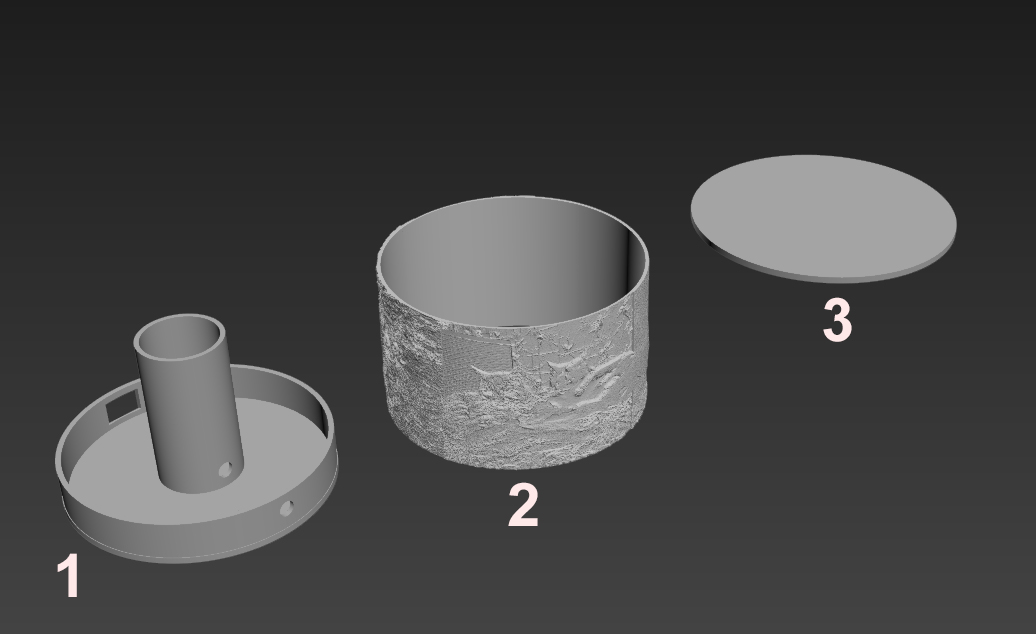

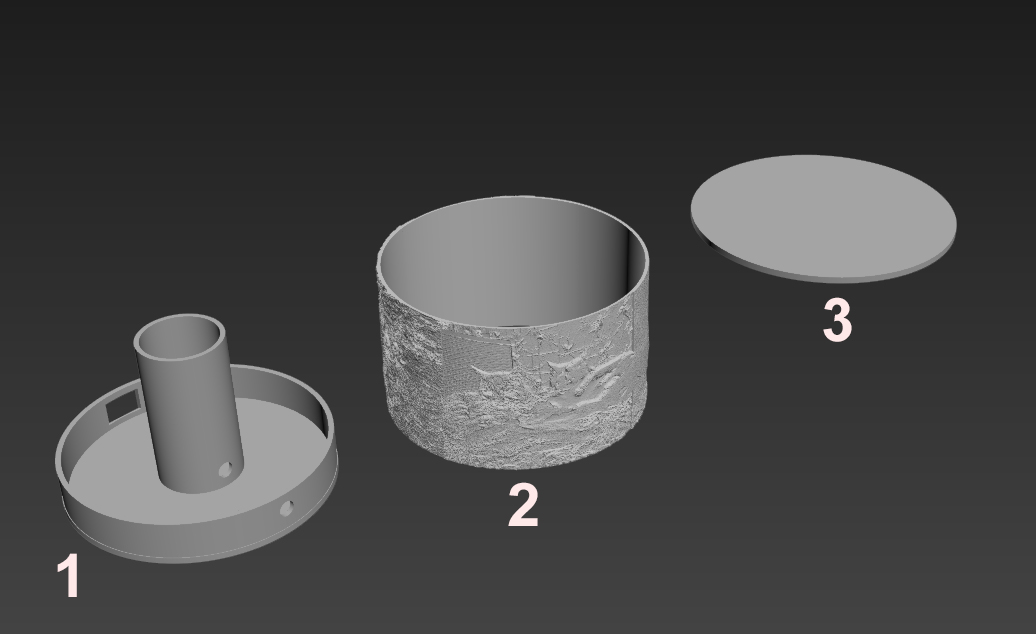

As you can see in the image, we need to design the basis of our design for its further printing on a 3D printer.

