Rusatom: 3D metal printing in Russia

Very soon, on April 19, Top 3D Expo - an exhibition-conference on additive technologies, robotics and digital production systems will take place in Technopolis “Moscow” on Volgogradsky Avenue.

We talk about the participants and topics of the conference: today we have the company “Rusatom - Additive Technologies” (LLC “RusAT”, an enterprise of the Fuel Company of Rosatom JSC “TVEL”) with domestic 3D-printers for metal printing and their use.

')

About the organization

RusAT LLC is an industry integrator uniting scientific and production enterprises of Rosatom within the framework of the development of domestic additive technologies.

The main activities of the company:

- production of 3D printers,

- the creation of metal powders and other materials for 3D printing,

- software development for additive systems,

- 3D printing services and its implementation, including the organization of additive production centers.

In the near future, the company plans to launch a second-generation 3D printer into mass production.

Alexey Dub, CEO of RusAT, shared the state corporation’s plans in this area for the near future:

"The All-Russian program for the development of additive technologies, consisting of six main sections: software, equipment, materials, regulatory documentation, training and the creation of pilot production

Along with the dynamic growth of the market, it is expected that by 2025 the global market for additive production will reach $ 45 billion, and by 2035 it will exceed $ 350 billion, and the competition will grow at a faster pace. Only recently, the price of 3D printers has decreased by 30%, and the cost of products manufactured on them - up to 90%. In the future, prices for 3D printers and additive printing powders may be reduced by another 30%. ”

The goal of RusAT by 2025 is to provide revenues of up to 50 billion rubles and to take up more than 1.5% of the global market for additive technologies.

Theme

A company representative in his speech will talk about three areas of activity:

- Serial production of industrial 3D printers using SLM technology,

- Development of new metal powders for 3D printing with different properties and composition,

- Plans for the opening of the first in Moscow Center for Additive Technologies with five industrial 3D-printers.

Design project of the Center for Additive Technologies of RusAT LLC. Provided by LLC RusAT

