How to promote a beginner and do not break anything

Search, interview, test assignment, selection, recruitment, adaptation - the path is hard and clear for each of us - both the employer and the employee.

A beginner does not have the necessary specialized competencies. Even an experienced specialist has to rebuild. Questions are being put on the manager, what tasks should be put to the new employee at the start and how much time should they take? While ensuring interest, involvement, drive and integration. But do not risk critical business challenges.

To do this, we run a relay internal projects. They consist of independent short stages. The results of such works serve as a foundation for further development and allow the novice to show themselves, join the team with an interesting task and without the risk of overwhelming an important project. Here and experience and acquaintance with colleagues, and the opportunity to show themselves from the best side when there are no strict restrictions on the part of legacy.

')

As an example of such a relay development, there was a topic of a rotational screen based on a stroboscopic effect with the possibility of outputting to it an arbitrary custom dynamic image made on the phone screen. Prototypes can be found here .

The works were carried out sequentially by several employees and will be continued with new ones for the time of their onboarding (from two weeks to a month depending on abilities and level of competence).

The stages were as follows:

a) think over the design (having studied the available samples, the description of analogs, having shown creative initiative);

b) to develop a circuit diagram, dissolve it on the board;

c) develop a protocol for transferring images from the phone to the device;

d) provide control from a smartphone via Bluetooth LE.

The starting variant was supposed to use something very compact, such as a three-lobed spinner, which, when manually rotated, began to show inscriptions. In one petal there was a BLE-module, in the second - ten RGB-LEDs, in the third optical sensor, in the center - the battery. A circuit diagram was drawn up and the first experiments were carried out. It became clear that the level of picture quality is very low, the resolution is small, the game effect is short, the possibilities are modest. Yes, and spinners are gone as quickly as they appeared. It was decided to raise the bar and develop a rotating strobe screen. At least it can be used for practical purposes at exhibitions and conferences and in the near future interest in such solutions will not disappear.

Regarding the design, the main issues were two: how to position the LEDs (in the vertical plane, as in the example above or in the horizontal) and how to power the rotating board with the LEDs.

For educational purposes, the LEDs were located only in the horizontal plane. As for the board power supply, there was an important choice: either we take the collector motor bulky, noisy, but cheap, or we use a more elegant solution with contactless power transmission using two coils - one on the engine, the other on the board. The solution is, of course, elegant, but more expensive and long, because the coil had to be calculated first, and then wound (preferably not on the knee).