1. This is the base in which the power connector and the power on / off key will be attached. In my project, I complicated the construction a bit by adding a key to 2 working positions, in which I is full light, 0 is off, II is half light (you can make any other light blinking, light or just insert 1 LED).

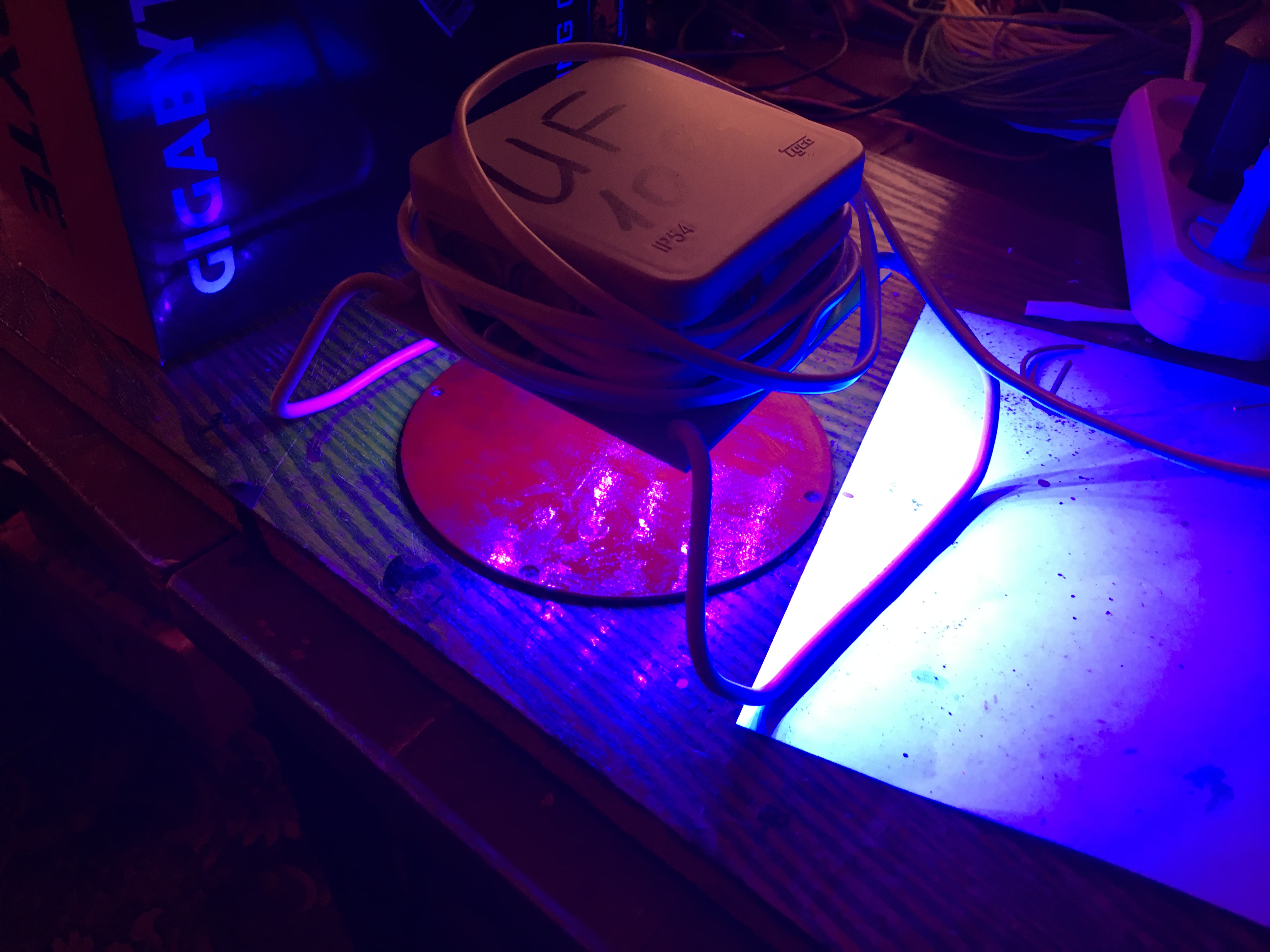

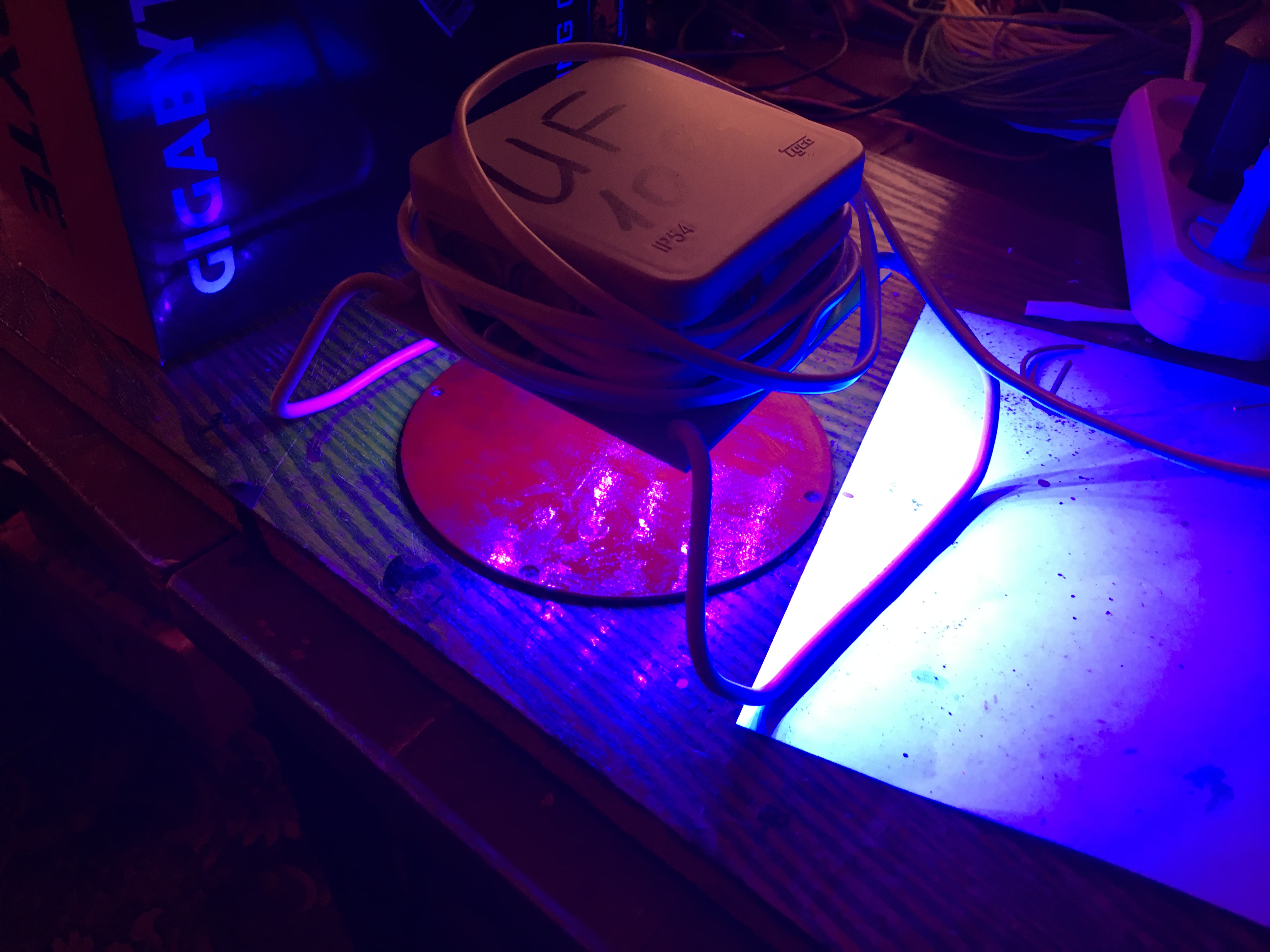

2. This is the body of the model through which the light will pass. A mandatory requirement for it in the future is to manufacture it from a matte material, for example ABS plastic (PLA, PETG or SBS are not suitable for this task - it is checked).

