76% of manufacturers do not have experience in adding additive - why it’s good

According to experts, the domestic market of additive technologies is growing by 20% annually and will reach 14 billion rubles in 2023. And this is the case all over the world - the EY study showed that 76% of industrial companies do not have experience in introducing additive technologies (AT) into their production.

How so: the market is growing, and the use of AT and digital production systems (DP) are so small?

')

Here we look at how it happened and what it means.

The study showed: the use of AT below expected

A study conducted by consulting company EY showed that

- 76% of manufacturing companies did not implement additive technologies at all,

- 4% are experimenting and testing the effectiveness of AT in their field,

- 9% use AT in advanced and experienced departments,

- and only 11% implement them fully, as part of the production process.

Why it happens

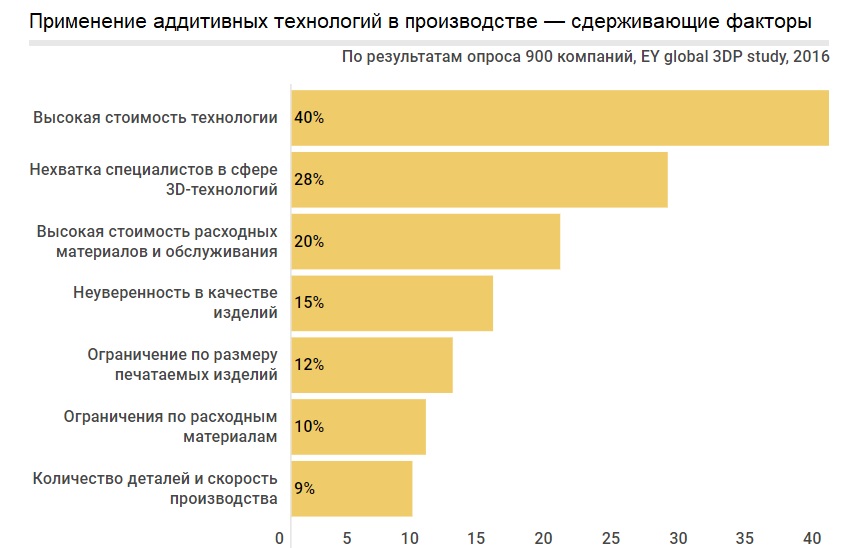

The reasons for such a small introduction of AT are unlikely to surprise anyone, they are natural and quite expected. Here are the reasons for the leaders of companies in which additive technologies have not been applied:

- 40% - high cost of equipment and implementation;

- 28% - lack of qualified specialists;

- 20% - expensive materials and service;

- 15% - doubts about product quality;

- 12% - restrictions on the size of the created objects;

- 10% - limited quantity of applicable materials;

- 9% - insufficient speed and volume of output.

These are all objectively existing factors, but they are often overvalued. Equipment and materials become cheaper as they are released more and more massively. Qualified personnel universities and institutions of additional education are already preparing and graduating around the world. Quality certification systems are also being developed everywhere, including the Russian Federation, where a special commission of Rosstandart is involved in this. The number of materials used for 3D printing is constantly increasing , and the size of industrial 3D printers and the parts they print are scaled.

The speed of production of small and medium-sized batches of AT products often exceeds traditional technologies, and in large-scale production they play an important role at the development and prototyping stages. What is convincingly proved by the following cases.

Cases

CB "Luch"

Problem: Creating parts of an unmanned aerial vehicle took several years.

Solution: Designing a model on a computer. The program offered the optimal design of the device. Print all major parts on a 3D printer.

Result: Printing details of the drone took 30 hours. Further only the assembly was necessary. It took 2 months to complete all the work, from design to manufacturing the device.

CJSC Promtractor Wagon

Problem: Creating a full-scale prototype of 50 parts from special clay required from several weeks to several months.

Solution: Using a 3D printer to print prototype details.

Result: It takes an average of 20-40 minutes to print a part, depending on the complexity. The ability to print parts in different colors allows you to create a complete design model in less than a week.

Perm Engine Company Aviadvigatel

Problem: It is extremely difficult or impossible to develop parts whose geometry is traditional methods (casting, turning).

Solution: For the manufacture of models used technology SLS. Titanium, nickel, steel, cobalt-chromium powders are used: for laser melting - a diameter of 10-63 microns, for surfacing - 40-80 microns.

Result: The creation of complex parts (swirl, bracket, comb) takes from 6 to 40 hours.

Nissan plant in St. Petersburg

Problem: High cost of manufacturing auxiliary tools by third-party contractors.

Solution: Implementation of 3D printers for the needs of rapid prototyping and manufacturing of assembly equipment and templates. The use of 3D-printer Dimension 1200ES company Stratasys, working on the technology of layer-by-layer fusion polymer rod (FDM / FFF).

Result: During the year of operation of the 3D printer, the company saved about one million rubles in the production of prototypes, templates and accessories.

Concern "Oceanpribor" in St. Petersburg

Problem: low speed of obtaining prototype splitters from polyurethane (several months).

Solution: ProJet x60 ZPrinter is used. The frame is made, which is then poured with silicone. After polymerization - at the exit is a finished silicone form suitable for pouring with any other material, usually polyurethane is poured into it. The result is not a prototype, but a finished part.

Result: the creation of a prototype product takes one day, the cost of developing a prototype has decreased significantly.

State Corporation "Roscosmos"

Problem: the traditional method of producing a mixing head requires more than two hundred parts, which are connected by sixty-two welds. Long and complex manufacturing process

Solution: Using 3D printing allows you to make a solid piece, it takes seventy-seven hours to print.

Result: The use of additive technologies will reduce the labor intensity of production by 20% immediately, according to expert estimates .

What does this mean in practice?

At first glance, it may seem that everything is bad, 3D printing technologies have not justified the hopes placed, and this explains the low level of their use. And so it will seem exactly until the moment of familiarization with studies showing a steady increase in the share of AT in production.

The conclusions are simple: the low involvement of production companies in the use of AT and DP now leaves open a huge space for implementation, while the market is not very busy and continues to grow, its poor development means very good prospects.

The purpose of Top 3D Expo is to make knowledge of the introduction of additive technologies and digital production publicly accessible, to ensure the exchange of experience between the manufacturers of additive technologies, the companies involved in their implementation and the end customer - the companies operating the operators.

At the Top 3D Expo conference and the round table on 3D metal printing, held within its framework, more than twenty domestic and international speakers will share their experience and practical cases on using 3D technologies to solve business problems.

Read reviews about conference experts and topics presented:

- “Shining 3D Experience in Creating 3D Digitization Solutions” , Sunny Wong, Shining 3D;

- "The use of 3D metal printing in the aviation and space industry" , Anton Sotov, Samara University;

- "Anisoprinting - a new technology for 3D printing of composite structures" , Fedor Antonov, Anisoprint;

- "3D-printing of organs and tissues" , Yousef Hesuani, 3D Bioprinting Solutions.

Join us and find out how 3D technologies revolutionize industries such as manufacturing, medicine, architecture, the aerospace industry, the automotive industry and many others.

In one of the conference speeches, Vasily Kiselev, Managing Director of the Top 3D Group, will tell about the new product of the company, designed to solve the problem of integration at a deeper level. Join now !

Source: https://habr.com/ru/post/446950/

All Articles