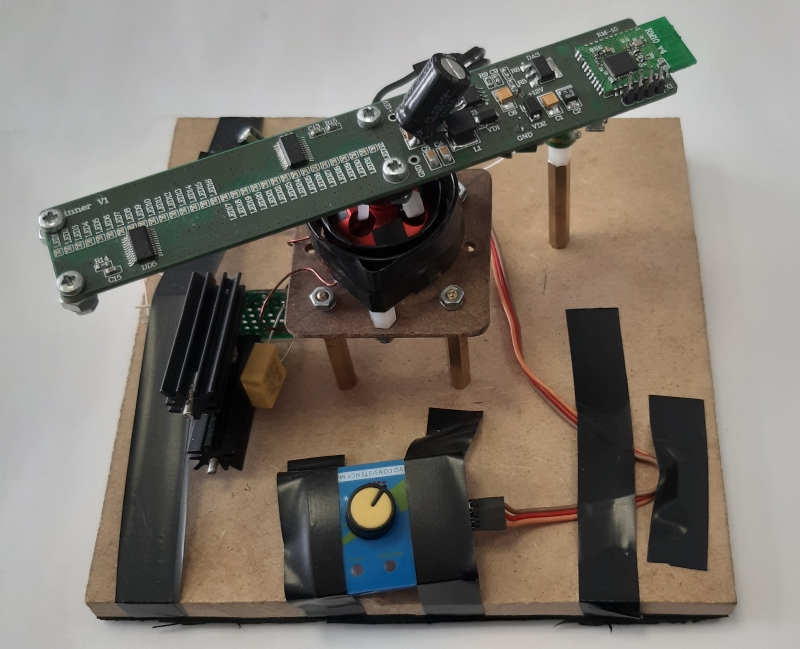

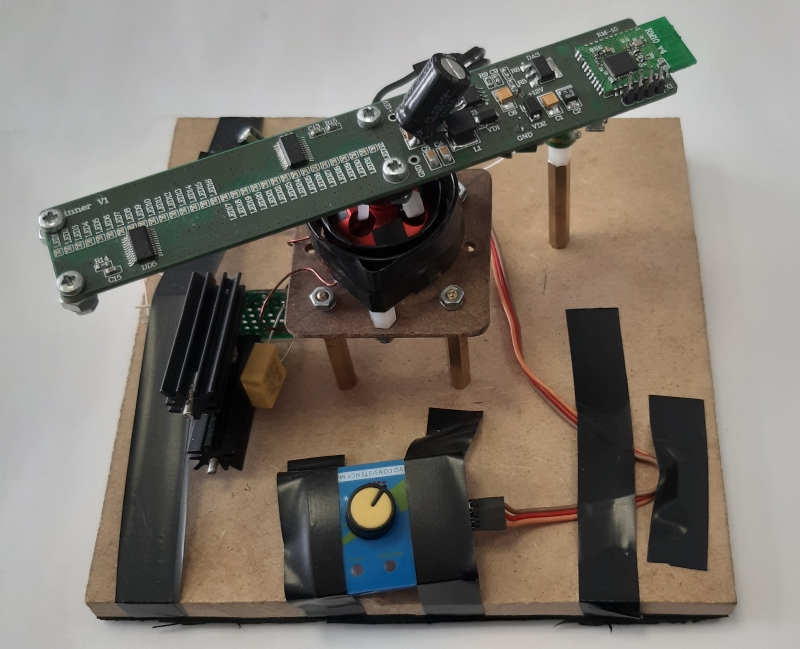

It looks like the resulting prototype

The specificity of mass production products is such that every extra cent in the cost price is of importance. Success can be determined by the cost of a handful of passives. Therefore, it is often necessary to choose a less efficient, but cheaper option, so that the manufacturer can maintain commercial competitiveness. Therefore, imagining that the rotary screen will be launched into mass production, the developer chose a collector engine.

The resulting prototype at the start fervently sparkled, rustled and shook the table. The design that provided stability turned out so heavy and overall that it did not make sense to bring it up to the serial prototype. Having rejoiced at the intermediate success, we decided to replace the motor with a rotating transformer with an air gap. Another reason was the inability to power the engine from the USB port of the computer.

The base of the board with LEDs is our RM10 module and six MBI5030 LED drivers.

Drivers have 16 channels with the ability to independently control each. Thus, 6 such drivers and 32 RGB-LEDs in total have the ability to show 16 million colors.

To synchronize and stabilize the displayed image, two MRSS23E magnetoresistive Hall sensors were used.

The plan was simple - the sensor gives an interruption for each turn of the board, the position of the LEDs is determined by the tact between the two passes and their azimuth is calculated and the illumination in the sweep is 360 degrees.

But something went wrong - regardless of the speed of the board rotation, the sensor gave randomly one or two interruptions per pass. Thus, the image was smeared and folded inward.

Replacing sensors did not change the situation, so the Hall sensor was replaced with a photoresistor.

Who has any thoughts on why a magnetoresistive sensor could lead itself this way? Share in the comments.