Projects

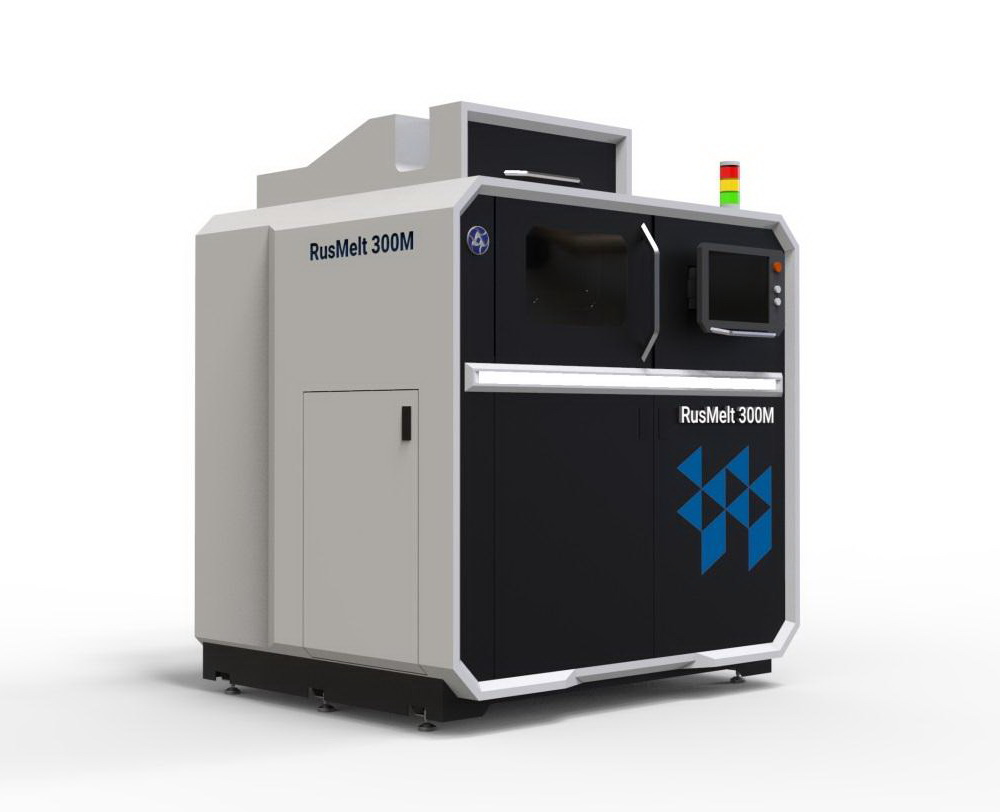

3D printer for metal printing

For several years, the state corporation has been developing a domestic 3D printer for printing with metals. Prototypes produce consistently high-quality results; prints are used for testing and further developing technology.

Read about application cases below, but as for the printer itself.

Modular 3D printer RusAT LLC, prototype

The printer in the photo above is a pre-production model, its design will be scaled to create more compact devices that Rosatom will supply to medical institutions and manufacturing companies.

Evgeny Tretyakov, Deputy Director of the Institute of Surface Technology and Nanomaterials:

“In many ways, the work is going well thanks to the machine itself and its software, also developed at TsNIITMASH. Foreign manufacturers sell such equipment with certain conditions on the materials. For example, you need steel 12x18 N / OT, and this is a domestic powder. Their programs it is not provided. We can work on any materials - our software allows you to choose the appropriate mode. And if we are talking about Russian production, then, of course, we need to work on domestic powders. ”

In 2018, a new sample was presented, capable of printing with two different metal powder materials, for which it is equipped with two lasers.

The performance of the two-laser system is 60% higher. The printer has already passed the trials of printing a sample of two materials. In the near future it is planned to print a blisk of a turbine (turbine wheel of a jet engine), with a base of one alloy and blades of another, which will reduce its weight and increase the energy efficiency of use and resource.

Deputy Director General, Director of the Institute of Surface Technology and Nanomaterials at TsNIITMASH Vladimir Beregovsky:

“The difficulty of creating parts from two materials is that each of them must have certain properties at the exit, corresponding to the material passport. In addition, at their interface there should be another property that would also meet certain requirements. ”

Alexey Dub, CEO of LLC RusAT:

“The unique powder regeneration system will allow, in parallel with the printing process, to separate two types of powders differing in fractional composition, returning the regenerated powder back to the printing unit. This significantly reduces the consumption of powders and, as a consequence, the cost of products. Regeneration regimes are currently being developed. ”

Jaw, eye socket, joint

According to TASS and AIF

In 2020, Rosatom plans to launch pilot production of 3D-printed medical implants.

Fragment of the jaw. Photo courtesy of RusAT LLC

RusAT General Director Alexey Dub:

“We have to launch pilot production of implants for medicine from 2020. In 2020, we also need to create domestic 3D printing software, the so-called “virtual printer”. ”

The development of domestic technology for the production of medical implants is now being carried out at the State Scientific Center of the Russian Federation TsNIITMASH, one of the institutes of Rosatom.

The development object is an SLM printer with a triaxial optical system. Like any SLM printer, it melts metal powder in layers, “growing” a given 3D model.

The main difficulty in the development of this technology is the selection of laser operating modes for the manufacture of titanium products with a complex, finely cellular structure suitable for bone tissue splicing.

The eye socket. Photo courtesy of RusAT LLC

Aliy Delov, Head of Research Projects Implementation:

“If we talk about traditional technologies, I simply cannot imagine how it would be possible to mill an eye socket,” he says, running his finger along its intricate bends. - And we got it quite similar to the original. After us, the implant needs only to be sterilized - and it is ready for use. ”

Samples are all possible tests in third-party organizations, the results of studies indicate their full compliance with the specified properties and suitability for medical use.

Thanks to such a printer installed in a hospital or medical institute, doctors can print an individual and ideally suitable implant for any patient, based on his tomogram, in a very short time. The performance of such a printer is 5-50 cm³ / hour, which is about 40 prosthetic cups of the hip joint per shift.

