Top 3D Expo themes: 3D printing in auto tuning, Artem Solomnikov, "Imprint"

On the eve of the upcoming exhibition and conference Top 3D Expo , which will be held on April 19 in Technopolis Moscow, we are talking about the conference participants.

You will speak in Krasnoyarsk entrepreneur, CEO of Imprint Artem Solomnikov.

Artem Solomnikov

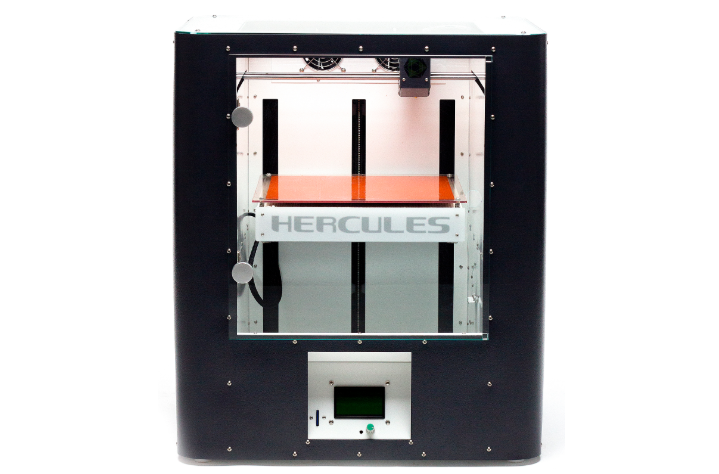

Artem Solomnikov, a graduate of the Polytechnic Institute of the Siberian Federal University, is one of the first people in Krasnoyarsk to engage in the commercial use of 3D printing. At first it was a print to order and an episodic sale of equipment and consumables, which he worked with his wife, but he wanted something more. And the opportunity presented itself - in 2013, Ewald Lepp came to the company, who was already trying to design and assemble 3D printers - another engineer, and at the same time a designer, and it was decided to create his own 3D printer. A year later, the first Siberian 3D-printer Hercules was assembled.

')

Theme

The theme of the speech of Artem Solomnikov: "The real history of modern auto-tuning is Generative design and 3D printing."

Speaker will talk about the use of Hercules 3D printers for printing parts for tuning and customizing cars.

About company

Founded in 2013, IMPRINTA provided 3D printing services. The idea of creating your own 3D printers only appeared.

In February 2014, the development of our own 3D-printer began, which was tasked with meeting the buyer's expectations to the maximum, to be easy to handle and reliable. The assembly of the first prototypes began in March, and the first finished copy was released after five months of development.

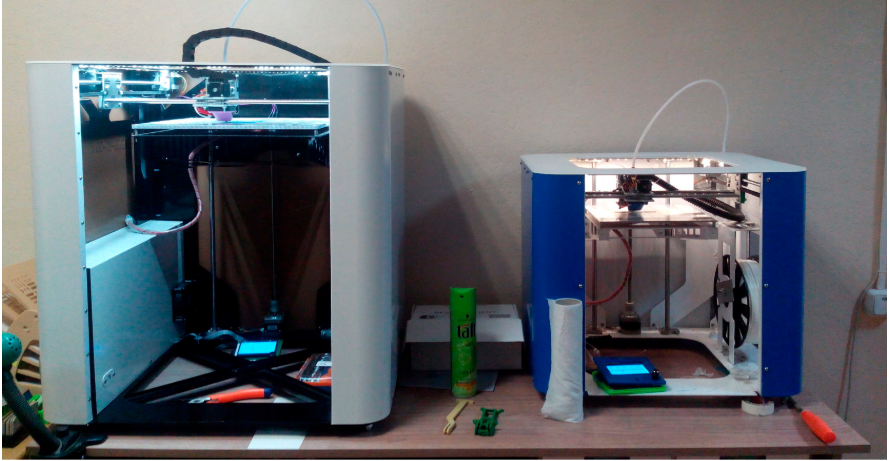

By the end of 2014, the first dozen of Hercules were sold. Then they looked like this:

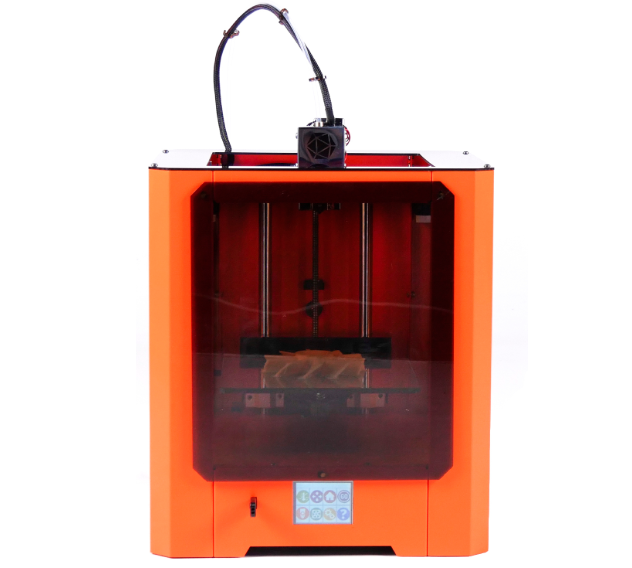

In 2015, the first enlarged “Hercules” - Hercules Strong was created, which took into account the problems of the first printers and significantly expanded the working volume.

In 2016, a reduced version of “Strong” was introduced, incorporating improvements in mechanics and a new design, but in a compact package - the updated Hercules. In the same year, enhanced quality control was introduced .

To improve the quality of the Hercules buildings, in 2017 we launched our own powder painting and metal working shop, our own production of carriages, guides, nozzles and other parts. Also in 2017 updated Hercules Strong and its design. The printer received the Brand of the Year award at the 3D Print EXPO exhibition.

2018 - another update, a new Hercules released, with low noise and improved print quality.

Cases

Tests of 3D-printed parts for strength

Tensile test links printed from common plastics - ABS, PLA, TPU, PETG, PA12 and others.

Mazda car tuning and testing at 200 km / h

Sea trials for 3D print racks for rear wing on a Mazda RX8.

3D printing of trophies

Nikolai Vorobiev - sculptor and founder of the VoronFab workshop.

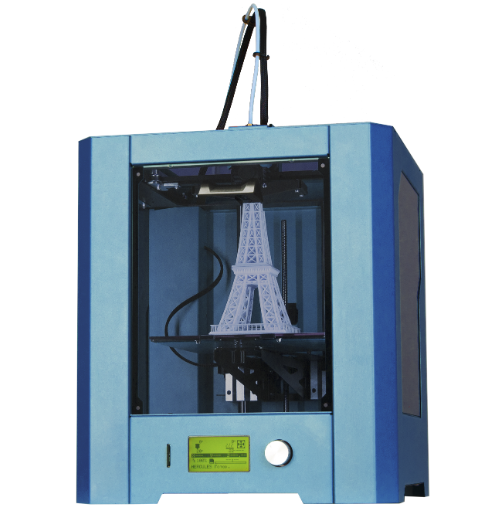

The workshop is engaged in the creation of various volume objects, including interior decorations in the form of hunting trophies. Printed in the workshop on a single-extruder 3D-printer Hercules.

Nikolai Vorobev:

“ Since I initially went to the idea of my own production from digital sculpture, I did not see any alternative to 3D printing. More precisely - the very possibility of 3D printing has become an incentive - it’s very cool to hold your own model in your hands, which you used to see only on the monitor. ”

All models are printed differently, for example the wolf was printed with supports, ears down. It was possible to print it without support, but in this position layers will be visible on the eyebrows, so they must be located in a different plane.

Some models are printed composite, separated along the axis of symmetry. On the cut there are fixing inserts and sockets for them.

PLA is mainly printed, as it almost does not shrink and does not require a thermostatic chamber for high-quality printing.

The smoothness of the models is achieved by reducing the height of the layer, which greatly stretches the printing time, or by post-processing. Large parts print with a small thickness of the layer is irrational, it takes several hours, so that they are subjected to post-processing.

PLA is very mechanically polished, but dichloromethane can be used for chemical polishing. Baths and immersions of the model in the solvent in the workshop are not used; they use brushes made of stiff bristles.

Nikolai Vorobev:

“Hercules was my first printer, so there was nothing to compare with. Actually, I studied 3D printing on it, and for certain at first I did something wrong, I was mistaken. A decent result was not immediately obtained. And therefore, when choosing a printer, technical support was very desirable, and the ability to simply get the printer out of the box and start experimenting without building designers. So the choice fell on Hercules for this reason, plus the cost at that time from the finished printers it was suitable.

