Wafer-mounted switch with motor attachment for replica Minivac 601

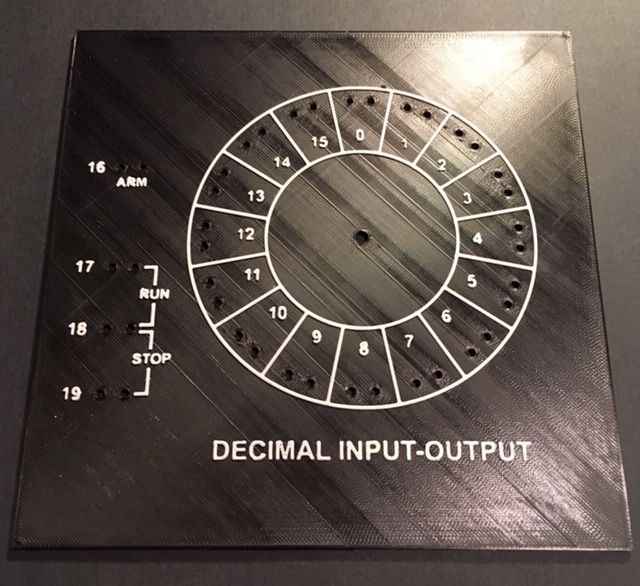

In the course of work on the replica Minivac 601 - released in 1961 (just in the theme of today's holiday), an educational layout of an electromechanical computer with 6-bit RAM in size - the author needed a switch with the following characteristics:

- 1 direction, 16 positions

- no stopper

- opening the previous pair of contacts before closing the next

- front panel mounting

- manual or motor rotation

Here in the engine and a hitch. Ready-made switches that are suitable for the rest of the parameters are either too tiny or require a large torque to change positions. I had to print my own, on reed switches.

')

The author has set up a 3D printer as follows:

Resolution - 0.2 mm

Filling - 20%

Filament - AMZ3D PLA

Without support

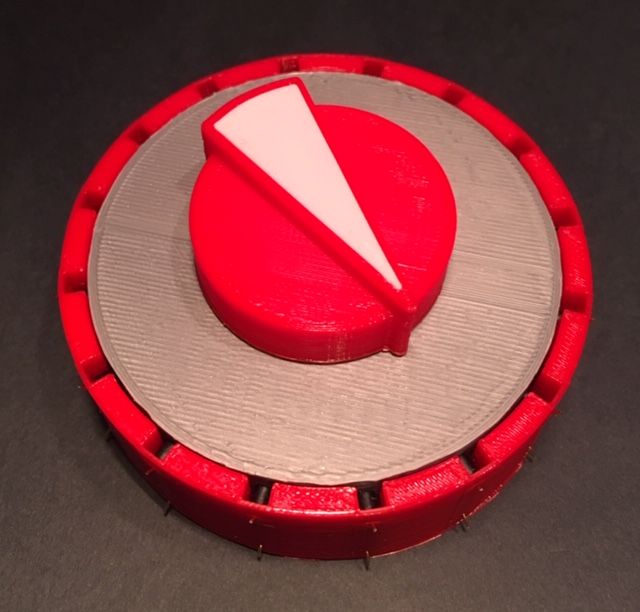

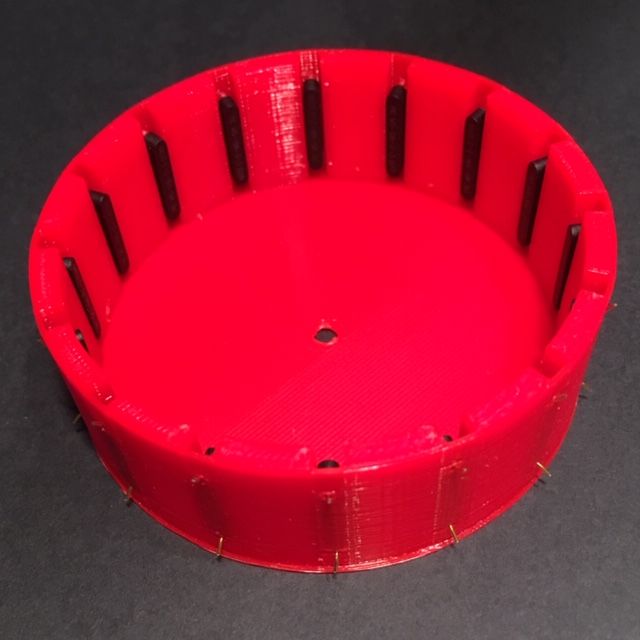

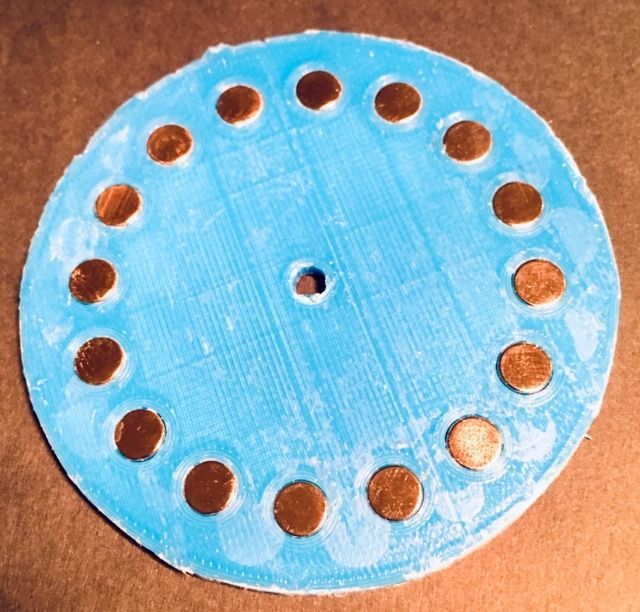

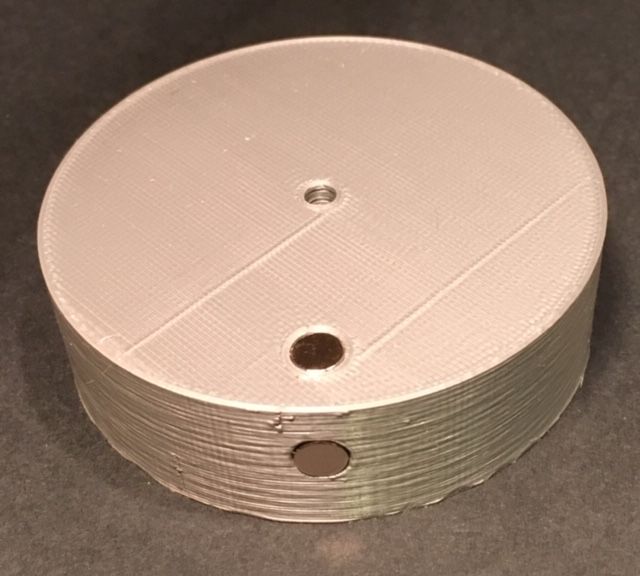

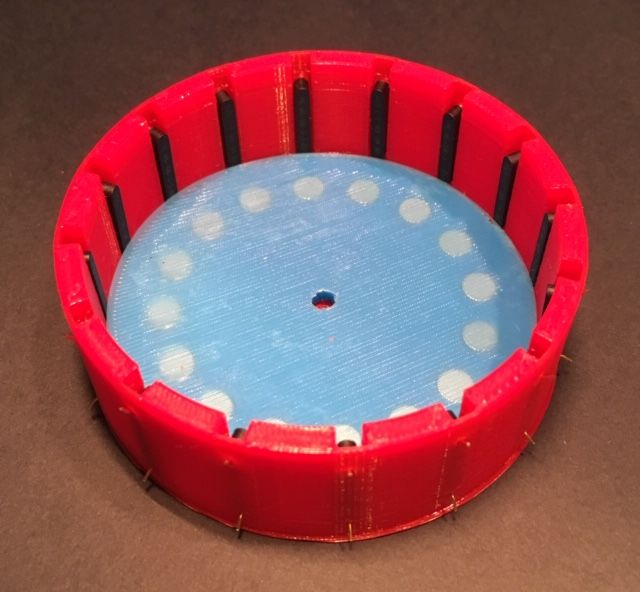

The switch consists of a base , a handle , a magnet holder , gaskets for the rotor and the rotor itself (the STL files are downloaded from the links). Of the finished parts, 16 reed switches and 18 disk magnets with a diameter of 6 mm and a thickness of 3 mm are required.

Switch assembly should begin with the installation of reed switches in the base. At first, the author tried to use reed switches without shells, but with shells they turned out to be more convenient.

Then glue 16 magnets into the magnet holder, flush with the surface, with the same poles facing up. These magnets are far from the reed switches and do not interact with them.

Paste the remaining two magnets into the rotor. The one at the bottom must be positioned so that it is attracted to the stationary magnets. So the switch will be fixed in any of 16 positions. And the one on the side will affect the selected reed switch.

Mount the magnet holder in the base so that it fits into the groove, then the location of the magnets will exactly correspond to the switch positions.

Place a rotor gasket on the magnet holder.

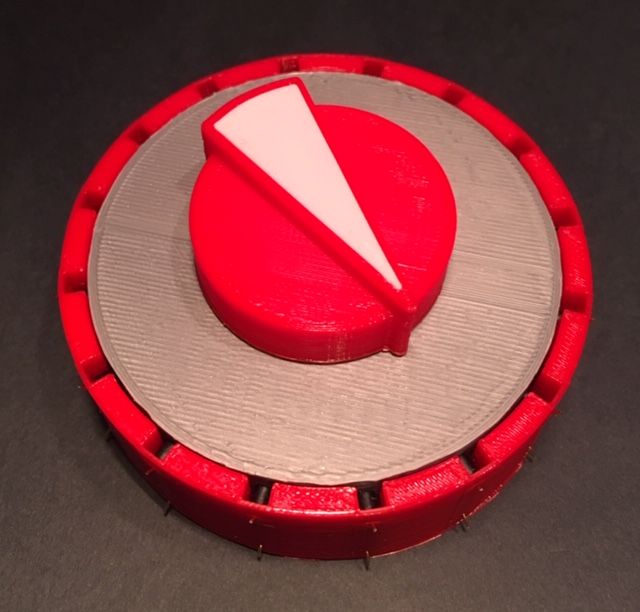

Temporarily glue the handle to the rotor with double-sided tape so that the beak points to a magnet on its side.

Place the rotor with the handle in the switch. Check whether it is well fixed in all positions.

Changing switch positions, ring all reed switches.

Unstick the handle. Set the switch on the back of the front panel of the Minivac 601 replica, and the knob - with the front one, connecting them with a pin through the hole in the panel, and at the same time, combine the “beak” of the handle with the magnet on the side of the rotor. From the bottom of the switch base, through the hole in it, press the motor shaft with the gearbox into the switch rotor.

When using a replica, do not bring the magnets to the switch, so as not to cause the closure of several reed switches at the same time.

Source: https://habr.com/ru/post/447780/

All Articles