Low, high, last. GLC - the fifth element of Lakhta Center

We are often asked the question - are there any more skyscrapers in Lahta? High-rise area, like Moscow City or La Defense? It can be seen that another construction is gaining momentum near Lakhta Center. Maybe behind her blue fence lies the birth of a new, even more incredible super-skyscraper?

Yes, indeed, since last year, geotechnics and concrete workers, steel fixers and surveyors, crane operators and designers have all been put under the gun again. The best building forces are thrown on the construction of the final facility of the Lakhta Center complex. And, like any final, this building intrigues the imagination. Let's see what is there?

The builders call the new object simply and intelligibly “Lakhta-2”.

')

The official name is GLC, almost a rebus. Its decoding - “Complex of buildings and structures” does not add anything to the understanding. The building is just one.

And the meaning is unexpected. The so-called corporate residence of Gazprom in Moscow was called, and the St. Petersburg headquarters was named after them as a souvenir. From corporations do not expect sentimentality, but sometimes it happens.

GLC becomes the final facility of Lakhta Center. A tower, a multifunctional building, a main entrance arch and a stylobate have already been put into operation. GLC is the second and final phase.

GLC is made in an easily recognizable style, but the beginner has something to add to the architectural concept. The fifth element, continuing the MFZ axis, balances the tower horizontally. It turns out a complete and proportional architectural ensemble that makes the St. Petersburg coast of the Baltic recognizable.

The object itself is a building divided into two buildings by a covered inner courtyard and united by a common stylobate.

Floors - variable, from 2 to 13 floors with a peak at around 85 meters. Even by the most loyal estimates, it does not reach the skyscraper, but due to the long low-rise part, it sends a message to the camp of supporters of low headquarters “like Apple”. The area of the object is more than 150 thousand m2. With the commissioning of the KZS in the metric area of Lakhta Center, the half-million mark has been stepped over. The complex, with its 572 thousand m2, will become the largest headquarters in the world.

The main parameters of the GLC are similar to the Multifunctional Building of Lakhta Center, but the differences are obvious.

At the GLC there is a long low-rise part, as if the roof of the atrium “recessed” between the buildings, the “island” in the center of the courtyard - there will be a kind of MCC - dispatch center. All this seems to be a beautiful architectural variation, but in fact the background is more complex than aesthetic issues.