Now, after a while, having gained experience in printing and having communicated with the printer, I’ll probably note its reliability. By inserting a bar and sending a file to print, I can be sure that the work will be completed. I don’t remember the case when the printer doesn’t finish building, cut off the seal. Print times have been 24 hours. ”

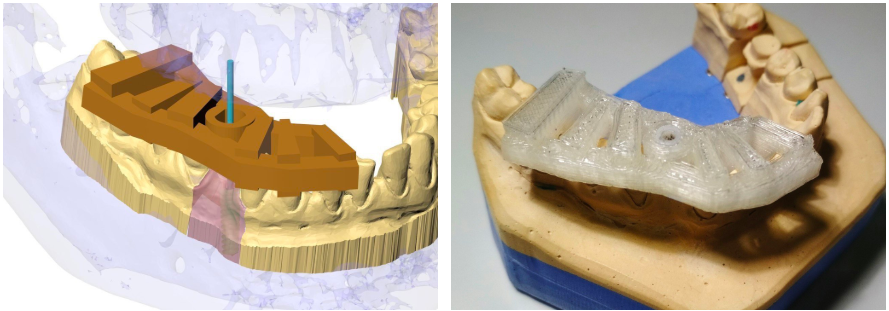

3D printing for dentistry

Nikolai Zakharov is the founder of the Phantom Lab orthodontist studio, where they make aligners, and surgical navigation templates.

Navigation patterns allow you to perform dental operations with great precision, directing the drill or surgeon's scalpel exactly as planned.

Aligners are used to align the bite - a gradual change in the location of the teeth in the jaw. They are made on a digital model, which is obtained by direct 3D-scanning of the teeth or, as here, by scanning the impressions taken from the patient. The model obtained by scanning is changed by the doctor so that it performs its function (the position of the teeth on it changes for very small distances - each pair of aligners moves them no more than a quarter of a millimeter), and then printed on a 3D printer and used to create aligners.

Nikolay Zakharov:

“For the production of each aligner, we print a separate model of the jaw on the Hercules 3D printer.

Then we take a transparent dental plate made of special hypoallergenic materials, heat it and press it with vacuum to the 3D-printed jaw model, to which it fits tightly. Everything, cap is ready, it remains to cut and process. In essence, this is thermoplasticization: vacuum thermoplastic forming. ”

