Tesla's transformer on a single square inch board

Seeing the title of the article “One inch tesla coil”, I initially thought that this was a Tesla transformer with a height of one inch. It turned out that it is somewhat larger, but it is made on a board with an area of one square inch - these are the conditions of the competition . But even this is interesting enough to take up the translation.

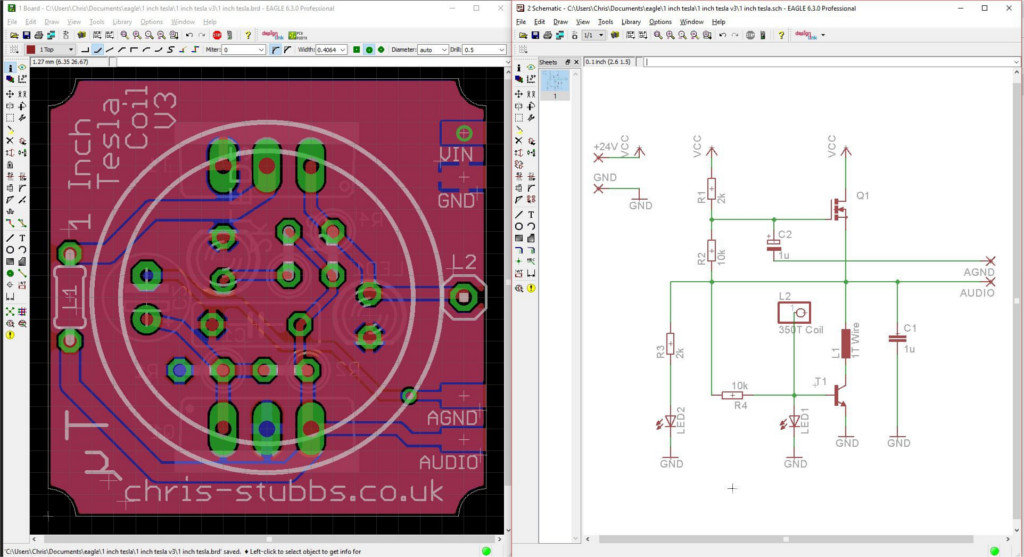

According to the scheme, parameters and degree of danger the design does not differ from that made from the average Chinese designer for the assembly of Tesla's transformer. They work well, but the place on the board, according to the author, is used irrationally - how can you not try to reduce it?

')

Structure of the device:

1 PC. printed circuit board

2 pcs. 2 kΩ resistor

2 pcs. 10 kΩ resistor

2 pcs. 3mm LED

1 PC. 1 μF electrolytic capacitor

1 PC. lavsan capacitor of the same capacity

1 PC. transistor IRF530

1 PC. transistor TIP41

1 PC. winding of two turns of hard wire (counterclockwise)

1 PC. winding of 350 turns of winding wire on a PVC pipe with an outer diameter of 20 mm

Audio input from such designers is often included as standard, and here it is copied along with the rest of the circuit:

The boards came to the author shortly before the trip to the EMFcamp festival, and he decided to take them there along with the details and assemble them there. But everyone who has been to such festivals knows that it is impossible to do this. You always do not have time to do everything that is planned, or at least as planned.

For some reason, the author decided that it was better to take up work at Ballmer’s Peak, and of course, nothing worked. When he returned home, he rechecked everything - it turned out that everything was collected correctly, which means that something was incorrectly designed. Comparing his circuit with several similar ones, he realized that one of the LEDs was involved in the bias circuit of the bipolar transistor. A small adjustment - and it works. The correct scheme is attached to the article.

Links: circuit and board , both in EAGLE format.

The assembly should begin with soldering all components except transistors and windings. Then install the transistors on the heat sinks (with thermal paste), then solder them. The heatsinks are also card holders. Glue the frame of the 350-turn winding to the board with hot glue, solder one of its turns to the board. Wind the double-turn winding with a diameter of 30 mm counterclockwise and solder, the beginning of the winding corresponds to the site nearest to figure 1 in the printed article header (if you made silk-screen printing, otherwise see the picture to the left of the diagram).

The design is ready, the supply voltage is from 15 to 24 V, the polarity is indicated on the board (again, in the presence of screen printing). In the reviews of Chinese sets it is said that at 19 V, the current consumed is about 1 A, and there is not enough heat sink area. If it is the same here, the advice is the same: either not to turn it on for a long time, or to cool it with a fan.

If you use the audio input, make a cable long enough so that the signal source can be far away from the device. The common wire of the signal source should not be connected to the common wire of the device’s power source. The signal is better to apply through a capacitor, even better - through an isolation transformer.

Now at Hackaday.io, another author is working on Tesla's even more interesting transformer — with printed spools . No need to shake anything - just make a board and solder three components into it. But there is not yet laid out the scheme - only shows the device in action.

Source: https://habr.com/ru/post/447306/

All Articles