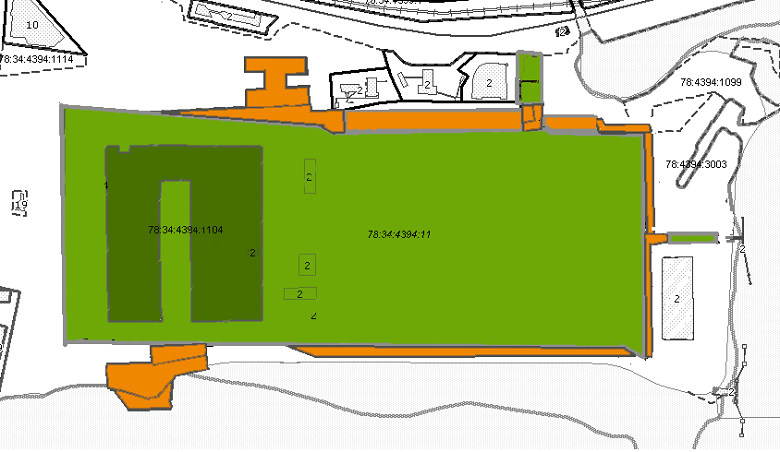

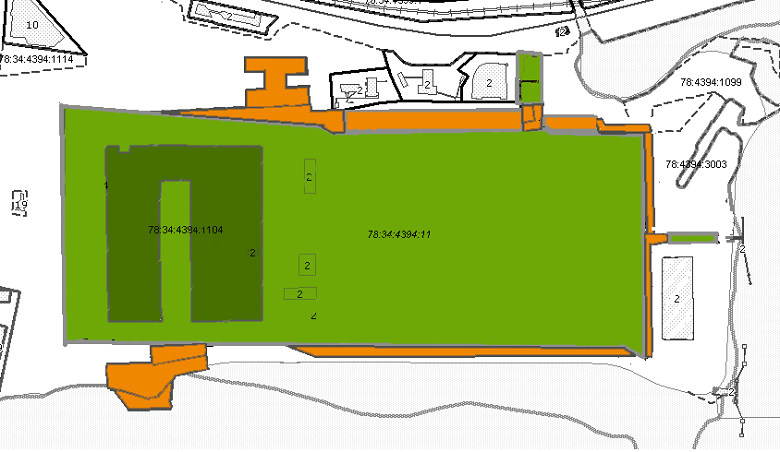

GLC is located at two sites at once due to a small territorial impregnation within the boundaries of the main building spot.

The historically established cadastral collision could lead to a deadlock: the high-altitude regulation of “autonomy” is standard 27 meters versus 500 on the main part of the plot. But, due to the uneven height of the GLC and the skill of the architects, the building was able to fit into the restriction without sacrificing functionality and aesthetics. It seemed to go under the "glass ceiling" in order to go upwards at the turn to the harbor, to observe the high-altitude regulations, but to remain itself - part of the recognizable complex Lakhta Center.

***

The difference in the photo - just a year. Speed is one of the main characteristics of this building. A powerful handicap - already familiar soils, recipes of materials, organizational and technological schemes and techniques. However, the negative factors have not been canceled. The main force majeure, the weather, is still in force.

Irina Anisimova, Development Director, MFC Lakhta Center JSC:

The zero cycle started in the summer of 2017. Experience has shown that the device of the pile field before digging the pit is the best option in local ground conditions. Piles work as anchors and keep the ground from moving, which keeps it in a compacted state and reduces the subsequent draft of buildings. So the primacy of the piles is not discussed.

Armor cages of bored piles

Drilling of wells for installation of piles goes under the protection of casing so that water from the upper layers of the ground does not enter the well

By November, the builders are completing the arrangement of the pile field by installing more than 1,400 bored piles with a diameter of mainly 1,180 mm and a depth of 35 m.

Digging the pit - it is always a struggle against the pressure of the soil. On the Lakhta coast to a mark of minus 4 m. The pressure in the soil increases to 2399 kN / l.m. If nothing is done with this, but simply digging, pushing into the walls of the pit cannot be avoided.

The beginning of work on digging the foundation of the GLC. Winter 2018, project archive

Builders solve this problem differently - for example, in the foundation pit of the tower walls are closed with reinforced concrete spacer disks.

Space system: temporary discs on the walls of the pit of the tower Lakhta Center. Summer 2013

The KZS has a relatively simpler spacer system. A reinforced concrete wall in the ground, 800 mm wide, is made for protection against water in the upper layers of the soil. A metal beam was laid along it along the perimeter, to which the struts were welded — pipes 1.2 meters in diameter to hold the external walls of the excavation “in the design position” —that is, without bending inwards.

Spacer trench of KZS

By the spring of 2018, the landscape at the bottom of individual sections of the pit resembles Easter Island.

Like stone statues, the heads of the piles rise.

They have to be cut down.

When a pile is poured, heavy concrete displaces the bentonite solution and sludge to the top - particles of drilled soil, which sometimes remain at the bottom of the pile well. Immediately, at the top - rubble, which temporarily blocked the mouth of the newly made pile. Therefore, such a “terminator” comes here, drills and cuts pile heads.

The “Terminator” works remotely - the operator with the control panel is at a respectful distance and in full protective gear.

KZS rests on a slab grillage - a slab in which the pile caps are reinforced and embedded in a monolith. The foundation is long - a whole concrete field of 4.2 hectares.

Pour this at once does not work, and not necessary. The foundation is concreted with parts-grippers. The foundation plate itself will be a monolithic structure. But a little higher - at the level of the stylobate, in several places make expansion joints - narrow cuts filled with an elastic insulator. Such seams make parts of the extended building more independent of each other during the subsequent draft and prevent plate deformation.