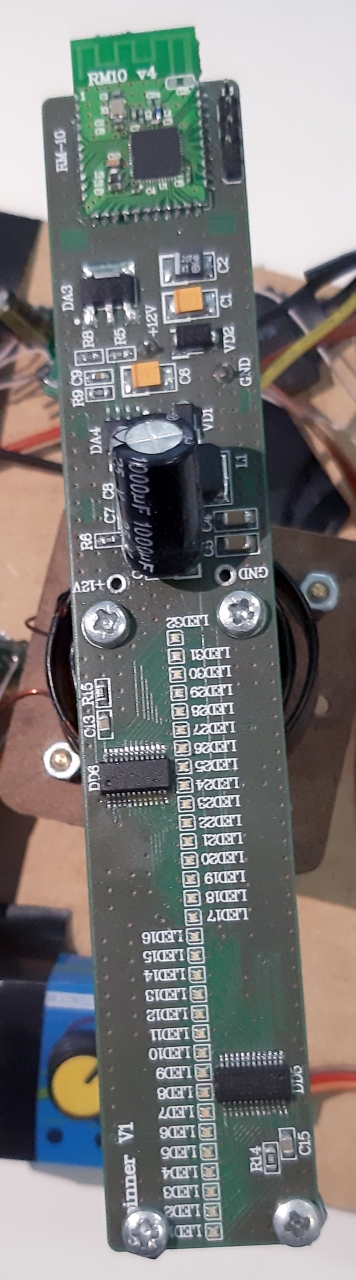

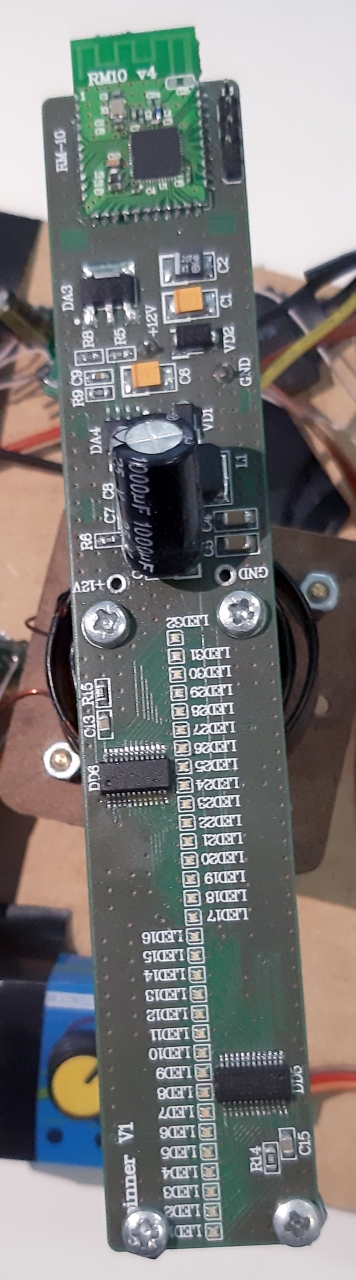

Upper side of the board

With an optical sensor, the image is clear, but it stabilizes for about 30 seconds. This happens for a complex of reasons, one of which is the timer discreteness. These are 4 million ticks per second, divided by 360 degrees with the remainder, which distorts the output image.

In the Chinese stroboscopic clock, the image is set in a couple of seconds at the cost of the fact that a small segment of the circle is simply not displayed: there is an empty space on the circular image, it is not visible on the text, but the image is incomplete.

However, the problems are not over. The nRF52832 microcontroller cannot provide the necessary data transfer rate for the possible number of colors (approx. 16 MHz) - the screen gives 1 frame per second, which is not enough for the human eye. Obviously, you need to place on the board a separate microcontroller for image management, but for now the decision has been made to replace MBI5030 with MBI5039 . These are only 7 colors, including white, but this is enough for testing the software part.

Well, and not least, for the sake of what this educational task was started - to program the microcontroller and implement control through the application on the smartphone.

Now the scan is transmitted via Bluetooth directly via nRF Connect, and the application interface is in development.

Thus, the intermediate results of the relay team are as follows:

The rotary screen has a line of 32 LEDs and an image diameter of 150 mm. It displays 7 colors, sets an image or text in 30 seconds (which is not ideal, but acceptable for a start). Through a Bluetooth connection, you can issue a command to change the image.

