Released the world's first propeller, created on a 3D printer

WAAMpeller - the first propeller created in an additive way, which received typical approval

After more than six months of hard work, the WAAMpeller, made on a 3D printer — the first of its kind ship propeller that received type approval — was finally tested and presented at the Damen Shipyards Group headquarters in the Netherlands.

The project began when RAMLAB, the Netherlands Laboratory for Additive Technologies for Shipbuilding , located in the port of Rotterdam, presented in collaboration with software developer Autodesk its first product - a prototype ship propeller, made using hybrid technology.

')

The project was carried out in partnership with Promarin, Damen and Bureau Veritas and pursued the goal of creating the world's first propeller screw printed on a 3D printer that would receive typical approval. The WAAMpeller screw is named after the WAAM (Wire and Arc Additive Manufacturing) additive method used in its manufacture, which is a fast and relatively inexpensive 3D printing technology widely used by RAMLAB.

This project was an excellent example of collaboration: Promarin designed a WAAMpeller screw based on a three-blade design, similar to that used on the Damen Stan Tug 1606, which was used in full-scale running trials. Damen also provided a development base, while RAMLAB, using Autodesk solutions in the field of additive technology, robotics, and software, and using WAAM technology, produced a propeller. Finally, Bureau Veritas has audited the design, manufacturing and testing process.

WAAMpeller screw mounting

“The WAAMpeller project is outstanding for a number of reasons. For the first time in the world, a rowing propeller was printed on a 3D printer , which received typical approval, and the project was completed in just 7 months - one year after the official opening of RAMLAB, ”Allard Castelain, director of the port of Rotterdam, said.

“This was made possible through the hard work of all project participants. Damen, Autodesk and Bureau Veritas provided comprehensive support throughout the project. In fine-tuning the WAAMpeller, the experience of Promarin was fully utilized. Last but not least, a round-the-clock production process was organized at RAMLAB, and laboratory specialists were available at any time. ”

The 3D printing process of the prototype WAAMpeller was completed after the mandatory testing of materials, confirming that the nickel-aluminum-bronze alloy used conforms to Bureau Veritas standards. Then, the prototype was sent to the Autodesk Laboratory in the UK for processing on a CNC machine. Immediately after the project was completed, the team proceeded to manufacture a second WAAMpeller propeller with the aim of obtaining type approval.

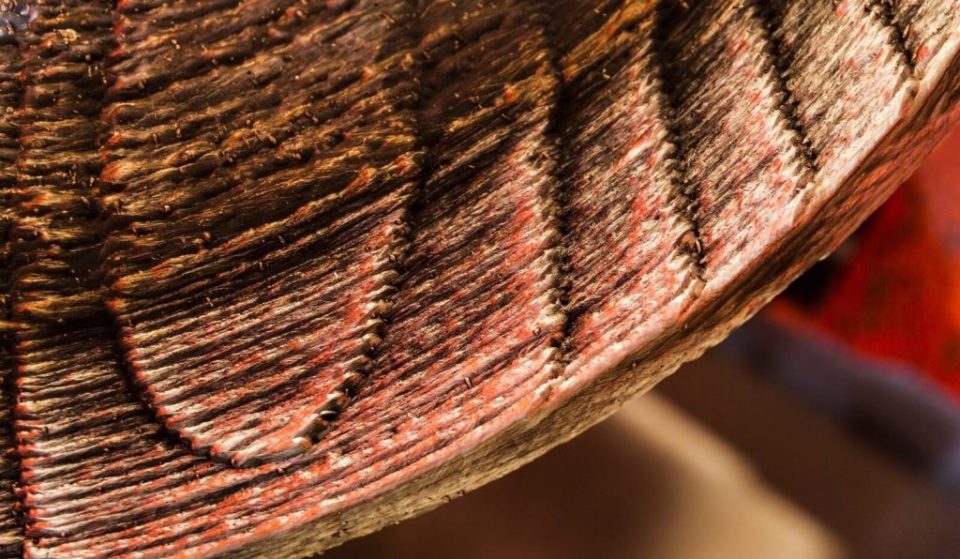

Close-up propeller printed on a 3D printer

“It was much easier to make the second WAAMpeller screw, because we learned a lot when creating the prototype. It was mainly about the use of equipment and software , because when applying 298 layers of nickel-aluminum-bronze alloy, strict control of all technological parameters is extremely important, ”said Vincent Wegener, managing director of RAMLAB.

For the first time in the world, a propeller was printed on a 3D printer, which received typical approval, and the project was completed in just 7 monthsWhen the second WAAMpeller screw weighing about 180 kg was ready, extensive tests were carried out that began with the installation on the Damen Stan Tug 1606 vessel.

Allard Kastelein, Director of the Port of Rotterdam

Martin de Bruin, Damen’s managing director for auxiliary vessels, explained: “This vessel is of particular interest because it is equipped with an engine that meets the requirements of the Tier III standard, and therefore more stringent environmental standards and regulations introduced in ports around the world.”

Sea trials of the WAAMpeller were carried out in Dordrecht under the supervision of Bureau Veritas auditors. “Bureau Veritas’s task was to monitor every stage of WAAMpeller manufacturing and testing,” explained Martin Nievenhuis, Executive Director for Maritime and Offshore Technologies, Bureau Veritas, the Netherlands. “We faced some difficulties, but the final product is ready for commercial use.”

Participants of the WAAMpeller project at the presentation of their offspring

Representatives of the five consortium participants also attended the tests, which included traction tests at mooring lines, speed tests and emergency reverse.

“Of course, before the tests we were all a little nervous, because innovation is always associated with a fraction of risk - but everything went well. We are pleased to announce that in all tests WAAMpeller has demonstrated the qualities of a conventional cast screw. In particular, the same characteristics were confirmed during an emergency stop, that is, when going from full speed to full reverse, creating the maximum load on the propeller, ”said Keys Kaster, design engineer of Damen.

The finished WAAMpeller screw was officially unveiled at Damen headquarters. This project not only demonstrates the unique capabilities of each of the consortium participants, but may also have important implications for shipbuilding in general.

“The project demonstrated to the shipbuilding industry the potential of 3D printing technology in the manufacture of ship parts,” explained Kastelein. “We are continuing intensive research in this very interesting field.”

Based on 3dprint.com

Source: https://habr.com/ru/post/446470/

All Articles