We will prepare it from 4 images - photos that we will fit into one format in size and perform a bit of processing in a software package for working with raster images, for example, everyone's favorite Adobe Photoshop.

The prepared models undergo a distillation and further preparation for work in the 3D editor. I will not describe this in detail, I will only indicate a link to the site, in which the raster image will be converted into relief tile and saved in the STL format.

Site for the manufacture of tiles from raster images .

I tell about this in great detail in the following video:

3. This is the cover of our product. It is copied from the base or modified at your discretion. Ideally, prepare holes in it for fastening the cover to the body of the product with screws. This is necessary for further intervention in the design, in the event of a malfunction or repair.

After you have made a model, you need to send it to print - this is the longest process of our entire venture and lasts about 1.5-2 days, depending on the accuracy of printing and the model of your printer.

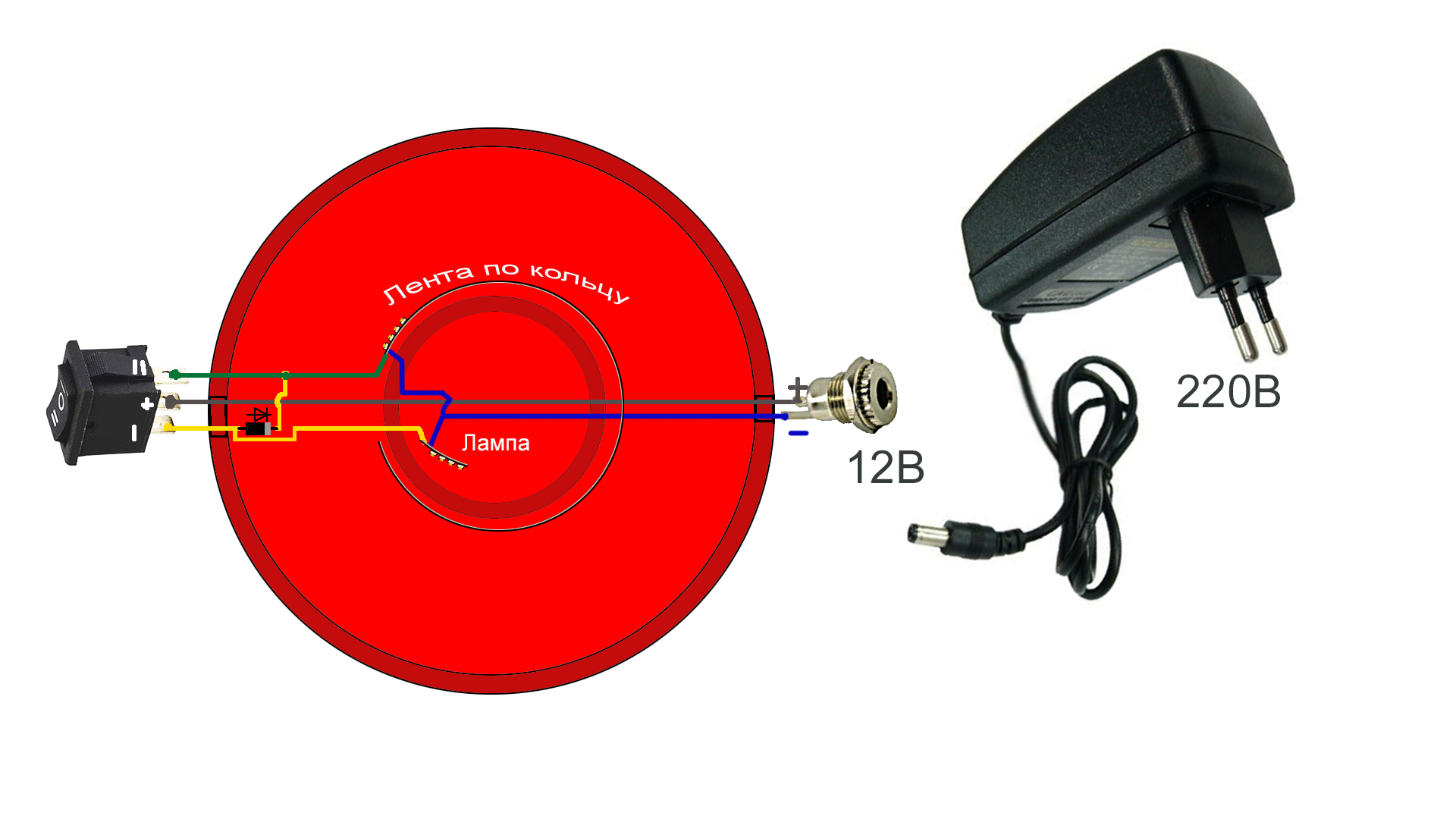

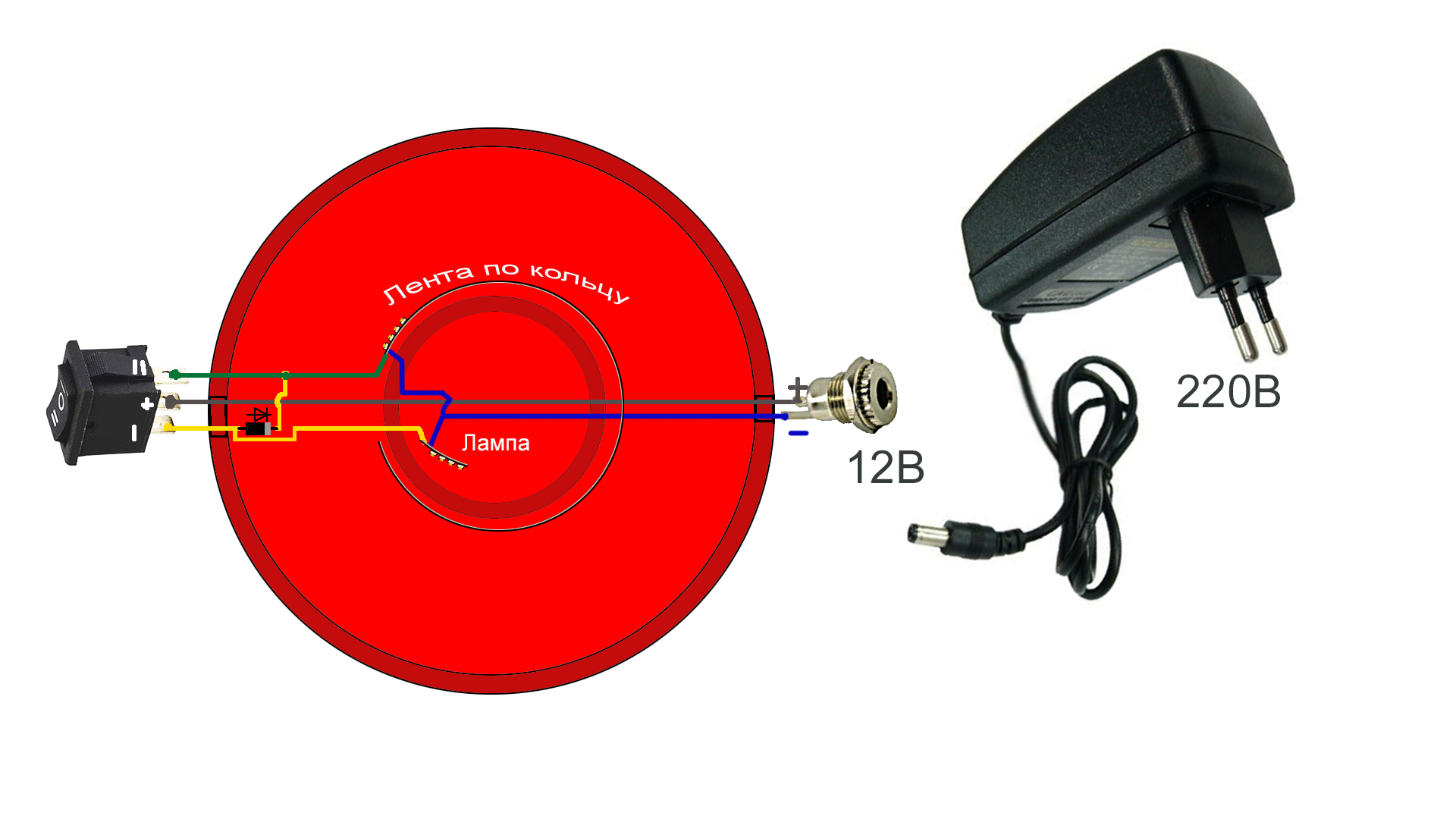

In the future, when the parts are ready, we will need to prepare the electrical components for our project. We will collect the following scheme:

We will need:

In detail the assembly of the design I have outlined in the video. This is clearly and in detail.

The only thing you want to add, the lower and upper parts of the parts can be processed and painted. It will be necessary only to dry and assemble the product.