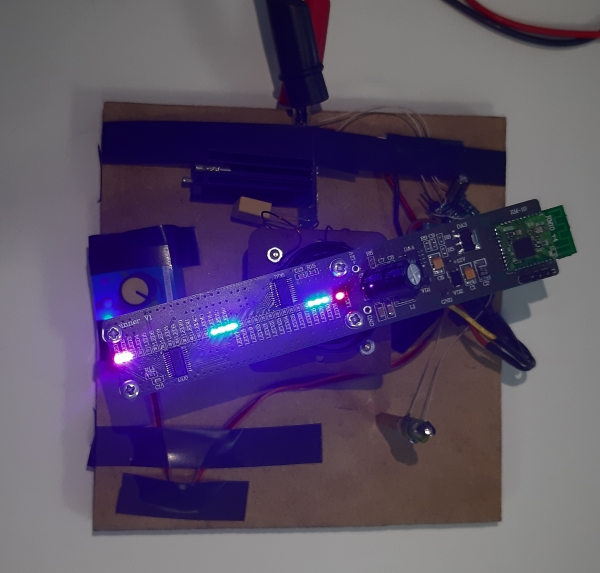

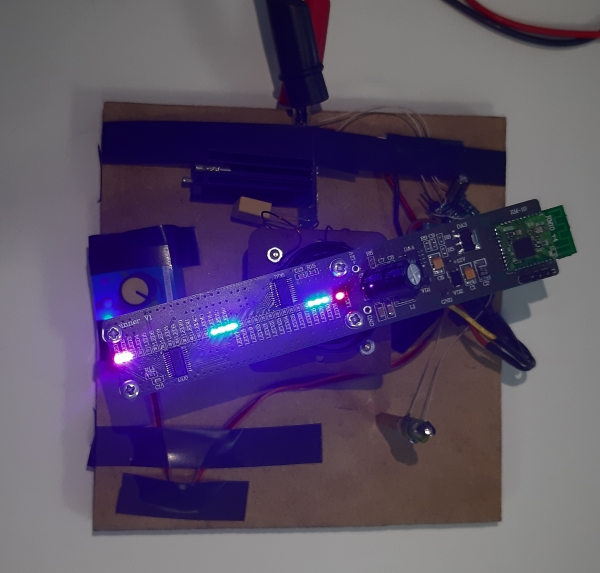

And so it looks

And new young developers for successful training have to solve the following tasks:

Overcome the lack of microcontroller RAM for full-color color palette display. Finalize the application for the formation and transmission of static or dynamic images. Give the design a finished look. We will keep you informed.

PS Of course, after completing work on Bluetooth LE ( nrf52832 ), we will design and implement a Wi-Fi / Bluetooth version on ESP32 But this will be a new story.

A beginner does not have the necessary specialized competencies. Even an experienced specialist has to rebuild. Questions are being put on the manager, what tasks should be put to the new employee at the start and how much time should they take? While ensuring interest, involvement, drive and integration. But do not risk critical business challenges.

To do this, we run a relay internal projects. They consist of independent short stages. The results of such works serve as a foundation for further development and allow the novice to show themselves, join the team with an interesting task and without the risk of overwhelming an important project. Here and experience and acquaintance with colleagues, and the opportunity to show themselves from the best side when there are no strict restrictions on the part of legacy.

')

As an example of such a relay development, there was a topic of a rotational screen based on a stroboscopic effect with the possibility of outputting to it an arbitrary custom dynamic image made on the phone screen. Prototypes can be found here .

The works were carried out sequentially by several employees and will be continued with new ones for the time of their onboarding (from two weeks to a month depending on abilities and level of competence).

The stages were as follows:

a) think over the design (having studied the available samples, the description of analogs, having shown creative initiative);

b) to develop a circuit diagram, dissolve it on the board;

c) develop a protocol for transferring images from the phone to the device;

d) provide control from a smartphone via Bluetooth LE.

The starting variant was supposed to use something very compact, such as a three-lobed spinner, which, when manually rotated, began to show inscriptions. In one petal there was a BLE-module, in the second - ten RGB-LEDs, in the third optical sensor, in the center - the battery. A circuit diagram was drawn up and the first experiments were carried out. It became clear that the level of picture quality is very low, the resolution is small, the game effect is short, the possibilities are modest. Yes, and spinners are gone as quickly as they appeared. It was decided to raise the bar and develop a rotating strobe screen. At least it can be used for practical purposes at exhibitions and conferences and in the near future interest in such solutions will not disappear.