Preparation for concrete casting, spring 2018

In the photo - the technological seam between the grips of the slab grillage

Ready base plate:

Releases of reinforcement from it become the basis for the reinforcement cage of future walls in the stylobate. The slab is recessed - on top of it will be minus the first and minus the second floors of the building

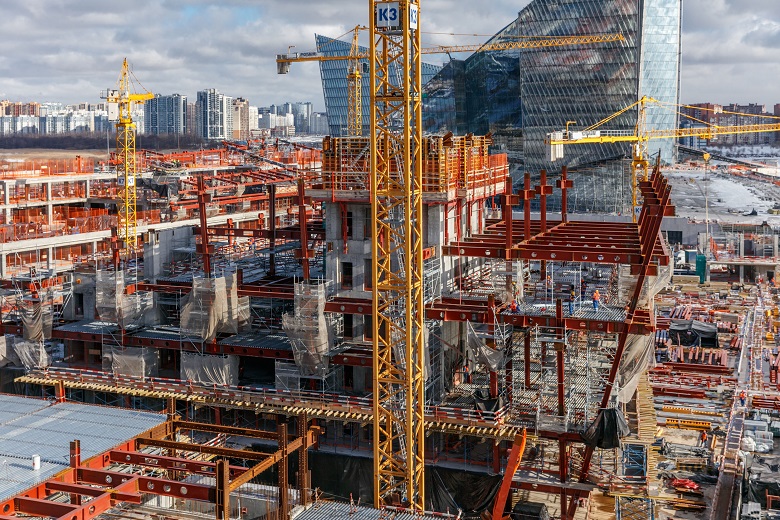

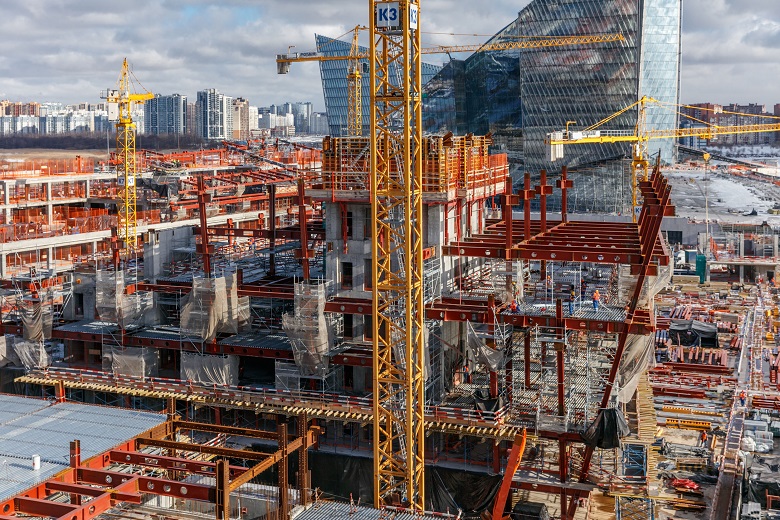

To date, builders - in the process of climbing. Now building the avant-garde - installers of steel structures, working at around 10 floors. The appearance of GLC is becoming more readable.

