European Space Agency is exploring the possibility of using 3D metal printing

In cooperation with the European Space Agency (ESA), 3D Systems, with the active participation of its custom-made parts division, produces nozzles, combustion chambers and expanding nozzles for two-component fuel satellite communications engines using 3D printing with metals ( DMP) .

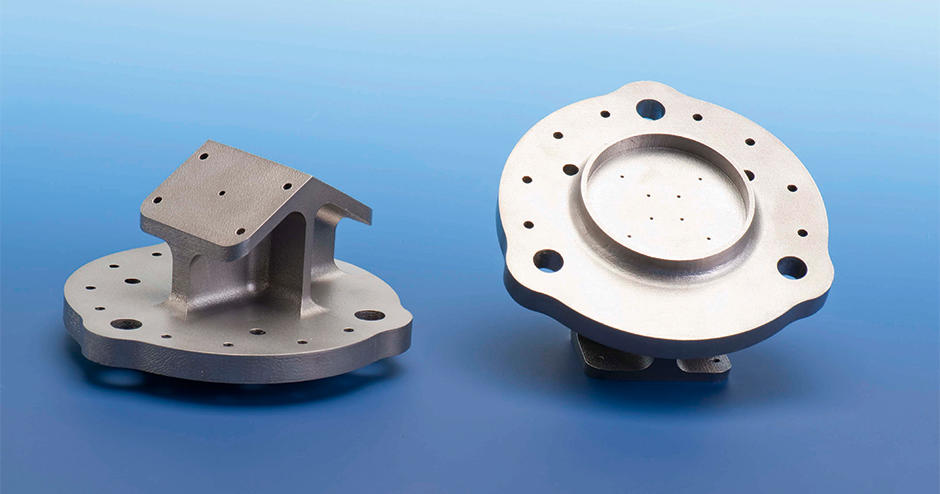

Injector line grown on a DMP series 3D printer from 3D Systems

')

These details provide ESA with an opportunity to assess the potential for further improving the manufacturing techniques of existing structures. In addition, ESA specialists and 3D Systems use the capabilities of DMP technology to develop design solutions with separate functions for the above-mentioned satellite engine parts. It is, for example, a monolithic design of the combustion chamber, including a thin-walled high-pressure vessel with an external reinforcing mesh design. DMP technology reduces weight, simplifies assembly, speeds production, and makes design changes easy at later design stages. Cooperation with ESA complies with the strategy of 3D Systems in introducing its unique know-how to improve production technology in the space and aerospace industries.

The current state of the technology of 3D printing with metals

Communication satellites are needed for mobile Internet operations and secure financial connectivity between banks, live TV broadcasts and Earth observation for weather forecasting. One of the tasks of ESA is to monitor the development of technologies for the manufacture of engines of space satellites. As part of its own-funded program, ESA explores the state-of-the-art technology of 3D printing with metals, evaluates its potential and degree of maturity in the light of future engine developments.

Analysis of the image in X-rays with a resolution of 130 microns allows us to conclude that the DMP technology can be effectively used for the manufacture of nozzles

As part of its research program, ESA chose 3D Systems, given its rich technological experience and level of customer support. 3D Systems implemented design solutions for three critical parts, as well as their alternatives using DMP technology.

A controlled mixture of two types of fuel, their spontaneous ignition and continuous burning occur in the nozzle part of the satellite engine. In the combustion chamber in the form of a Venturi tube, the gaseous products of combustion are accelerated, bringing the satellite to the desired orbit. The expanding nozzle affects the characteristics of motion, affecting the gas flow.

“DMP technology provides the ability to produce an innovative line to optimize flow from the fuel valve to the combustion chamber,” says Simon Hyde. The design freedom inherent in this method allows ESA to reduce the number of nozzle parts from five (using traditional production technology) to one. In addition, many unsafe sealing seams are eliminated, which ensure the reliability of fuel injection, as well as significantly reduce the cost of manufacture and reduce the risks. 3D Systems was able to create homogeneous structures with a relative density of up to 99.98%, which will allow the use of an increasing number of metals and alloys , including titanium.

Innovative nozzle line

The technology of 3D printing with metals is also suitable for performing thermal design of the nozzle, which prevents the return of heat leakage to the sensitive seats of the fuel valves and to the spacecraft itself. The lack of restrictions on access to the tool allows you to change the design of thermal insulation, controlling thermal conductivity due to the reinforcing mesh design. The nozzle parts made of aviation titanium alloy (Ti6Al4V) generally comply with the requirements of the space sector and the developer of rocket engines to ensure product quality.

An innovative line made using 3D metal printing technology makes it possible to optimize the flow of fuel between the valve and the combustion chamber.

Simon Hyde, European Space Agency

Separation of combustion chamber functions

The combustion chambers of a compact satellite engine usually consist of a supersonic nozzle and an outlet nozzle without attachment. The fuel reactions are completed in a tapering section, from where gaseous products of combustion get through the throat into the supercritical section, where they expand at supersonic speed. Modern cameras are designed to withstand the non-working loads associated with the launch - these transient loads are perceived by the thick walls of the chamber. After being placed into orbit and with a working load, the chambers do not need such thick walls.

The separation of the functions of the combustion chamber of the working and non-working design loads leads to the need to use a compression frame supporting the thin wall

According to Simon Hyde, DMP technology allows you to divide the functions of the camera between work and non-working load conditions. An obvious solution seems to be the creation of a compression frame made of ribs supporting a thin wall of the combustion chamber and a welding flange for fixing the exit nozzle. However, instead of the primitive framework, 3D Systems manufactured a supporting structure in the form of a low-density mesh. Since its bulk density is only 12%, the use of DMP technology can significantly reduce the weight of the combustion chamber or increase the safety margin of the structure.

Currently, the camera is made of titanium alloy Ti6Al4V. In the future, it is planned to produce it from a refractory alloy (for example, based on niobium, molybdenum, tantalum, tungsten and / or rhenium) so that it can withstand ultrahigh temperatures of fuel combustion. Further study of this revolutionary design of the combustion chamber involves the study of the isotropy of the grid in the stress field, as well as detailed thermal analysis. The grid will increase the effective surface radiation, so it will undoubtedly affect the heat fluxes around the chamber.

3D printing of large metal parts

Enhanced design capabilities made it possible to create a low-density grid on the radiating surface supporting the thin wall of the engine's combustion chamber.

ESA engineers also explored the possibility of using DMP technology to manufacture an exit nozzle with an outlet diameter of up to 50 cm. At the time of the project, the capabilities of the DMP technology made it possible to print products with dimensions up to 275 x 275 x 450 mm. The nozzle voltages are relatively low, and reducing the mass of the cantilever part of the nozzle is a critical factor in increasing engine safety. 3D Systems manufactures a titanium alloy exit nozzle (Ti6Al4V), which basically meets the mechanical and thermal requirements for expanding exit nozzles.

According to Hyde, DMP technology offers clear advantages in production compared to traditional rotary extrusion of sheet material, which excludes any flexibility in design. It allows you to adapt engine specifications to the specific requirements of the customer to the thrust profile, making it possible to change many decisions at the latest design stages.

Translation from English. The original of this material on the site 3D Systems.

Source: https://habr.com/ru/post/446840/

All Articles