The cost of a domestic 3D printer for printing with metals will be 20% lower than foreign analogues.

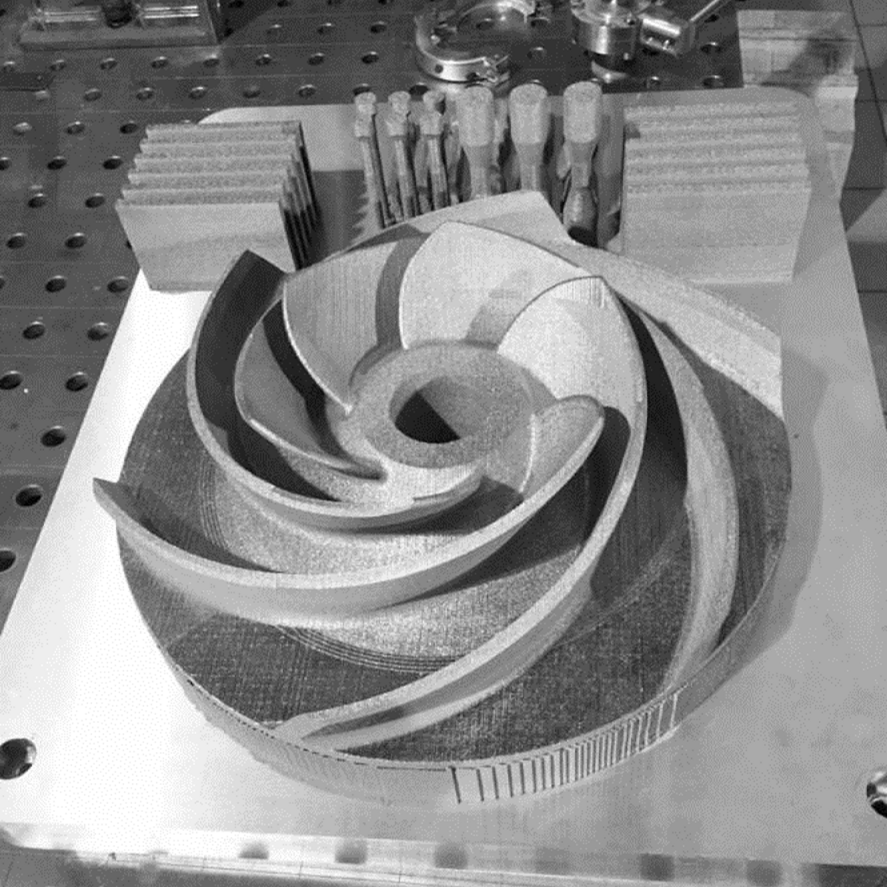

Wheel for industrial pump

Specialists of NPO TsNIITMASH manufactured, on the order of AO Afrikantov OKBM, on the first domestic 3D printer for metal of its own design, a wheel of complex geometry for an industrial electric pump. For printing used domestic metal powder.

Printing this sample will determine the next steps necessary for the introduction of 3D printing with metals in the manufacture of critical loaded parts.

Vladimir Beregovsky, Deputy General Director, Director of the Institute of Surface Technology and Nanomaterials, NPO TsNIITMASH:

“In the process of this work, we realized that our installation and our specialists are ready for such non-standard tasks, for such a complicated part in geometry. Then we are talking about improving the accuracy of product manufacturing and obtaining mechanical strength characteristics corresponding to the characteristics of the alloy used. There is still a lot of work ahead. ”

The introduction of 3D printing with metals and alloys will make it possible to significantly reduce the time needed to manufacture parts with complex geometry, and now their production is a long and laborious process.

Exhibition Materials

The videos that will be shot at the upcoming Top 3D Expo 2019 conference will be available only to Business and VIP class ticket holders.

Read about the types and cost of tickets and register on the site: register .

Source: https://habr.com/ru/post/447582/

All Articles