KZS, March 2019

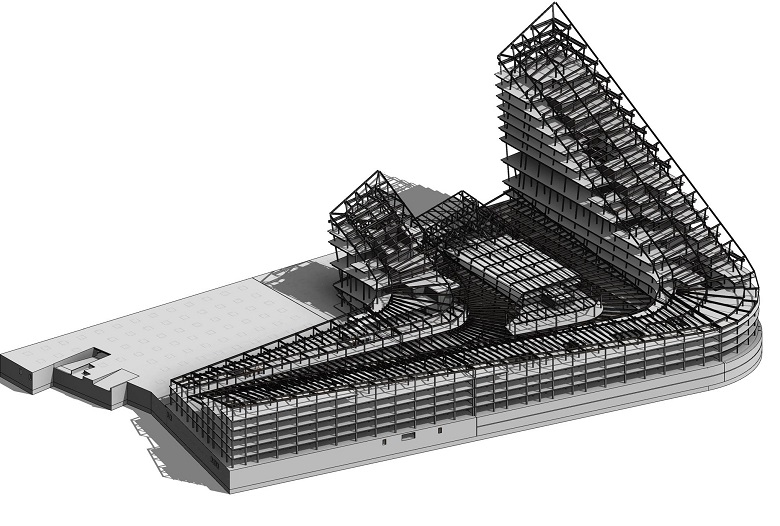

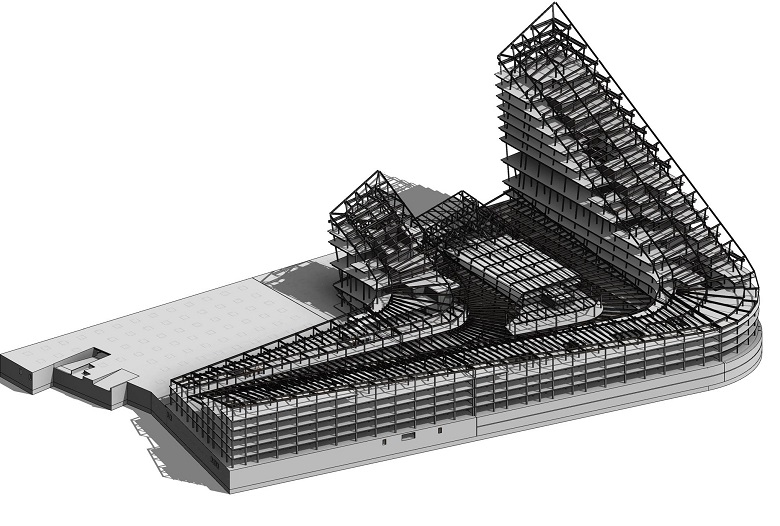

GLC visualization

The main complexity of the GLC in terms of ensuring the sustainability of its above-ground part is the length of the building and the presence of large-span spaces inside it.

The basis of the solution of the problem is, of course, reinforced concrete cores, which simultaneously form elevator and stair shafts.

Due to the length and division of the GLC into blocks, there are fifteen such cores! They are the main perceptions of vertical and horizontal loads.

They also play the role of vertical communication arteries of the building. Inside - escape routes, safety zones and elevators - 57 Kone cabs, including 9, which can be used to transport firefighters. The most elevator lift is designed for 3,250 kg. For comparison - in the tower the main heavy truck lifts up to 5,000 kg

In the meantime, the role of vertical transport is played by a construction hoist. Its installation is a sure sign of an older building.

Structural scheme of the building - frame.

The frame is formed by longitudinal and cantilever beams of high-strength steel brand Histar 460. In the areas of large-span spaces - over 36 m. Without support in the form of columns, transverse and longitudinal trusses with rigid nodes are additionally installed.

Interfloor overlappings - ferro-concrete according to the professional list. The professional sheet is fastened to the bearing beams with stud-bolts, the fittings are knitted, then the floor is concreted.

The facades of the KZS are made of multifunctional glass: metal spraying improves almost all consumer properties - energy efficiency, mechanical strength, and others. This glass - plus a hundred points to aesthetics - it gives the effect of continuous reflection of the environment - the bay, the clouds, and in the meantime mainly - the building realities.

Caring for those who will work behind the facade is a sunscreen coating and a safe inner layer of tempered glass.

The glass module in a lightweight aluminum profile has dimensions of 1500 * 4200 and covers the entire height of the floor without additional bolts.

Double-glazed windows are hung on interfloor overlappings on brackets installed with a step of 1, 5 m. Fastenings are fixed on one side and hinged on the other.

This ensures some independence of the facade from temperature fluctuations of the rest of the building. Own expansions and contractions of glass are compensated by rubber seals and non-hardening sealants.

On curvilinear sections of the facade the glass will be cold-formed, as well as - molded - that is, heat-bent.

A double façade is planned in the frontal parts - the second glass wall will go a meter from the first, a half-timbered structure made of steel profile will serve as a support.

