Top 3D Expo 2019 Topics: 3D Metal Printing, Anton Sotov, Samara University

On the eve of the upcoming exhibition and conference Top 3D Expo , which will be held on April 19 in Technopolis Moscow, we are talking about the conference participants.

From the Samara National Research University named after Academician S.P. Anton Vladimirovich Sotov, winner in the nomination “Young Scientist”, assistant professor of engine production technologies, junior researcher of IPIT-216 (Institute of Industrial Innovative Technologies) will make a speech on Korolyov.

')

Samara University took part in the creation and testing of the first in Russia aircraft engine with a 3D-printed combustion chamber and its improved models, the development of 3D metal printing implants for the spine and the creation of Russia's first 3D printer for metal printing. Read more - next.

Anton Sotov

Last year, at the youth forum-exhibition “The Future of Aviation and Cosmonautics for Young Russia”, held at the International Engine Building Forum (MDF-2018), Anton Vladimirovich won the first place in the “Young Scientist” category, presenting the development of 3D design techniques to the competition - the press of combustion chambers from powder of heat resisting alloy.

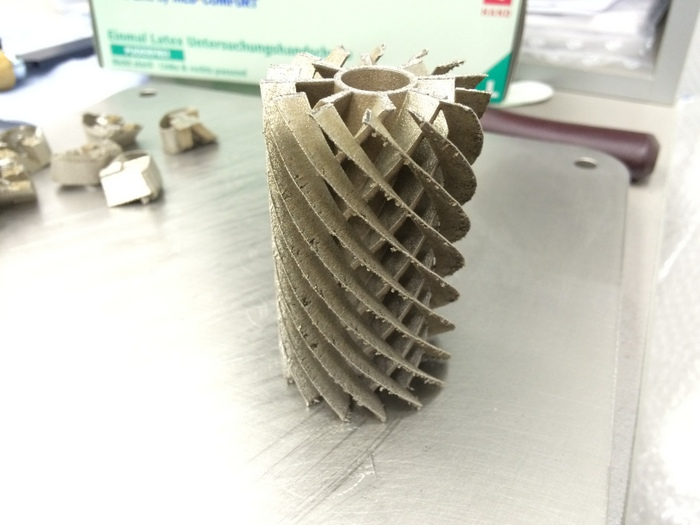

The importance of developing methods for applying 3D printing with metals in aircraft and designing models for it is that they will allow the technology to be used on a large scale in the manufacture of aircraft engines, which will reduce costs and costs and speed up the development and production of new types of aviation and space technology.

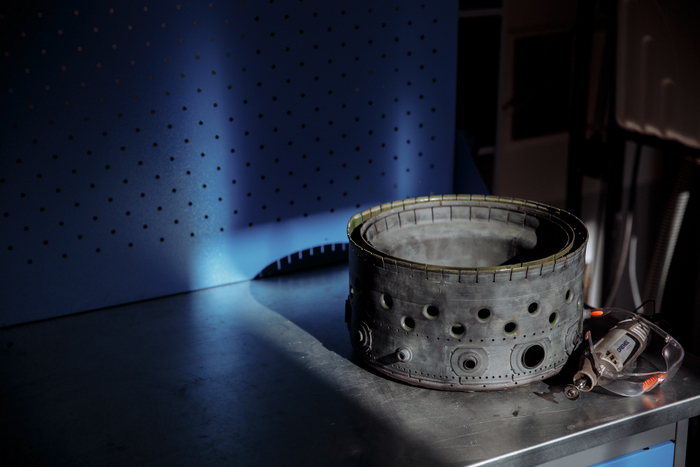

The forum participants showed interest in the gas turbine combustion chamber made using additive technologies from heat-resistant metal powder, as well as an internal combustion engine with an acoustic exhaust system SCORPIO-S-33-2,5.

Topic

The theme of the speech by Anton Sotov:

“Development of complex additive technologies and production of experimental-industrial samples of aerospace equipment parts”

In his speech, the speaker will talk about the development and application of 3D metal printing methods in the Russian aviation and space industry and research conducted in this area.

3D-printed combustion chamber gas turbine engine TA-8.

About the organization

In 1942, the Kuibyshev Aviation Institute was established in the city of Kuybyshev, designed to provide training for engineering personnel for organizations of the aviation industry.

After the war, the institute participated in the development of many jet fighters and bomber design offices MIG, Il, Tu, created aircraft engines.

Since 1957, the Institute has been training specialists in rocket and space technology. Its graduates and employees participated in the development and production of intercontinental ballistic missiles and launch vehicles for spacecraft.

Cases

Seal of the combustion chamber for aircraft engine

Development and 3D printing of a combustion chamber for a MGTD gas turbine engine and the subsequent creation and testing of a new MGTD A-8 gas turbine aircraft engine with a 3D-printed combustion chamber used for the further development of 3D printing methods for the production of aviation and space engines.

Head of the Laboratory of Additive Technologies of Samara University Vitaly Smelov:

“We were the first in the country to manufacture and test the combustion chamber as part of full-scale MGDT. And we believe that this is a breakthrough - to create a working serial engine unit with the help of additive technologies, although this is the first step of our great work.

In order to obtain products that meet the stringent requirements of aviation, it took a large set of experimental studies of the properties of powders, the study of mechanical properties and metallographic studies of the structure of the synthesized samples. ”

Partners in the project were:

Kuznetsov PJSC (Samara), Sintez Scientific Production Enterprise (Samara), Samara Electrotechnical Plant CJSC (Samara), University of Lund (Lund University, Sweden), Carleton University (Ottawa, Canada), Central Institute of Aviation Motors named PI Baranova ”(CIAM), Institute of Nanoscience and Nanotechnology of the National Center for Scientific Research“ Democritus ”(NCSR“ Demokritos ”, Athens, Greece), St. Petersburg Polytechnic University of Peter the Great, University of Stuttgart (Germany).

Creating a vertebral implant

An experimental sample of a cervical vertebral implant was created using a metal 3D printer in a joint project with scientists and specialists of Samara State Medical University and Samara City Clinical Hospital No. 1 named after. N.I. Pirogov.

Created individually for each patient, the implant is made of domestic materials and costs several times cheaper than imported counterparts. Thanks to this development, thousands of patients with a damaged spine can return to a full life.

Participation in the first project of a Russian 3D metal printer

SSAU took part in the creation of a 3D printer for printing with refractory alloys in the framework of the Federal Target Program “Research and Development in Priority Areas for the Development of the Scientific and Technological Complex of Russia for 2014–2020”. This is the first development of this kind in Russia.

Exhibition Materials

The videos that will be shot at the upcoming Top 3D Expo 2019 conference will be available only to Business and VIP class ticket holders.

Read about the features of different tickets and prices for them and make registration on the event website .

Source: https://habr.com/ru/post/446760/

All Articles