I sincerely hope that you liked the idea and it will be extremely useful to someone as an opportunity to create a unique and memorable, and most importantly, a memorable gift to friends and dear people! All good!

The idea did not come to me, I will be honest, I saw the realization of my internet comrade, Nikolai Ralkov (for which I want to express special thanks to him for the idea and help in solving the problems that arise).

')

So let's go through the order.

The first thing to start with is to describe the structure:

As you can see in the image, we need to design the basis of our design for its further printing on a 3D printer.

1. This is the base in which the power connector and the power on / off key will be attached. In my project, I complicated the construction a bit by adding a key to 2 working positions, in which I is full light, 0 is off, II is half light (you can make any other light blinking, light or just insert 1 LED).

2. This is the body of the model through which the light will pass. A mandatory requirement for it in the future is to manufacture it from a matte material, for example ABS plastic (PLA, PETG or SBS are not suitable for this task - it is checked).

We will prepare it from 4 images - photos that we will fit into one format in size and perform a bit of processing in a software package for working with raster images, for example, everyone's favorite Adobe Photoshop.

The prepared models undergo a distillation and further preparation for work in the 3D editor. I will not describe this in detail, I will only indicate a link to the site, in which the raster image will be converted into relief tile and saved in the STL format.

Site for the manufacture of tiles from raster images .

I tell about this in great detail in the following video:

3. This is the cover of our product. It is copied from the base or modified at your discretion. Ideally, prepare holes in it for fastening the cover to the body of the product with screws. This is necessary for further intervention in the design, in the event of a malfunction or repair.

After you have made a model, you need to send it to print - this is the longest process of our entire venture and lasts about 1.5-2 days, depending on the accuracy of printing and the model of your printer.

In the future, when the parts are ready, we will need to prepare the electrical components for our project. We will collect the following scheme:

We will need:

- LED Strip Light. Length, power and quantity at your discretion. But it is important to remember that the power and length of the tape is selected commensurate with the power supply. In my case, the total length of the tape power 9.6 W / meter does not exceed 1 meter for the power supply 12V 1A - 12W.

- Power Supply.

- On / Off key

- Power connector under the connector of your PSU

- Wires and soldering kit + soldering equipment itself

- 1 diode was still used in the project

- A little patience and enthusiasm

In detail the assembly of the design I have outlined in the video. This is clearly and in detail.

The only thing you want to add, the lower and upper parts of the parts can be processed and painted. It will be necessary only to dry and assemble the product.

I sincerely hope that you liked the idea and it will be extremely useful to someone as an opportunity to create a unique and memorable, and most importantly, a memorable gift to friends and dear people! All good!

Source: https://habr.com/ru/post/447976/

All Articles