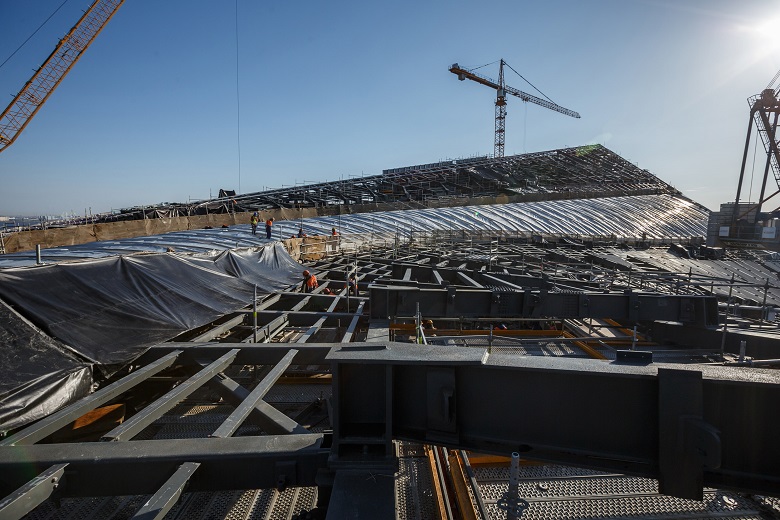

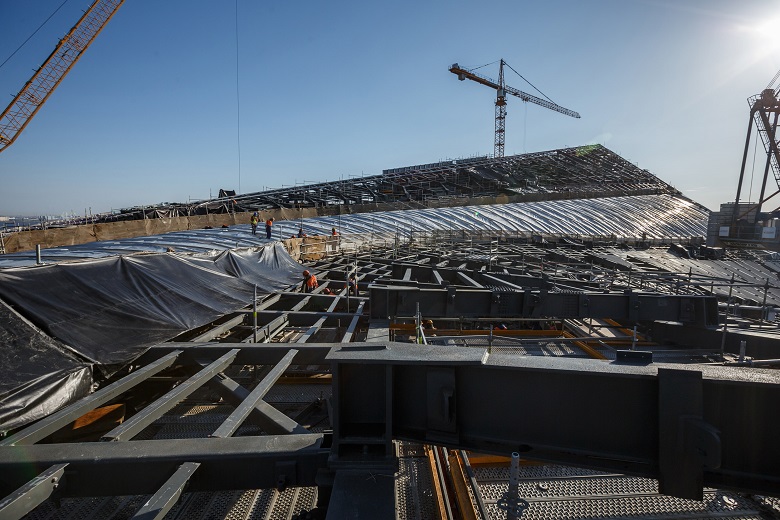

The most curious top point is, of course, the roof of the atrium. Here, as in the MD, instead of glazing, ETFE membranes forming a recognizable pattern will be used.

Cushions are formed from 4 layers of polymer, snapped into the metal profile, which are then pumped with air under a pressure of about 200 Pa. Here is how it looked on the roof of the atrium of the MFZ:

"Pillows" from ETFE in the initial state. Demonstration on the example of the roof of the atrium of the MFZ Lakhta Center. Photo - spring 2018, archive

And after the injection of air ... Demonstration on the example of the roof of the atrium of the MFZ Lakhta Center. Photos - Summer 2018, archive

The membranes are light, their light transmittance exceeds the characteristics of the glass, and practically the only damage that is possible is a puncture of the pillow - there is no danger for those who are below. And in general it is unlikely to be noticeable due to the pneumatic pump system.

The light transmittance of ETFE membranes is exemplified by the roof of the atrium of the Moscow Physical Shop of Lakhta Center Photos from the artwork "Lakhta Center"

Roofing of buildings is a place of work and rest of cranes of the service system of the GLC facades. In the parking position, the cranes will hide on special platforms; when they enter the service, they will move along the “rails” laid on the roof.

Inside the roof there are lattice floorings for movement of specialists serving the facades, parking spaces for the SOF equipment, rails for the movement of cranes. Demonstration on the example of the roof of the atrium MFZ. Photo - spring, 2018, archive

The lower level of the GLC is also associated with transport.

A parking lot will be located on the two underground floors of the stylobate, which runs almost to the borders of the site, as well as a variety of technical rooms.

The roof of the stylobate will be exploited - paths in stone paving, greenery and ponds are planned.