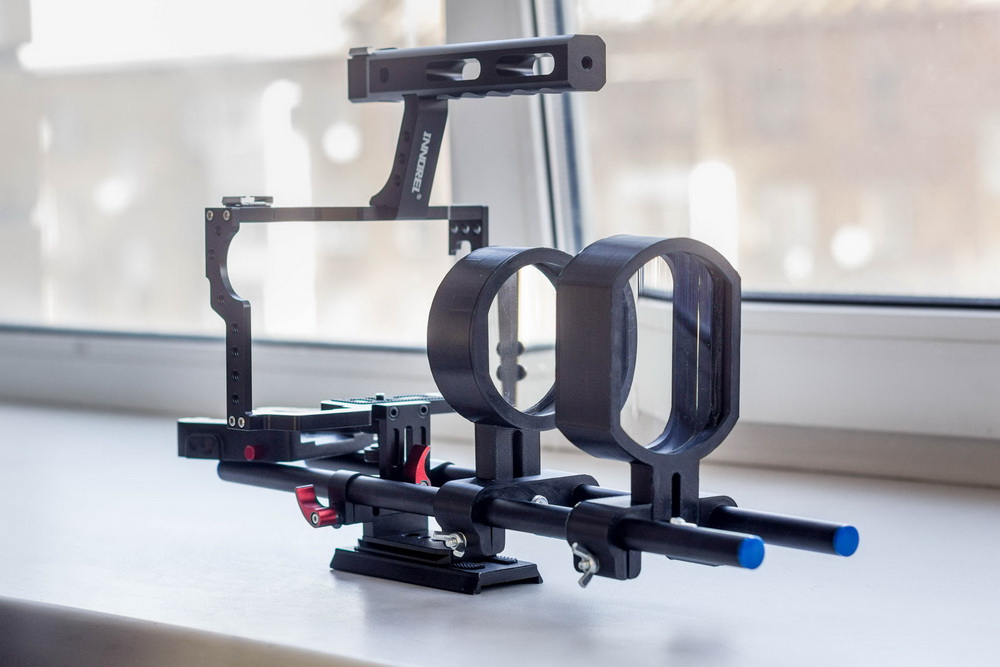

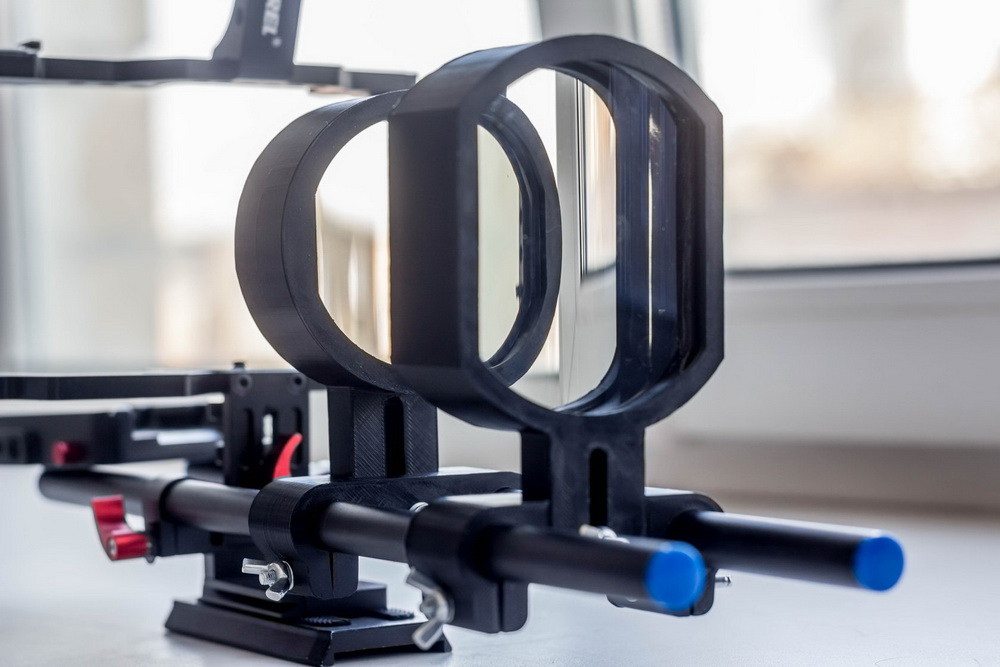

3D printing for cinema

Nikita is a cameraman in a video studio who, in his spare time, is keen on what he earns - shoots videos.

To get a beautiful picture, Nikita needed an anamorphic lens - such lenses are used when shooting a movie, they stretch the image vertically and narrow horizontally, which is then corrected during editing but leaves beautiful visual effects, such as horizontal flares and distortions on the edges of the frame.

Anamorphic lenses are professional equipment that costs a lot of money and is not suitable for budget cameras. To get the desired effect, you can buy a special lens, at a cost approaching 20 Hercules 3D printers, or a lens attachment worth one Hercules. But all this is not necessary if you have Hercules.

Nikita found a decommissioned film projector with the necessary lenses, created holders for lenses in the software for 3D modeling, printed them on Hercules and assembled the nozzle for shooting itself.

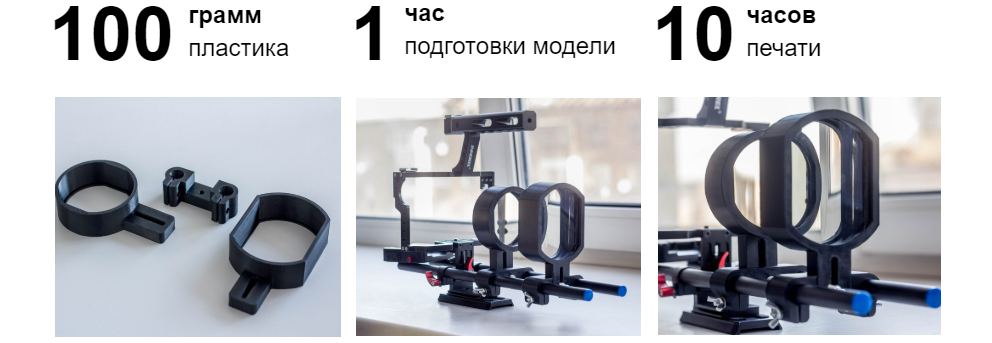

It took no more than an hour to draw, 10 hours and 100 grams of plastic to print. The cost of plastic and electricity is negligible compared to the price of purchased analogues of such nozzles. In addition, there is no need to wait for delivery from abroad.

Nikita:

“Anamorphic nozzles cost from $ 1000, so you understand how much I saved by making this nozzle with your own hands. Now I am filming a movie with it.

In general, I often type various mounts and plugs on the Hercules. Especially it helps me out when something is not available in the store. And all this little thing is lost very quickly. "

Exhibition Materials

The videos that will be shot at the upcoming Top 3D Expo 2019 conference will be available only to Business and VIP class ticket holders.

Read about the types and cost of tickets and register on the site: register .

Source: https://habr.com/ru/post/447356/

All Articles