Regarding the design, the main issues were two: how to position the LEDs (in the vertical plane, as in the example above or in the horizontal) and how to power the rotating board with the LEDs.

For educational purposes, the LEDs were located only in the horizontal plane. As for the board power supply, there was an important choice: either we take the collector motor bulky, noisy, but cheap, or we use a more elegant solution with contactless power transmission using two coils - one on the engine, the other on the board. The solution is, of course, elegant, but more expensive and long, because the coil had to be calculated first, and then wound (preferably not on the knee).

It looks like the resulting prototype

The specificity of mass production products is such that every extra cent in the cost price is of importance. Success can be determined by the cost of a handful of passives. Therefore, it is often necessary to choose a less efficient, but cheaper option, so that the manufacturer can maintain commercial competitiveness. Therefore, imagining that the rotary screen will be launched into mass production, the developer chose a collector engine.

The resulting prototype at the start fervently sparkled, rustled and shook the table. The design that provided stability turned out so heavy and overall that it did not make sense to bring it up to the serial prototype. Having rejoiced at the intermediate success, we decided to replace the motor with a rotating transformer with an air gap. Another reason was the inability to power the engine from the USB port of the computer.

The base of the board with LEDs is our RM10 module and six MBI5030 LED drivers.

Drivers have 16 channels with the ability to independently control each. Thus, 6 such drivers and 32 RGB-LEDs in total have the ability to show 16 million colors.

To synchronize and stabilize the displayed image, two MRSS23E magnetoresistive Hall sensors were used.

The plan was simple - the sensor gives an interruption for each turn of the board, the position of the LEDs is determined by the tact between the two passes and their azimuth is calculated and the illumination in the sweep is 360 degrees.

But something went wrong - regardless of the speed of the board rotation, the sensor gave randomly one or two interruptions per pass. Thus, the image was smeared and folded inward.

Replacing sensors did not change the situation, so the Hall sensor was replaced with a photoresistor.

Who has any thoughts on why a magnetoresistive sensor could lead itself this way? Share in the comments.

Upper side of the board

With an optical sensor, the image is clear, but it stabilizes for about 30 seconds. This happens for a complex of reasons, one of which is the timer discreteness. These are 4 million ticks per second, divided by 360 degrees with the remainder, which distorts the output image.

In the Chinese stroboscopic clock, the image is set in a couple of seconds at the cost of the fact that a small segment of the circle is simply not displayed: there is an empty space on the circular image, it is not visible on the text, but the image is incomplete.

However, the problems are not over. The nRF52832 microcontroller cannot provide the necessary data transfer rate for the possible number of colors (approx. 16 MHz) - the screen gives 1 frame per second, which is not enough for the human eye. Obviously, you need to place on the board a separate microcontroller for image management, but for now the decision has been made to replace MBI5030 with MBI5039 . These are only 7 colors, including white, but this is enough for testing the software part.

Well, and not least, for the sake of what this educational task was started - to program the microcontroller and implement control through the application on the smartphone.

Now the scan is transmitted via Bluetooth directly via nRF Connect, and the application interface is in development.

Thus, the intermediate results of the relay team are as follows:

The rotary screen has a line of 32 LEDs and an image diameter of 150 mm. It displays 7 colors, sets an image or text in 30 seconds (which is not ideal, but acceptable for a start). Through a Bluetooth connection, you can issue a command to change the image.

And so it looks

And new young developers for successful training have to solve the following tasks:

Overcome the lack of microcontroller RAM for full-color color palette display. Finalize the application for the formation and transmission of static or dynamic images. Give the design a finished look. We will keep you informed.

PS Of course, after completing work on Bluetooth LE ( nrf52832 ), we will design and implement a Wi-Fi / Bluetooth version on ESP32 But this will be a new story.

Source: https://habr.com/ru/post/445974/

All Articles