GLC with adjacent territory, visualization

Staircase leading from the 1st floor to the gallery of the courtyard of the GLC

All work on the construction of the KZS goes in parallel - metal structures are being installed at the top, concrete floors are poured below, lower partitions are already plastering partitions, pulling communications, and double-glazed windows.

How electricians work, while there is no light

Service engineers will not stop anything

Fencing of all installation perimeters - signs of the activity of invisible, but omnipresent service of labor protection

Surveyors - people without whom you can not build a complex building geometry

24-hour construction of the KZS

As soon as the work of some specialists is completed, the workplace of others immediately appears. In the rearguard - work on the underground parking - he seems to be ready to receive visitors.

Up to this point, there really remains a bit of time - the construction should be completed in the spring of 2021. This time the builders will leave this corner of the coast and the famous construction site in Lahta forever.

***

We thank for the assistance in the preparation of the material by the Director for Development of MFC Lakhta Center, JSC, Irina Anisimova.

Yes, indeed, since last year, geotechnics and concrete workers, steel fixers and surveyors, crane operators and designers have all been put under the gun again. The best building forces are thrown on the construction of the final facility of the Lakhta Center complex. And, like any final, this building intrigues the imagination. Let's see what is there?

PRO BUILDING

Why is KZS?

The builders call the new object simply and intelligibly “Lakhta-2”.

')

The official name is GLC, almost a rebus. Its decoding - “Complex of buildings and structures” does not add anything to the understanding. The building is just one.

And the meaning is unexpected. The so-called corporate residence of Gazprom in Moscow was called, and the St. Petersburg headquarters was named after them as a souvenir. From corporations do not expect sentimentality, but sometimes it happens.

Architectural Quintet

GLC becomes the final facility of Lakhta Center. A tower, a multifunctional building, a main entrance arch and a stylobate have already been put into operation. GLC is the second and final phase.

GLC is made in an easily recognizable style, but the beginner has something to add to the architectural concept. The fifth element, continuing the MFZ axis, balances the tower horizontally. It turns out a complete and proportional architectural ensemble that makes the St. Petersburg coast of the Baltic recognizable.

High and low headquarters

The object itself is a building divided into two buildings by a covered inner courtyard and united by a common stylobate.

Floors - variable, from 2 to 13 floors with a peak at around 85 meters. Even by the most loyal estimates, it does not reach the skyscraper, but due to the long low-rise part, it sends a message to the camp of supporters of low headquarters “like Apple”. The area of the object is more than 150 thousand m2. With the commissioning of the KZS in the metric area of Lakhta Center, the half-million mark has been stepped over. The complex, with its 572 thousand m2, will become the largest headquarters in the world.

Gemini or not?

The main parameters of the GLC are similar to the Multifunctional Building of Lakhta Center, but the differences are obvious.

At the GLC there is a long low-rise part, as if the roof of the atrium “recessed” between the buildings, the “island” in the center of the courtyard - there will be a kind of MCC - dispatch center. All this seems to be a beautiful architectural variation, but in fact the background is more complex than aesthetic issues.

Territorial autonomy

GLC is located at two sites at once due to a small territorial impregnation within the boundaries of the main building spot.

The historically established cadastral collision could lead to a deadlock: the high-altitude regulation of “autonomy” is standard 27 meters versus 500 on the main part of the plot. But, due to the uneven height of the GLC and the skill of the architects, the building was able to fit into the restriction without sacrificing functionality and aesthetics. It seemed to go under the "glass ceiling" in order to go upwards at the turn to the harbor, to observe the high-altitude regulations, but to remain itself - part of the recognizable complex Lakhta Center.

***

HOW GOES BUILDING

Quickly

The difference in the photo - just a year. Speed is one of the main characteristics of this building. A powerful handicap - already familiar soils, recipes of materials, organizational and technological schemes and techniques. However, the negative factors have not been canceled. The main force majeure, the weather, is still in force.

Irina Anisimova, Development Director, MFC Lakhta Center JSC:

“... During a strong wind, cranes cannot work, and temperature swings increase the running time. One day we fight with snow, the other with water and wind. It makes me alert all the time. ” (From an interview with the Paper portal)This is how the struggle continued, begun by Petersburg builders 300 years ago.

Pit and piles - in reverse order

The zero cycle started in the summer of 2017. Experience has shown that the device of the pile field before digging the pit is the best option in local ground conditions. Piles work as anchors and keep the ground from moving, which keeps it in a compacted state and reduces the subsequent draft of buildings. So the primacy of the piles is not discussed.

Armor cages of bored piles

Drilling of wells for installation of piles goes under the protection of casing so that water from the upper layers of the ground does not enter the well

By November, the builders are completing the arrangement of the pile field by installing more than 1,400 bored piles with a diameter of mainly 1,180 mm and a depth of 35 m.

Under pressure

Digging the pit - it is always a struggle against the pressure of the soil. On the Lakhta coast to a mark of minus 4 m. The pressure in the soil increases to 2399 kN / l.m. If nothing is done with this, but simply digging, pushing into the walls of the pit cannot be avoided.

The beginning of work on digging the foundation of the GLC. Winter 2018, project archive

Builders solve this problem differently - for example, in the foundation pit of the tower walls are closed with reinforced concrete spacer disks.

Space system: temporary discs on the walls of the pit of the tower Lakhta Center. Summer 2013

The KZS has a relatively simpler spacer system. A reinforced concrete wall in the ground, 800 mm wide, is made for protection against water in the upper layers of the soil. A metal beam was laid along it along the perimeter, to which the struts were welded — pipes 1.2 meters in diameter to hold the external walls of the excavation “in the design position” —that is, without bending inwards.

Spacer trench of KZS

Head off

By the spring of 2018, the landscape at the bottom of individual sections of the pit resembles Easter Island.

Like stone statues, the heads of the piles rise.

They have to be cut down.

When a pile is poured, heavy concrete displaces the bentonite solution and sludge to the top - particles of drilled soil, which sometimes remain at the bottom of the pile well. Immediately, at the top - rubble, which temporarily blocked the mouth of the newly made pile. Therefore, such a “terminator” comes here, drills and cuts pile heads.

The “Terminator” works remotely - the operator with the control panel is at a respectful distance and in full protective gear.

Foundation

KZS rests on a slab grillage - a slab in which the pile caps are reinforced and embedded in a monolith. The foundation is long - a whole concrete field of 4.2 hectares.

Pour this at once does not work, and not necessary. The foundation is concreted with parts-grippers. The foundation plate itself will be a monolithic structure. But a little higher - at the level of the stylobate, in several places make expansion joints - narrow cuts filled with an elastic insulator. Such seams make parts of the extended building more independent of each other during the subsequent draft and prevent plate deformation.

Preparation for concrete casting, spring 2018

In the photo - the technological seam between the grips of the slab grillage

Ready base plate:

Releases of reinforcement from it become the basis for the reinforcement cage of future walls in the stylobate. The slab is recessed - on top of it will be minus the first and minus the second floors of the building

Spring walk on the construction site

To date, builders - in the process of climbing. Now building the avant-garde - installers of steel structures, working at around 10 floors. The appearance of GLC is becoming more readable.

KZS, March 2019

GLC visualization

Stability system for a very long building

The main complexity of the GLC in terms of ensuring the sustainability of its above-ground part is the length of the building and the presence of large-span spaces inside it.

The basis of the solution of the problem is, of course, reinforced concrete cores, which simultaneously form elevator and stair shafts.

Due to the length and division of the GLC into blocks, there are fifteen such cores! They are the main perceptions of vertical and horizontal loads.

They also play the role of vertical communication arteries of the building. Inside - escape routes, safety zones and elevators - 57 Kone cabs, including 9, which can be used to transport firefighters. The most elevator lift is designed for 3,250 kg. For comparison - in the tower the main heavy truck lifts up to 5,000 kg

In the meantime, the role of vertical transport is played by a construction hoist. Its installation is a sure sign of an older building.

Structural scheme of the building - frame.

The frame is formed by longitudinal and cantilever beams of high-strength steel brand Histar 460. In the areas of large-span spaces - over 36 m. Without support in the form of columns, transverse and longitudinal trusses with rigid nodes are additionally installed.

Interfloor overlappings - ferro-concrete according to the professional list. The professional sheet is fastened to the bearing beams with stud-bolts, the fittings are knitted, then the floor is concreted.

Facades in shades of the sea

The facades of the KZS are made of multifunctional glass: metal spraying improves almost all consumer properties - energy efficiency, mechanical strength, and others. This glass - plus a hundred points to aesthetics - it gives the effect of continuous reflection of the environment - the bay, the clouds, and in the meantime mainly - the building realities.

Caring for those who will work behind the facade is a sunscreen coating and a safe inner layer of tempered glass.

The glass module in a lightweight aluminum profile has dimensions of 1500 * 4200 and covers the entire height of the floor without additional bolts.

Double-glazed windows are hung on interfloor overlappings on brackets installed with a step of 1, 5 m. Fastenings are fixed on one side and hinged on the other.

This ensures some independence of the facade from temperature fluctuations of the rest of the building. Own expansions and contractions of glass are compensated by rubber seals and non-hardening sealants.

On curvilinear sections of the facade the glass will be cold-formed, as well as - molded - that is, heat-bent.

A double façade is planned in the frontal parts - the second glass wall will go a meter from the first, a half-timbered structure made of steel profile will serve as a support.

Extreme levels: above and below

The most curious top point is, of course, the roof of the atrium. Here, as in the MD, instead of glazing, ETFE membranes forming a recognizable pattern will be used.

Cushions are formed from 4 layers of polymer, snapped into the metal profile, which are then pumped with air under a pressure of about 200 Pa. Here is how it looked on the roof of the atrium of the MFZ:

"Pillows" from ETFE in the initial state. Demonstration on the example of the roof of the atrium of the MFZ Lakhta Center. Photo - spring 2018, archive

And after the injection of air ... Demonstration on the example of the roof of the atrium of the MFZ Lakhta Center. Photos - Summer 2018, archive

The membranes are light, their light transmittance exceeds the characteristics of the glass, and practically the only damage that is possible is a puncture of the pillow - there is no danger for those who are below. And in general it is unlikely to be noticeable due to the pneumatic pump system.

The light transmittance of ETFE membranes is exemplified by the roof of the atrium of the Moscow Physical Shop of Lakhta Center Photos from the artwork "Lakhta Center"

Roofing of buildings is a place of work and rest of cranes of the service system of the GLC facades. In the parking position, the cranes will hide on special platforms; when they enter the service, they will move along the “rails” laid on the roof.

Inside the roof there are lattice floorings for movement of specialists serving the facades, parking spaces for the SOF equipment, rails for the movement of cranes. Demonstration on the example of the roof of the atrium MFZ. Photo - spring, 2018, archive

The lower level of the GLC is also associated with transport.

A parking lot will be located on the two underground floors of the stylobate, which runs almost to the borders of the site, as well as a variety of technical rooms.

The roof of the stylobate will be exploited - paths in stone paving, greenery and ponds are planned.

GLC with adjacent territory, visualization

Staircase leading from the 1st floor to the gallery of the courtyard of the GLC

Next to next

All work on the construction of the KZS goes in parallel - metal structures are being installed at the top, concrete floors are poured below, lower partitions are already plastering partitions, pulling communications, and double-glazed windows.

How electricians work, while there is no light

Service engineers will not stop anything

Fencing of all installation perimeters - signs of the activity of invisible, but omnipresent service of labor protection

Surveyors - people without whom you can not build a complex building geometry

24-hour construction of the KZS

As soon as the work of some specialists is completed, the workplace of others immediately appears. In the rearguard - work on the underground parking - he seems to be ready to receive visitors.

Up to this point, there really remains a bit of time - the construction should be completed in the spring of 2021. This time the builders will leave this corner of the coast and the famous construction site in Lahta forever.

***

We thank for the assistance in the preparation of the material by the Director for Development of MFC Lakhta Center, JSC, Irina Anisimova.

Source: https://habr.com/ru/post/447106/

All Articles